Nissan Ariya: Dtc/circuit Diagnosis

- B2001-45 Intelligent Key Unit

- B2010-1c Battery Voltage

- B203e-14 Outside Antenna

- B2046-42 Eeprom

- B2086-23 Request Sw (bd/tr)

- B2087-08 One Touch Sensor (fl)

- B2087-11 One Touch Sensor (fl)

- B2087-23 One Touch Sensor (fl)

- B2409-12 Half Latch Switch

- B2409-14 Half Latch Switch

- B2416-15 Touch Sensor Circuit Rh Open

- B2422-78 Back Door Position Abnormal

- B2426-11 Spindle Sensor Lh

- B2426-12 Spindle Sensor Lh

- B2426-13 Spindle Sensor Lh

- B2426-25 Spindle Sensor Lh

- B2428-44 Automatic Back Door Control Unit

- B2428-54 Automatic Back Door Control Unit

- B242a-11 Closure Motor

- B242a-98 Closure Motor

- B242f-11 Automatic Back Door Warning Buzzer

- B242f-13 Automatic Back Door Warning Buzzer

- B2f06-11 Trunk/back Door Opener Sw

- U0075-00 Communication Bus C Off

- U2118-87 Can Comm Circuit

- U2141-87 Can Comm Circuit

- U2148-87 Can Comm Circuit. Intelligent Key Unit

- U214e-87 Can Comm Circuit. Intelligent Key Unit

- U214f-87 Can Comm Circuit. Intelligent Key Unit

- U215b-87 Can Comm Circuit. Intelligent Key Unit

- Automatic Back Door Close Switch

- Automatic Back Door Warning Buzzer

- Back Door Switch. With Automatic Back Door System

- Back Door Opener Actuator

- Back Door Request Switch

- Door Lock Actuator. Driver Side

- Door Lock and Unlock Switch. Driver Side

- Door Switch

- Hazard Function

- Intelligent Key Battery

- Intelligent Key Warning Buzzer

- Power Supply and Ground Circuit

- Touch Sensor

- Unlock Sensor

- Serial Signal Circuit

B2001-45 Intelligent Key Unit Nissan Ariya 1st generation

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC Detection Condition | |

|---|---|---|---|

| B2001–45 | Intelligent Key unit | Diagnosis condition | Power switch ON |

| Signal (terminal) | — | ||

| Threshold | Intelligent Key unit is internal malfunctioning | ||

| Diagnosis delay time | 1 second or less | ||

POSSIBLE CAUSE

Intelligent Key unit

FAIL-SAFE

—

DTC CONFIRMATION PROCEDURE

DTC CONFIRMATION

With CONSULT

With CONSULT

-

Power switch ON.

-

Select “Self Diagnostic Result” mode of “INTELLIGENT KEY” using CONSULT.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO–1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO–2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

REPLACE INTELLIGENT KEY UNIT

When DTC “B2001–45” is detected, replace Intelligent Key unit.

>>

Replace Intelligent Key unit. Refer to Removal and Installation.

B2010-1c Battery Voltage Nissan Ariya: FE0

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC Detection Condition | |

|---|---|---|---|

| B2010–1C | Battery voltage | Diagnosis condition | All times |

| Signal (terminal) | Intelligent Key unit battery power supply signal | ||

| Threshold | Less than 4 V or more than 16 V | ||

| Diagnosis delay time | — | ||

POSSIBLE CAUSE

-

Harness or connector (power supply circuit)

-

Intelligent Key unit

-

Battery

FAIL-SAFE

—

DTC CONFIRMATION PROCEDURE

DTC CONFIRMATION

With CONSULT

With CONSULT

-

Power switch ON.

-

Select the “Self Diagnostic Result” of “INTELLIGENT KEY” using CONSULT.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO–1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO–2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

CHECK BATTERY VOLTAGE

Measure the battery voltage. Refer to Work Flow.

Is the inspection result normal?

YES>>GO TO 2.

NO>>Replace battery.

CHECK POWER SUPPLY CIRCUIT

Check Intelligent Key unit power supply circuit. Refer to Diagnosis Procedure.

Is the inspection result normal?

YES>>Replace Intelligent Key unit. Refer to Removal and Installation.

NO>>Repair the malfunctioning part.

B203e-14 Outside Antenna Nissan Ariya 1st generation

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC detecting condition | |

|---|---|---|---|

| B203E–14 | Outside antenna | Diagnosis condition | Work support “Inside/outside antenna diagnosis”: activated |

| Signal (terminal) | Outside key antenna (rear door LH) signal (Intelligent Key unit connector terminal: 35, 36) | ||

| Threshold | Outside key antenna (rear door LH) circuit is open or shorted | ||

| Diagnosis delay time | 1 second or less | ||

POSSIBLE CAUSE

-

Intelligent Key unit

-

Outside key antenna (rear door LH)

-

Harness or connector [outside key antenna (rear door LH) circuit is open or shorted]

FAIL-SAFE

—

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Select “Inside/outside antenna diagnosis” in “Work support” mode of “INTELLIGENT KEY”.

-

Select the “Self Diagnosis Result” mode of “INTELLIGENT KEY” using CONSULT.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

CHECK OUTSIDE KEY ANTENNA INPUT SIGNAL 1

-

Power switch ON.

-

Check signal between Intelligent Key unit harness connector and ground using oscilloscope.

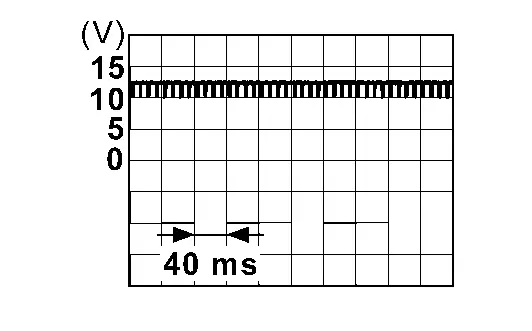

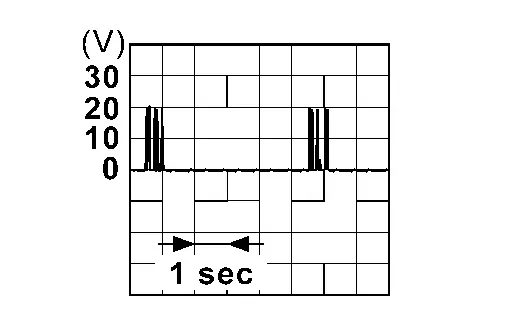

(+) (–) Condition Signal

(Reference value)Intelligent Key unit Connector Terminal M79 35 Ground Power switch pressed when Intelligent Key is in the antenna detection area

Power switch pressed when Intelligent Key is not in the antenna detection area

36 Power switch pressed when Intelligent Key is in the antenna detection area

Power switch pressed when Intelligent Key is not in the antenna detection area

Is the inspection result normal?

YES>>Replace Intelligent Key unit. Refer to Removal and Installation.

NO>>GO TO 2.

CHECK OUTSIDE KEY ANTENNA CIRCUIT

-

Power switch OFF.

-

Disconnect Intelligent Key unit connector and outside key antenna (rear door LH) connector.

-

Check continuity between Intelligent Key unit harness connector and outside key antenna (rear door LH) connector.

Intelligent Key unit Outside key antenna (rear door LH) Continuity Connector Terminal Connector Terminal M79 35 D103 2 Existed 36 1 -

Check continuity between Intelligent Key unit harness connector and ground.

Intelligent Key unit — Continuity Connector Terminal M79 35 Ground Not existed 36

Is the inspection result normal?

YES>>GO TO 3.

NO>>Repair or replace harness.

CHECK OUTSIDE KEY ANTENNA INPUT SIGNAL 2

-

Replace outside key antenna (rear door LH). (New antenna or other antenna)

-

Connect Intelligent Key unit connector and outside key antenna (rear door LH) connector.

-

Power switch ON.

-

Check signal between Intelligent Key unit harness connector and ground using oscilloscope.

(+) (–) Condition Signal

(Reference value)Intelligent Key unit Connector Terminal M79 35 Ground Power switch pressed when Intelligent Key is in the antenna detection area

Power switch pressed when Intelligent Key is not in the antenna detection area

36 Power switch pressed when Intelligent Key is in the antenna detection area

Power switch pressed when Intelligent Key is not in the antenna detection area

Is the inspection result normal?

YES>>Replace outside key antenna (rear door LH). Refer to Removal and Installation.

NO>>Replace Intelligent Key unit. Refer to Removal and Installation.

B2046-42 Eeprom Nissan Ariya SUV

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC Detection Condition | |

|---|---|---|---|

| B2046–42 | EEPROM | Diagnosis condition | Power switch ON |

| Signal (terminal) | — | ||

| Threshold | EEPROM in Intelligent Key unit is malfunctioning | ||

| Diagnosis delay time | 1 second or less | ||

POSSIBLE CAUSE

-

Intelligent Key unit

-

Mistook the "Configuration"

FAIL-SAFE

—

DTC CONFIRMATION PROCEDURE

DTC CONFIRMATION

With CONSULT

With CONSULT

-

Power switch ON.

-

Select “Self Diagnostic Result” mode of “INTELLIGENT KEY” using CONSULT.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO–1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO–2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

PERFORM "CONFIGURATION"

With CONSULT

With CONSULT

-

Perform "Configuration".

-

Erase DTC.

-

Power switch OFF.

-

Power switch ON.

-

Select “Self Diagnostic Result” mode of “INTELLIGENT KEY” using CONSULT.

Is DTC detected?

YES>>GO TO 2.

NO>>INSPECTION END

REPLACE INTELLIGENT KEY UNIT

Replace Intelligent Key unit. Refer to Intermittent Incident.

>>

INSPECTION END

B2086-23 Request Sw (bd/tr) Nissan Ariya 2026

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms | DTC Detection Condition | |

|---|---|---|---|

| B2086–23 | Request switch (Back door/Trunk) | Diagnosis condition | Power switch ON |

| Signal (terminal) | Back door request switch signal (Intelligent Key unit connector terminal 5) | ||

| Threshold | Intelligent Key unit detects that the back door request switch is stuck ON | ||

| Diagnosis delay time | 10 seconds or more | ||

POSSIBLE CAUSE

-

Back door opener switch assembly (back door request switch)

-

Harness or connector

[Back door opener switch assembly (back door request switch) circuit is shorted]

-

Intelligent Key unit

FAIL-SAFE

—

DTC CONFIRMATION PROCEDURE

CHECK SELF-DIAG RESULT

With CONSULT

With CONSULT

-

Power switch ON and wait for 10 seconds or more.

-

Select “Self Diagnostic Result” mode of “INTELLIGENT KEY” using CONSULT.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

CHECK BACK DOOR REQUEST SWITCH INPUT SIGNAL

-

Power switch OFF.

-

Disconnect back door opener switch assembly connector.

-

Check voltage between back door opener switch assembly harness connector and ground.

(+) (–) Voltage Back door opener switch assembly Connector Terminal D121 4 Ground 12 V

Is the inspection result normal?

YES>>GO TO 3.

NO>>GO TO 2.

CHECK BACK DOOR REQUEST SWITCH CIRCUIT

-

Disconnect Intelligent Key unit connector.

-

Check continuity between back door opener switch assembly harness connector and Intelligent Key unit harness connector.

Back door opener switch assembly Intelligent Key unit Continuity Connector Terminal Connector Terminal D121 4 M79 5 Existed -

Check continuity between back door opener switch assembly harness connector and ground.

Back door opener switch assembly — Continuity Connector Terminal D121 4 Ground Not existed

Is the inspection result normal?

YES>>Replace Intelligent Key unit. Refer to Removal and Installation.

NO>>Repair or replace harness.

CHECK BACK DOOR REQUEST SWITCH GROUND CIRCUIT

Check continuity between back door opener switch assembly harness connector and ground.

| Back door opener switch assembly | — | Continuity | |

|---|---|---|---|

| Connector | Terminal | ||

| D121 | 3 | Ground | Existed |

Is the inspection result normal?

YES>>GO TO 4.

NO>>Repair or replace harness.

CHECK BACK DOOR REQUEST SWITCH

Refer to Component Inspection.

Is the inspection result normal?

YES>>Check intermittent incident. Refer to Intermittent Incident.

NO>>Replace back door opener switch assembly. Refer to Removal and Installation.

B2087-08 One Touch Sensor (fl) Nissan Ariya 1st generation

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC Detection Condition | |

|---|---|---|---|

| B2087-08 | One touch sensor (front left) | Diagnosis condition | One touch sensor is operated |

| Signal (terminal) | One touch sensor signal | ||

| Threshold | When Intelligent Key unit detects communication error by one touch sensor (front LH) | ||

| Diagnosis delay time | 1 second or less | ||

POSSIBLE CAUSE

-

Intelligent Key unit

-

One touch sensor (front LH)

-

Harness or connector [one touch sensor (front LH) circuit is open or shorted]

FAIL-SAFE

—

DTC CONFIRMATION PROCEDURE

CHECK SELF-DIAG RESULT

With CONSULT

With CONSULT

-

Lock or unlock doors by one touch sensor.

-

Check “Self Diagnostic Result” mode of “INTELLIGENT KEY” using CONSULT.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

CHECK ONE TOUCH SENSOR INPUT SIGNAL

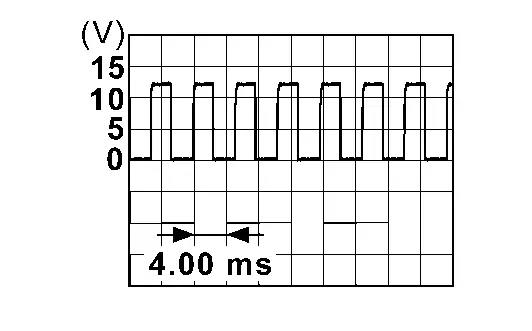

Check signal between Intelligent Key unit harness connector and ground using oscilloscope.

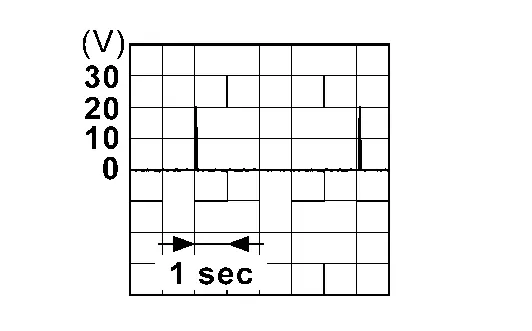

| (+) | (–) | Condition |

Signal (Reference value) | ||

|---|---|---|---|---|---|

| Intelligent Key unit | |||||

| Connector | Terminal | ||||

| M79 | 8 | Ground | One touch sensor (front LH) | Touched |

|

| Not touched | 12 V | ||||

Is the inspection result normal?

YES>>Replace front door outside handle (front LH). Refer to Removal & Installation.

NO>>GO TO 2.

CHECK ONE TOUCH SENSOR INPUT SIGNAL CIRCUIT

-

Power switch OFF.

-

Disconnect Intelligent Key unit connector and one touch sensor (front LH) connector.

-

Check continuity between Intelligent Key unit harness connector and one touch sensor (front LH) harness connector.

Intelligent Key unit One touch sensor (front LH) Continuity Connector Terminal Connector Terminal M79 8 D55 1 Existed -

Check continuity between Intelligent Key unit harness connector and ground.

Intelligent Key unit — Continuity Connector Terminal M79 8 Ground Not existed

Is the inspection result normal?

YES>>GO TO 3.

NO>>Repair or replace harness.

CHECK ONE TOUCH SENSOR GROUND CIRCUIT

Check continuity between one touch sensor (front LH) harness connector and ground.

| One touch sensor (front LH) | — | Continuity | |

|---|---|---|---|

| Connector | Terminal | ||

| D55 | 2 | Ground | Existed |

Is the inspection result normal?

YES>>GO TO 4.

NO>>Repair or replace harness.

REPLACE ONE TOUCH SENSOR

-

Replace front door outside handle (front LH). Refer to Removal & Installation.

-

Erase DTC, and then check “DTC CONFIRMATION PROCEDURE”. Refer to DTC Description.

Is DTC detected?

YES>>Replace Intelligent Key unit. Refer to Removal and Installation.

NO>>INSPECTION END

B2087-11 One Touch Sensor (fl) Nissan Ariya: FE0

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC Detection Condition | |

|---|---|---|---|

| B2087-11 | One touch sensor (front left) | Diagnosis condition | One touch sensor is operated |

| Signal (terminal) | One touch sensor signal | ||

| Threshold | When Intelligent Key unit detects shorted to ground of one touch sensor (front LH) signal circuit | ||

| Diagnosis delay time | 3 second or more | ||

POSSIBLE CAUSE

-

Intelligent Key unit

-

Harness or connector [one touch sensor (front LH) circuit is shorted to ground]

FAIL-SAFE

—

DTC CONFIRMATION PROCEDURE

CHECK SELF-DIAG RESULT

With CONSULT

With CONSULT

-

Lock or unlock doors by one touch sensor.

-

Wait for 3 seconds or more.

-

Check “Self Diagnostic Result” mode of “INTELLIGENT KEY” using CONSULT.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

CHECK ONE TOUCH SENSOR INPUT SIGNAL

Check signal between Intelligent Key unit harness connector and ground using oscilloscope.

| (+) | (–) | Condition |

Signal (Reference value) | ||

|---|---|---|---|---|---|

| Intelligent Key unit | |||||

| Connector | Terminal | ||||

| M79 | 8 | Ground | One touch sensor (front LH) | Touched |

|

| Not touched | 12 V | ||||

Is the inspection result normal?

YES>>Replace Intelligent Key unit. Refer to Removal and Installation.

NO>>GO TO 2.

CHECK ONE TOUCH SENSOR INPUT SIGNAL CIRCUIT (FOR SHORT)

-

Power switch OFF.

-

Disconnect Intelligent Key unit connector and one touch sensor (front LH) connector.

-

Check continuity between Intelligent Key unit harness connector and ground.

Intelligent Key unit — Continuity Connector Terminal M79 8 Ground Not existed

Is the inspection result normal?

YES>>Check intermittent incident. Refer to Intermittent Incident.

NO>>Repair or replace harness.

B2087-23 One Touch Sensor (fl) Nissan Ariya 2026

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC Detection Condition | |

|---|---|---|---|

| B2087-23 | One touch sensor (front left) | Diagnosis condition | When operating one touch sensor (front LH) inside of outside handle |

| Signal (terminal) | One touch sensor signal | ||

| Threshold | When Intelligent Key unit detects malfunction in one touch sensor (front LH) inside of outside handle | ||

| Diagnosis delay time | 4 second or more | ||

POSSIBLE CAUSE

One touch sensor (front LH)

FAIL-SAFE

—

DTC CONFIRMATION PROCEDURE

CHECK SELF-DIAG RESULT

With CONSULT

With CONSULT

-

Unlock doors by one touch sensor.

-

Wait for 4 seconds or more.

-

Check “Self Diagnostic Result” mode of “INTELLIGENT KEY” using CONSULT.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

REPLACE ONE TOUCH SENSOR

Replace front door outside handle (front LH). Refer to Removal & Installation.

>>

INSPECTION END

B2409-12 Half Latch Switch Nissan Ariya SUV

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC Detection Condition | |

|---|---|---|---|

| B2409-12 | Half latch switch | Diagnosis condition | When the door unlock operates while power switch is OFF (auto ACC OFF status) or the battery terminal is removed |

| Signal (terminal) | Half latch switch signal | ||

| Threshold | Automatic back door control unit detects shorted to battery of half latch switch circuit | ||

| Diagnosis delay time | 1 second or less | ||

POSSIBLE CAUSE

-

Harness or connector (half latch switch circuit is shorted to battery)

-

Automatic back door control unit

-

Back door lock assembly (half latch switch)

FAIL-SAFE

Inhibit automatic back door system [only operate back door closure function (open function)]

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Door unlock operates by Intelligent Key, one touch sensor or door request switch while power switch is OFF (auto ACC OFF status).

-

Check “Self Diagnostic Result” mode of “AUTOMATIC BACK DOOR” using CONSULT.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

CHECK HALF LATCH SWITCH INPUT SIGNAL

Check voltage between automatic back door control unit harness connector and ground.

| (+) | (–) | Condition | Voltage | ||

|---|---|---|---|---|---|

| Automatic back door control unit | |||||

| Connector | Terminal | ||||

| B159 | 10 | Ground | Back door | Other than bellow | 0 – 1 V |

| Fully closed/ half latch | 9 – 16 V | ||||

Is the inspection result normal?

YES>>Replace automatic back door control unit. Refer to Removal and Installation.

NO>>GO TO 2.

CHECK HALF LATCH SWITCH CIRCUIT (FOR SHORT)

-

Power switch OFF.

-

Disconnect automatic back door control unit connector and back door lock assembly connector.

-

Check voltage between automatic back door control unit harness connector and ground.

Automatic back door control unit — Voltage

(Approx.)Connector Terminal B159 10 Ground 0 V

Is the inspection result normal?

YES>>Replace back door lock assembly. Refer to Removal & Installation.

NO>>Repair or replace harness.

B2409-14 Half Latch Switch Nissan Ariya SUV

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC Detection Condition | |

|---|---|---|---|

| B2409-14 | Half latch switch | Diagnosis condition | When back door open |

| Signal (terminal) | Half latch switch signal | ||

| Threshold |

Automatic back door control unit detects when one of the following conditions is satisfied

|

||

| Diagnosis delay time | 1 second or less | ||

POSSIBLE CAUSE

-

Harness or connector (half latch switch circuit is open or shorted to ground)

-

Automatic back door control unit

-

Back door lock assembly (half latch switch)

FAIL-SAFE

Inhibit automatic back door system [only operate back door closure function (open function)]

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Power switch ON.

-

Open the back door.

-

Check “Self Diagnostic Result” mode of “AUTOMATIC BACK DOOR” using CONSULT.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

CHECK HALF LATCH SWITCH INPUT SIGNAL

Check voltage between automatic back door control unit harness connector and ground.

| (+) | (–) | Condition | Voltage | ||

|---|---|---|---|---|---|

| Automatic back door control unit | |||||

| Connector | Terminal | ||||

| B159 | 10 | Ground | Back door | Other than bellow | 0 – 1 V |

| Fully closed/ half latch | 9 – 16 V | ||||

Is the inspection result normal?

YES>>Replace automatic back door control unit. Refer to Removal and Installation.

NO>>GO TO 2.

CHECK HALF LATCH SWITCH CIRCUIT

-

Power switch OFF.

-

Disconnect automatic back door control unit connector and back door lock assembly connector.

-

Check continuity between automatic back door control unit harness connector and back door lock assembly harness connector.

Automatic back door control unit Back door lock assembly Continuity Connector Terminal Connector Terminal B159 10 D134 6 Existed -

Check continuity between automatic back door control unit harness connector and ground.

Automatic back door control unit — Continuity Connector Terminal B159 10 Ground Not existed

Is the inspection result normal?

YES>>Replace back door lock assembly. Refer to Removal & Installation.

NO>>Repair or replace harness.

B2416-15 Touch Sensor Circuit Rh Open Nissan Ariya 1st generation

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC Detection Condition | |

|---|---|---|---|

| B2416-15 | Touch sensor circuit RH open | Diagnosis condition | Power switch ON |

| Signal (terminal) | Touch sensor RH signal | ||

| Threshold |

Automatic back door control unit detects when one of the following conditions is satisfied

|

||

| Diagnosis delay time | 1 second or less | ||

POSSIBLE CAUSE

-

Harness or connector (touch sensor RH circuit is open or shorted)

-

Automatic back door control unit

-

Touch sensor RH

FAIL-SAFE

Inhibit automatic back door system (only operate back door closure function)

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Power switch ON.

-

Check “Self Diagnostic Result” mode of “AUTOMATIC BACK DOOR” using CONSULT.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

CHECK TOUCH SENSOR INPUT SIGNAL

Check voltage between automatic back door control unit harness connector and ground.

| (+) | (–) | Condition | Voltage | ||

|---|---|---|---|---|---|

| Automatic back door control unit | |||||

| Connector | Terminal | ||||

| B159 | 13 | Ground | Touch sensor RH | Detect obstruction | 0.2 – 3 V |

| Other than above | 3.4 – 6.5 V | ||||

Is the inspection result normal?

YES>>Replace automatic back door control unit. Refer to Removal and Installation.

NO>>GO TO 2.

CHECK TOUCH SENSOR CIRCUIT

-

Power switch OFF.

-

Disconnect automatic back door control unit connector and touch sensor RH connector.

-

Check continuity between automatic back door control unit harness connector and touch sensor RH harness connector.

Automatic back door control unit Touch sensor RH Continuity Connector Terminal Connector Terminal B159 13 D140 1 Existed -

Check continuity between automatic back door control unit harness connector and ground.

Automatic back door control unit — Continuity Connector Terminal B159 13 Ground Not existed

Is the inspection result normal?

YES>>GO TO 3.

NO>>Repair or replace harness.

CHECK TOUCH SENSOR GROUND CIRCUIT

-

Disconnect touch sensor LH connector.

-

Check continuity between automatic back door control unit harness connector and touch sensor RH harness connector.

Automatic back door control unit Touch sensor RH Continuity Connector Terminal Connector Terminal B159 14 D140 2 Existed -

Check continuity between automatic back door control unit harness connector and ground.

Automatic back door control unit — Continuity Connector Terminal B159 14 Ground Not existed

Is the inspection result normal?

YES>>GO TO 4.

NO>>Repair or replace harness.

CHECK TOUCH SENSOR

Check touch sensor. Refer to Component Inspection.

Is the inspection result normal?

YES>>Check intermittent incident. Refer to Intermittent Incident.

NO>>Replace touch sensor RH. Refer to Removal & Installation.

B2422-78 Back Door Position Abnormal Nissan Ariya 2026

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC Detection Condition | |

|---|---|---|---|

| B2422-78 | Back door position abnormal | Diagnosis condition | Power switch ON |

| Signal (terminal) |

|

||

| Threshold | When the automatic back door control unit detects back door position malfunction according to the encoder signal | ||

| Diagnosis delay time | 1 second or less | ||

POSSIBLE CAUSE

-

Spindle unit LH

-

Spindle unit RH

-

Automatic back door control unit

-

Harness or connector (encoder LH circuit is open or shorted)

-

Harness or connector (encoder RH circuit is open or shorted)

FAIL-SAFE

Inhibit automatic back door system (only operate back door closure function)

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Power switch ON.

-

Check “Self Diagnostic Result” mode of “AUTOMATIC BACK DOOR” using CONSULT.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

CHECK ENCODER SIGNAL

-

Power switch ON.

-

Select “AUTOMATIC BACK DOOR” using CONSULT.

-

Select “Spindle sensor LH” and “Spindle sensor RH” in “Data Monitor” mode.

-

Check that the function operates normally according to the following conditions.

Monitor item Condition Status Spindle sensor LH Back door Open The numeral value increases Close The numeral value decreases Spindle sensor RH Back door Open The numeral value increases Close The numeral value decreases

Is the inspection result normal?

YES>>Check intermittent incident. Refer to Intermittent Incident.

NO-1>>Spindle sensor LH: GO TO 2.

NO-2>>Spindle sensor RH: GO TO 4.

CHECK ENCODER LH INPUT SIGNAL

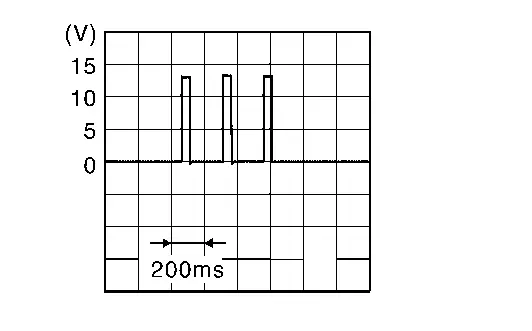

Check signal between automatic back door control unit harness connector and ground using oscilloscope.

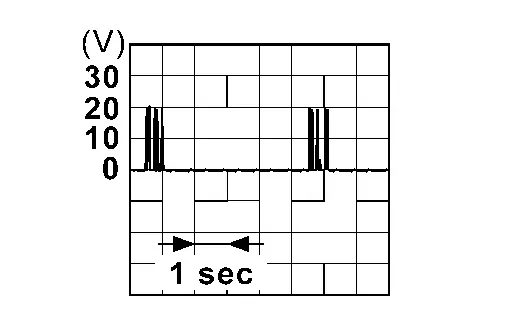

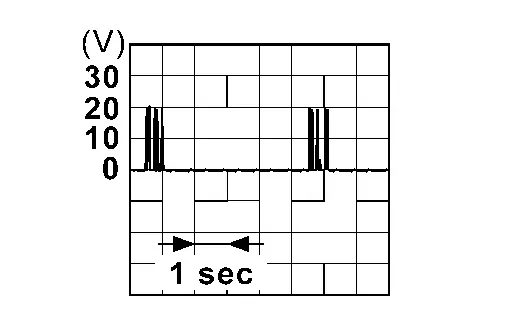

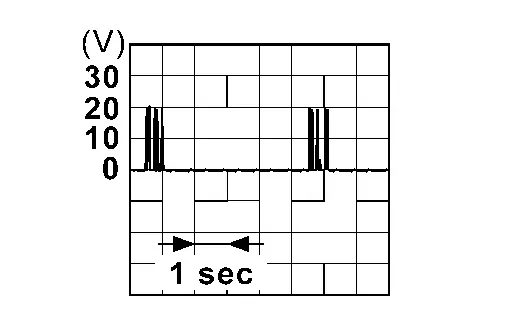

| (+) | (–) | Condition |

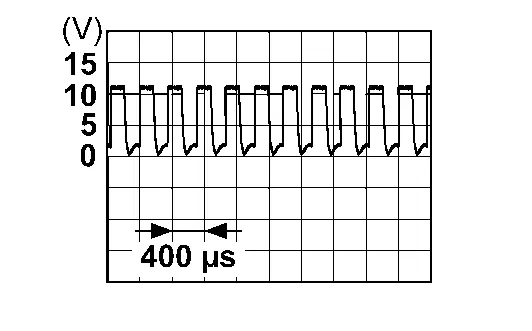

Signal (Reference value) | ||

|---|---|---|---|---|---|

| Automatic back door control unit | |||||

| Connector | Terminal | ||||

| B159 | 29 | Ground | Back door | Moving (manual) |

|

| When stopped | 0 – 1 V or 9 – 16 V | ||||

| 30 | Moving (manual) |

|

|||

| When stopped | 0 – 1 V or 9 – 16 V | ||||

Is the inspection result normal?

YES>>Replace automatic back door control unit. Refer to Removal and Installation.

NO>>GO TO 3.

CHECK ENCODER LH CIRCUIT

-

Power switch OFF.

-

Disconnect automatic back door control unit connector and spindle unit LH connector.

-

Check continuity between automatic back door control unit harness connector and spindle unit LH harness connector.

Automatic back door control unit Spindle unit LH Continuity Connector Terminal Connector Terminal B159 29 B196 5 Existed 30 4 -

Check continuity between automatic back door control unit harness connector and ground.

Automatic back door control unit — Continuity Connector Terminal B159 29 Ground Not existed 30

Is the inspection result normal?

YES>>Replace spindle unit LH. Refer to Removal & Installation.

NO>>Repair or replace harness.

CHECK ENCODER RH INPUT SIGNAL

Check signal between automatic back door control unit harness connector and ground using oscilloscope.

| (+) | (–) | Condition |

Signal (Reference value) | ||

|---|---|---|---|---|---|

| Automatic back door control unit | |||||

| Connector | Terminal | ||||

| B159 | 18 | Ground | Back door | Moving (manual) |

|

| When stopped | 0 – 1 V or 9 – 16 V | ||||

| 19 | Moving (manual) |

|

|||

| When stopped | 0 – 1 V or 9 – 16 V | ||||

Is the inspection result normal?

YES>>Replace automatic back door control unit. Refer to Removal and Installation.

NO>>GO TO 5.

CHECK ENCODER RH CIRCUIT

-

Power switch OFF.

-

Disconnect automatic back door control unit connector and spindle unit RH connector.

-

Check continuity between automatic back door control unit harness connector and spindle unit RH harness connector.

Automatic back door control unit Spindle unit RH Continuity Connector Terminal Connector Terminal B159 18 B197 5 Existed 19 4 -

Check continuity between automatic back door control unit harness connector and ground.

Automatic back door control unit — Continuity Connector Terminal B159 18 Ground Not existed 19

Is the inspection result normal?

YES>>Replace spindle unit RH. Refer to Removal & Installation.

NO>>Repair or replace harness.

B2426-11 Spindle Sensor Lh Nissan Ariya 2026

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC Detection Condition | |

|---|---|---|---|

| B2426-11 | Spindle sensor LH | Diagnosis condition | When automatic back door open/close function operate |

| Signal (terminal) | Encoder LH signal | ||

| Threshold | Automatic back door control unit cannot detects the encoder LH signal | ||

| Diagnosis delay time | 1 second or less | ||

POSSIBLE CAUSE

-

Spindle unit LH

-

Automatic back door control unit

-

Harness or connector (encoder LH circuit is shorted to ground)

FAIL-SAFE

Inhibit automatic back door system (only operate back door closure function)

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Power switch ON.

-

Operate automatic back door.

-

Check “Self Diagnostic Result” mode of “AUTOMATIC BACK DOOR” using CONSULT.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

CHECK ENCODER SIGNAL

-

Power switch ON.

-

Select “AUTOMATIC BACK DOOR” using CONSULT.

-

Select “Spindle sensor LH” in “Data Monitor” mode.

-

Check that the function operates normally according to the following conditions.

Monitor item Condition Status Spindle sensor LH Back door Open The numeral value increases Close The numeral value decreases

Is the inspection result normal?

YES>>Check intermittent incident. Refer to Intermittent Incident.

NO>>GO TO 2.

CHECK ENCODER POWER SUPPLY

-

Power switch OFF.

-

Disconnect spindle unit LH connector.

-

Check voltage between spindle unit LH harness connector and ground.

(+) (–) Voltage Spindle unit LH Connector Terminal B196 3 Ground 9 – 16 V

Is the inspection result normal?

YES>>GO TO 4.

NO>>GO TO 3.

CHECK ENCODER CIRCUIT-1

-

Disconnect automatic back door control unit connector.

-

Check continuity between automatic back door control unit harness connector and ground.

Automatic back door control unit — Continuity Connector Terminal B159 31 Ground Not existed

Is the inspection result normal?

YES>>Replace automatic back door control unit. Refer to Removal and Installation.

NO>>Repair or replace harness.

CHECK ENCODER CIRCUIT-2

-

Disconnect automatic back door control unit connector and spindle unit RH connector.

-

Check continuity between automatic back door control unit harness connector and ground.

Automatic back door control unit — Continuity Connector Terminal B159 28 Ground Not existed

Is the inspection result normal?

YES>>Replace spindle unit LH. Refer to Removal & Installation.

NO>>Repair or replace harness.

B2426-12 Spindle Sensor Lh Nissan Ariya

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC Detection Condition | |

|---|---|---|---|

| B2426-12 | Spindle sensor LH | Diagnosis condition | When the door unlock operates while power switch is OFF (auto ACC OFF status) or the battery terminal is removed |

| Signal (terminal) | Encoder LH signal | ||

| Threshold | When automatic back door control unit detects shorted to battery of encoder LH circuit | ||

| Diagnosis delay time | 1 second or less | ||

POSSIBLE CAUSE

-

Spindle unit LH

-

Automatic back door control unit

-

Harness or connector (encoder LH circuit is shorted to battery)

FAIL-SAFE

Inhibit automatic back door system (only operate back door closure function)

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Door unlock operates by Intelligent Key, one touch sensor or door request switch while power switch is OFF (auto ACC OFF status).

-

Check “Self Diagnostic Result” mode of “AUTOMATIC BACK DOOR” using CONSULT.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

CHECK ENCODER SIGNAL

-

Power switch ON.

-

Select “AUTOMATIC BACK DOOR” using CONSULT.

-

Select “Spindle sensor LH” in “Data Monitor” mode.

-

Check that the function operates normally according to the following conditions.

Monitor item Condition Status Spindle sensor LH Back door Open The numeral value increases Close The numeral value decreases

Is the inspection result normal?

YES>>Check intermittent incident. Refer to Intermittent Incident.

NO>>GO TO 2.

CHECK ENCODER CIRCUIT

-

Power switch OFF.

-

Disconnect automatic back door control unit connector, spindle unit LH connector and spindle unit RH connector.

-

Check voltage between automatic back door control unit harness connector and ground.

Automatic back door control unit — Voltage

(Approx.)Connector Terminal B159 28 Ground 0 V 31

Is the inspection result normal?

YES>>GO TO 3.

NO>>Repair or replace harness.

REPLACE SPINDLE UNIT LH

Replace spindle unit LH. Refer to Removal & Installation.

Is the inspection result normal?

YES>>INSPECTION END

NO>>Replace automatic back door control unit. Refer to Removal and Installation.

B2426-13 Spindle Sensor Lh Nissan Ariya 2026

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC Detection Condition | |

|---|---|---|---|

| B2426-13 | Spindle sensor LH | Diagnosis condition | When automatic back door open/close function operate |

| Signal (terminal) | Encoder LH signal | ||

| Threshold | Automatic back door control unit cannot detects the encoder LH signal | ||

| Diagnosis delay time | 1 second or less | ||

POSSIBLE CAUSE

-

Spindle unit LH

-

Automatic back door control unit

-

Harness or connector (encoder LH circuit is opened)

FAIL-SAFE

Inhibit automatic back door system (only operate back door closure function)

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Power switch ON.

-

Operate automatic back door.

-

Check “Self Diagnostic Result” mode of “AUTOMATIC BACK DOOR” using CONSULT.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

CHECK ENCODER SIGNAL

-

Power switch ON.

-

Select “AUTOMATIC BACK DOOR” using CONSULT.

-

Select “Spindle sensor LH” in “Data Monitor” mode.

-

Check that the function operates normally according to the following conditions.

Monitor item Condition Status Spindle sensor LH Back door Open The numeral value increases Close The numeral value decreases

Is the inspection result normal?

YES>>Check intermittent incident. Refer to Intermittent Incident.

NO>>GO TO 2.

CHECK ENCODER INPUT SIGNAL

Check signal between automatic back door control unit harness connector and ground using oscilloscope.

| (+) | (–) | Condition |

Signal (Reference value) | ||

|---|---|---|---|---|---|

| Automatic back door control unit | |||||

| Connector | Terminal | ||||

| B159 | 29 | Ground | Back door | Moving (manual) |

|

| When stopped | 0 – 1 V or 9 – 16 V | ||||

| 30 | Moving (manual) |

|

|||

| When stopped | 0 – 1 V or 9 – 16 V | ||||

Is the inspection result normal?

YES>>GO TO 4.

NO>>GO TO 3.

CHECK ENCODER CIRCUIT

-

Power switch OFF.

-

Disconnect automatic back door control unit connector and spindle unit LH connector.

-

Check continuity between automatic back door control unit harness connector and spindle unit LH harness connector.

Automatic back door control unit Spindle unit LH Continuity Connector Terminal Connector Terminal B159 29 B196 5 Existed 30 4

Is the inspection result normal?

YES>>Replace spindle unit LH. Refer to Removal & Installation.

NO>>Repair or replace harness.

CHECK ENCODER POWER SUPPLY

-

Power switch OFF.

-

Disconnect spindle unit LH connector.

-

Check voltage between spindle unit LH harness connector and ground.

(+) (–) Voltage Spindle unit LH Connector Terminal B196 3 Ground 9 – 16 V

Is the inspection result normal?

YES>>GO TO 6.

NO>>GO TO 5.

CHECK ENCODER CIRCUIT-1

-

Disconnect automatic back door control unit connector.

-

Check continuity between automatic back door control unit harness connector and spindle unit LH harness connector.

Automatic back door control unit Spindle unit LH Continuity Connector Terminal Connector Terminal B159 31 B196 3 Existed

Is the inspection result normal?

YES>>Replace automatic back door control unit. Refer to Removal and Installation.

NO>>Repair or replace harness.

CHECK ENCODER CIRCUIT-2

-

Disconnect automatic back door control unit connector and spindle unit RH connector.

-

Check continuity between automatic back door control unit harness connector and spindle unit LH harness connector.

Automatic back door control unit Spindle unit LH Continuity Connector Terminal Connector Terminal B159 28 B196 6 Existed

Is the inspection result normal?

YES>>Replace spindle unit LH. Refer to Removal & Installation.

NO>>Repair or replace harness.

B2426-25 Spindle Sensor Lh Nissan Ariya 2026

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC Detection Condition | |

|---|---|---|---|

| B2426-25 | Spindle sensor LH | Diagnosis condition | When automatic back door open/close function operate |

| Signal (terminal) | Encoder LH signal | ||

| Threshold | Automatic back door control unit cannot detects the encoder LH signal | ||

| Diagnosis delay time | Less than 40 pulse | ||

POSSIBLE CAUSE

-

Spindle unit LH

-

Automatic back door control unit

-

Harness or connector (encoder LH circuit is open or shorted)

FAIL-SAFE

Inhibit automatic back door system (only operate back door closure function)

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Power switch ON.

-

Operate automatic back door.

-

Check “Self Diagnostic Result” mode of “AUTOMATIC BACK DOOR” using CONSULT.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

CHECK ENCODER SIGNAL

-

Power switch ON.

-

Select “AUTOMATIC BACK DOOR” using CONSULT.

-

Select “Spindle sensor LH” in “Data Monitor” mode.

-

Check that the function operates normally according to the following conditions.

Monitor item Condition Status Spindle sensor LH Back door Open The numeral value increases Close The numeral value decreases

Is the inspection result normal?

YES>>Check intermittent incident. Refer to Intermittent Incident.

NO>>GO TO 2.

CHECK ENCODER INPUT SIGNAL

Check signal between automatic back door control unit harness connector and ground using oscilloscope.

| (+) | (–) | Condition |

Signal (Reference value) | ||

|---|---|---|---|---|---|

| Automatic back door control unit | |||||

| Connector | Terminal | ||||

| B159 | 29 | Ground | Back door | Moving (manual) |

|

| When stopped | 0 – 1 V or 9 – 16 V | ||||

| 30 | Moving (manual) |

|

|||

| When stopped | 0 – 1 V or 9 – 16 V | ||||

Is the inspection result normal?

YES>>Replace automatic back door control unit. Refer to Removal and Installation.

NO>>GO TO 3.

CHECK ENCODER CIRCUIT

-

Power switch OFF.

-

Disconnect automatic back door control unit connector and spindle unit LH connector.

-

Check continuity between automatic back door control unit harness connector and spindle unit LH harness connector.

Automatic back door control unit Spindle unit LH Continuity Connector Terminal Connector Terminal B159 29 B196 5 Existed 30 4 -

Check continuity between automatic back door control unit harness connector and ground.

Automatic back door control unit — Continuity Connector Terminal B159 29 Ground Not existed 30

Is the inspection result normal?

YES>>Replace spindle unit LH. Refer to Removal & Installation.

NO>>Repair or replace harness.

B2428-44 Automatic Back Door Control Unit Nissan Ariya 2026

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC Detection Condition | |

|---|---|---|---|

| B2428-44 | Automatic back door control unit | Diagnosis condition | Power switch ON |

| Signal (terminal) | — | ||

| Threshold | Automatic back door control unit internal malfunction (data memory error) | ||

| Diagnosis delay time | — | ||

POSSIBLE CAUSE

Automatic back door control unit

FAIL-SAFE

Inhibit automatic back door system all function

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Power switch ON.

-

Check “Self Diagnostic Result” mode of “AUTOMATIC BACK DOOR” using CONSULT.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

REPLACE AUTOMATIC BACK DOOR CONTROL UNIT

When DTC "B2428-44" is detected, replace automatic back door control unit.

>>

Replace automatic back door control unit. Refer to Removal and Installation.

B2428-54 Automatic Back Door Control Unit Nissan Ariya 2023

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC Detection Condition | |

|---|---|---|---|

| B2428-54 | Automatic back door control unit | Diagnosis condition | Power switch ON |

| Signal (terminal) | — | ||

| Threshold | When the calibration of [CALIBRATION OF AUTOMATIC BACK DOOR POSITION INFORMATION] is not complete | ||

| Diagnosis delay time | 1 second or less | ||

POSSIBLE CAUSE

[CALIBRATION OF AUTOMATIC BACK DOOR POSITION INFORMATION]: not complete

FAIL-SAFE

Inhibit automatic back door system all function

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Power switch ON.

-

Check “Self Diagnostic Result” mode of “AUTOMATIC BACK DOOR” using CONSULT.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

CALIBRATION OF AUTOMATIC BACK DOOR POSITION INFORMATION

-

Perform initialization setting of automatic back door position information. Refer to Work Procedure.

-

Erase DTC, and then check “DTC CONFIRMATION PROCEDURE”. Refer to DTC Description.

Is DTC detected?

YES>>Replace automatic back door control unit. Refer to Removal and Installation.

NO>>INSPECTION END

B242a-11 Closure Motor Nissan Ariya first Gen

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC Detection Condition | |

|---|---|---|---|

| B242A-11 | Closure motor | Diagnosis condition | Power switch ON |

| Signal (terminal) | Closure motor signal | ||

| Threshold | Automatic back door control unit cannot detects the closure motor signal | ||

| Diagnosis delay time | 1 second or less | ||

POSSIBLE CAUSE

-

Harness or connector (closure motor circuit is shorted to ground)

-

Automatic back door control unit

-

Back door lock assembly (closure motor)

FAIL-SAFE

Inhibit automatic back door system all function

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Power switch ON.

-

Check “Self Diagnostic Result” mode of “AUTOMATIC BACK DOOR” using CONSULT.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

CHECK BACK DOOR CLOSURE MOTOR CIRCUIT

-

Power switch OFF.

-

Disconnect automatic back door control unit connector and back door lock assembly connector.

-

Check continuity between automatic back door control unit harness connector and ground.

Automatic back door control unit — Continuity Connector Terminal B158 33 Ground Not existed 34

Is the inspection result normal?

YES>>GO TO 2.

NO>>Repair or replace harness.

REPLACE BACK DOOR LOCK ASSEMBLY

-

Replace back door lock assembly. Refer to Removal & Installation.

-

Erase DTC, and then check "DTC CONFIRMATION PROCEDURE". Refer to DTC Description.

Is DTC detected?

YES>>Replace automatic back door control unit. Refer to Removal and Installation.

NO>>INSPECTION END

B242a-98 Closure Motor Nissan Ariya 1st generation

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC Detection Condition | |

|---|---|---|---|

| B242A-98 | Closure motor | Diagnosis condition | When back door auto closure function operate |

| Signal (terminal) | — | ||

| Threshold | When thermal protection operate of the closure motor | ||

| Diagnosis delay time | 20 seconds or more | ||

POSSIBLE CAUSE

-

Back door lock assembly (closure motor)

-

Continuous operation of the closure motor

-

Automatic back door control unit

FAIL-SAFE

Inhibit automatic back door system all function

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Operate back door auto closure function.

-

Check “Self Diagnostic Result” mode of “AUTOMATIC BACK DOOR” using CONSULT.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

CHECK SELF DIAGNOSTIC RESULT

-

Back door auto closure function is operated, and wait for 40 seconds or more.

-

Erase DTC.

-

Select “Self Diagnostic Result” mode of “AUTOMATIC BACK DOOR” using CONSULT.

Is DTC detected?

YES>>Replace automatic back door control unit. Refer to Removal and Installation.

NO>>INSPECTION END

B242f-11 Automatic Back Door Warning Buzzer Nissan Ariya SUV

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC Detection Condition | |

|---|---|---|---|

| B242F-11 | Automatic back door warning buzzer | Diagnosis condition | When automatic back door open/close function operate |

| Signal (terminal) | Automatic back door warning buzzer signal | ||

| Threshold | Automatic back door control unit cannot detects the automatic back door warning buzzer signal | ||

| Diagnosis delay time | 1 second or less | ||

POSSIBLE CAUSE

-

Automatic back door warning buzzer

-

Harness or connector (automatic back door warning buzzer circuit is shorted to ground)

-

Automatic back door control unit

FAIL-SAFE

—

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Power switch ON.

-

Operate automatic back door.

-

Check “Self Diagnostic Result” mode of “AUTOMATIC BACK DOOR” using CONSULT.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

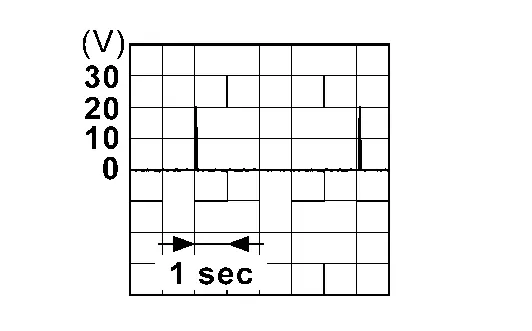

CHECK AUTOMATIC BACK DOOR WARNING BUZZER OUTPUT SIGNAL

Check signal between automatic back door warning buzzer harness connector and ground using oscilloscope.

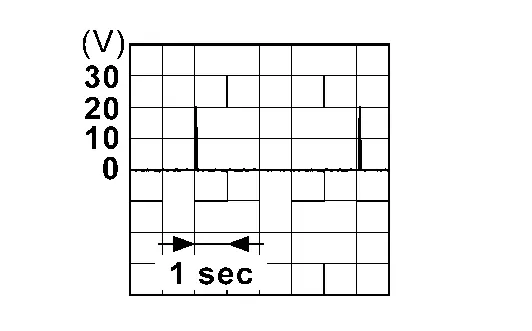

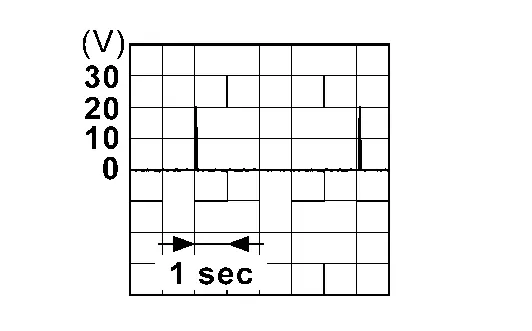

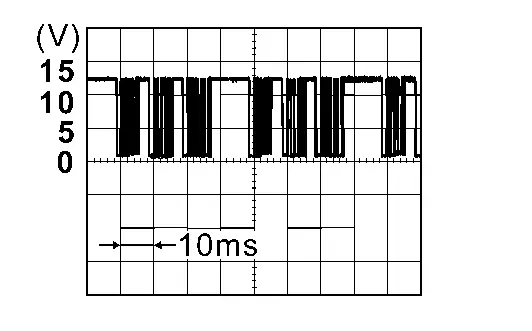

| (+) | (–) | Condition |

Signal (Reference value) | ||

|---|---|---|---|---|---|

| Automatic back door warning buzzer | |||||

| Connector | Terminal | ||||

| B157 | 1 | Ground | Automatic back door warning buzzer | Sounding (auto open/ close operation) |

|

| Not sounding | 0 – 1 V | ||||

Is the inspection result normal?

YES>>Replace automatic back door control unit. Refer to Removal and Installation.

NO>>GO TO 2.

CHECK AUTOMATIC BACK DOOR WARNING BUZZER OUTPUT SIGNAL CIRCUIT

-

Power switch OFF.

-

Disconnect automatic back door control unit connector and automatic back door warning buzzer connector.

-

Check continuity between automatic back door control unit harness connector and ground.

Automatic back door control unit — Continuity Connector Terminal B159 15 Ground Not existed

Is the inspection result normal?

YES>>Check intermittent incident. Refer to Intermittent Incident.

NO>>Repair or replace harness.

B242f-13 Automatic Back Door Warning Buzzer Nissan Ariya 1st generation

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC Detection Condition | |

|---|---|---|---|

| B242F-13 | Automatic back door warning buzzer | Diagnosis condition | When automatic back door open/close function operate |

| Signal (terminal) | Automatic back door warning buzzer signal | ||

| Threshold | Automatic back door control unit cannot detects the automatic back door warning buzzer signal | ||

| Diagnosis delay time | 1 second or less | ||

POSSIBLE CAUSE

-

Automatic back door warning buzzer

-

Harness or connector (automatic back door warning buzzer circuit is open or shorted)

-

Automatic back door control unit

FAIL-SAFE

—

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Power switch ON.

-

Operate automatic back door.

-

Check “Self Diagnostic Result” mode of “AUTOMATIC BACK DOOR” using CONSULT.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

CHECK AUTOMATIC BACK DOOR WARNING BUZZER OUTPUT SIGNAL

Check signal between automatic back door warning buzzer harness connector and ground using oscilloscope.

| (+) | (–) | Condition |

Signal (Reference value) | ||

|---|---|---|---|---|---|

| Automatic back door warning buzzer | |||||

| Connector | Terminal | ||||

| B157 | 1 | Ground | Automatic back door warning buzzer | Sounding (auto open/ close operation) |

|

| Not sounding | 0 – 1 V | ||||

Is the inspection result normal?

YES>>Replace automatic back door control unit. Refer to Removal and Installation.

NO>>GO TO 2.

CHECK AUTOMATIC BACK DOOR WARNING BUZZER OUTPUT SIGNAL CIRCUIT

-

Power switch OFF.

-

Disconnect automatic back door control unit connector and automatic back door warning buzzer connector.

-

Check continuity between automatic back door control unit harness connector and automatic back door warning buzzer harness connector.

Automatic back door control unit Automatic back door warning buzzer Continuity Connector Terminal Connector Terminal B159 15 B157 1 Existed -

Check continuity between automatic back door control unit harness connector and ground.

Automatic back door control unit — Continuity Connector Terminal B159 15 Ground Not existed

Is the inspection result normal?

YES>>GO TO 3.

NO>>Repair or replace harness.

CHECK AUTOMATIC BACK DOOR WARNING BUZZER GROUND CIRCUIT

Check continuity between automatic back door warning buzzer harness connector and ground.

| Automatic back door warning buzzer | — | Continuity | |

|---|---|---|---|

| Connector | Terminal | ||

| B157 | 3 | Ground | Existed |

Is the inspection result normal?

YES>>GO TO 4.

NO>>Repair or replace harness.

CHECK AUTOMATIC BACK DOOR WARNING BUZZER

Check automatic back door warning buzzer. Refer to Component Inspection.

Is the inspection result normal?

YES>>Check intermittent incident. Refer to Intermittent Incident.

NO>>Replace automatic back door warning buzzer. Refer to Removal and Installation.

B2f06-11 Trunk/back Door Opener Sw Nissan Ariya 2023

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC detecting condition | |

|---|---|---|---|

| B2F06-11 | Back door/trunk opener switch | Diagnosis condition | Power switch ON |

| Signal (terminal) | Back door opener switch signal (BCM connector terminal: 98) | ||

| Threshold | When the BCM detects back door opener switch circuit is shorted to ground | ||

| Diagnosis delay time | 1 second or less | ||

POSSIBLE CAUSE

-

Back door opener switch assembly (back door opener switch)

-

Harness or connectors [back door opener switch assembly (back door opener switch) circuit is shorted to ground]

-

BCM

FAIL-SAFE

–

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

-

Power switch ON.

-

Check “Self Diagnostic Result” mode of “BCM” using CONSULT.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

CHECK BACK DOOR OPENER INPUT SIGNAL

-

Power switch OFF.

-

Disconnect back door opener switch assembly connector.

-

Check voltage between back door opener switch assembly harness connector and ground.

(+) (–) Voltage Back door opener switch assembly Connector Terminal D121 1 Ground 9 – 16 V

Is the inspection result normal?

YES>>Check intermittent incident. Refer to Intermittent Incident.

NO>>GO TO 2.

CHECK BACK DOOR OPENER SWITCH CIRCUIT

-

Disconnect BCM connector.

-

Check continuity between BCM harness connector and back door opener switch assembly harness connector.

BCM Back door opener switch assembly Continuity Connector Terminal Connector Terminal B16 98 D121 1 Existed -

Check continuity between BCM harness connector and ground.

BCM — Continuity Connector Terminal B16 98 Ground Not existed

Is the inspection result normal?

YES>>Replace BCM. Refer to Removal and Installation.

NO>>Repair or replace harness.

U0075-00 Communication Bus C Off Nissan Ariya

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC Detection Condition | |

|---|---|---|---|

| U0075-00 | Control module communication Bus C Off | Diagnosis condition | Power switch ON |

| Signal (terminal) | CAN communication signal | ||

| Threshold |

Automatic back door control unit is unable to receive the CAN communication signal from the following control unit.

|

||

| Diagnosis delay time | 2 seconds or more | ||

POSSIBLE CAUSE

CAN communication system

FAIL-SAFE

Inhibit automatic back door system all function

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Power switch ON and wait for 2 seconds or more.

-

Check “Self Diagnostic Result” mode of “AUTOMATIC BACK DOOR” using CONSULT.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

CHECK CAN COMMUNICATION

Check CAN communication. Refer to Trouble Diagnosis Flow Chart.

Is DTC “U0075-00” displayed?

YES>>Repair or replace the malfunctioning part.

NO>>Check intermittent incident. Refer to Intermittent Incident.

U2118-87 Can Comm Circuit Nissan Ariya: FE0

DTC Description

DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time applications. It is an on-Nissan Ariya vehicle multiplex communication line with high data communication speed and excellent error detection ability. Modern Nissan Ariya vehicle is equipped with many electronic control unit, and each control unit shares information and links with other control units during operation (not independent). In CAN communication, control units are connected with 2 communication lines (CAN H-line, CAN L-line) allowing a high rate of information transmission with less wiring. Each control unit transmits/receives data but selectively reads required data only. CAN Communication Signal Chart. Refer to CAN Communication Signal Chart.

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC Detection Condition | |

|---|---|---|---|

| U2118-87 | CAN communication error (Intelligent Key) | Diagnosis condition | Power switch ON |

| Signal (terminal) | CAN communication signal | ||

| Threshold | Automatic back door control unit is unable to receive the CAN communications signal from Intelligent Key unit | ||

| Diagnosis delay time | 2 seconds or less | ||

POSSIBLE CAUSE

CAN communication system

FAIL-SAFE

Inhibit automatic back door system all function

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Power switch ON and wait for 2 seconds or more.

-

Check “Self Diagnostic Result” mode of “AUTOMATIC BACK DOOR” using CONSULT.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

CHECK CAN COMMUNICATION

Check CAN communication. Refer to Trouble Diagnosis Flow Chart.

Is DTC “U2118-87” displayed?

YES>>Repair or replace the malfunctioning part.

NO>>Check intermittent incident. Refer to Intermittent Incident.

U2148-87 Can Comm Circuit. Intelligent Key Unit Nissan Ariya SUV

DTC Description

DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time applications. It is an on-Nissan Ariya vehicle multiplex communication line with high data communication speed and excellent error detection ability. Modern Nissan Ariya vehicle is equipped with many electronic control unit, and each control unit shares information and links with other control units during operation (not independent). In CAN communication, control units are connected with 2 communication lines (CAN H-line, CAN L-line) allowing a high rate of information transmission with less wiring. Each control unit transmits/receives data but selectively reads required data only. CAN Communication Signal Chart. Refer to CAN Communication Signal Chart.

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC Detection Condition | |

|---|---|---|---|

| U2148-87 | CAN communication error (brake control unit) | Diagnosis condition | Power switch ON |

| Signal (terminal) | CAN communication signal | ||

| Threshold | Intelligent Key unit cannot communicate CAN communication signal | ||

| Diagnosis delay time | 2 seconds or more | ||

POSSIBLE CAUSE

CAN communication system

FAIL-SAFE

—

DTC CONFIRMATION PROCEDURE

CHECK SELF-DIAG RESULT

With CONSULT

With CONSULT

-

Power switch ON and wait for 2 seconds or more.

-

Select “Self Diagnostic Result” mode of “INTELLIGENT KEY” using CONSULT.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

CHECK CAN COMMUNICATION

Check CAN communication. Refer to Trouble Diagnosis Flow Chart.

Is DTC “U2148-87” displayed?

YES>>Repair or replace the malfunctioning part.

NO>>Check intermittent incident. Refer to Intermittent Incident.

U214e-87 Can Comm Circuit. Intelligent Key Unit Nissan Ariya 1st generation

DTC Description

DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time applications. It is an on-Nissan Ariya vehicle multiplex communication line with high data communication speed and excellent error detection ability. Modern Nissan Ariya vehicle is equipped with many electronic control unit, and each control unit shares information and links with other control units during operation (not independent). In CAN communication, control units are connected with 2 communication lines (CAN H-line, CAN L-line) allowing a high rate of information transmission with less wiring. Each control unit transmits/receives data but selectively reads required data only. CAN Communication Signal Chart. Refer to CAN Communication Signal Chart.

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC Detection Condition | |

|---|---|---|---|

| U214E-87 | CAN communication error (combination meter) | Diagnosis condition | Power switch ON |

| Signal (terminal) | CAN communication signal | ||

| Threshold | Intelligent Key unit cannot communicate CAN communication signal | ||

| Diagnosis delay time | 2 seconds or more | ||

POSSIBLE CAUSE

CAN communication system

FAIL-SAFE

—

DTC CONFIRMATION PROCEDURE

CHECK SELF-DIAG RESULT

With CONSULT

With CONSULT

-

Power switch ON and wait for 2 seconds or more.

-

Select “Self Diagnostic Result” mode of “INTELLIGENT KEY” using CONSULT.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

CHECK CAN COMMUNICATION

Check CAN communication. Refer to Trouble Diagnosis Flow Chart.

Is DTC “U214E-87” displayed?

YES>>Repair or replace the malfunctioning part.

NO>>Check intermittent incident. Refer to Intermittent Incident.

U214f-87 Can Comm Circuit. Intelligent Key Unit Nissan Ariya 1st generation

DTC Description

DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time applications. It is an on-Nissan Ariya vehicle multiplex communication line with high data communication speed and excellent error detection ability. Modern Nissan Ariya vehicle is equipped with many electronic control unit, and each control unit shares information and links with other control units during operation (not independent). In CAN communication, control units are connected with 2 communication lines (CAN H-line, CAN L-line) allowing a high rate of information transmission with less wiring. Each control unit transmits/receives data but selectively reads required data only. CAN Communication Signal Chart. Refer to CAN Communication Signal Chart.

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC Detection Condition | |

|---|---|---|---|

| U214F–87 | CAN communication error (BCM) | Diagnosis condition | Power switch ON |

| Signal (terminal) | CAN communication signal | ||

| Threshold | Intelligent Key unit cannot communicate CAN communication signal | ||

| Diagnosis delay time | 2 seconds or more | ||

POSSIBLE CAUSE

CAN communication system

FAIL-SAFE

—

DTC CONFIRMATION PROCEDURE

CHECK SELF-DIAG RESULT

With CONSULT

With CONSULT

-

Power switch ON and wait for 2 seconds or more.

-

Select “Self Diagnostic Result” mode of “INTELLIGENT KEY” using CONSULT.

Is DTC detected?

YES>>Refer to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

CHECK CAN COMMUNICATION

Check CAN communication. Refer to Trouble Diagnosis Flow Chart.

Is DTC “U214F-87” displayed?

YES>>Repair or replace the malfunctioning part.

NO>>Check intermittent incident. Refer to Intermittent Incident.

U215b-87 Can Comm Circuit. Intelligent Key Unit Nissan Ariya: FE0

DTC Description

DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time applications. It is an on-Nissan Ariya vehicle multiplex communication line with high data communication speed and excellent error detection ability. Modern Nissan Ariya vehicle is equipped with many electronic control unit, and each control unit shares information and links with other control units during operation (not independent). In CAN communication, control units are connected with 2 communication lines (CAN H-line, CAN L-line) allowing a high rate of information transmission with less wiring. Each control unit transmits/receives data but selectively reads required data only. CAN Communication Signal Chart. Refer to CAN Communication Signal Chart.

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC Detection Condition | |

|---|---|---|---|

| U215B–87 | CAN communication error (IPDM E/R) | Diagnosis condition | Power switch ON |

| Signal (terminal) | CAN communication signal | ||

| Threshold | Intelligent Key unit cannot communicate CAN communication signal | ||

| Diagnosis delay time | 2 seconds or more | ||

POSSIBLE CAUSE

CAN communication system

FAIL-SAFE

—

DTC CONFIRMATION PROCEDURE

CHECK SELF-DIAG RESULT

With CONSULT

With CONSULT

-

Power switch ON and wait for 2 seconds or more.

-

Select “Self Diagnostic Result” mode of “INTELLIGENT KEY” using CONSULT.

Is DTC detected?

YES>>Refer to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

CHECK CAN COMMUNICATION

Check CAN communication. Refer to Trouble Diagnosis Flow Chart.

Is DTC “U215B-87” displayed?

YES>>Repair or replace the malfunctioning part.

NO>>Check intermittent incident. Refer to Intermittent Incident.

Automatic Back Door Close Switch Nissan Ariya first Gen

Component Function Check

CHECK FUNCTION

-

Power switch ON.

-

Select “AUTOMATIC BACK DOOR” using CONSULT.

-

Select “Automatic back door close switch” in “Data Monitor” mode.

-

Check that the function operates normally according to the following conditions.

| Monitor item | Condition | Status | |

|---|---|---|---|

| Automatic back door close switch | Automatic back door close switch | Pressed | ON |

| Released | OFF | ||

Is the inspection result normal?

YES>>Automatic back door close switch is OK.

NO>>Refer to Diagnosis Procedure.

Diagnosis Procedure

CHECK AUTOMATIC BACK DOOR CLOSE SWITCH INPUT SIGNAL

-

Power switch OFF.

-

Disconnect automatic back door close switch assembly connector.

-

Check voltage between automatic back door close switch assembly harness connector and ground.

(+) (–) Voltage Automatic back door close switch assembly Connector Terminal D135 2 Ground 9 – 16 V

Is the inspection result normal?

YES>>GO TO 3.

NO>>GO TO 2.

CHECK AUTOMATIC BACK DOOR CLOSE SWITCH CIRCUIT

-

Disconnect automatic back door control unit connector.

-

Check continuity between automatic back door control unit harness connector and automatic back door close switch assembly harness connector.

Automatic back door control unit Automatic back door close switch assembly Continuity Connector Terminal Connector Terminal B159 3 D135 2 Existed -

Check continuity between automatic back door control unit harness connector and ground.

Automatic back door control unit — Continuity Connector Terminal B159 3 Ground Not existed

Is the inspection result normal?

YES>>Replace automatic back door control unit. Refer to Removal and Installation.

NO>>Repair or replace harness.

CHECK AUTOMATIC BACK DOOR CLOSE SWITCH GROUND CIRCUIT

Check continuity between automatic back door close switch assembly harness connector and ground.

| Automatic back door close switch assembly | — | Continuity | |

|---|---|---|---|

| Connector | Terminal | ||

| D135 | 3 | Ground | Existed |

Is the inspection result normal?

YES>>GO TO 4.

NO>>Repair or replace harness.

CHECK AUTOMATIC BACK DOOR CLOSE SWITCH

Check automatic back door close switch. Refer to Component Inspection.

Is the inspection result normal?

YES>>GO TO 5.

NO>>Replace automatic back door close switch assembly. Refer to Removal and Installation.

CHECK INTERMITTENT INCIDENT

Check intermittent incident. Refer to Intermittent Incident.

>>

INSPECTION END

Component Inspection

CHECK AUTOMATIC BACK DOOR CLOSE SWITCH

-

Power switch OFF.

-

Disconnect automatic back door close switch assembly connector.

-

Check continuity between automatic back door close switch assembly terminals.

| Automatic back door close switch assembly | Condition | Continuity | ||

|---|---|---|---|---|

| Terminal | ||||

| 2 | 3 | Automatic back door close switch | Pressed | Existed |

| Released | Not existed | |||

Is the inspection result normal?

YES>>INSPECTION END

NO>>Replace automatic back door close switch assembly. Refer to Removal and Installation.

Automatic Back Door Warning Buzzer Nissan Ariya first Gen

Component Inspection

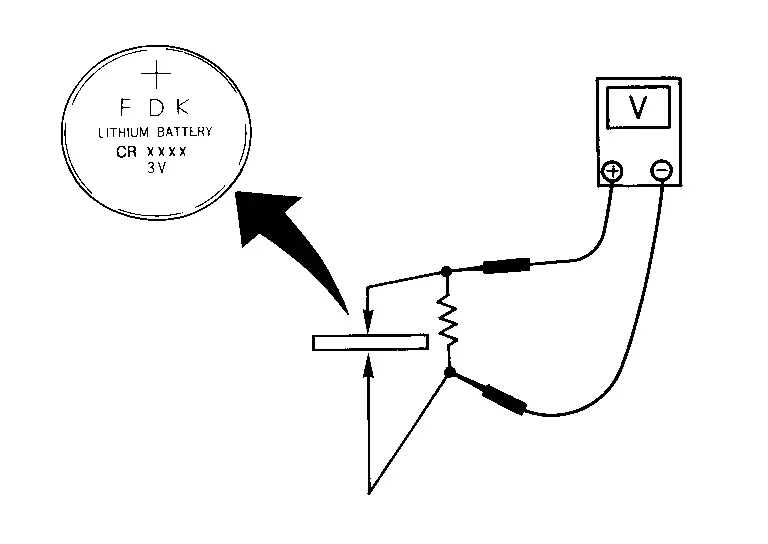

CHECK AUTOMATIC BACK DOOR WARNING BUZZER

-

Power switch OFF.

-

Disconnect automatic back door warning buzzer connector.

-

Check battery power supply directly to automatic back door warning buzzer terminals and check the operation.

| Automatic back door warning buzzer | Operation | |

|---|---|---|

| Terminal | ||

| (+) | (-) | |

| 1 | 3 | Buzzer sounds |

Is the inspection result normal?

YES>>INSPECTION END

NO>>Replace automatic back door warning buzzer. Refer to Removal and Installation.

Back Door Switch. With Automatic Back Door System Nissan Ariya SUV

Component Function Check

CHECK FUNCTION

-

Power switch ON.

-

Select “TRUNK” of “BCM” using CONSULT.

-

Select “Back door/trunk lid switch” in “Data Monitor” mode.

-

Check that the function operates normally according to the following conditions.

| Monitor item | Condition | Status | |

|---|---|---|---|

| Back door/trunk lid switch | Back door | Open | ON |

| Closed | OFF | ||

Is the inspection result normal?

YES >>Back door switch is OK.

NO>>Refer to Diagnosis Procedure.

Diagnosis Procedure

CHECK BACK DOOR SWITCH INPUT SIGNAL

-

Power switch OFF.

-

Disconnect back door lock assembly connector.

-

Check voltage between back door lock assembly harness connector and ground.

(+) (–) Voltage Back door lock assembly Connector Terminal D134 7 Ground 9 – 16 V

Is the inspection result normal?

YES>>GO TO 3.

NO>>GO TO 2.

CHECK BACK DOOR SWITCH CIRCUIT

-

Disconnect BCM connector.

-