Nissan Ariya: Electric Shift System

- Diagnosis and Repair Work Flow

- Additional Service When Replacing Electric Shift Control Module

- Actuator Position Learning

Diagnosis and Repair Work Flow Nissan Ariya: FE0

Work Flow

OBTAIN A PROBLEM REPORT

Clarify customer complaints before inspection. First of all, perform an interview utilizing Diagnostic Work Sheet (Refer to Diagnostic Work Sheet.) and reproduce symptoms as well as fully understand it. Ask customer about his/her complaints carefully. Check symptoms by driving Nissan Ariya vehicle with customer, if necessary.

CAUTION:

Customers are not professional. Never guess easily like “maybe the customer means that...,” or “maybe the customer mentions this symptom”.

>>

GO TO 2.

CHECK DETECTION OF DTC

-

Before checking the malfunction, check whether any DTC exists.

-

If DTC exists, perform the following operations.

-

Record the DTC and freeze frame data. (Print out the data using CONSULT and affix them to the Work Order Sheet. )

-

Erase DTCs.

-

Check the relationship between the cause that is clarified with DTC and the malfunction information described by the customer.

-

Do malfunction information and DTC exist?

Malfunction information and DTC exists.>>GO TO 3.

Malfunction information exists, but no DTC.>>GO TO 4.

No malfunction information, but DTC exists.>>GO TO 5.

REPRODUCE MALFUNCTION SYMPTOM

-

Check any malfunction described by a customer, except those with DTC on the Nissan Ariya vehicle.

-

Also investigate whether the symptom is a fail-safe or normal operation. Refer to Protection Function.

-

When a malfunction symptom is reproduced, the Interview sheet is effective. Refer to Diagnostic Work Sheet.

-

Verify the relationship between the symptom and the conditions in which the malfunction described by the customer occurs.

>>

GO TO 5.

REPRODUCE MALFUNCTION SYMPTOM

-

Check any malfunction described by a customer, except those with DTC on the Nissan Ariya vehicle.

-

Also verify if the phenomenon occurs as part of the normal operating condition. Refer to Protection Function.

-

When a malfunction symptom is reproduced, the Interview sheet is effective. Refer to Diagnostic Work Sheet.

-

Verify the relationship between the symptom and the conditions in which the malfunction described by the customer occurs.

>>

GO TO 7.

PERFORM THE "DTC CONFIRMATION PROCEDURE"

Perform the "Confirmation Procedure" corresponding to the DTC and verify if the DTC is detected again.

If multiple DTCs are detected at the same time, determine the order for performing the diagnosis based on DTC Inspection Priority Chart. Refer to DTC Inspection Priority Chart.

NOTE:

NOTE:

If no DTC is detected, use the freeze frame data for reference.

Is any DTC detected?

YES>>GO TO 6.

NO>>Refer to Intermittent Incident.

REPAIR OR REPLACE THE MALFUNCTIONING PARTS

Repair or replace the detected malfunctioning parts.

After the repair or replacement, reconnect the removed parts and connectors, and erase DTCs.

>>

GO TO 7.

FINAL CHECK

Perform “Confirmation Procedure” again to make sure that the repair is correctly performed.

Check that malfunctions are not reproduced when obtaining the malfunction information from the customer, referring to the symptom inspection result in step 3 or 4.

Is DTC or malfunction symptom reproduced?

YES>>GO TO 2.

NO>>Before delivering the Nissan Ariya vehicle to the customer, make sure that DTC is erased.

Diagnostic Work Sheet

DESCRIPTION

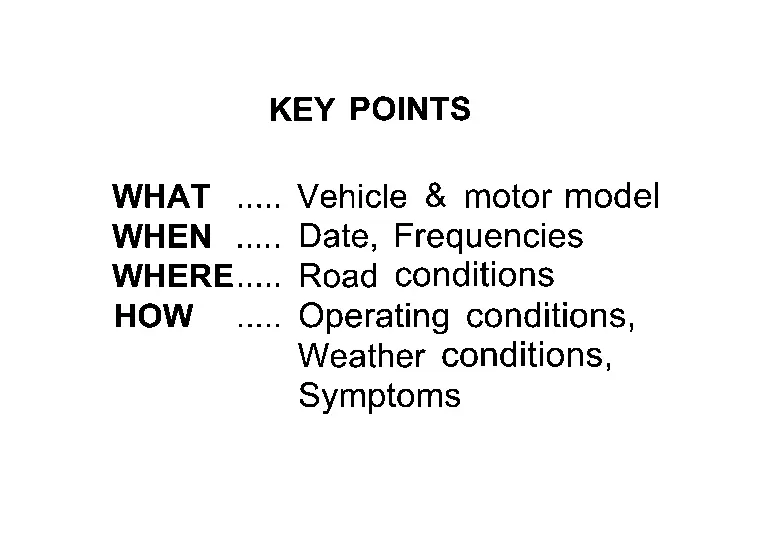

There are many operating conditions that may cause a malfunction of the system. By understanding those conditions properly, a quick and exact diagnosis can be achieved.

In general, customers have their own criteria for a problem. Therefore, it is important to understand the symptom and status well enough by asking the customer about the concerns carefully. In order to systemize all the information for the diagnosis, prepare the uestion sheet referring to the question points.

In some cases, multiple conditions that appear simultaneously may cause a DTC to be detected.

WORKSHEET SAMPLE

| Interview sheet | |||||

|---|---|---|---|---|---|

| Customer name | MR/MS | Registration number | Manuf. date | ||

| Nissan Ariya Vehicle model | VIN | ||||

| In service date | Engine/ Motor | Mileage |

km ( Mile) | ||

| Symptom | □ Nissan Ariya Vehicle does not move (□ Any position □ Specified position) | ||||

| □ Does not shift P position | |||||

| □ Does not shift other than P position | |||||

|

□ Others ( ) |

|||||

| First occurrence | □ Recently □ Others ( ) | ||||

| Frequency of occurrence | □ Always □ Under certain conditions □ Sometimes (time(s)/day) | ||||

| Climate conditions | □ Not affected | ||||

| Weather | □ Fine □ Cloud □ Rain □ Snow □ Others ( ) | ||||

| Temperature | □ Hot □ Warm □ Cool □ Cold □ Temperature [Approx. °C ( °F)] | ||||

| Relative humidity | □ High □ Moderate □ Low | ||||

| Road conditions | □ Not affected | ||||

|

□ Urban area □ Suburb area □ High way □ Mounting road (uphill or down hill) □ Rough road |

|||||

| Driving conditions | □ Not affected | ||||

|

□ At starting □ During idling □ During driving □ During acceleration □ At constant speed driving □ During deceleration □ During cornering (right curve or left curve) |

|||||

| □ Nissan Ariya Vehicle speed [ km/h ( MPH)] | |||||

| Other conditions |

|

||||

|

Memo |

|||||

Additional Service When Replacing Electric Shift Control Module Nissan Ariya 2023

Description

When the electric shift control module was replaced, it is necessary to learn the parking actuator P position information.

Work Procedure

PARKING ACTUATOR P POSITION LEARNING

Perform learning of the parking actuator P position. Refer to Description.

>>

WORK END

Actuator Position Learning Nissan Ariya

Description

Because the electric shift control module stores the parking actuator P position information, it is necessary to erase and relearn the learning value when the following work was performed.

-

Replacement of the electric shift control module

-

Replacement of the reduction gear

-

Removal and installation of the parking actuator

NOTE:

NOTE:

The parking actuator is replaced together with the reduction gear assembly.

Work Procedure

ERASING THE P POSITION INFORMATION

NOTE:

NOTE:

When the electric shift control module is new, it does not contain P position information. Therefore, erasing the P position information (this work) is not necessary.

With CONSULT

With CONSULT

-

Power switch OFF to ON.

-

Press the P position switch to shift to the P position.

-

Select “ACTUATOR LEARNING VALUE ELIMINATION” in “Work support” for “SHIFT”.

-

Select “Start”.

-

Touch “End”.

-

Power switch OFF and wait for 11 seconds under those conditions.

-

Power switch OFF to ON and then wait 5 seconds under those conditions.

-

Power switch OFF.

>>

GO TO 2.

RELEARNING THE P POSITION

-

Power switch OFF to ON.

-

Press the P position switch.

-

Press the P position switch even if P position is already selected.

-

-

Power switch OFF and wait for 60 seconds under those conditions.

CAUTION:

Never perform any shift operations.

>>

GO TO 3

OPERATION CHECK

-

Power switch OFF to ON.

-

Check that the park lock functions in P position and that park lock is released in N position.

-

Power switch OFF.

>>

WORK END

Nissan Ariya (FE0) 2023-2026 Service & Repair Manual

Electric Shift System

- Diagnosis and Repair Work Flow

- Additional Service When Replacing Electric Shift Control Module

- Actuator Position Learning

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image