Nissan Ariya: Basic Inspection

- Diagnosis and Repair Work Flow

- Additional Service When Replacing Air Bag Diagnosis Sensor Unit

- Configuration (air Bag Diagnosis Sensor Unit)

- Additional Service When Replacing Occupant Detection System Control Unit

- Zero Point Reset

Diagnosis and Repair Work Flow Nissan Ariya: FE0

Work Flow

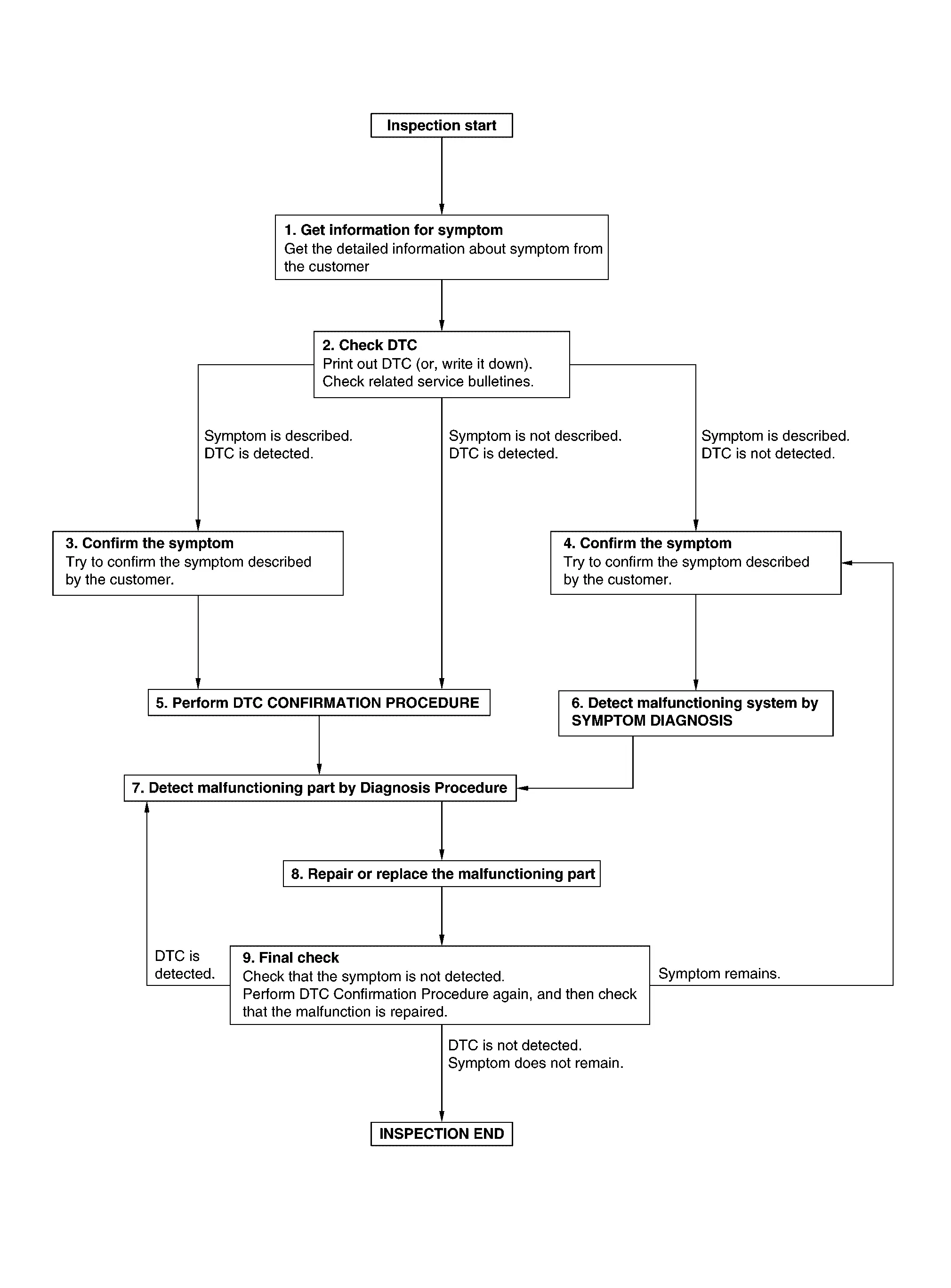

OVERALL SEQUENCE

DETAILED FLOW

GET INFORMATION FOR SYMPTOM

-

Get detailed information from the customer about the symptom (the condition and the environment when the incident/malfunction occurs).

-

Check operation condition of the function that is malfunctioning.

>>

GO TO 2.

CHECK DTC

-

Check DTC.

-

Perform the following procedure if DTC is detected.

-

Record DTC (Print them out using CONSULT).

-

Erase DTC.

-

Study the relationship between the cause detected by DTC and the symptom described by the customer.

-

-

Check related service bulletins for information.

Are any symptoms described and any DTC detected?

Symptom is described, DTC is detected>>GO TO 3.

Symptom is described, DTC is not detected>>GO TO 4.

Symptom is not described, DTC is detected>>GO TO 5.

CONFIRM THE SYMPTOM

Try to confirm the symptom described by the customer.

Verify relation between the symptom and the condition when the symptom is detected.

>>

GO TO 5.

CONFIRM THE SYMPTOM

Try to confirm the symptom described by the customer.

Verify relation between the symptom and the condition when the symptom is detected.

>>

GO TO 6.

PERFORM DTC CONFIRMATION PROCEDURE

Perform DTC CONFIRMATION PROCEDURE for the detected DTC, and then check that DTC is detected again.

Is DTC detected?

YES>>GO TO 7.

NO>>Check according to Intermittent Incident.

DETECT MALFUNCTIONING SYSTEM BY SYMPTOM DIAGNOSIS

Detect malfunctioning system according to SYMPTOM DIAGNOSIS based on the confirmed symptom in step 4, and determine the trouble diagnosis order based on possible causes and symptom.

>>

GO TO 7.

DETECT MALFUNCTIONING PART BY DIAGNOSIS PROCEDURE

Inspect according to Diagnosis Procedure of the system.

Is malfunctioning part detected?

YES>>GO TO 8.

NO>>Check according to Intermittent Incident.

REPAIR OR REPLACE THE MALFUNCTIONING PART

-

Repair or replace the malfunctioning part.

-

Reconnect parts or connectors disconnected during Diagnosis Procedure again after repair and replacement.

-

Check DTC. If DTC is detected, erase it.

>>

GO TO 9.

FINAL CHECK

When DTC is detected in step 2, perform DTC CONFIRMATION PROCEDURE again, and then check that the malfunction is repaired securely.

When symptom is described by the customer, refer to confirmed symptom in step 3 or 4, and check that the symptom is not detected.

Is DTC detected and does symptom remain?

YES-1>>DTC is detected: GO TO 7.

YES-2>>Symptom remains: GO TO 4.

NO>>Before returning the Nissan Ariya vehicle to the customer, always erase DTC.

Additional Service When Replacing Air Bag Diagnosis Sensor Unit Nissan Ariya 1st generation

Description

After replaced air bag diagnosis sensor unit, it is necessary to perform control unit configuration with CONSULT. For details, refer to Work Procedure.

Work Procedure

REPLACE AIR BAG DIAGNOSIS SENSOR UNIT

Replace air bag diagnosis sensor unit. Refer to Removal & Installation.

>>

GO TO 2.

WRITING Nissan Ariya Vehicle SPECIFICATION

Perform configuration for air bag diagnosis sensor unit. Refer to Description.

>>

WORK END

Configuration (air Bag Diagnosis Sensor Unit) Nissan Ariya first Gen

Description

Vehicle specification needs to be written with CONSULT because it is not written after replacing the air bag diagnosis sensor unit.

CONSULT connects to network and then it downloads the configuration data from the server. Then CONSULT writes the Nissan Ariya vehicle specification to the air bag diagnosis sensor unit. Refer to Work Procedure.

NOTE:

NOTE:

For details the operation, refer to “CONSULT Operation Manual”.

Work Procedure

WRITING VEHICLE SPECIFICATION

With CONSULT

With CONSULT

Perform writing Nissan Ariya vehicle specification to air bag diagnosis sensor unit according to "Replace ECU" in "CONSULT Operation Manual".

>>

GO TO 2

CHECK ALL ECU SELF-DIAGNOSIS RESULTS

With CONSULT

With CONSULT

-

Erase all ECU self-diagnosis results using CONSULT.

-

Power switch OFF.

-

Power switch ON.

-

Check that all ECU self-diagnosis results have no DTC.

>>

WORK END

Additional Service When Replacing Occupant Detection System Control Unit Nissan Ariya 2026

Description

When replacing occupant detection system control unit or removing and installing passenger seat, always perform zero point reset so that occupant detection system is activated normally. Refer to Work Procedure.

Work Procedure

PERFORM ZERO POINT RESET

Perform zero point reset. Refer to Description.

>>

WORK END

Zero Point Reset Nissan Ariya first Gen

Description

Zero point reset is an initializing procedure for occupant detection system that must be performed when replacing occupant detection system control unit or removing and installing passenger seat.

If zero point reset is not performed, the initialization is incomplete and occupant detection system does not operate normally. Refer to Work Procedure.

NOTE:

NOTE:

-

When replacing passenger seat with a NISSAN genuine part, SRS air bag warning lamp turns ON if zero point reset is incomplete.

-

When zero point reset is performed once after removal and installation of passenger seat, CONSULT displays “Already performed” and SRS air bag warning lamp does not ON.

-

When reinstalling passenger seat after removal, the initial value for occupant detection system sensor changes, and occupant detection system does not operate normally.

-

Always perform zero point reset after performing the work as per the following.

-

Reinstallation of passenger seat

-

Replacement of passenger seat with a seat that is zero point reset complete.

-

Work Procedure

PERFORM ZERO POINT RESET

-

Perform zero point reset.

NOTE:

NOTE:

When performing zero point reset, be careful of the items described as per the following.

-

Perform zero point reset after installing passenger seat to the Nissan Ariya vehicle

-

Never put any objects on passenger seat

-

Never apply excessive vibration to the Nissan Ariya vehicle

-

Never touch the vehicle

-

Never tilt the vehicle

-

-

Select start on “Zero point reset function” screen from, WORK SUPPORT of CONSULT “OCCUPANT DETECTION”.

-

“Zero point reset” starts.

>>

GO TO 2.

CONFIRMATION OF SETTING

-

Proceed to “Zero point reset function” screen from work support of CONSULT “OCCUPANT DETECTION”.

-

Check that “Already performed” or “Not yet performed” is displayed on “Zero point reset current status”.

CAUTION:

-

“Already performed” is displayed on “Zero point reset current status” if the seat is reinstalled by seat removal and installation, or zero point reset is already performed.

-

“Zero point reset current status” displays “Not yet performed” if a new seat is installed. When power switch ON without performing zero point reset, SRS air bag warning lamp keeps turning ON. When zero point reset is performed, SRS air bag warning lamp turns OFF.

-

Air bag diagnosis sensor unit does not record whether or not zero point reset is performed.

Is condition “Already performed”?

YES>>WORK END

NO>>Check condition as per the following, and perform zero point reset again.

-

Passenger seat is occupied by an object.

-

Excessive vibration is applied while performing zero point reset.

-

Occupant detection system is malfunctioning.

NOTE:

NOTE:

If “Not yet performed” is displayed on “Zero point reset current status”, zero point reset is not completed normally. Check the condition as per the following and perform zero point reset again.

-

Passenger seat is occupied by an object.

-

Excessive vibration is applied while performing zero point reset.

-

Occupant detection system is malfunctioning.

Nissan Ariya (FE0) 2023-2026 Service & Repair Manual

Basic Inspection

- Diagnosis and Repair Work Flow

- Additional Service When Replacing Air Bag Diagnosis Sensor Unit

- Configuration (air Bag Diagnosis Sensor Unit)

- Additional Service When Replacing Occupant Detection System Control Unit

- Zero Point Reset

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image