Nissan Ariya: Removal and Installation

- Brake Pedal

- Front Brake Piping

- Rear Brake Piping

- Brake Power Supply Backup Unit

- Electrically-Driven Intelligent Brake Unit

- Warning Buzzer

- Front Brake Pad

- Front Brake Caliper Assembly

- Rear Brake Pad

- Rear Brake Caliper Assembly

Brake Pedal Nissan Ariya 1st generation

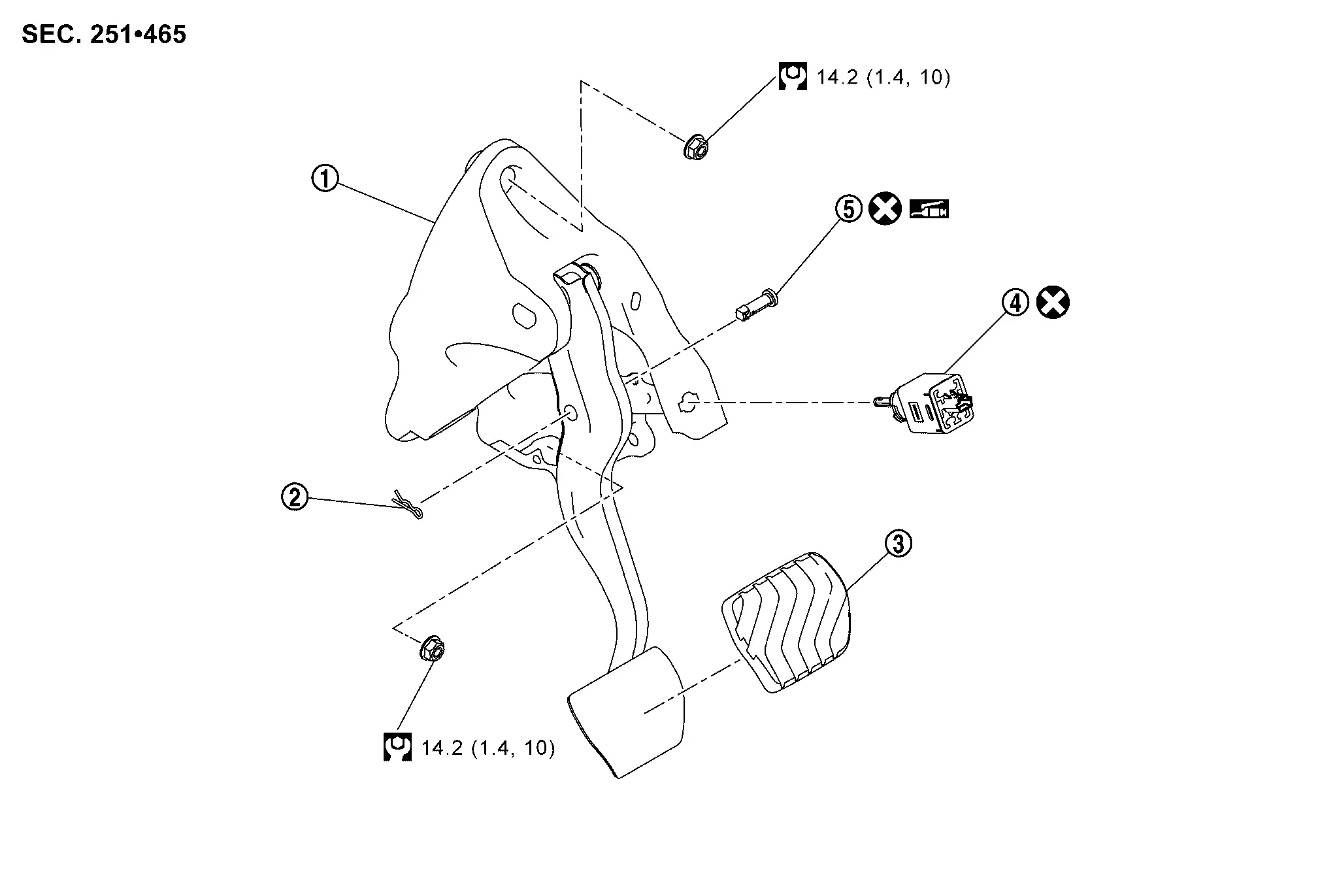

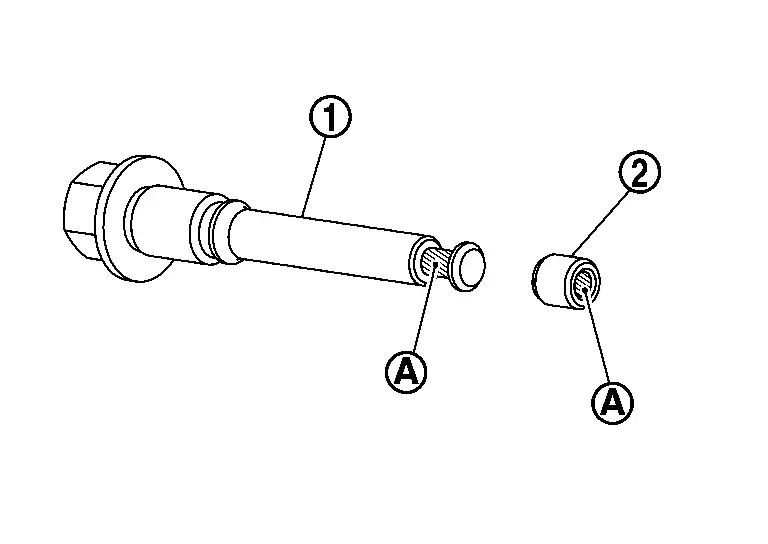

BRAKE PEDAL : Exploded View

|

Brake pedal assembly |  |

Snap pin |  |

Brake pedal pad |

|

Stop lamp switch |  |

Clevis pin | ||

|

: N·m (kg-m, ft-lb) | ||||

|

: Apply Nissan multi-purpose Special Grease No. 2. | ||||

|

: Always replace after every disassembly. | ||||

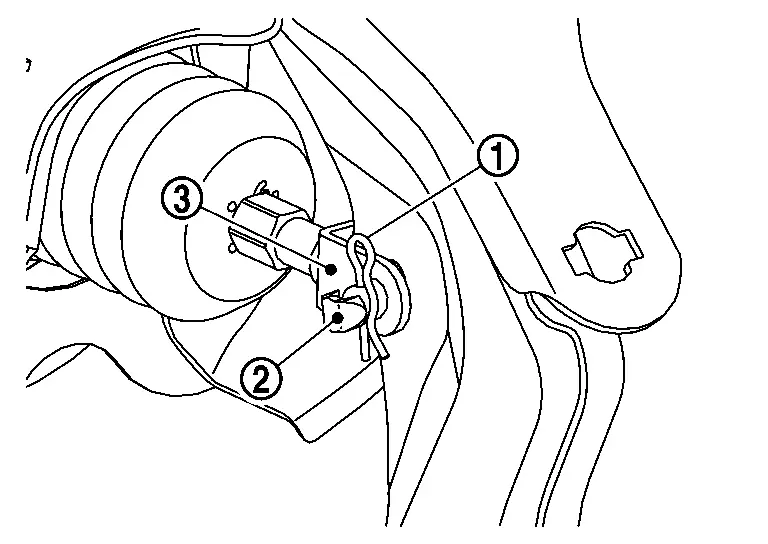

BRAKE PEDAL : Removal & Installation

REMOVAL

Disconnect 12V battery negative terminal. Refer to Removal & Installation.

Remove instrument lower panel. Refer to Removal & Installation.

Remove instrument finisher B. Refer to Removal & Installation.

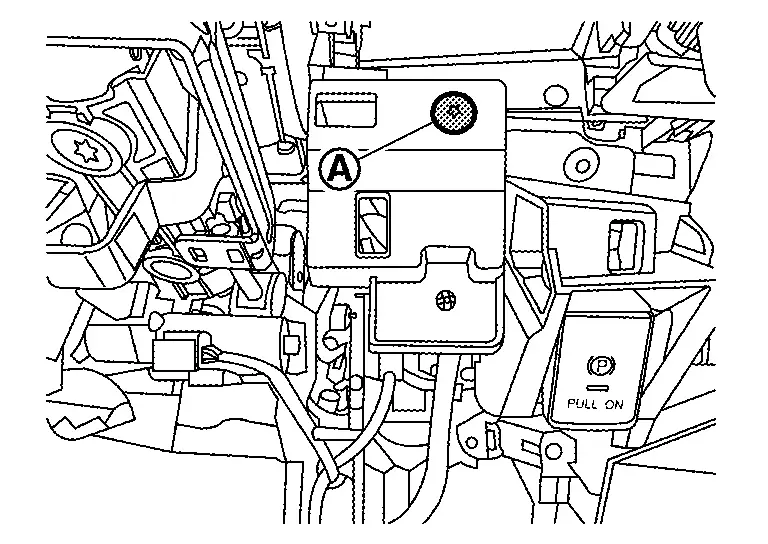

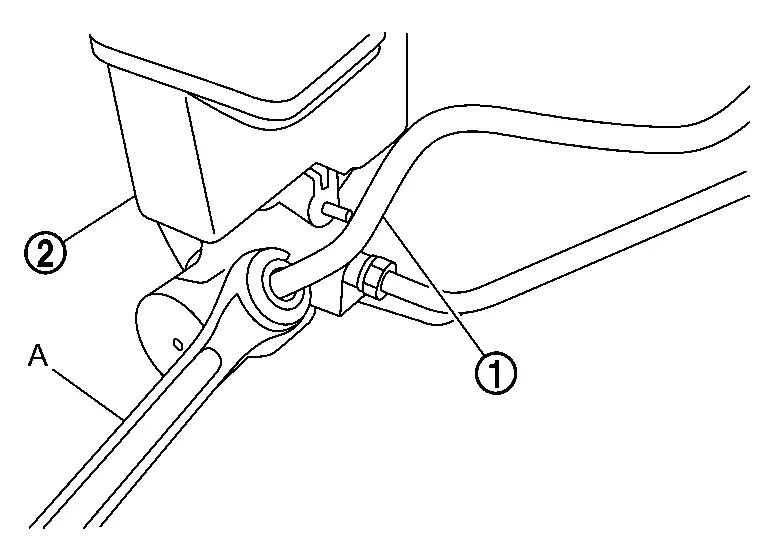

Remove screw  .

.

Remove mounting nuts  , and then remove bracket

, and then remove bracket  .

.

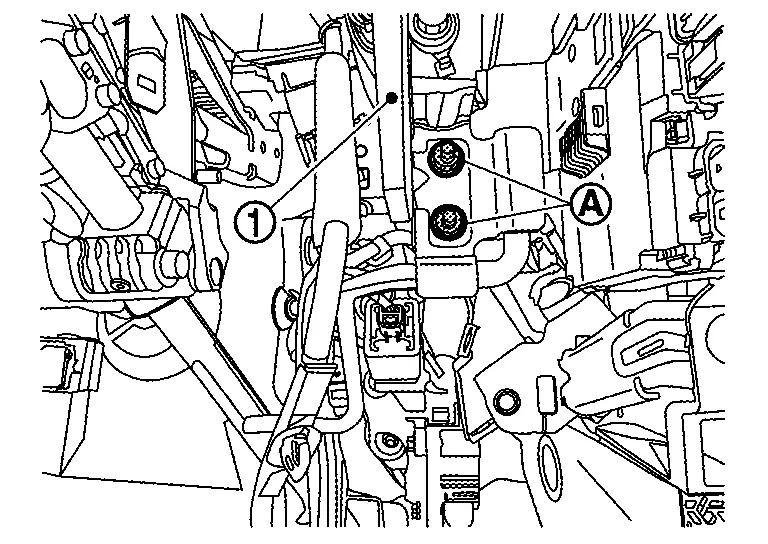

Remove negative harness mounting bolt  and screw

and screw  , and then remove bracket

, and then remove bracket .

.

Disconnect the stop lamp switch harness connector.

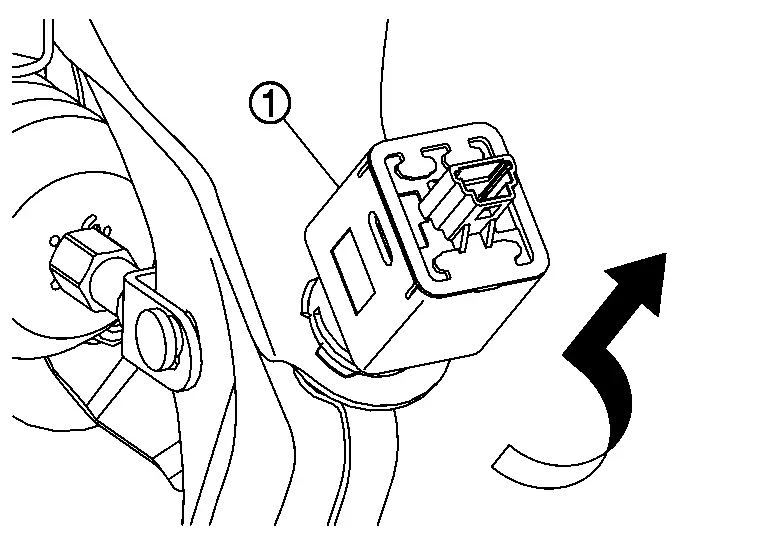

Remove stop lamp switch 90° rotate the stop lamp switch counterclockwise.

Disconnect the accelerator pedal harness connector.

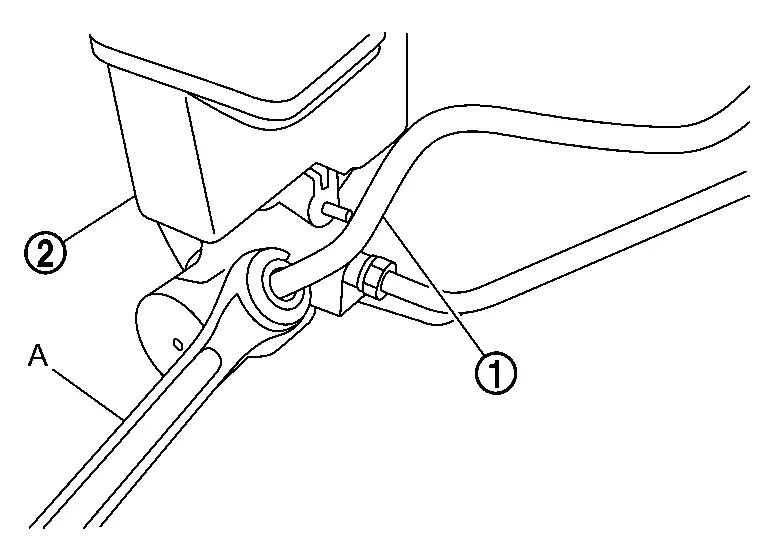

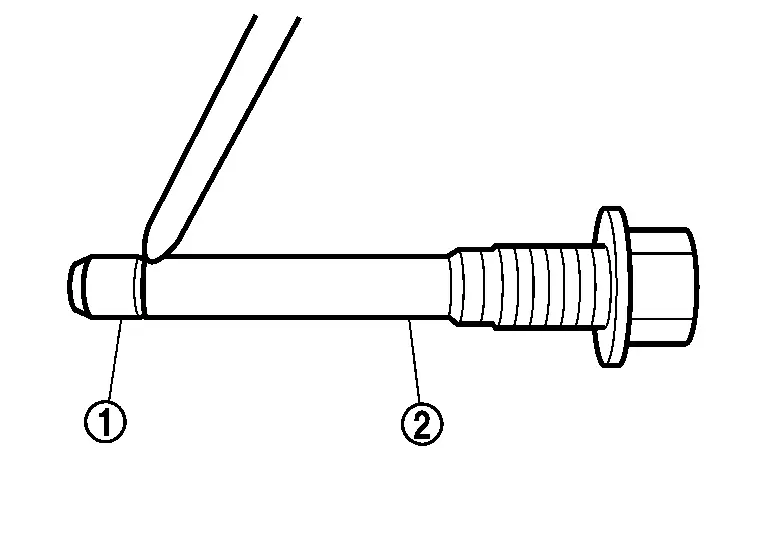

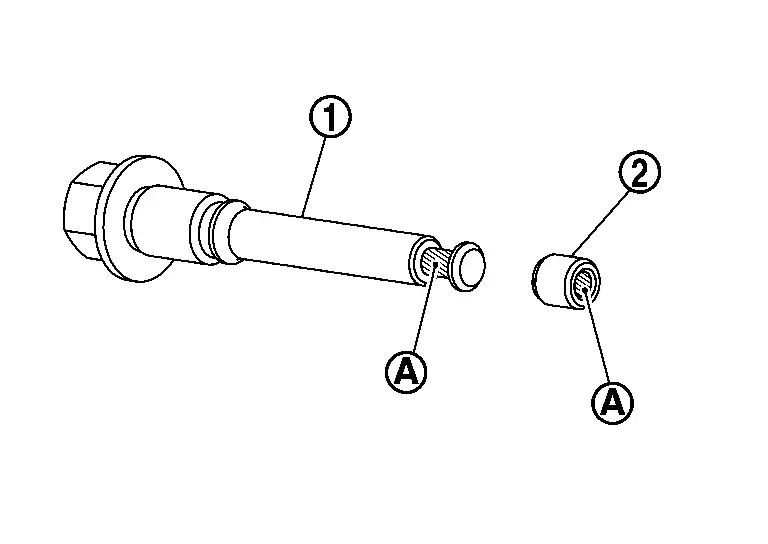

Remove snap pin  and clevis pin

and clevis pin  form the clevis

form the clevis  .

.

Remove harness clip from brake pedal assembly.

Remove electrically-driven intelligent brake unit mounting nuts and brake pedal assembly mounting nuts and then remove brake pedal assembly from the Nissan Ariya vehicle.

CAUTION:

To prevent damage to the parts, never drop electrically-driven intelligent brake unit.

Remove accelerator pedal from brake pedal assembly. Refer to Removal & Installation.

Perform inspection after removal. Refer to Inspection and Adjustment.

INSTALLATION

Note the following, and install in the reverse order of removal.

-

Never reuse the clevis pin.

-

Apply the Nissan multi-purpose Special Grease No. 2 to the clevis pin and the mating faces. (Not necessary if grease has been already applied)

NOTE:

NOTE:

The clevis pin may be inserted in either direction.

-

Never impact brake pedal such as drop and interference with tools and parts.

-

Replace brake pedal when impacting brake pedal.

-

Perform adjustment after installation. Refer to Inspection and Adjustment.

BRAKE PEDAL : Inspection and Adjustment

INSPECTION AFTER REMOVAL

Check the brake pedal assembly for bend, damage, and cracks on the welded parts. If any is found, replace brake pedal assembly.

ADJUSTMENT AFTER INSTALLATION

-

Adjust each item of brake pedal after installing the brake pedal assembly to the vehicle. Refer to Periodic Maintenance Operation .

-

Perform the release position learning of the accelerator pedal. Refer to Work Procedure.

-

Front Brake Piping Nissan Ariya 2023

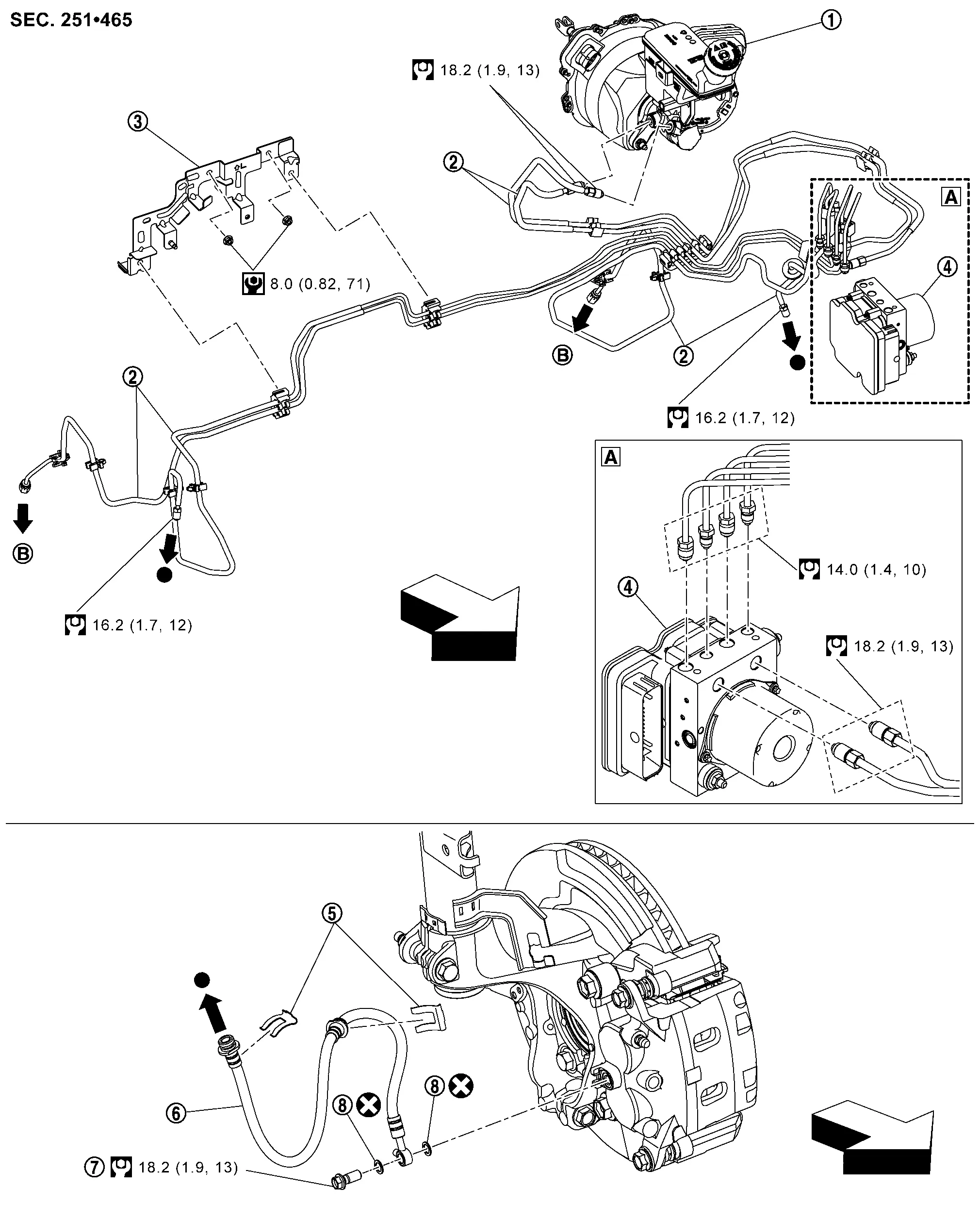

FRONT BRAKE PIPING : Exploded View

|

electrically-driven intelligent brake unit |  |

Brake tube |  |

Bracket |

|

ABS actuator and electric unit (control unit) |  |

Lock plate |  |

Brake hose |

|

Union bolt |  |

Copper washer | ||

|

To rear brake tube. Refer to Exploded View. | ||||

|

: Nissan Ariya Vehicle front | ||||

|

: N·m (kg-m, ft-lb) | ||||

|

: N·m (kg-m, in-lb) | ||||

|

: Always replace after every disassembly. | ||||

|

: Indicates that the part is connected at points with same symbol in actual Nissan Ariya vehicle. | ||||

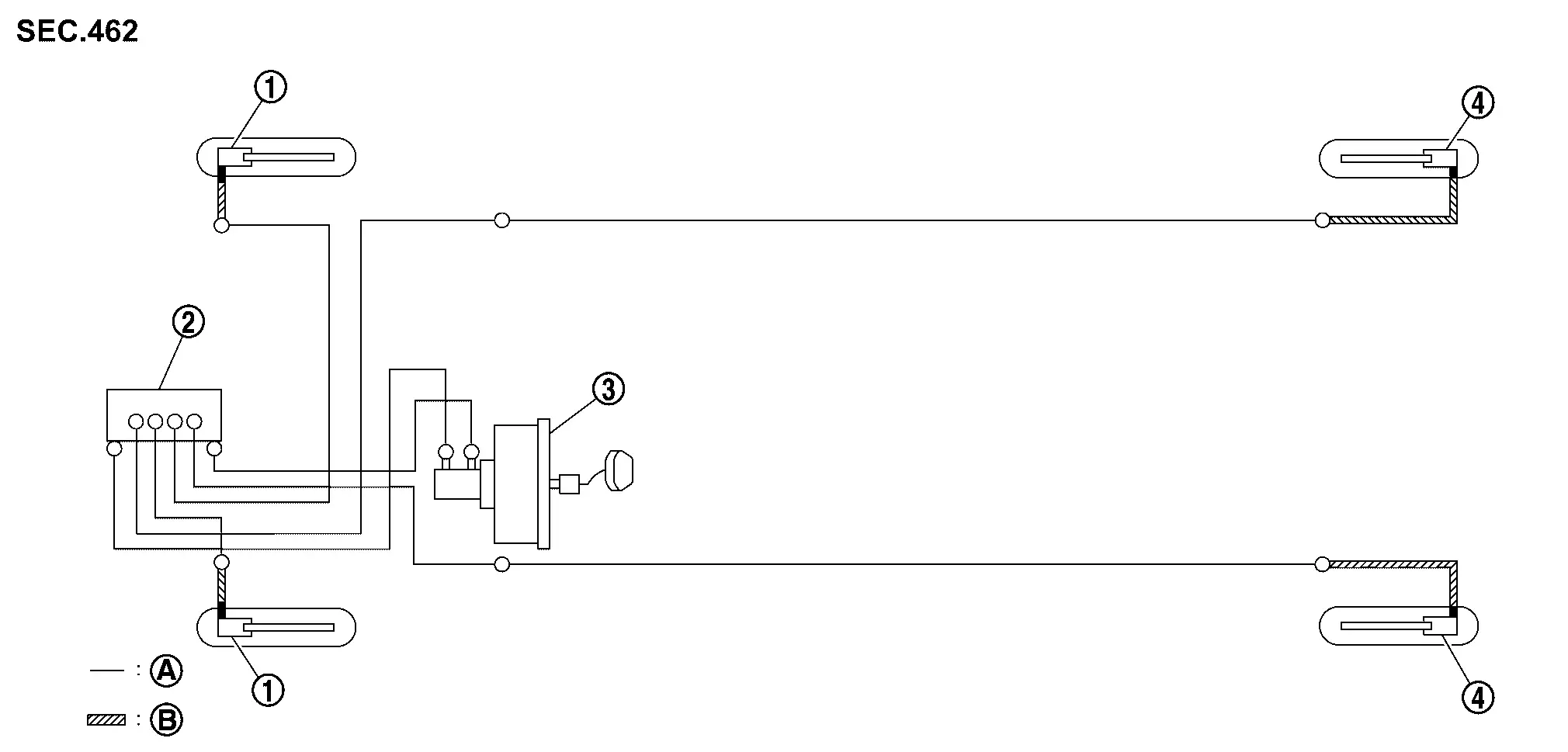

FRONT BRAKE PIPING : Hydraulic Layout

|

Front disc brake |  |

ABS actuator and electric unit (control unit) |  |

Electrically-driven intelligent brake unit |

|

Rear disc brake | ||||

|

Brake tube |  |

Brake hose | ||

|

: Flare nut | ||||

|

: Union bolt | ||||

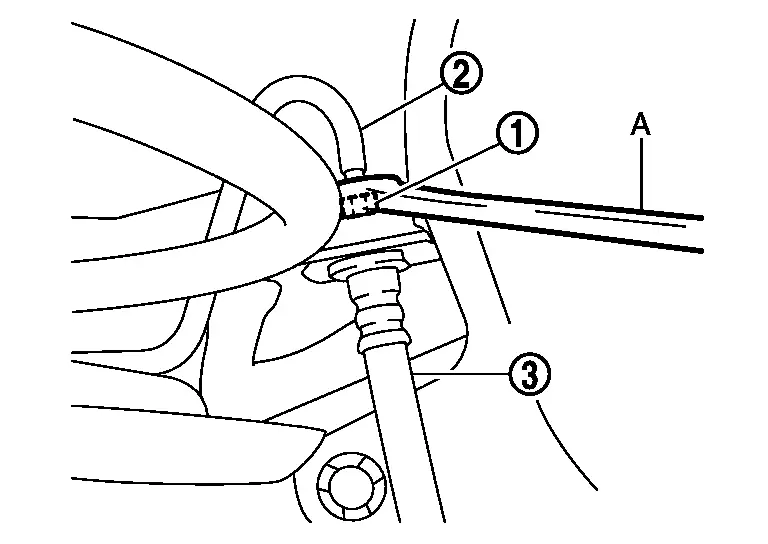

FRONT BRAKE PIPING : Removal & Installation

REMOVAL

CAUTION:

-

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off immediately and wash with water if it gets on a painted surface. For brake component parts, never wash them with water.

-

Never depress the brake pedal while removing the brake hose or brake tube. If this is not complied with, brake fluid may splash.

Remove tires. Refer to Removal and Installation.

Drain brake fluid. Refer to Draining.

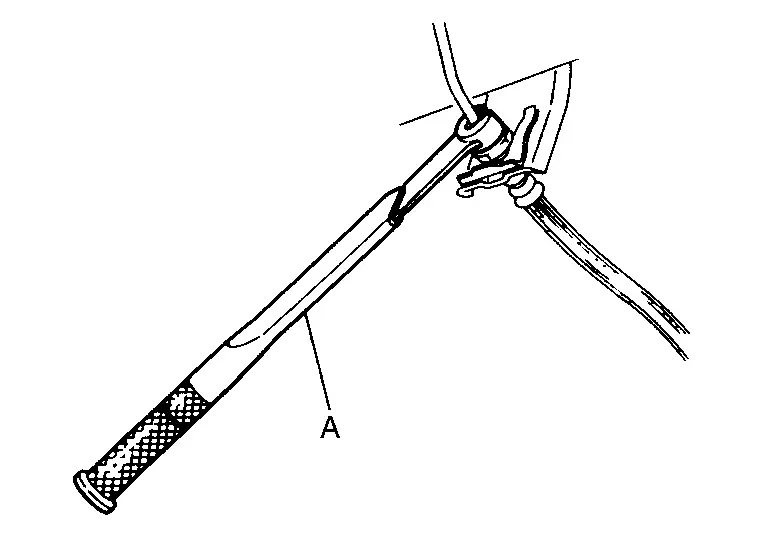

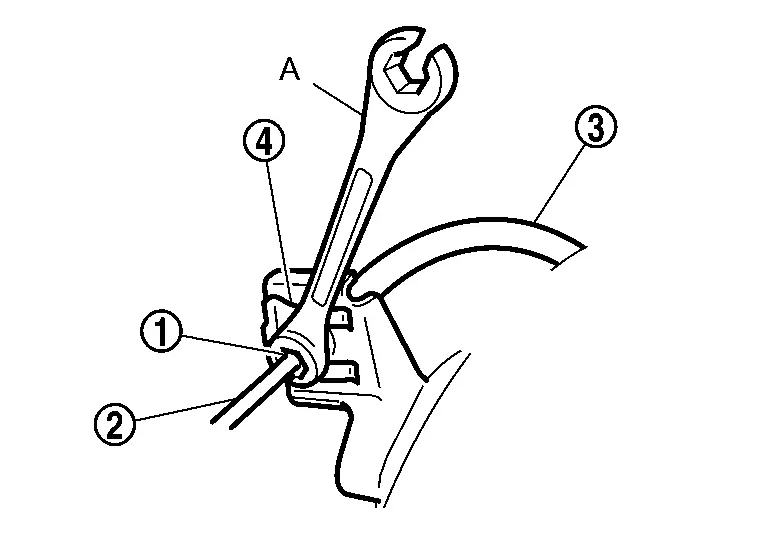

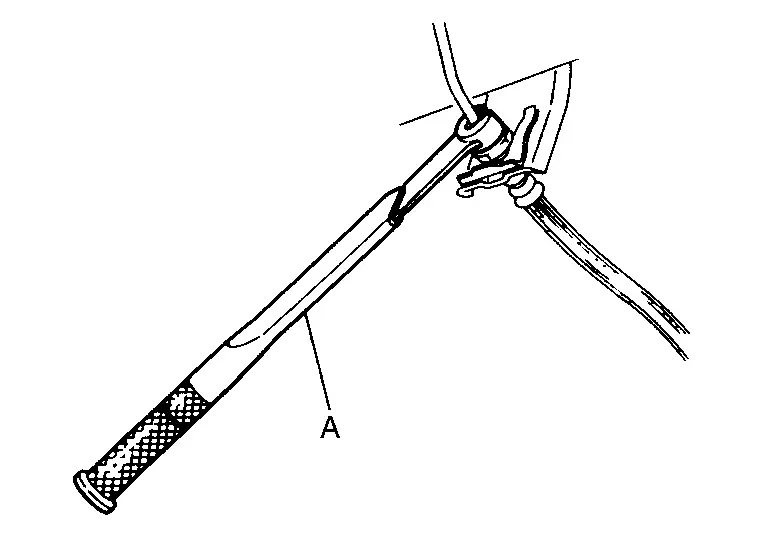

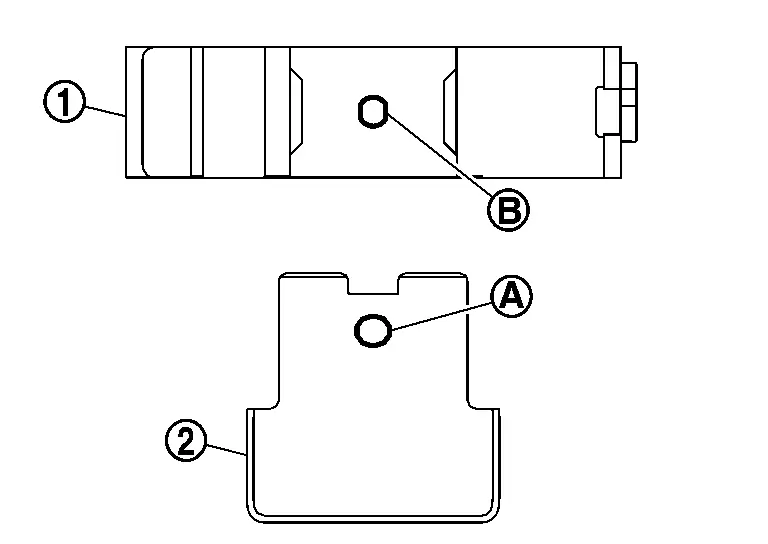

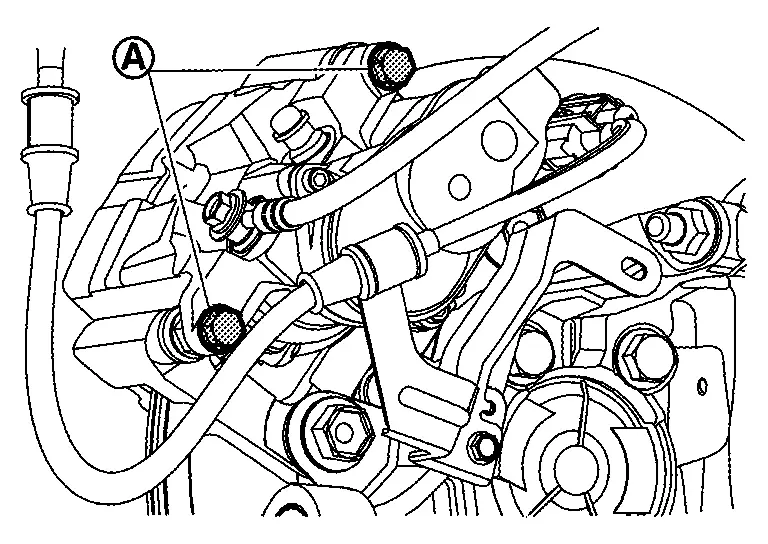

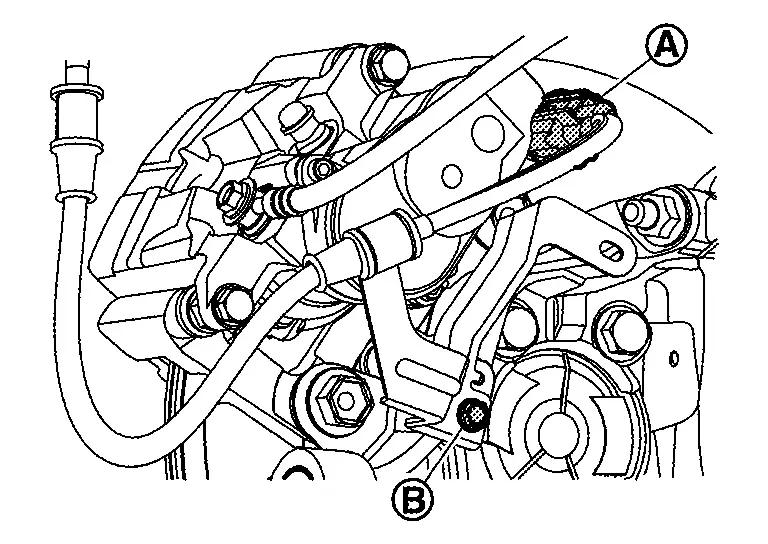

Loosen the flare nut  with a flare nut wrench (A) and separate the brake tube

with a flare nut wrench (A) and separate the brake tube  from the brake hose

from the brake hose  .

.

CAUTION:

-

Never scratch the flare nut and the brake tube.

-

Never bend sharply, twist or strongly pull out the brake hoses and tubes.

-

Cover open end of brake tubes and hoses when disconnecting to prevent entrance of dirt.

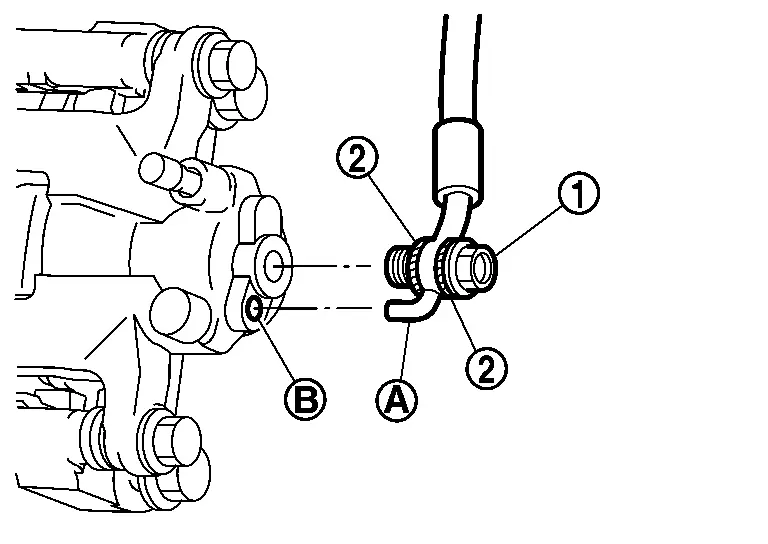

Remove the union bolt  and copper washers

and copper washers  , and remove the brake hose

, and remove the brake hose  from the brake caliper assembly.

from the brake caliper assembly.

Remove the lock plate  and remove the brake hose.

and remove the brake hose.

INSTALLATION

CAUTION:

-

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off immediately and wash with water if it gets on a painted surface. For brake component parts, never wash them with water.

-

Never depress the brake pedal while removing the brake hose or brake tube. If this is not complied with, brake fluid may splash.

-

Never allow foreign matter (e.g. dust) and oils other than brake fluid to enter the reservoir tank.

Assemble the union bolt  and the copper washer to the brake hose

and the copper washer to the brake hose  .

.

CAUTION:

Never reuse the copper washer.

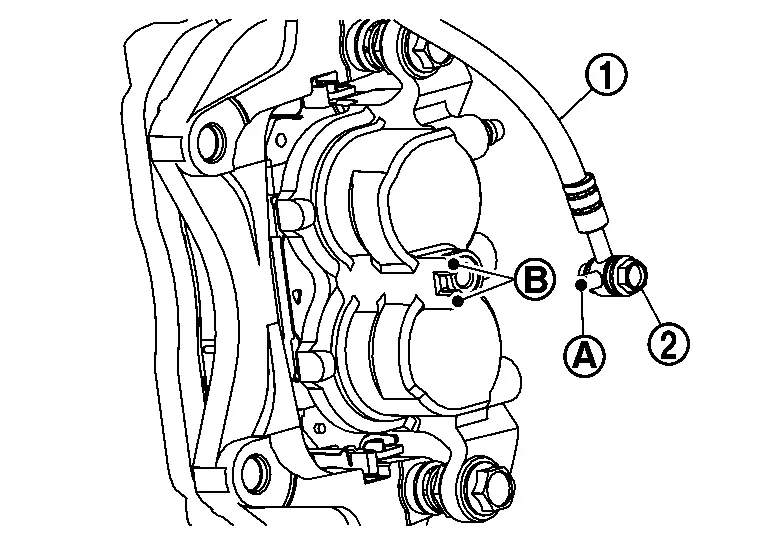

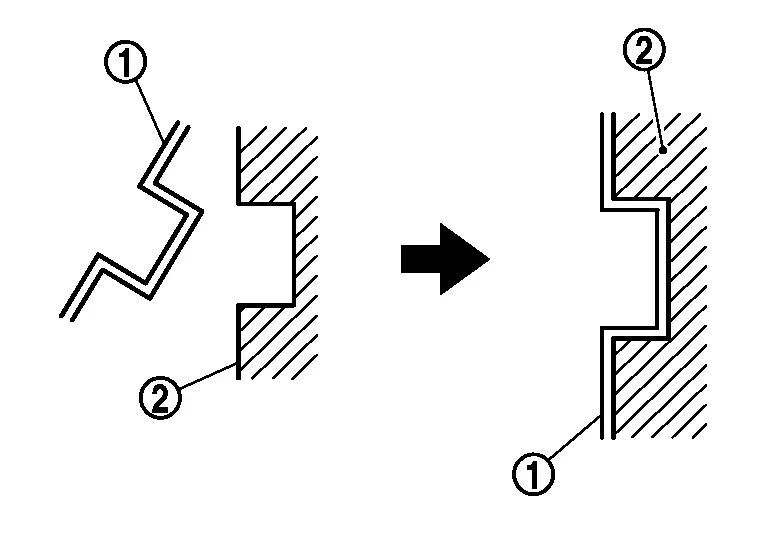

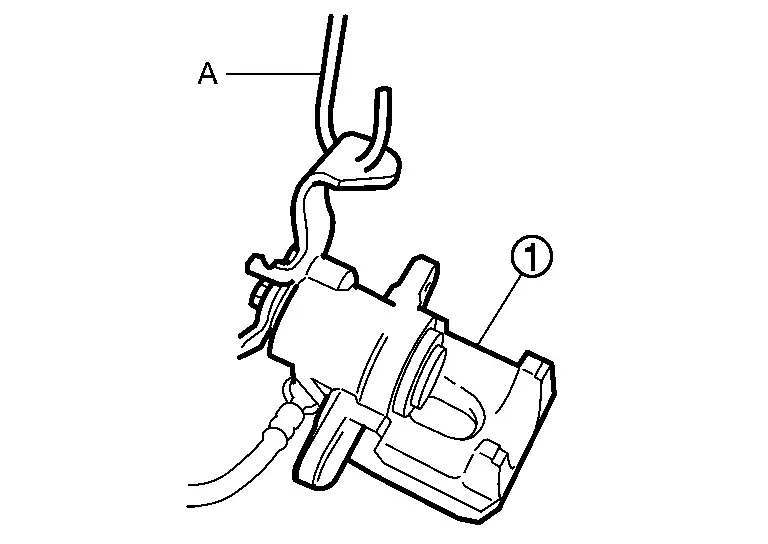

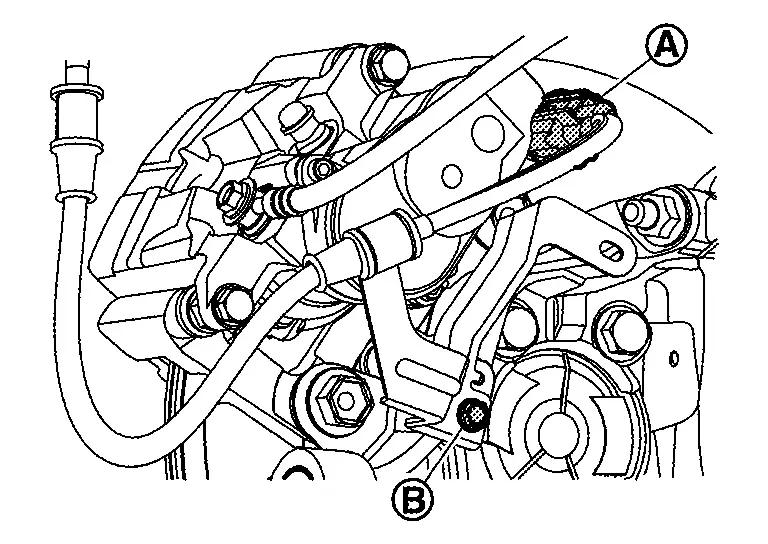

Align the brake hose pin  with the brake caliper assembly projection

with the brake caliper assembly projection  , and tighten the union bolt to the specified torque.

, and tighten the union bolt to the specified torque.

Install the brake tube  to the brake hose

to the brake hose  , temporarily tighten the flare nut

, temporarily tighten the flare nut  by hand until it does not rotate further, and fix the brake hose to the bracket

by hand until it does not rotate further, and fix the brake hose to the bracket  with the lock plate

with the lock plate  .

.

CAUTION:

Check that all brake hoses and brake tubes are not twisted and bent.

Tighten the flare nut to the specified torque with a flare nut torque wrench (A).

CAUTION:

Never scratch the flare nut and the brake tube.

Refill with new brake fluid and perform the air bleeding. Refer to Bleeding Brake System.

CAUTION:

Never reuse drained brake fluid.

Install tires. Refer to Removal and Installation.

Perform inspection after installation. Refer to Inspection.

FRONT BRAKE PIPING : Inspection

INSPECTION AFTER INSTALLATION

Check the brake hoses and tubes for the following: no scratches; no twist and deformation; no interference with other components when steering the steering wheel; no looseness at connections.

CAUTION:

Clearance with brake hose and each parts being secured more than 10 mm (0.39 in) in unladen condition*.

*: Fuel, engine coolant and lubricant are quantity to specified. Spare tire, jack, hand tools and mats are brought out of Nissan Ariya vehicle.

Depress the brake pedal with a force of 785 N (80 kg, 176 lb) and hold down the pedal for approximately 5 seconds with the engine running. Check for any fluid leakage.

CAUTION:

Retighten the applicable connection to the specified torque and repair any abnormal (damaged, worn or deformed) part if any brake fluid leakage is present.

Rear Brake Piping Nissan Ariya first Gen

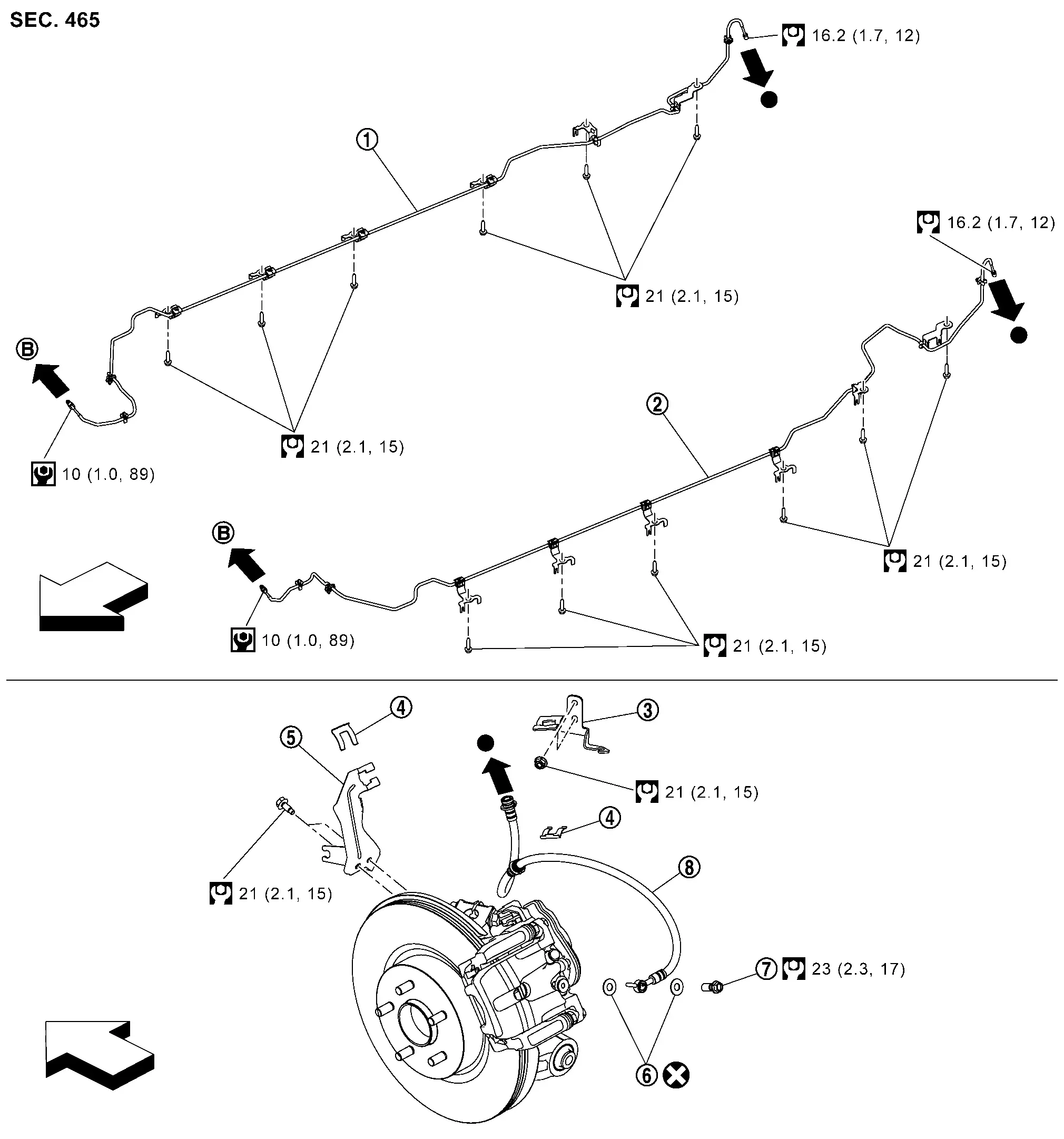

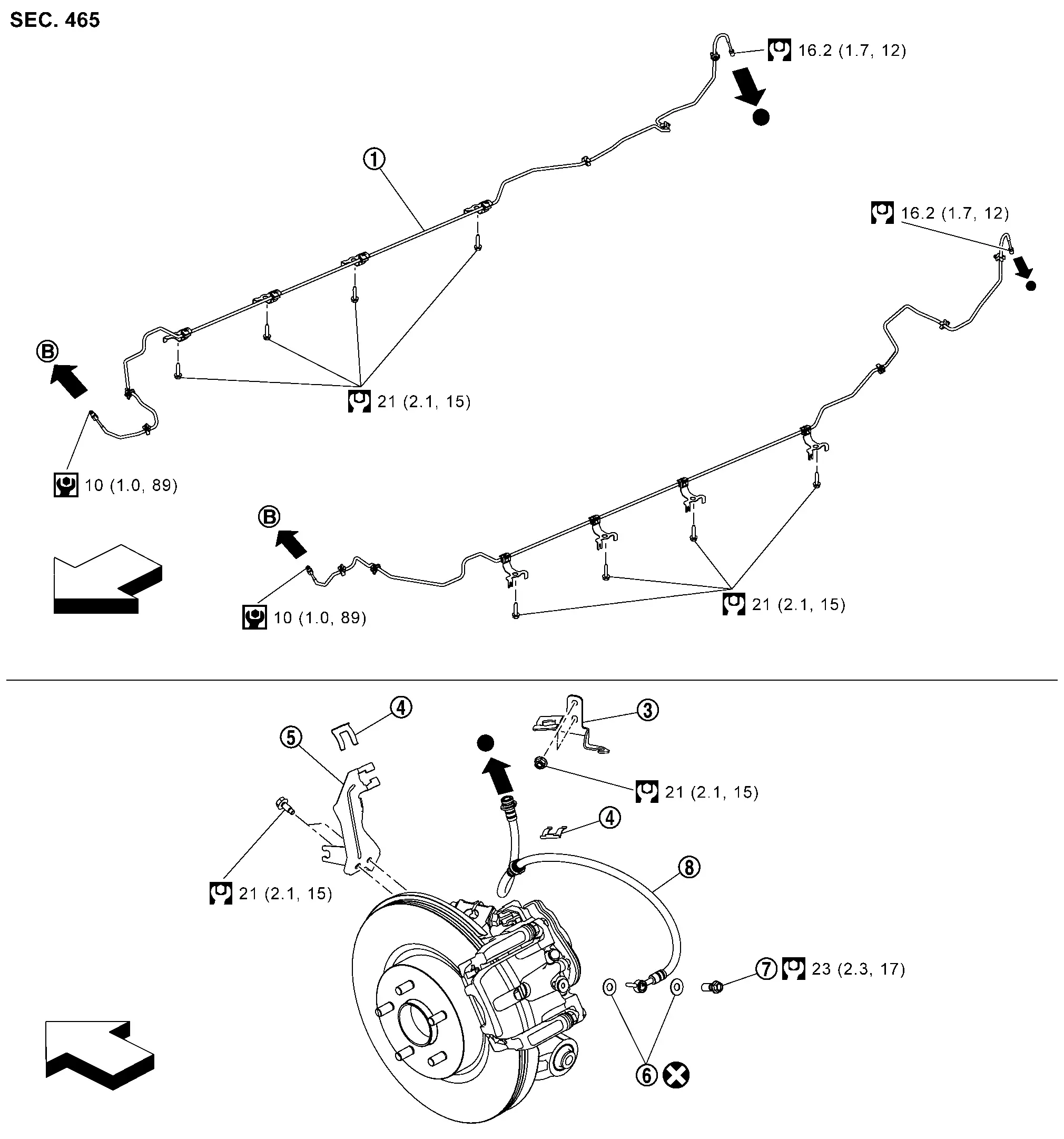

REAR BRAKE PIPING : Exploded View

2WD MODELS

|

Brake tube RH |  |

Brake tube LH |  |

Bracket |

|

Lock plate |  |

Bracket |  |

Aluminum washer |

|

Union bolt |  |

Brake hose | ||

|

To front brake tube. Refer to Exploded View. | ||||

|

: Nissan Ariya Vehicle front | ||||

|

: N·m (kg-m, ft-lb) | ||||

|

: N·m (kg-m, in-lb) | ||||

|

: Always replace after every disassembly. | ||||

|

: Indicates that the part is connected at points with same symbol in actual Nissan Ariya vehicle. | ||||

4WD MODELS

|

Brake tube RH |  |

Brake tube LH |  |

Bracket |

|

Lock plate |  |

Bracket |  |

Aluminum washer |

|

Union bolt |  |

Brake hose | ||

|

To front brake tube. Refer to Exploded View. | ||||

|

: Nissan Ariya Vehicle front | ||||

|

: N·m (kg-m, ft-lb) | ||||

|

: N·m (kg-m, in-lb) | ||||

|

: Always replace after every disassembly. | ||||

|

: Indicates that the part is connected at points with same symbol in actual Nissan Ariya vehicle. | ||||

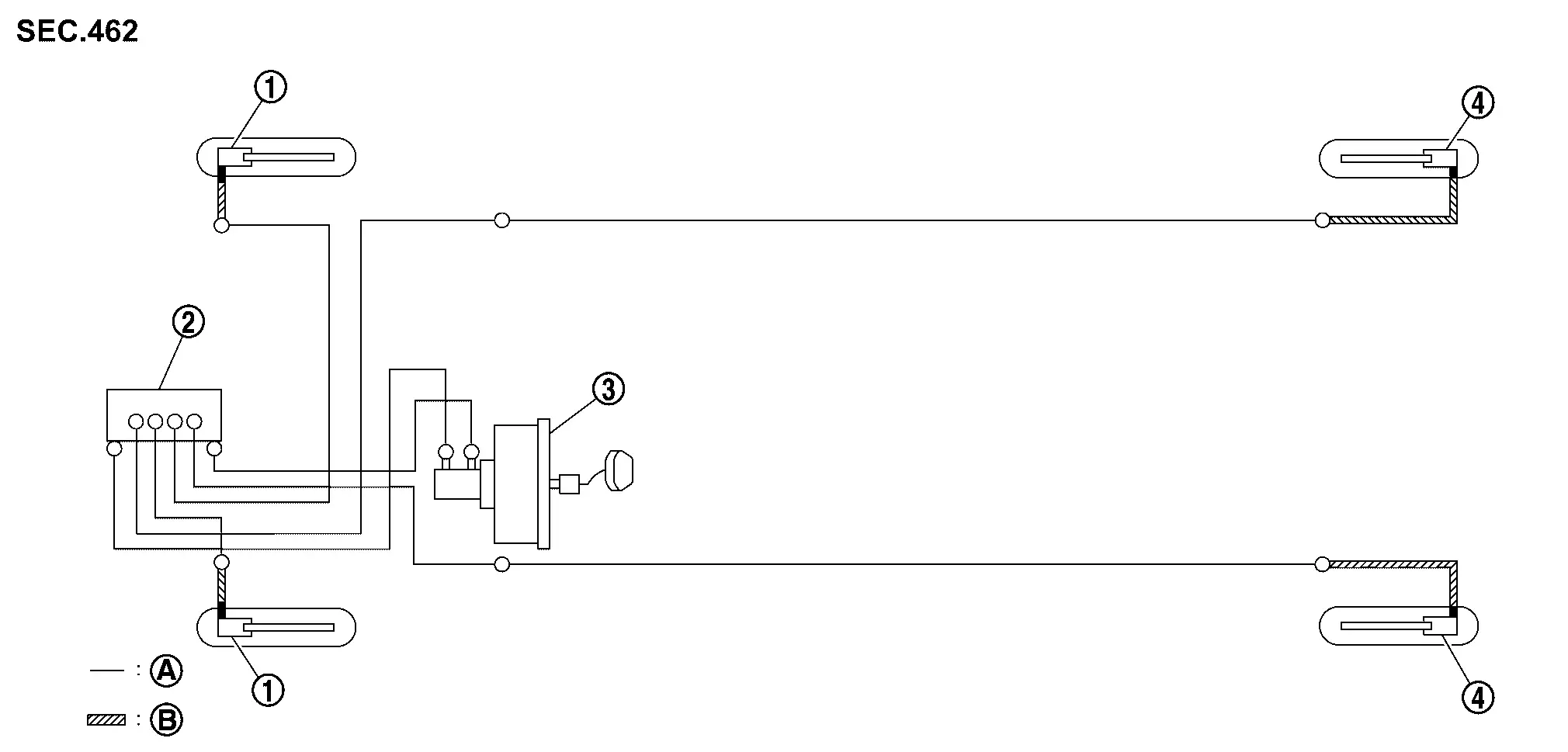

REAR BRAKE PIPING : Hydraulic Layout

|

Front disc brake |  |

ABS actuator and electric unit (control unit) |  |

Electrically-driven intelligent brake unit |

|

Rear disc brake | ||||

|

Brake tube |  |

Brake hose | ||

|

: Flare nut | ||||

|

: Union bolt | ||||

REAR BRAKE PIPING : Removal & Installation

REMOVAL

CAUTION:

-

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off immediately and wash with water if it gets on a painted surface. For brake component parts, never wash them with water.

-

Never depress the brake pedal while removing the brake hose or brake tube. If this is not complied with, brake fluid may splash.

-

Wipe off immediately when attaching brake fluid with disc rotor and caliper assembly.

Remove tires. Refer to Removal and Installation.

Remove the lock plate  , then remove the brake hose from the brake tube bracket.

, then remove the brake hose from the brake tube bracket.

Loosen the flare nut  with a flare nut wrench (A) and separate the brake tube

with a flare nut wrench (A) and separate the brake tube  from the brake hose

from the brake hose  .

.

CAUTION:

-

Never scratch the flare nut and the brake tube.

-

Never bend sharply, twist or strongly pull out the brake hoses and tubes.

-

Cover open end of brake tubes and brake hoses when disconnecting to prevent entrance of dirt.

Remove the lock plate  , then remove the brake tube B

, then remove the brake tube B  from the brake tube bracket.

from the brake tube bracket.

Remove the union bolt  and aluminum washers

and aluminum washers  , and remove the brake hose

, and remove the brake hose  from the brake caliper assembly.

from the brake caliper assembly.

INSTALLATION

CAUTION:

-

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off immediately and wash with water if it gets on a painted surface. For brake component parts, never wash them with water.

-

Never depress the brake pedal while removing the brake hose or brake tube. If this is not complied with, brake fluid may splash.

-

Never allow foreign matter (e.g. dust) and oils other than brake fluid to enter the reservoir tank.

-

Wipe off immediately when attaching brake fluid with disc rotor and caliper assembly.

Assemble the union bolt  and the aluminum washers

and the aluminum washers  to the brake hose.

to the brake hose.

CAUTION:

Never reuse the aluminum washer.

Align the brake hose L-pin  with the brake caliper assembly hole

with the brake caliper assembly hole  , and tighten the union bolt to the specified torque.

, and tighten the union bolt to the specified torque.

Install the brake hose to the brake tube, temporarily tighten the flare nut by hand until it does not rotate further, and fix the brake hose to the brake hose bracket with the lock plate.

CAUTION:

Check that all brake hoses and brake tubes are not twisted and bent.

Tighten the flare nut to the specified torque with a flare nut torque wrench (A).

CAUTION:

Never scratch the flare nut and the brake tube.

Refill with new brake fluid and perform the air bleeding. Refer to Bleeding Brake System.

CAUTION:

Never reuse drained brake fluid.

Install tires. Refer to Removal and Installation.

Perform inspection after installation. Refer to Inspection.

REAR BRAKE PIPING : Inspection

INSPECTION AFTER INSTALLATION

Check the brake hoses and tubes for the following: no scratches; no twist and deformation; no looseness at connections.

CAUTION:

Clearance with brake hose and each parts being secured more than 10 mm (0.39 in) in unladen condition*.

*: Fuel, engine coolant and lubricant are quantity to specified. Spare tire, jack, hand tools and mats are brought out of Nissan Ariya vehicle.

Depress the brake pedal with a force of 785 N (80 kg, 176 lb) and hold down the pedal for approximately 5 seconds with the engine running. Check for any fluid leakage.

CAUTION:

Retighten the applicable connection to the specified torque and repair any abnormal (damaged, worn or deformed) part if any brake fluid leakage is present.

Brake Power Supply Backup Unit Nissan Ariya

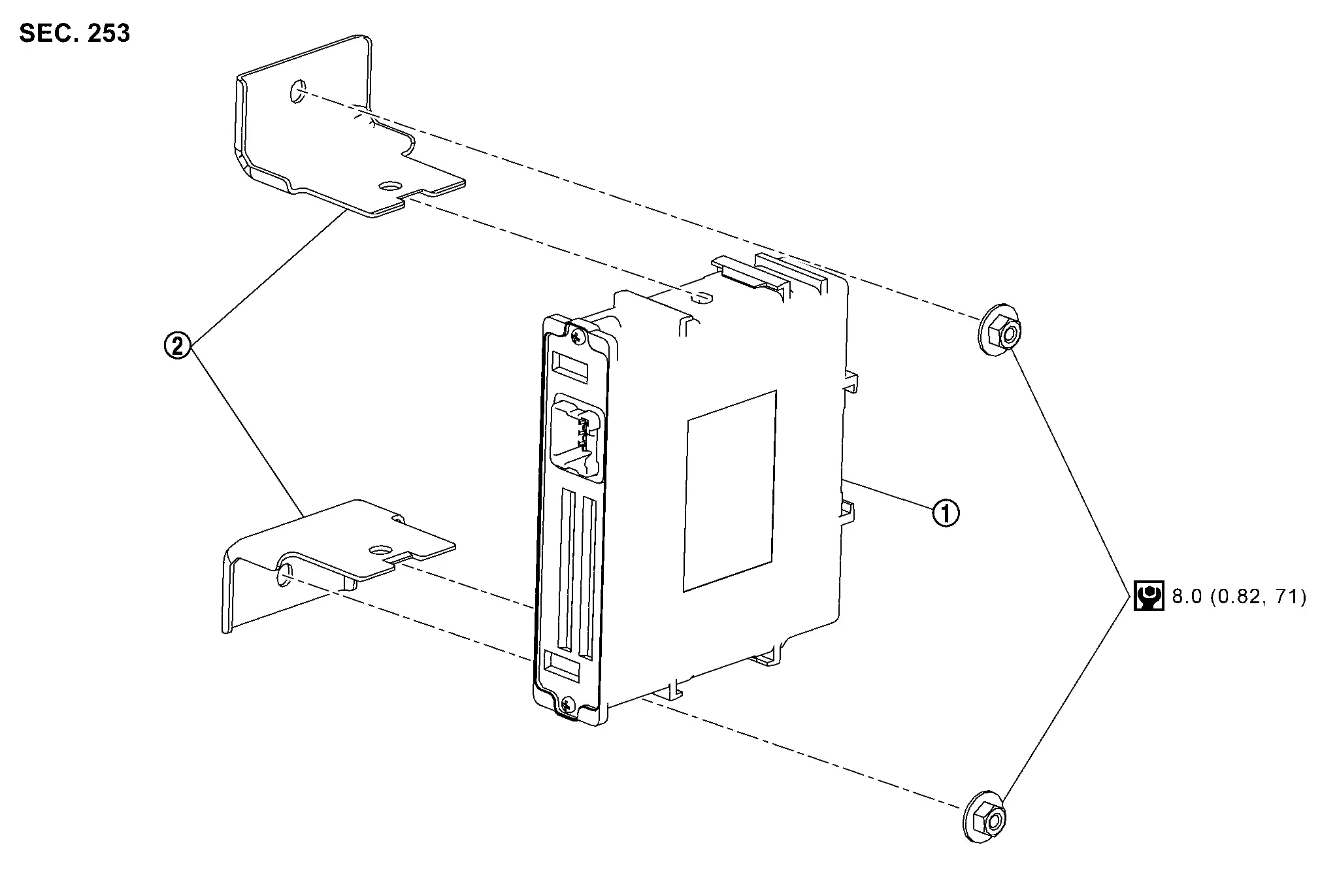

BRAKE POWER SUPPLY BACKUP UNIT : Exploded View

|

Brake power supply backup unit |  |

Bracket | ||

|

: N·m (kg-m, in-lb) | ||||

BRAKE POWER SUPPLY BACKUP UNIT : Removal & Installation

REMOVAL

Power switch OFF and disconnect CONSULT from DDL2 diagnosis connector.

Check that room lamps are turned OFF after closing all doors including back door, and then wait for 3 minutes or more at out side of Nissan Ariya vehicle.

CAUTION:

Never touch the vehicle during waiting.

Remove luggage side lower finisher (right).Refer to Removal & Installation.

Disconnect brake power supply backup unit harness connector.

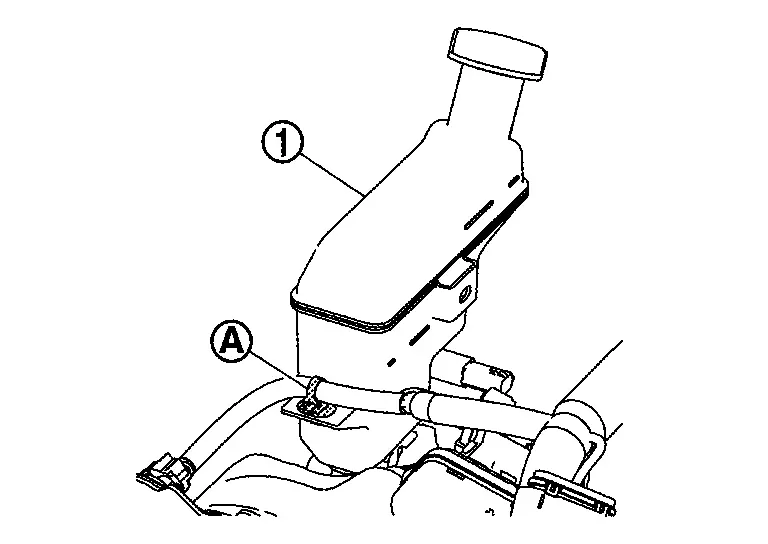

Remove nut  and then remove brake power supply backup unit assembly

and then remove brake power supply backup unit assembly  .

.

CAUTION:

Never drop parts after removal.

Remove bracket from brake power supply backup unit.

INSTALLATION

Note the following, and install in the reverse order of removal.

-

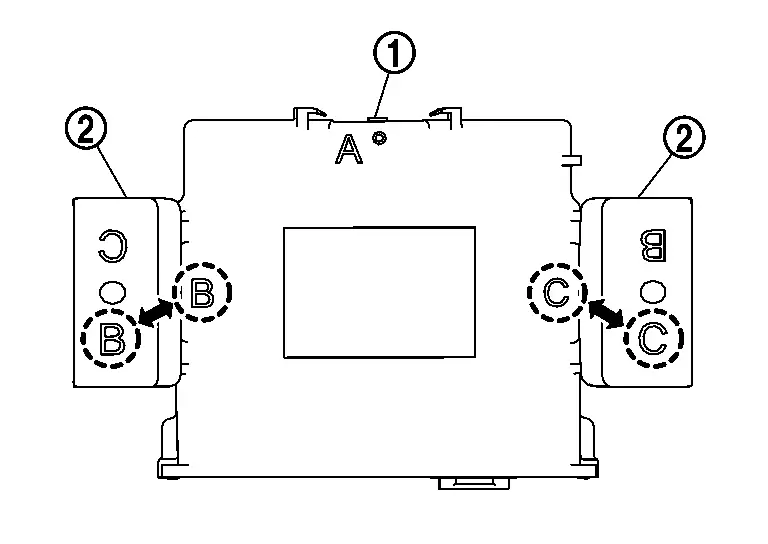

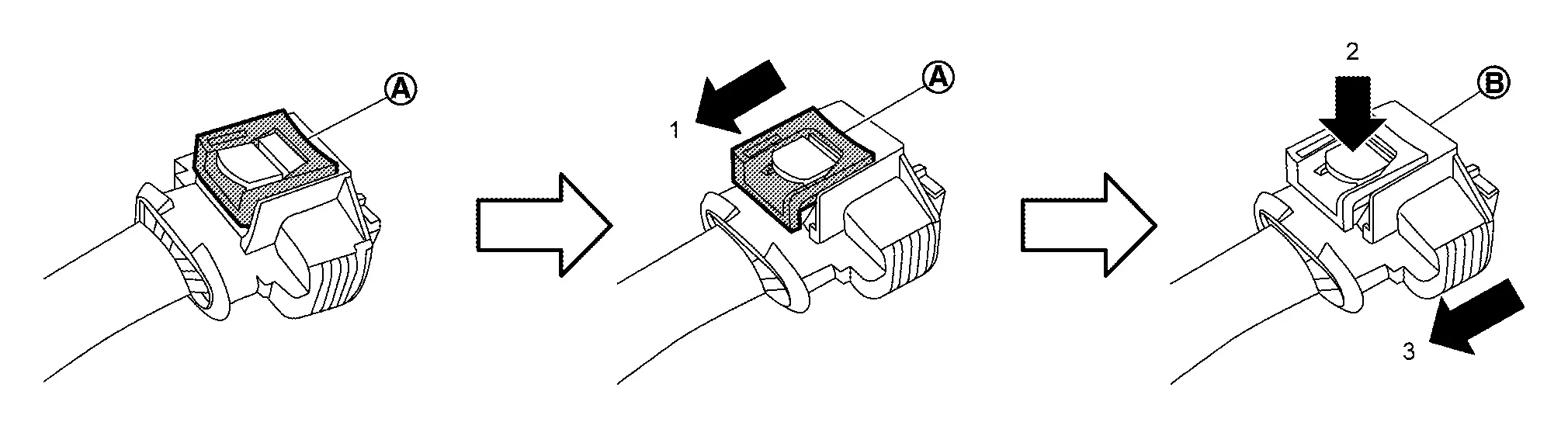

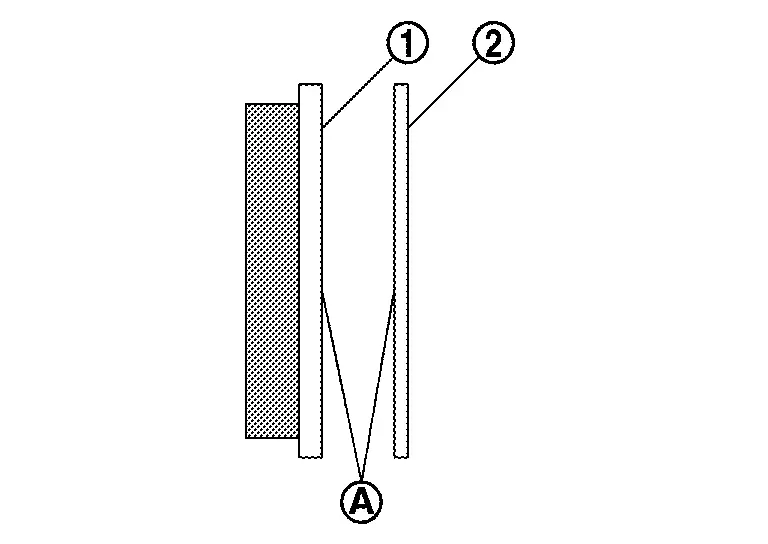

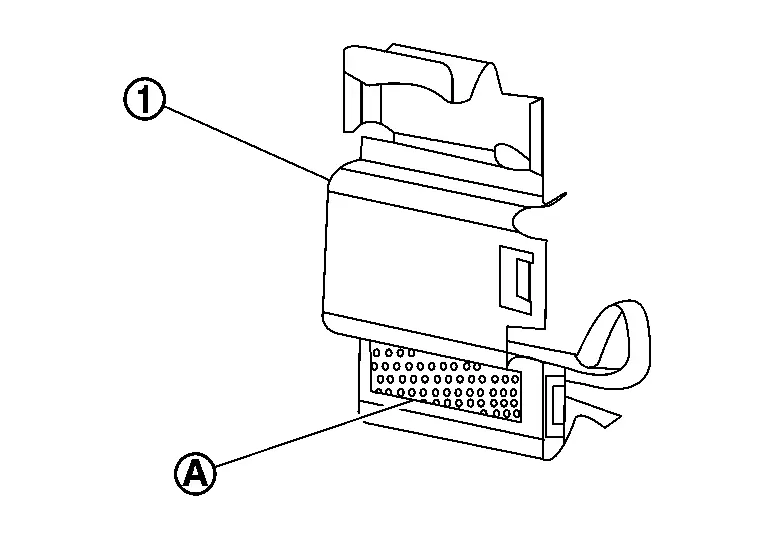

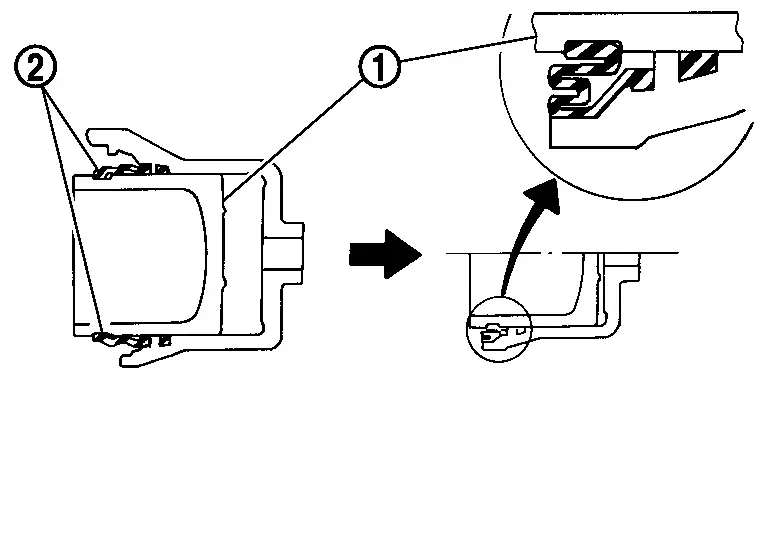

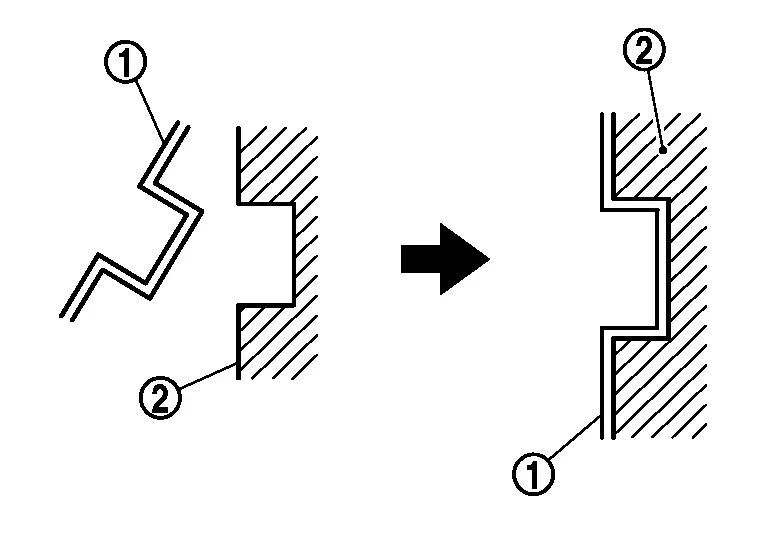

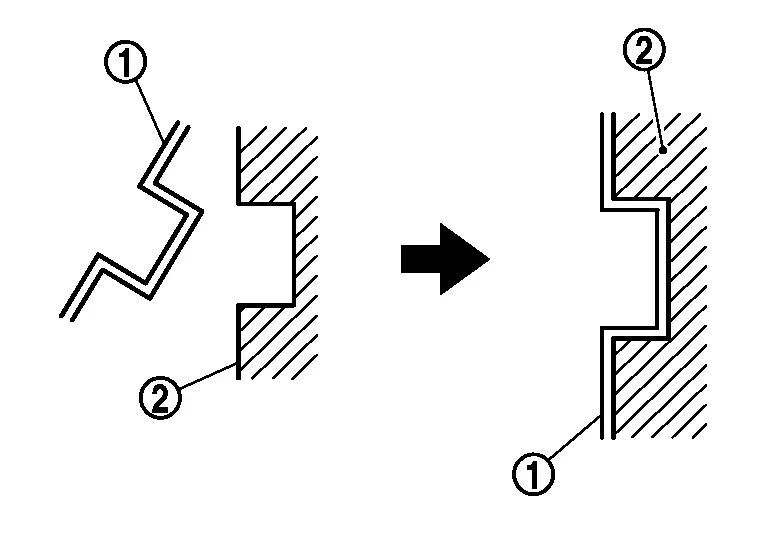

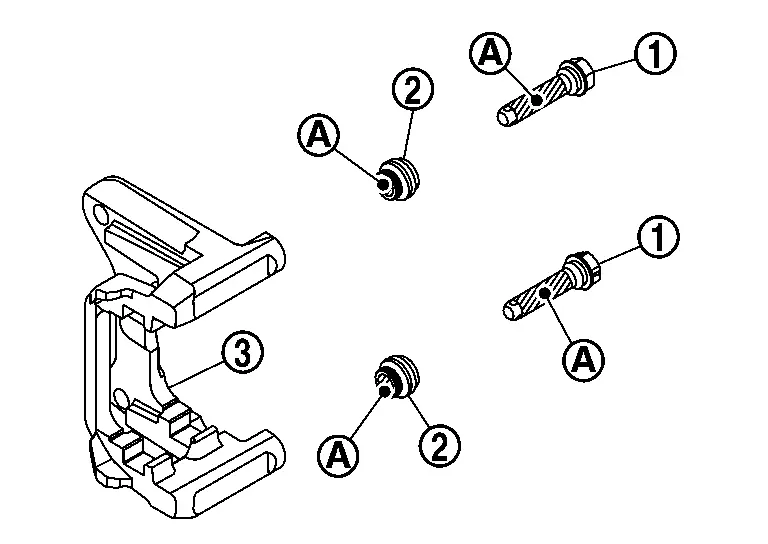

Align the direction of alphabet letters on the brake power supply backup unit

with the direction of the same alphabet letters on the bracket

with the direction of the same alphabet letters on the bracket  .

.

-

When installing bracket

to brake power supply backup unit

to brake power supply backup unit  , make sure to insert protrusion

, make sure to insert protrusion  of brake power supply backup to lock hole

of brake power supply backup to lock hole  of bracket unit protrudes from the opposite side of the lock hole.

of bracket unit protrudes from the opposite side of the lock hole.

Electrically-Driven Intelligent Brake Unit Nissan Ariya 2023

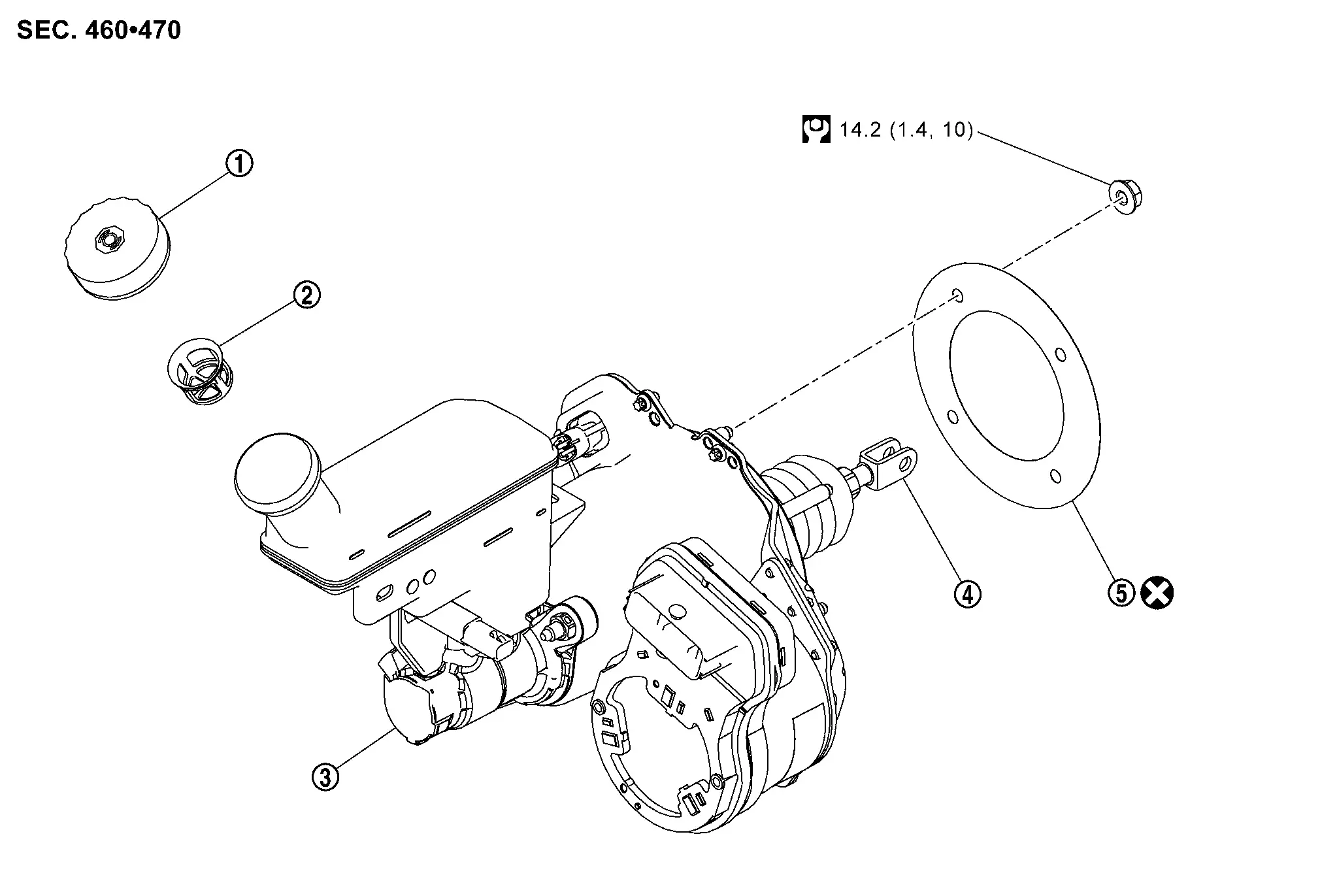

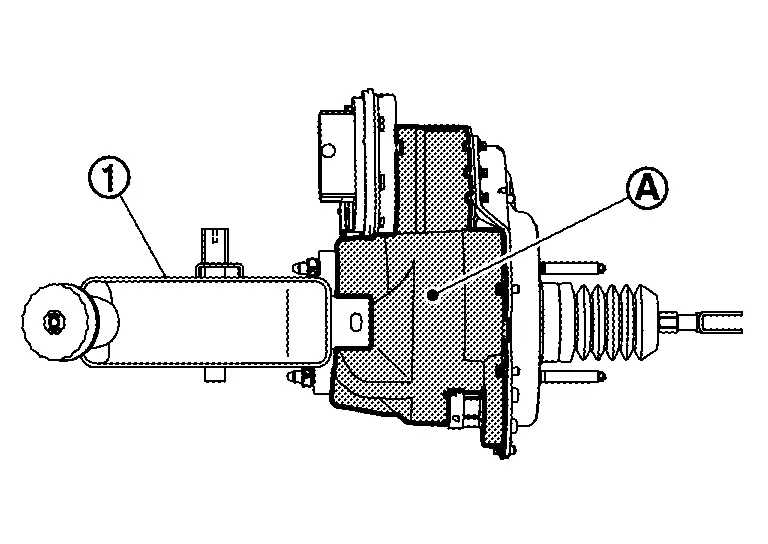

ELECTRICALLY-DRIVEN INTELLIGENT BRAKE UNIT : Exploded View

|

Reservoir cap |  |

Oil strainer |  |

Electrically-driven intelligent brake unit |

|

Clevis |  |

Gasket | ||

|

: N·m (kg-m, ft-lb) | ||||

|

: Always replace after every disassembly. | ||||

ELECTRICALLY-DRIVEN INTELLIGENT BRAKE UNIT : Removal & Installation

REMOVAL

CAUTION:

-

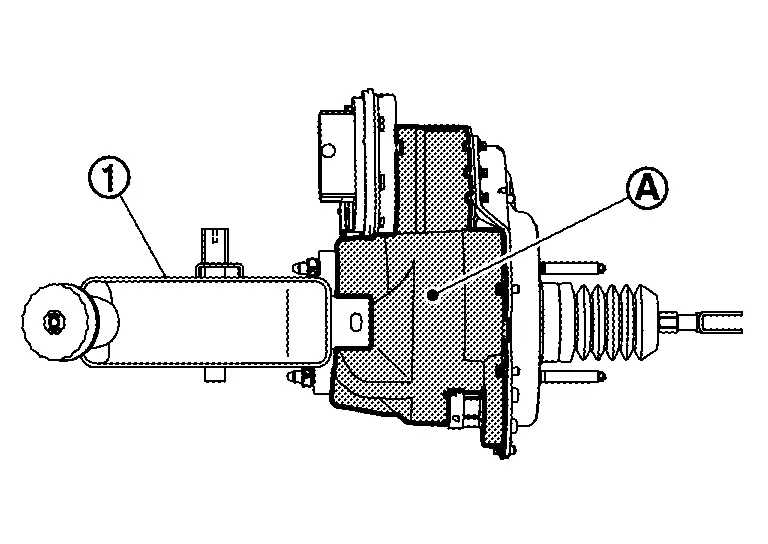

While electrically-driven intelligent brake unit

is removed, hold part

is removed, hold part  with hand.

with hand.

-

Never disassemble electrically-driven intelligent brake unit.

-

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off immediately and wash with water if it gets on a painted surface. For brake component parts, never wash them with water.

-

Never depress brake pedal during removal and installation of brake hose because brake fluid may scatter.

Perform inspection before removal. Refer to Inspection and Adjustment.

Power switch OFF and disconnect CONSULT from DDL2 diagnosis connector.

Check that room lamps are turned OFF after closing all doors including back door, and then wait for 3 minutes or more at out side of Nissan Ariya vehicle.

Disconnect negative terminal of 12 V battery. Refer to Removal and Installation.

Drain brake fluid. Refer to Draining.

Remove cowl top member. Refer to Removal & Installation.

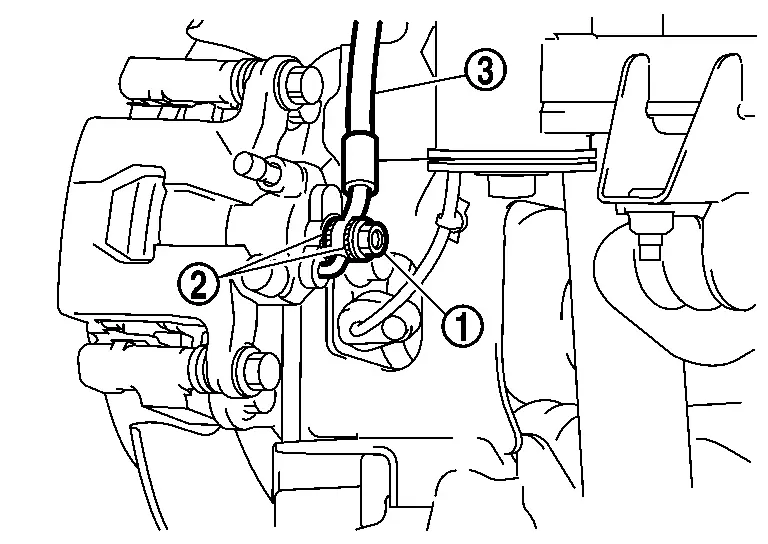

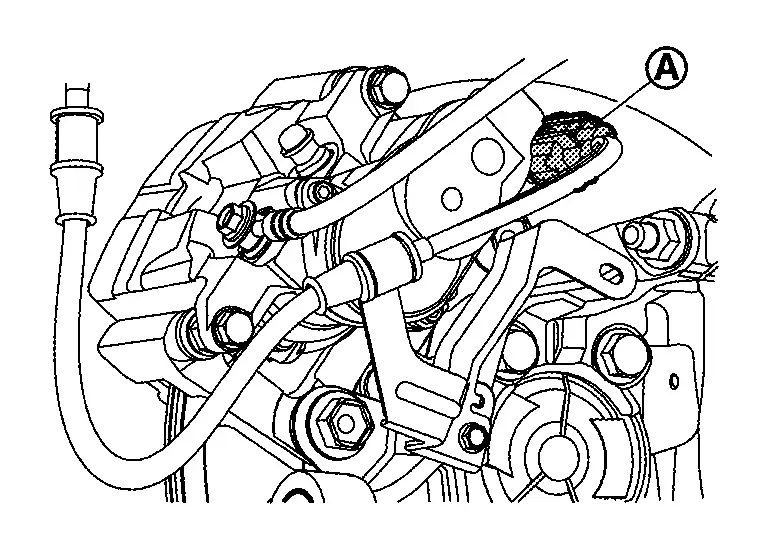

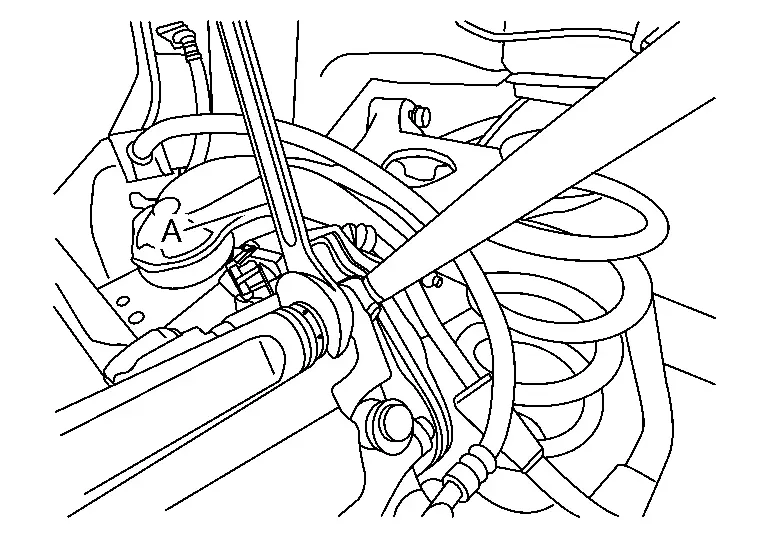

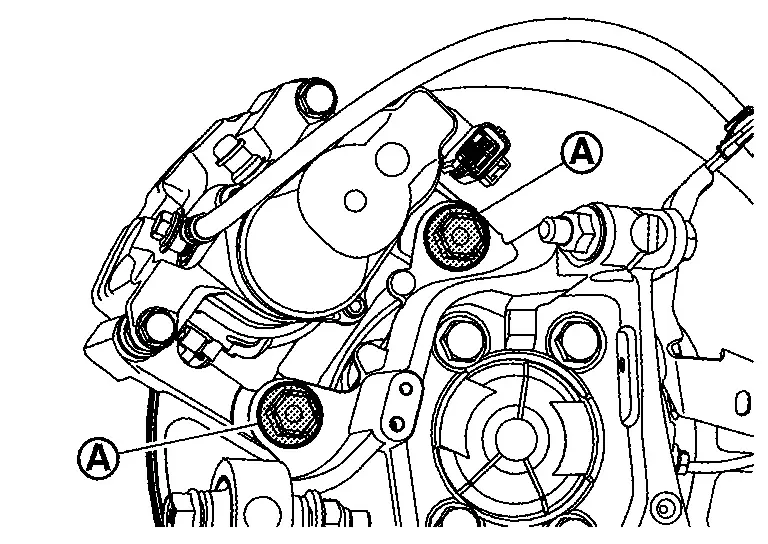

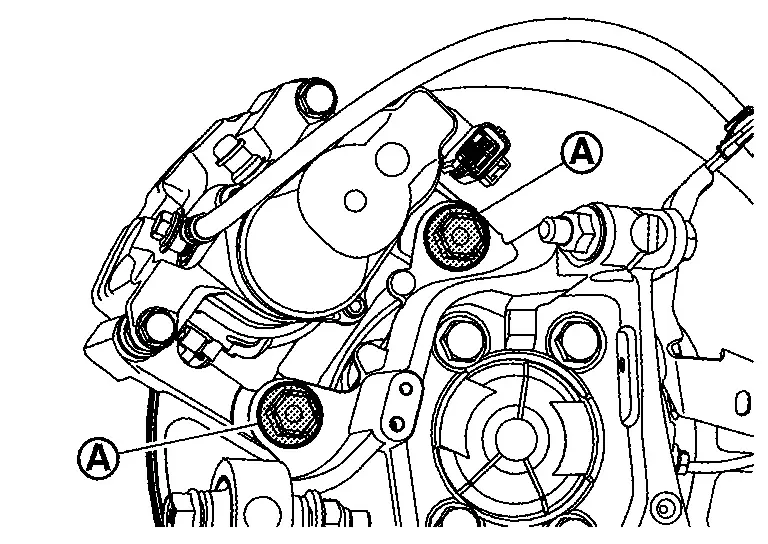

Separate the brake tube  from electrically-driven intelligent brake unit

from electrically-driven intelligent brake unit  with a flare nut wrench (A).

with a flare nut wrench (A).

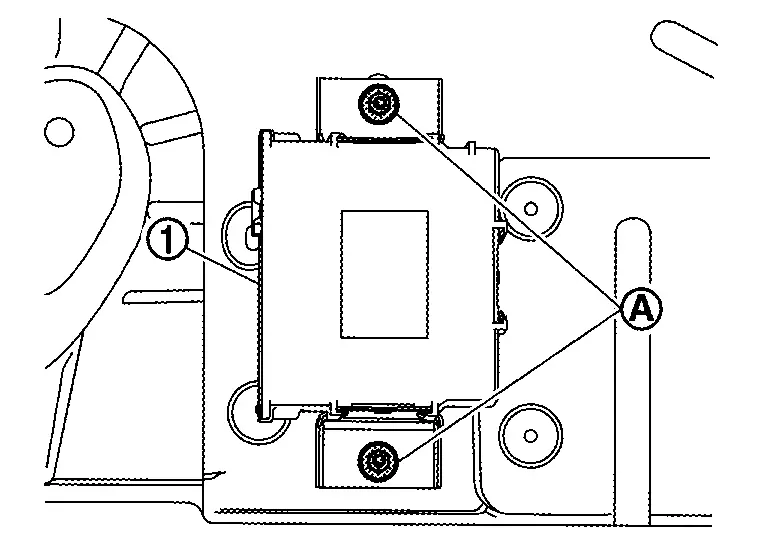

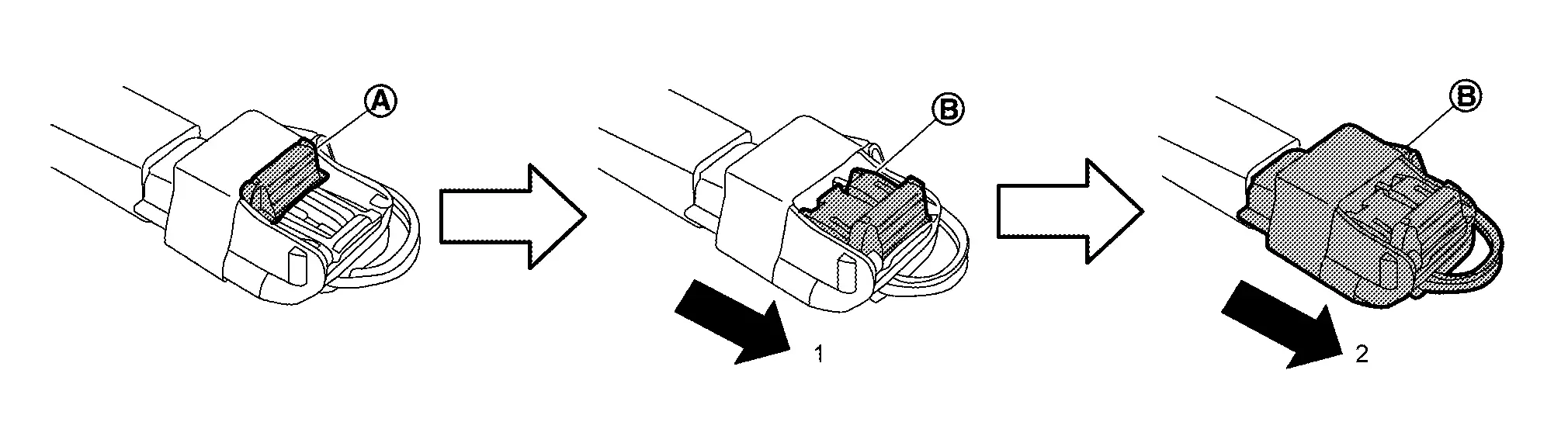

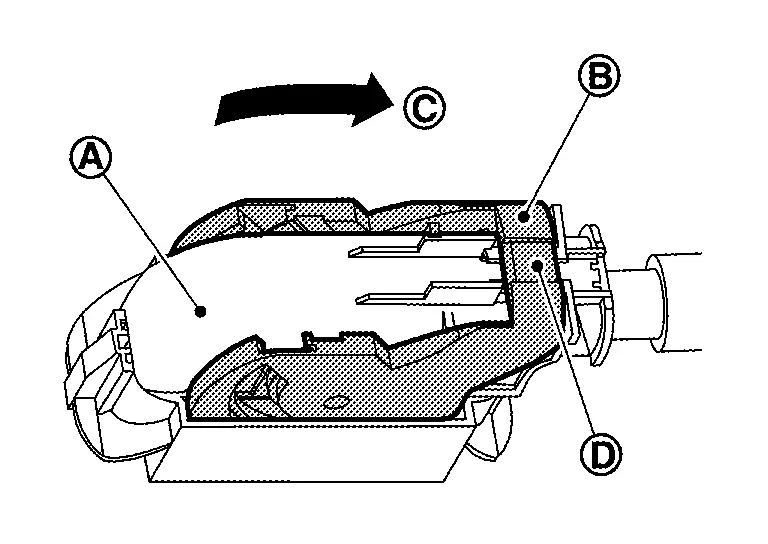

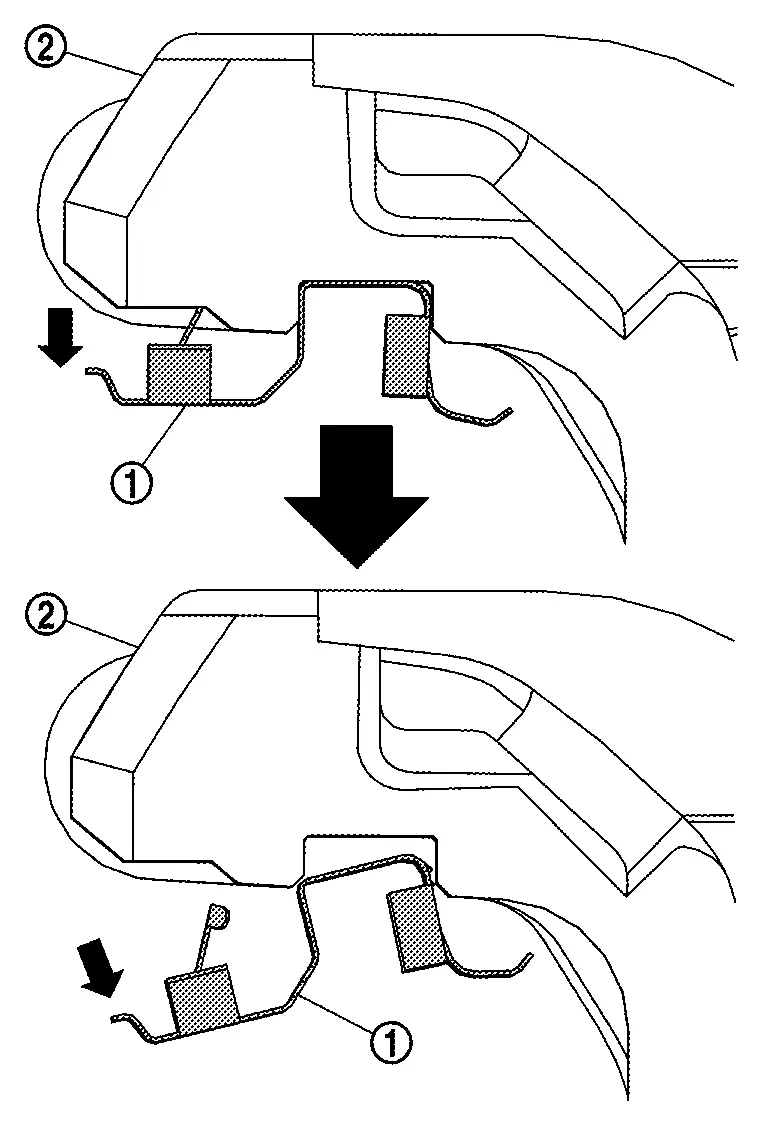

Remove brake fluid level switch as follows;Slide connector lock  to right (1) of Nissan Ariya vehicle. While connector lock is pushed in , disconnect brake fluid level switch harness connector

to right (1) of Nissan Ariya vehicle. While connector lock is pushed in , disconnect brake fluid level switch harness connector  in lateral direction (2) of Nissan Ariya vehicle.

in lateral direction (2) of Nissan Ariya vehicle.

Disconnect electrically-driven intelligent brake unit harness connector  as follows;

as follows;

direction. Disconnect electrically-driven intelligent brake unit harness connector.

direction. Disconnect electrically-driven intelligent brake unit harness connector.

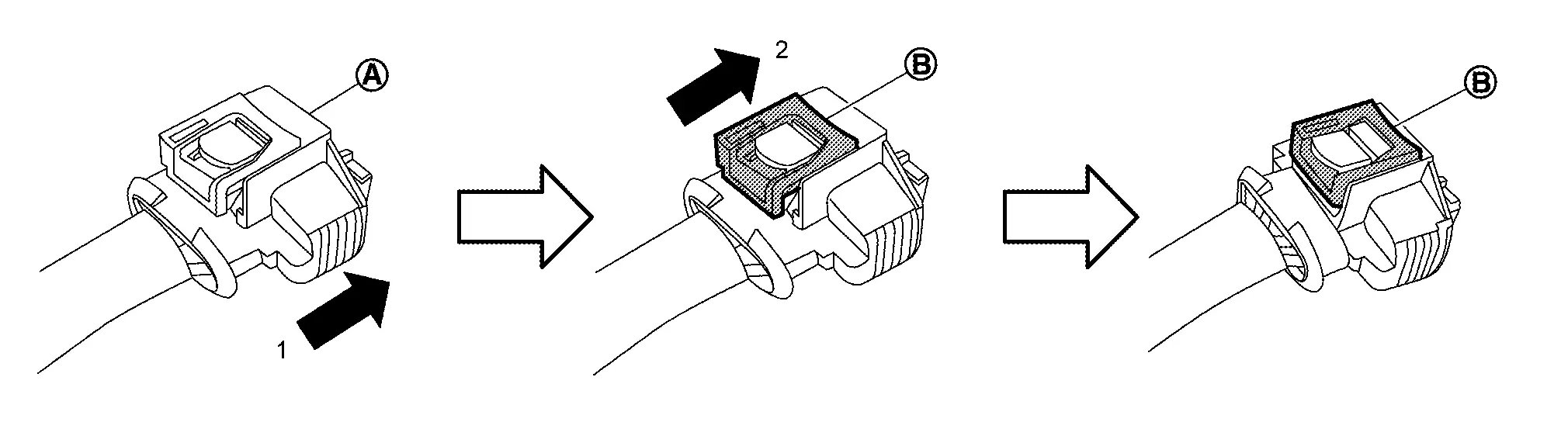

Disconnect stroke sensor harness connector as follows;Slide connector lock  to right (1) of Nissan Ariya vehicle. While connector lock (2) is pushed in , disconnect stroke sensor harness connector

to right (1) of Nissan Ariya vehicle. While connector lock (2) is pushed in , disconnect stroke sensor harness connector  in the front direction (3) of Nissan Ariya vehicle.

in the front direction (3) of Nissan Ariya vehicle.

Remove stroke sensor harness clip  behind brake master cylinder

behind brake master cylinder  .

.

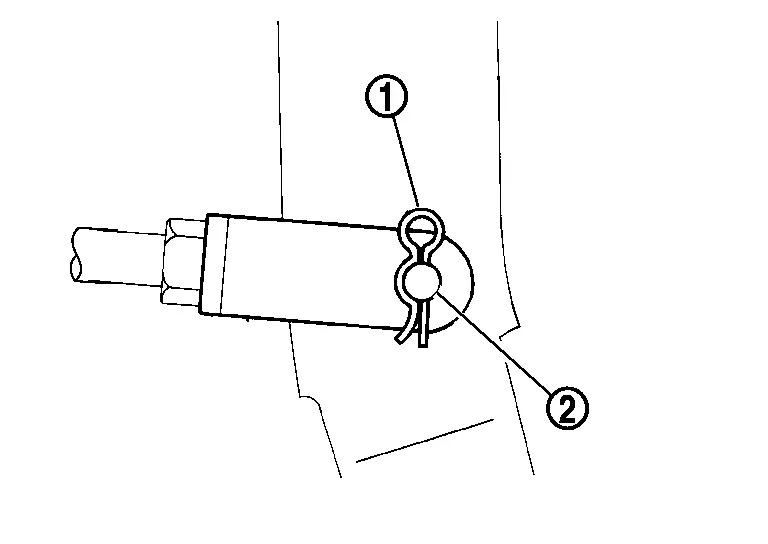

Remove snap pin and clevis pin from clevis.

Remove brake pedal bracket assembly. Refer to. Removal & Installation.

CAUTION:

Hold electrically-driven intelligent brake unit to prevent it from dropping.

Remove electrically-driven intelligent brake unit mounting nut.

Remove electrically-driven intelligent brake unit.

CAUTION:

Never deform the brake tube when removing electrically-driven intelligent brake unit.

Remove gasket from electrically-driven intelligent brake unit.

INSTALLATION

CAUTION:

When installing electrically-driven intelligent brake unit, never deform brake tube.

-

If electrically-driven intelligent brake unit is dropped or impacted, replace electrically-driven intelligent brake unit assembly.

-

When installing, hold part

of electrically-driven intelligent brake unit.

of electrically-driven intelligent brake unit.

-

Never apply grease or lubricant to the parts that contact with brake fluid and rubber parts.

-

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off immediately and wash with water if it gets on a painted surface. For brake component parts, never wash them with water.

-

Never depress brake pedal during removal and installation of brake hose because brake fluid may scatter.

Note the following, and install in the reverse order of removal.

-

Never crush threads of stud bolts of the electrically-driven intelligent brake unit. When installing diagonally, the dash panel may damage the threads.

-

Never deform brake tube when installing electrically-driven intelligent brake unit.

-

Never reuse clevis pin.

-

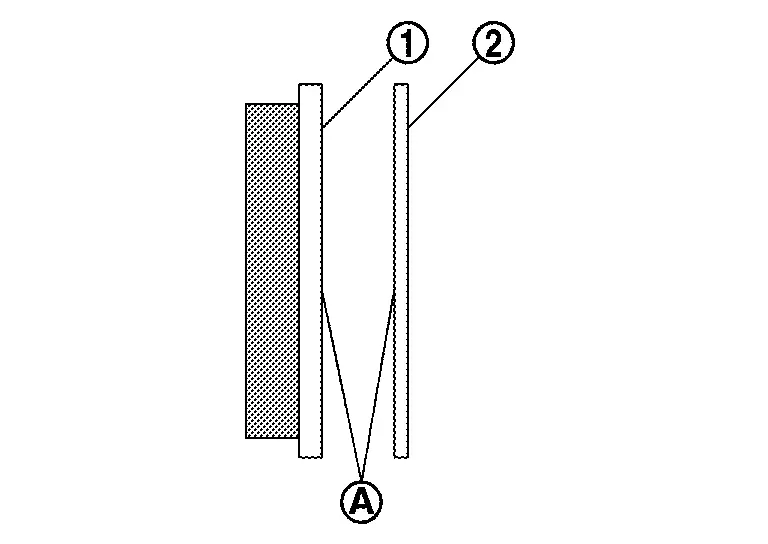

Temporarily tighten flare nut of brake tube

by hand, and then install it to the electrically-driven intelligent brake unit

by hand, and then install it to the electrically-driven intelligent brake unit  to the specified tightening torque using flare nut torque wrench (commercial tool) (A). Refer to Exploded View.

to the specified tightening torque using flare nut torque wrench (commercial tool) (A). Refer to Exploded View.

-

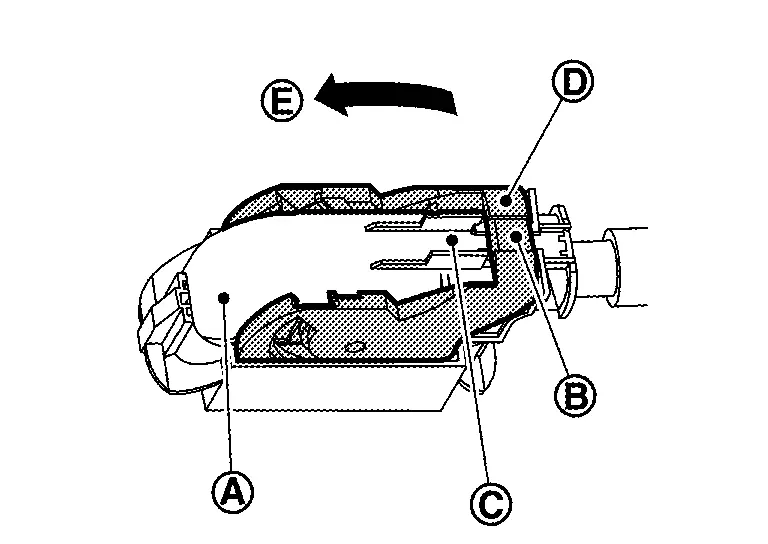

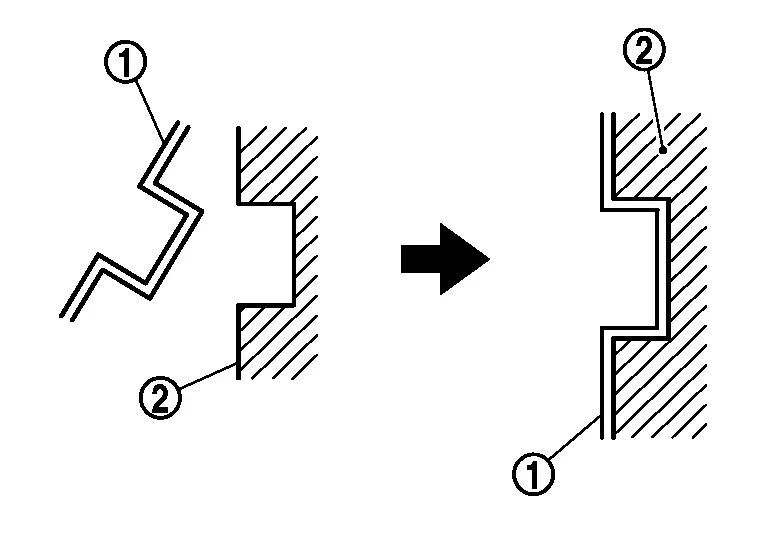

After installing electrically-driven intelligent brake unit harness connector

, move lever part

, move lever part  in the

in the  direction until it locks, and push in lock part

direction until it locks, and push in lock part  to lock it securely.

to lock it securely.

-

Install stroke sensor harness connector as follows;

-

Insert connector lock

into electrically-driven intelligent brake unit (1).

into electrically-driven intelligent brake unit (1). -

Push in the connector lock

in the (2) direction and securely lock.

in the (2) direction and securely lock.

-

-

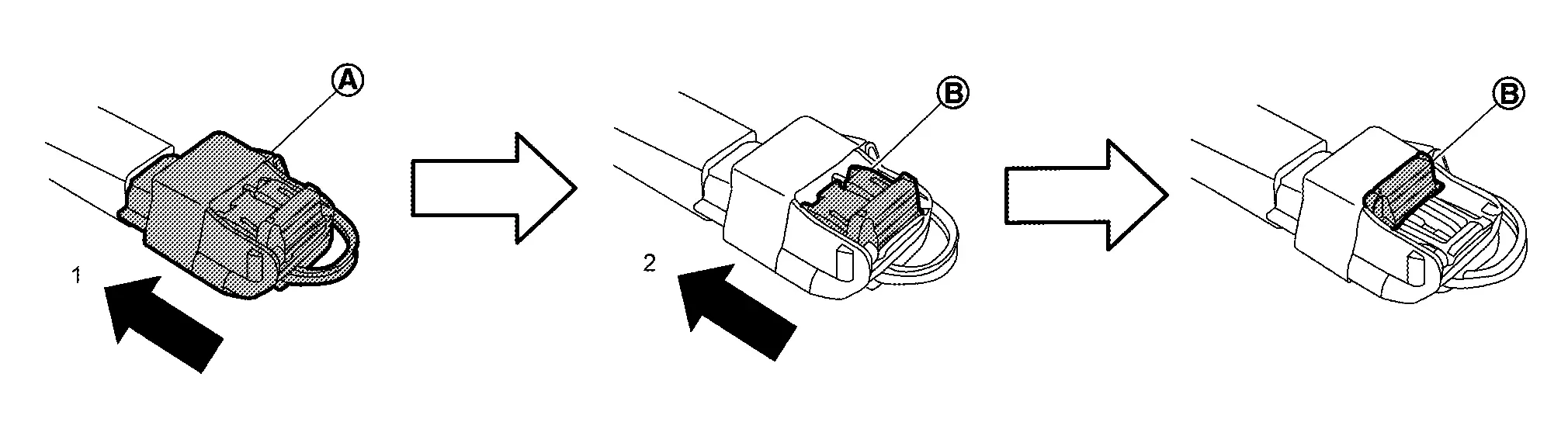

Install brake fluid level switch harness connector as follows;

-

Insert connector

to brake fluid level switch.

to brake fluid level switch. -

Push in connector lock

in the (2) direction and securely lock.

in the (2) direction and securely lock.

-

-

Perform air bleeding. Refer to Air Bleeding.

-

Check brake pedal for each item, adjust when there is deviation from the specified value. Refer to Periodic Maintenance Operation.

ELECTRICALLY-DRIVEN INTELLIGENT BRAKE UNIT : Inspection

INSPECTION BEFORE REMOVAL

Check brake fluid level switch. Refer to DTC Diagnosis Procedure.

INSPECTION AFTER REMOVAL

Check the following items, and replace the part if necessary.

-

Check for damage, deformation, interference with the other parts, and looseness of connection.

-

Check for fluid leakage from connection. Refer to Inspection

CAUTION:

When fluid leakage is occurred, tighten each bolt to the specified torque. Replace parts if there is still leakage.

INSPECTION AFTER INSTALLATION

Must be performed additional service when replacing electrically-driven intelligent brake unit. Refer to Description.

Warning Buzzer Nissan Ariya: FE0

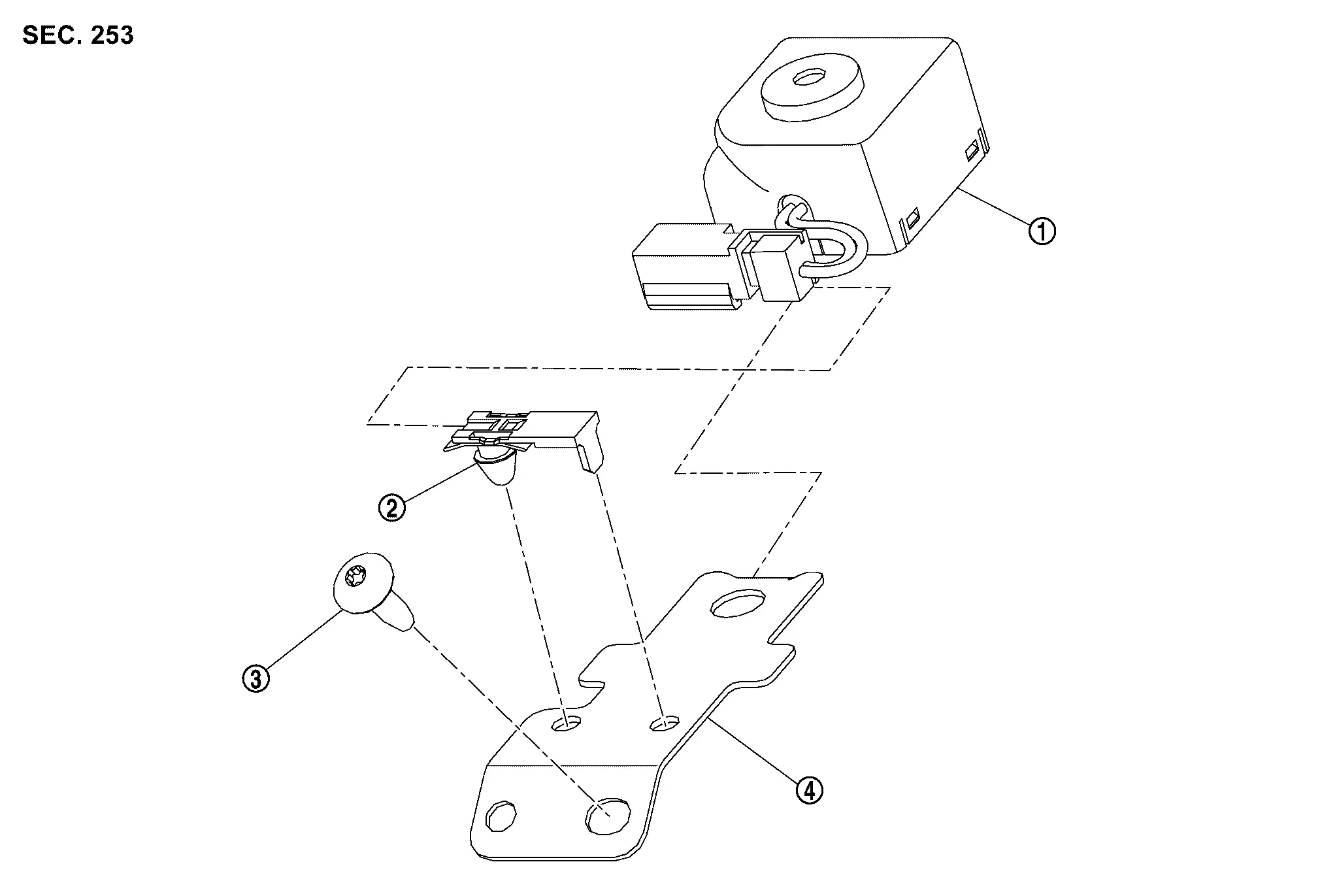

WARNING BUZZER : Exploded View

|

Warning buzzer |  |

Clip |  |

Screw |

|

Bracket |

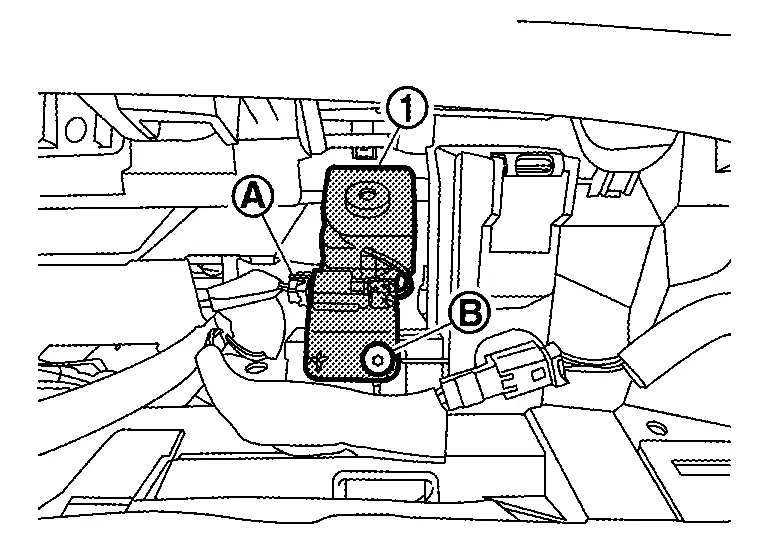

WARNING BUZZER : Removal & Installation

REMOVAL

Remove integrated interface display. Refer. Removal & Installation.

Disconnect warning buzzer harness connector  .

.

Remove mounting screw  and the remove warning buzzer

and the remove warning buzzer  .

.

INSTALLATION

Note the following, and install in the reverse order of removal.

Front Brake Pad Nissan Ariya 2023

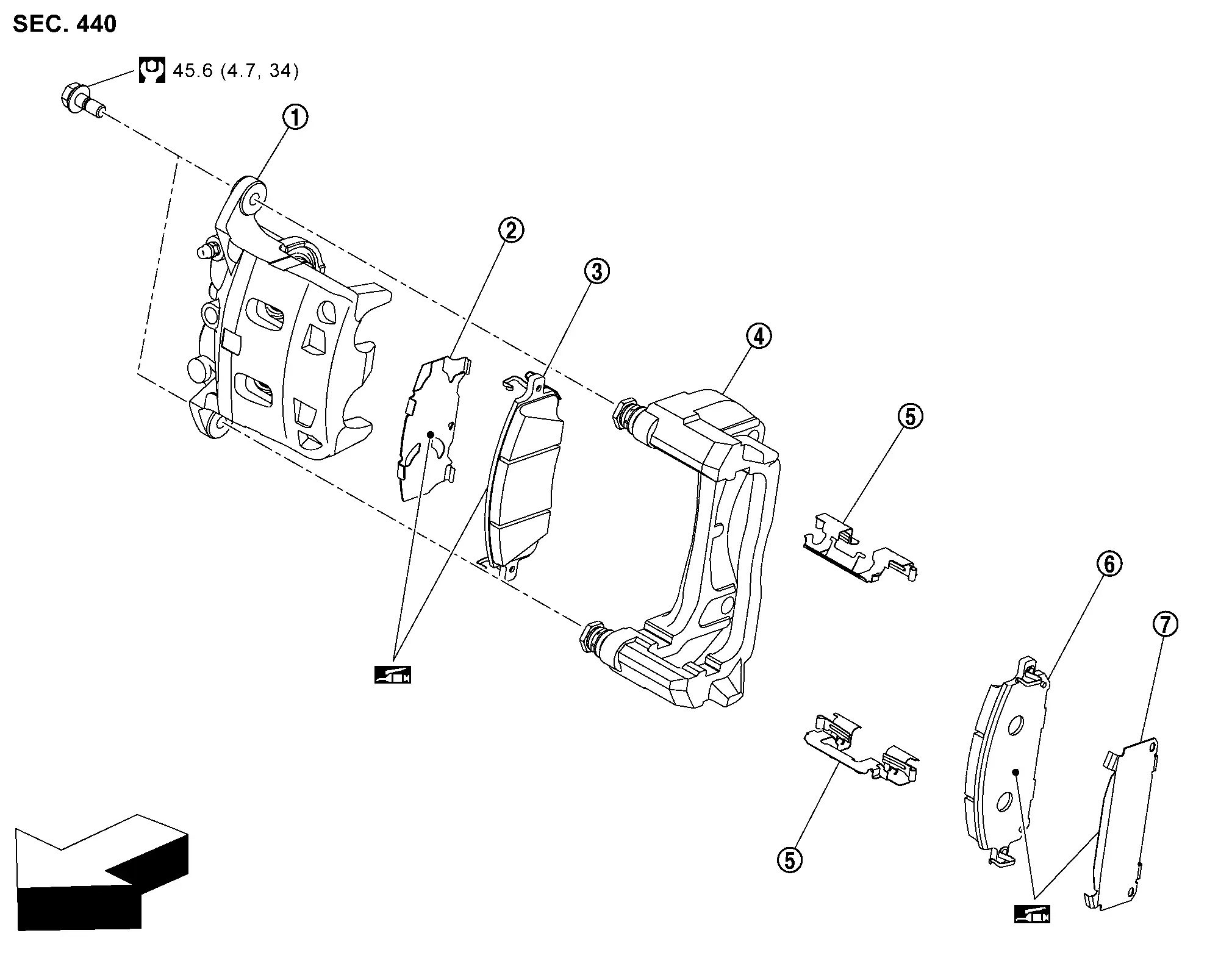

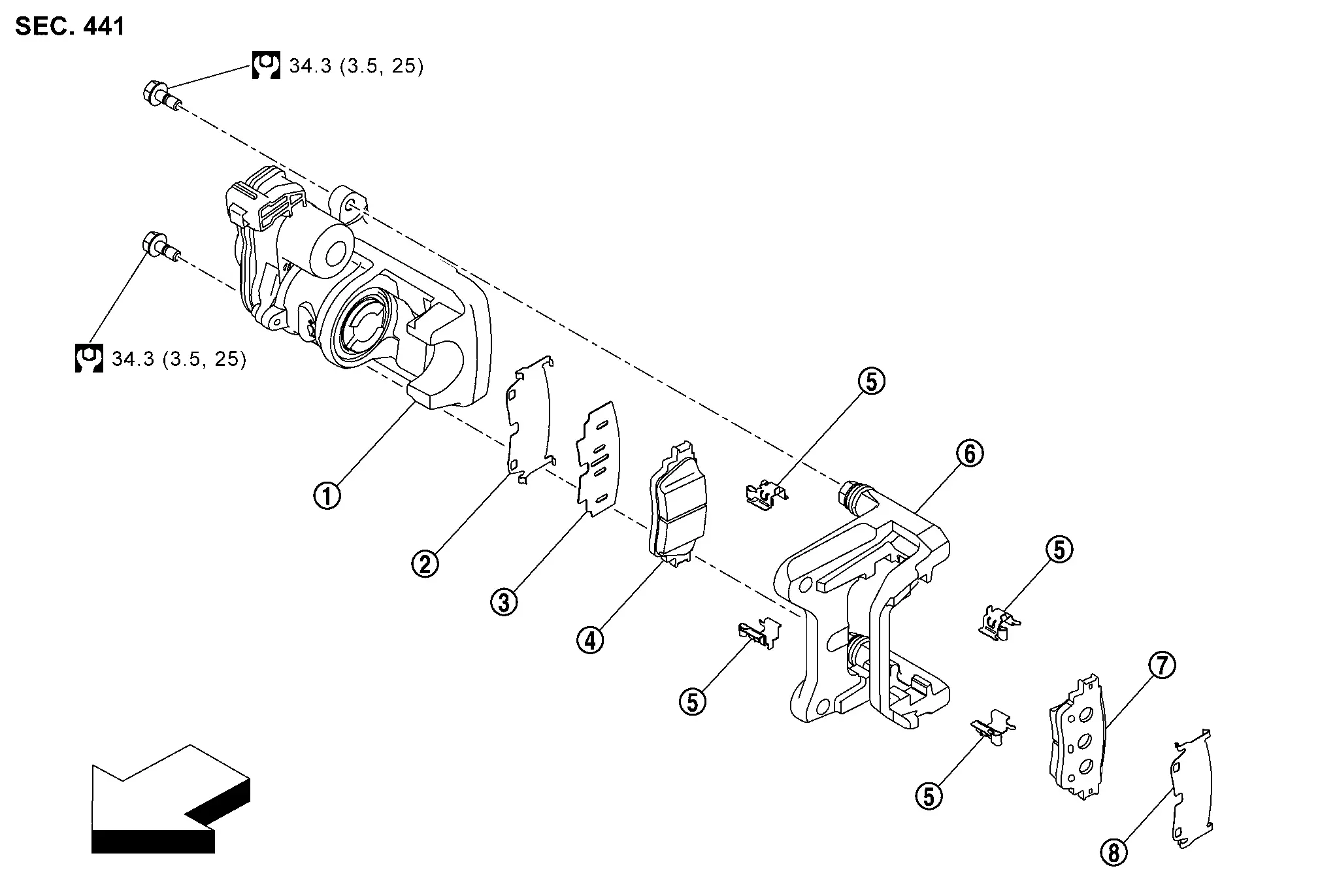

FRONT BRAKE PAD : Exploded View

FOR 31 SIZE NAO MODELS

|

Cylinder body |  |

Inner shim |  |

Inner pad (with pad wear sensor) |

|

Torque member |  |

Pad retainer |  |

Outer pad (with pad wear sensor) |

|

Outer shim | ||||

|

: Nissan Ariya Vehicle front | ||||

|

: N·m (kg-m, ft-lb) | ||||

|

: Nissan disc brake shim grease | ||||

FOR 36 SIZE NAO MODELS

|

Cylinder body |  |

Inner shim |  |

Inner pad (with pad wear sensor) |

|

Torque member |  |

Pad retainer (VHB foil) |  |

Outer pad |

|

Outer shim | ||||

|

: Nissan Ariya Vehicle front | ||||

|

: N·m (kg-m, ft-lb) | ||||

|

: Nissan disc brake shim grease | ||||

FRONT BRAKE PAD : Removal & Installation

FOR NAO 31 SIZE MODELS

REMOVAL

WARNING:

Remove dust covering brake caliper assembly and brake pad with a dust collector. Never splatter the dust with an air blow gun.

CAUTION:

-

Never depress the brake pedal while removing the brake pads because the piston may pop out.

-

If the brake fluid or grease adheres to the brake caliper assembly and disc rotor, quickly wipe it off.

Remove tires. Refer to Removal and Installation.

Remove sliding pin bolt (lower side).

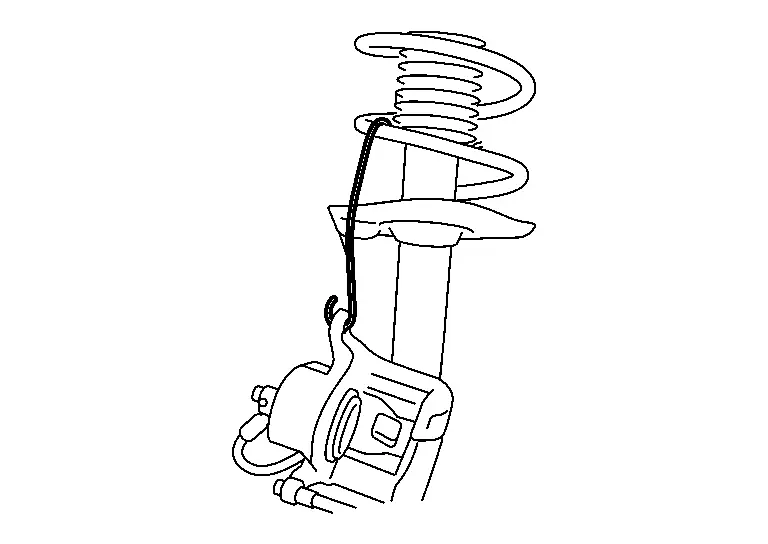

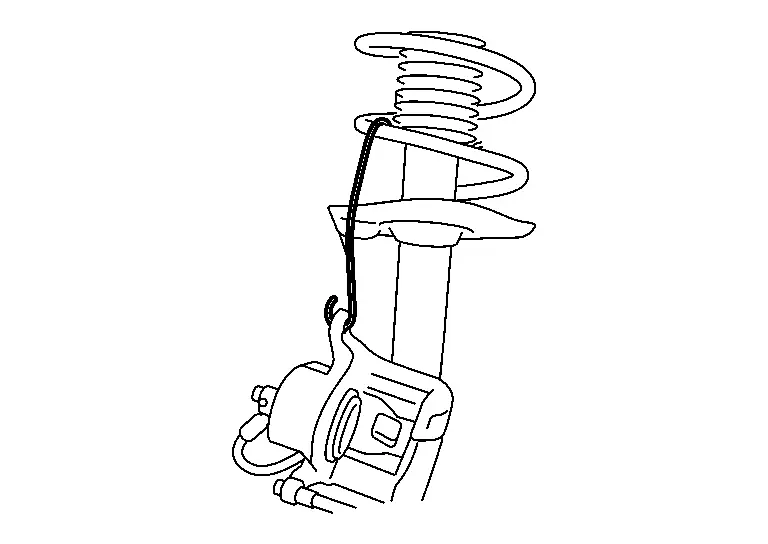

Hang cylinder body with suitable wire not to stretch brake hose.

Remove brake pads, shims, and pad retainer from torque member.

CAUTION:

-

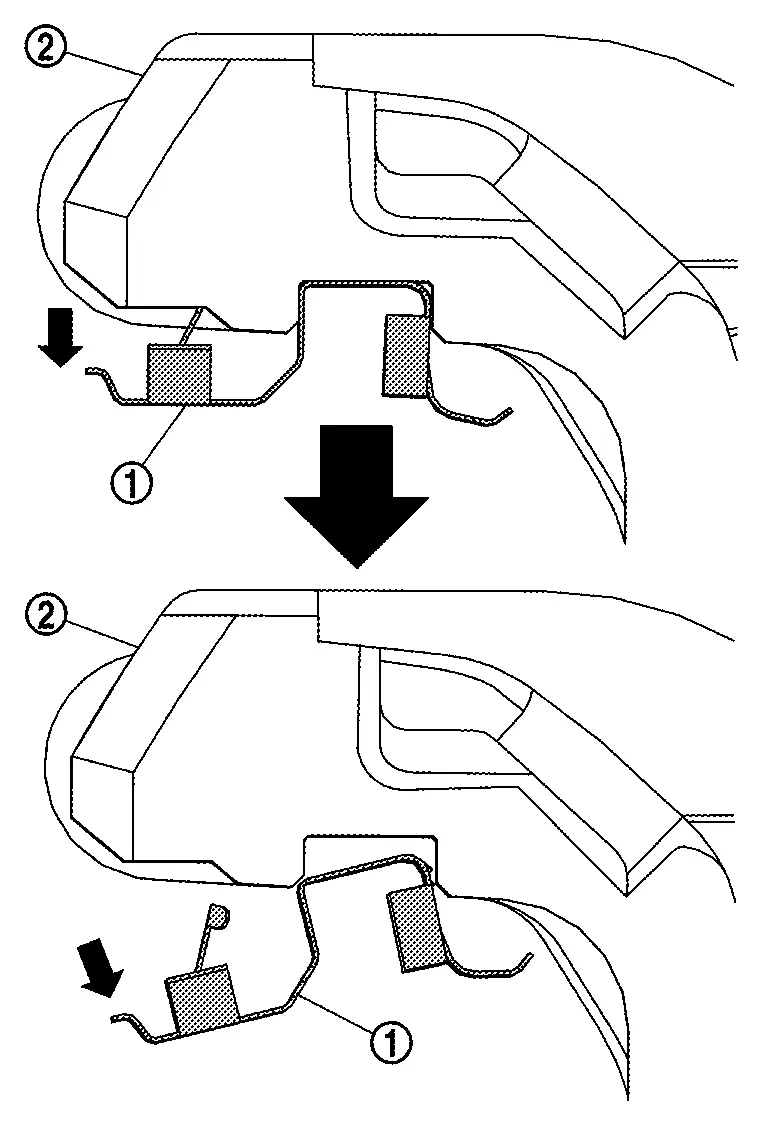

When removing pad retainer

from torque member

from torque member  , never deform pad retainer.

, never deform pad retainer.

-

Never damage piston boots.

-

Never drop brake pads, and shims.

-

Distinguish each position of removed brake pads.

Perform inspection after removal. Refer to Inspection and Adjustment.

INSTALLATION

WARNING:

Remove dust covering brake caliper assembly and brake pad with a dust collector. Never splatter the dust with an air blow gun.

CAUTION:

-

Never depress brake pedal while removing brake pads because the piston may pop out.

-

If the brake fluid or grease adheres to disc rotor and cylinder body, quickly wipe it off.

Install pad retainers  to torque members

to torque members  if pad retainers are removed before.

if pad retainers are removed before.

CAUTION:

-

Securely assemble pad retainers not to be lifted up from torque member.

-

Never deform pad retainers.

Apply Nissan disc brake shim grease to the matching surfaces  between brake pad

between brake pad  and shim cover

and shim cover  , and install shim covers to brake pad.

, and install shim covers to brake pad.

CAUTION:

When replacing the brake pad always replace the shims and shim covers as a set.

Install brake pads to torque member.

CAUTION:

Never damage pad retainer.

Install cylinder body to torque member.

CAUTION:

-

Never damage piston boot.

-

When installing cylinder body, check brake fluid level in reservoir tank because brake fluid returns to reservoir tank of brake master cylinder assembly by pressing piston in.

NOTE:

NOTE:

Use disc brake piston tool (commercial tool) to press piston easily.

Install slide pin bolt (lower side) and tighten to the specified torque.

Check front disc brake for dragging, while depressing brake pedal several times. Refer to Inspection and Adjustment.

Install tires. Refer to Removal and Installation.

FOR NAO 36 SIZE MODELS

REMOVAL

WARNING:

Remove dust covering brake caliper assembly and brake pad with a dust collector. Never splatter the dust with an air blow gun.

CAUTION:

-

Never depress the brake pedal while removing the brake pads because the piston may pop out.

-

If the brake fluid or grease adheres to the brake caliper assembly and disc rotor, quickly wipe it off.

Remove tires. Refer to Removal and Installation.

Remove sliding pin bolt (lower side).

Hang cylinder body with suitable wire not to stretch brake hose.

Remove brake pads, shims, and pad retainer from torque member.

CAUTION:

-

When removing pad retainer

from torque member

from torque member  , never deform pad retainer.

, never deform pad retainer.

-

Never damage piston boots.

-

Never drop brake pads, and shims.

-

Distinguish each position of removed brake pads.

Perform inspection after removal. Refer to Inspection and Adjustment.

INSTALLATION

WARNING:

Remove dust covering brake caliper assembly and brake pad with a dust collector. Never splatter the dust with an air blow gun.

CAUTION:

-

Never depress brake pedal while removing brake pads because the piston may pop out.

-

If the brake fluid or grease adheres to disc rotor and cylinder body, quickly wipe it off.

Install pad retainers  to torque members

to torque members  if pad retainers are removed before.

if pad retainers are removed before.

CAUTION:

-

Securely assemble pad retainers not to be lifted up from torque member.

-

Never deform pad retainers.

Install  pad retainer with

pad retainer with new VHB foil on pad retainer.

new VHB foil on pad retainer.

Apply Nissan disc brake shim grease to the matching surfaces  between brake pad

between brake pad  and shim cover

and shim cover  , and install shim covers to brake pad.

, and install shim covers to brake pad.

CAUTION:

When replacing the brake pad always replace the shims and shim covers as a set.

Install brake pads to torque member.

CAUTION:

Never damage pad retainer.

Install cylinder body to torque member.

CAUTION:

-

Never damage piston boot.

-

When installing cylinder body, check brake fluid level in reservoir tank because brake fluid returns to reservoir tank of brake master cylinder assembly by pressing piston in.

NOTE:

NOTE:

Use disc brake piston tool (commercial tool) to press piston easily.

Install slide pin bolt (lower side) and tighten to the specified torque.

Check front disc brake for dragging, while depressing brake pedal several times. Refer to Inspection and Adjustment.

Install tires. Refer to Removal and Installation.

FRONT BRAKE PAD : Inspection

INSPECTION AFTER REMOVAL

-

Replace the shims and shim covers if rust is excessively occurred.

-

Eliminate rust on pad retainers and the torque member. Replace them if rust is excessively occurred.

INSPECTION AFTER INSTALLATION

Check front disc brake for a dragging. If any drag is felt, follow the procedure described below.

Remove brake pads. Refer to Removal and Installation.

Return pistons of caliper. Refer to Removal and Installation.

Install brake pads. Refer to Removal and Installation.

Depress brake pedal several times.

Check front disc brake for a dragging again. If any drag is felt, disassemble cylinder body. Replace if necessary. Refer to Disassembly and Assembly.

If brake pads are replaced or ground, or if braking force is felt strange, perform break-in work. Refer to Periodic Maintenance Operation.

Front Brake Caliper Assembly Nissan Ariya 1st generation

FRONT BRAKE CALIPER ASSEMBLY : Exploded View

FOR NAO 31 SIZE MODELS

REMOVAL

|

Brake caliper assembly | ||||

|

: N·m (kg-m, ft-lb) | ||||

DISASSEMBLY

|

Cap |  |

Bleeder valve |  |

Cylinder body |

|

Piston seal |  |

Sliding pin |  |

Piston |

|

Sliding pin boot |  |

Piston boot |  |

Torque member |

|

Bushing | ||||

|

: Nissan Ariya Vehicle front | ||||

|

: N·m (kg-m, in-lb) | ||||

|

: NISSAN rubber grease. | ||||

|

: NISSAN brake fluid No.2500 | ||||

|

: Always replace after every disassembly. | ||||

FOR NAO 36 SIZE MODELS

REMOVAL

|

Brake caliper assembly | ||||

|

: N·m (kg-m, ft-lb) | ||||

DISASSEMBLY

|

Cap |  |

Bleeder valve |  |

Cylinder body |

|

Piston seal |  |

Sliding pin |  |

Piston |

|

Sliding pin boot |  |

Piston boot |  |

Torque member |

|

Bushing | ||||

|

: Nissan Ariya Vehicle front | ||||

|

: N·m (kg-m, in-lb) | ||||

|

: NISSAN rubber grease. | ||||

|

: NISSAN brake fluid No.2500 | ||||

|

: Always replace after every disassembly. | ||||

FRONT BRAKE CALIPER ASSEMBLY : Removal & Installation

REMOVAL

WARNING:

Remove dust covering brake caliper assembly and brake pad with a dust collector. Never splatter the dust with an air blow gun.

CAUTION:

-

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off immediately and wash with water if it gets on a painted surface. For brake component parts, never wash them with water.

-

Never depress brake pedal during removal and installation of brake hose because brake fluid may scatter.

-

Never depress the brake pedal while removing the brake pads because the piston may pop out.

-

Never drop parts after removal.

-

If the brake fluid or grease adheres to cylinder body and disc rotor, quickly wipe it off.

Remove tires. Refer to Removal and Installation.

Fix the disc rotor using wheel nuts.

Drain brake fluid. Refer to Draining.

CAUTION:

Never adhere brake fluid to disc rotor.

Remove union bolts and copper washer and then separate brake hose from brake caliper assembly. Refer to Removal & Installation

CAUTION:

Never depress brake pedal during removal and installation of brake hose because brake fluid may scatter.

Remove torque member mounting bolt and then remove brake caliper assembly.

CAUTION:

Never drop brake caliper assembly and brake pad.

INSTALLATION

WARNING:

Remove dust covering brake caliper assembly and brake pad with a dust collector. Never splatter the dust with an air blow gun.

CAUTION:

-

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off immediately and wash with water if it gets on a painted surface. However avoid washing brake components with water.

-

Never depress brake pedal while removing the brake pads because the piston may pop out.

-

If brake fluid or grease adheres to disc rotor and cylinder body, quickly wipe it off.

Install disc rotor. Refer to Removal & Installation.

Install brake caliper assembly to steering knuckle and tighten torque member mounting bolt to the specified torque.

CAUTION:

Never spill or splash any grease and moisture on the brake caliper assembly mounting face, threads, mounting bolts and washers. Wipe out any grease and moisture.

Install copper washers and brake hose to brake caliper and tighten union bolt to the specified torque. Refer to Removal & Installation.

CAUTION:

Never reuse copper washer.

Perform air bleeding. Refer to Air Bleeding.

CAUTION:

-

Never refill drained brake fluid.

-

Never adhere brake fluid to disc rotor.

Check front disc brake for dragging. Refer to Inspection.

Install tires. Refer to Removal and Installation.

Perform inspection after installation. Refer to Inspection.

FRONT BRAKE CALIPER ASSEMBLY : Disassembly & Assembly

DISASSEMBLY

CAUTION:

Never drop parts.

NOTE:

NOTE:

When disassembling, torque member, brake pad, and pad retainer are not required to remove. Refer to Removal & Installation.

Remove sliding pin bolts and then remove cylinder body from torque member.

CAUTION:

Never drop brake pad by fixing it with suitable tape.

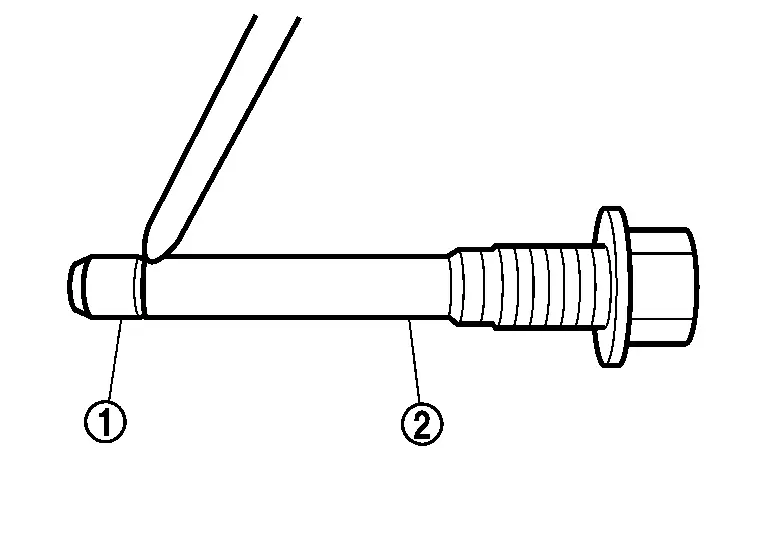

Remove sliding pin boots from torque member.

Remove bushing  from sliding pin

from sliding pin  .

.

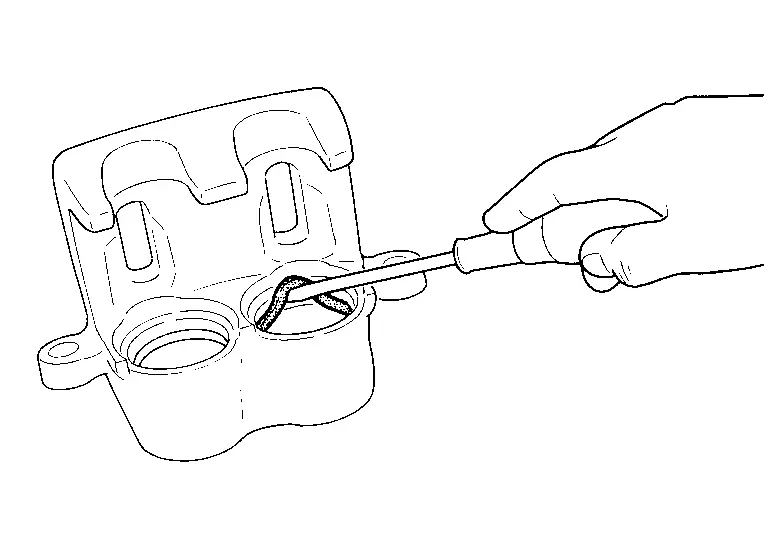

Place a wooden block as shown in the figure, and blow air into union bolt mounting hole to remove pistons and piston boots.

CAUTION:

Never get fingers caught in the pistons.

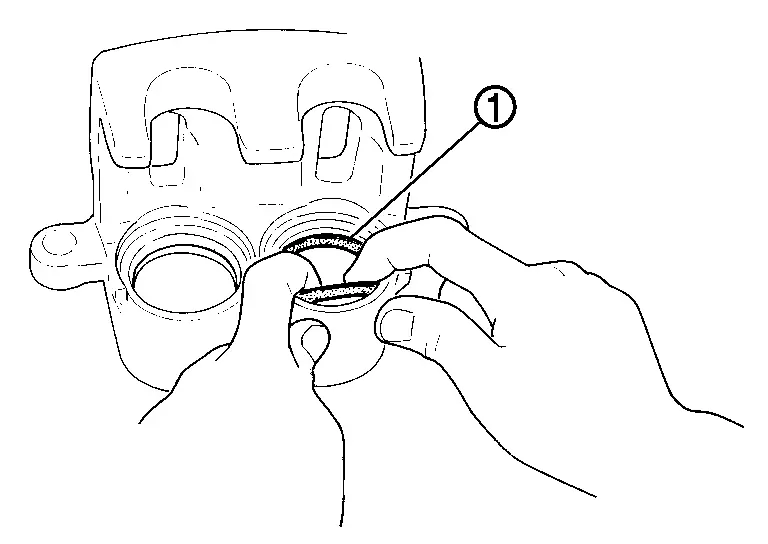

Remove piston seals from cylinder body using seal pick tool.

CAUTION:

Be careful not to damage a cylinder inner wall.

Remove bleeder valve and cap.

Perform inspection after disassembly. Refer to Inspection.

ASSEMBLY

CAUTION:

Never drop parts.

Install bleeder valve and cap.

Apply Nissan rubber grease to piston seals  , and install them to cylinder body.

, and install them to cylinder body.

CAUTION:

Never reuse piston seals.

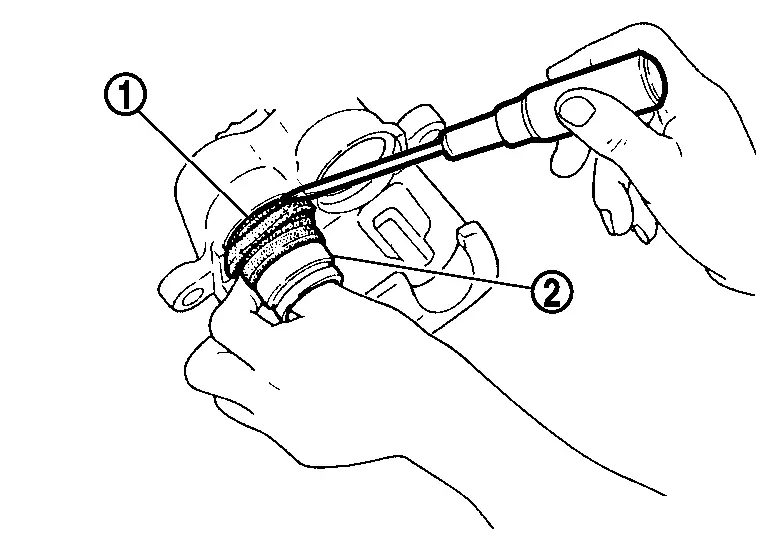

Apply Nissan rubber grease to piston boots  . Cover piston end

. Cover piston end  with piston boot, and then install cylinder side lip of piston boot securely into groove on cylinder body.

with piston boot, and then install cylinder side lip of piston boot securely into groove on cylinder body.

CAUTION:

Never reuse piston boots.

Apply new brake fluid to pistons  . Push piston into cylinder body and then install piston-side lip of piston boot

. Push piston into cylinder body and then install piston-side lip of piston boot  into the piston groove.

into the piston groove.

CAUTION:

Press the pistons evenly and vary the pressing point to prevent cylinder inner wall from being rubbed.

Apply rubber grease to mating faces  between sliding pin

between sliding pin  and bushing

and bushing  , and install bushing to sliding pin.

, and install bushing to sliding pin.

Apply rubber grease to mating faces  between sliding pins

between sliding pins  and sliding pin boots

and sliding pin boots  , and install sliding pins and sliding pin boots to torque member

, and install sliding pins and sliding pin boots to torque member  .

.

Install cylinder body to torque member and tighten sliding pin bolts to the specified torque.

FRONT BRAKE CALIPER ASSEMBLY : Inspection

INSPECTION AFTER DISASSEMBLY

Check the following items and replace if necessary.

Cylinder Body

Check cylinder inner wall for rust, wear, cracks or damage.

CAUTION:

Always clean with new brake fluid. Never clean with mineral oil such as gasoline and diesel fuel.

Torque Member

Check the torque member for rust, wear, cracks or damage.

Pistons

Check surface of piston for rust, wear, cracks or damage.

CAUTION:

Piston sliding surface is plated. Never polish with sandpaper.

Sliding Pin, Sliding Pin Boot and Bushing

Check sliding pins, sliding pin boots and bushing for rust, wear, cracks or damage.

INSPECTION AFTER INSTALLATION

Check front disc brake for dragging. If any drag is found, follow the procedure described below.

Remove brake pads. Refer to Removal and Installation.

Return pistons caliper. Refer to Removal and Installation.

Install brake pad. Refer to Removal and Installation.

Depress the brake pedal several times.

Check front disc brake for dragging again. When any drag is found, disassemble the cylinder body and replace if necessary. Refer to Disassembly and Assembly.

If brake pads are replaced or ground, or if braking force is felt strange, perform break-in work. Refer to Periodic Maintenance Operation .

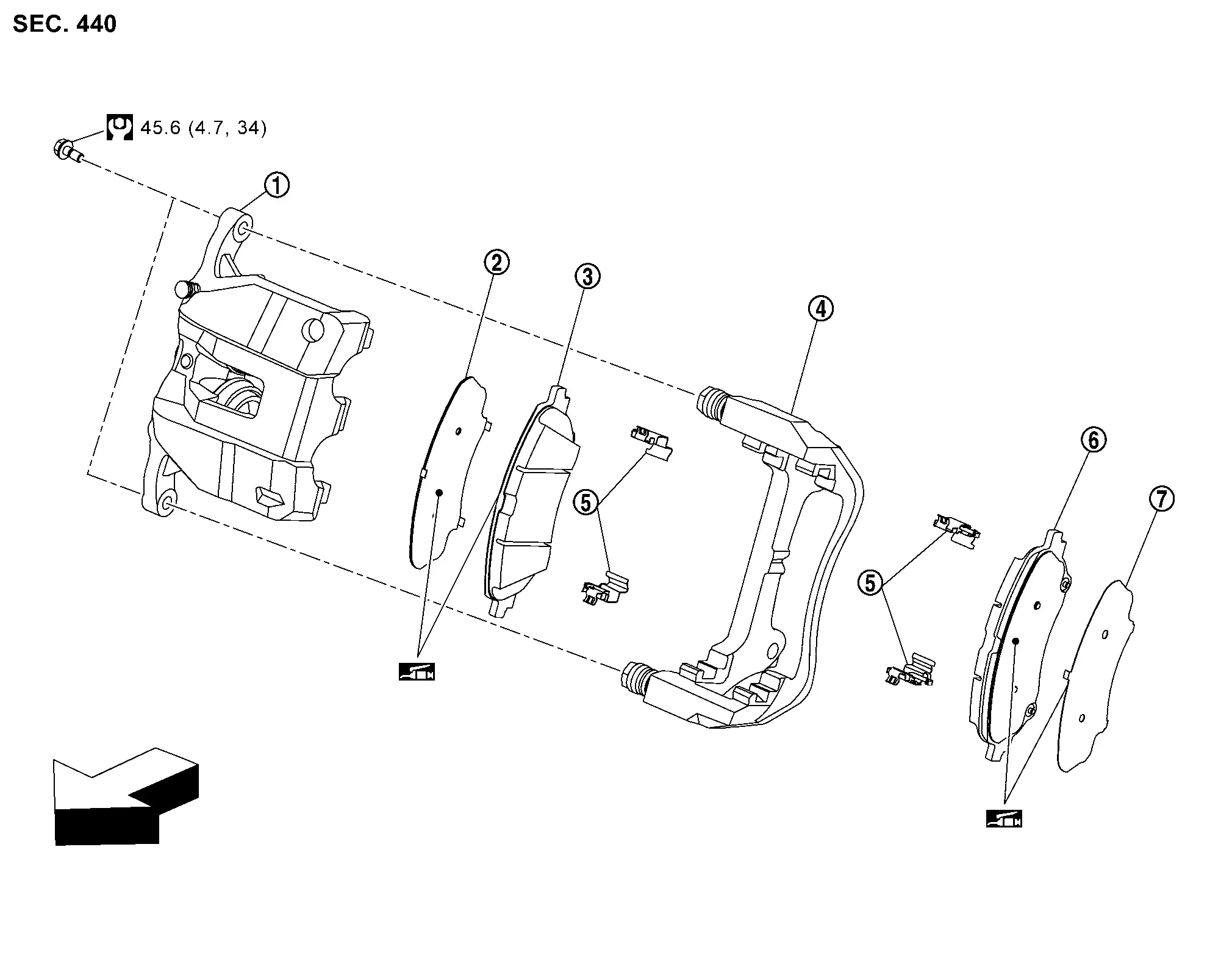

Rear Brake Pad Nissan Ariya

REAR BRAKE PAD : Exploded View

|

Cylinder body |  |

Inner shim cover |  |

Inner shim |

|

Inner pad (with pad wear sensor) |  |

Pad retainer |  |

Torque member |

|

Outer pad (with pad wear sensor) |  |

Outer shim cover | ||

|

: Nissan Ariya Vehicle front | ||||

|

: N·m (kg-m, ft-lb) | ||||

REAR BRAKE PAD : Removal & Installation

REMOVAL

WARNING:

Remove dust covering brake caliper assembly and brake pad with a dust collector. Never splatter the dust with an air blow gun.

CAUTION:

-

Never depress the brake pedal while removing the brake pads because the piston may pop out.

-

Never adhere brake fluid to disc rotor.

-

If the brake fluid or grease adheres to disc rotor, quickly wipe it off.

Release parking brake.

Must be performed additional service when replacing brake pad or rear brake caliper. Refer to Description.

Remove tires. Refer to Removal and Installation.

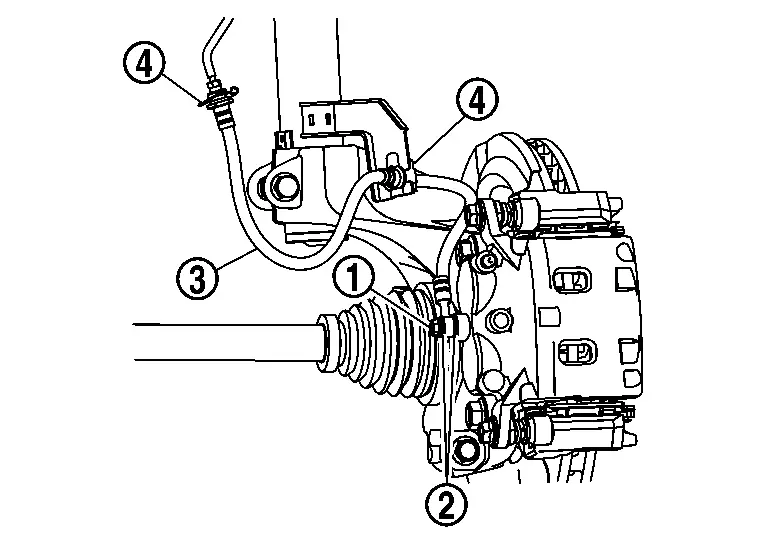

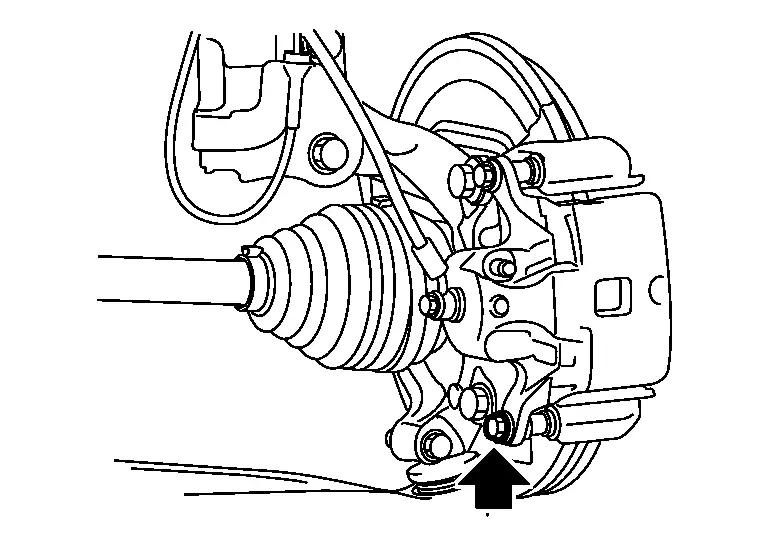

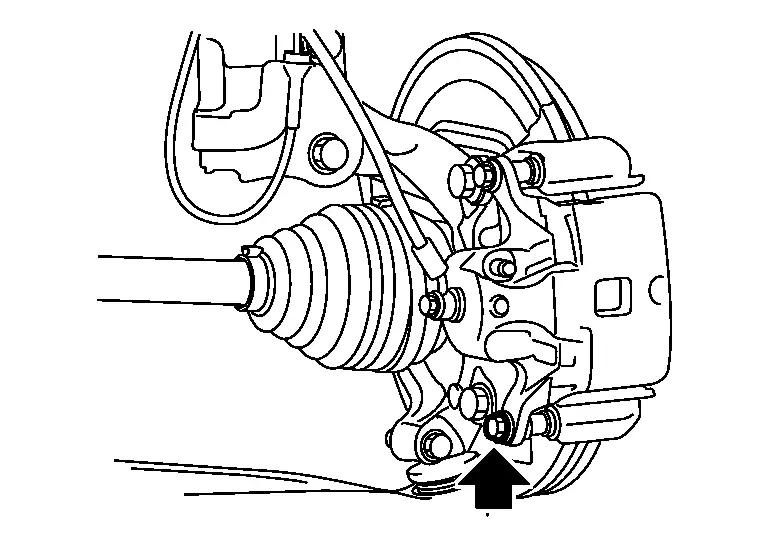

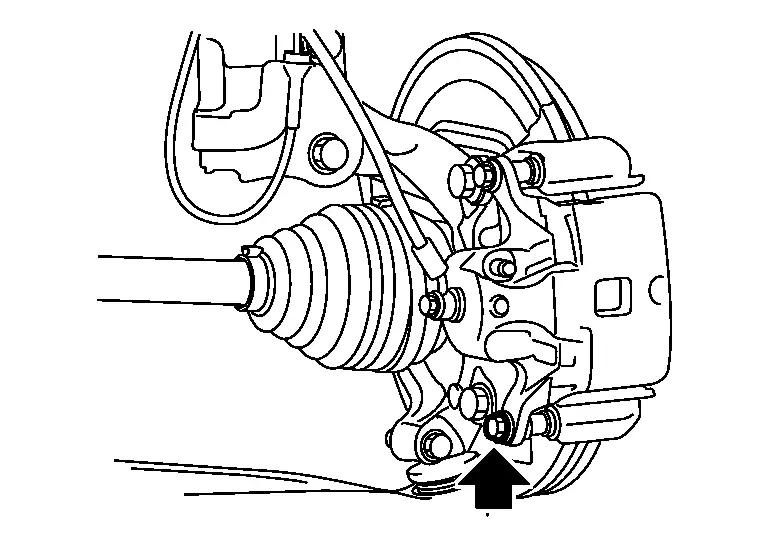

Disconnect parking brake actuator harness connector  .

.

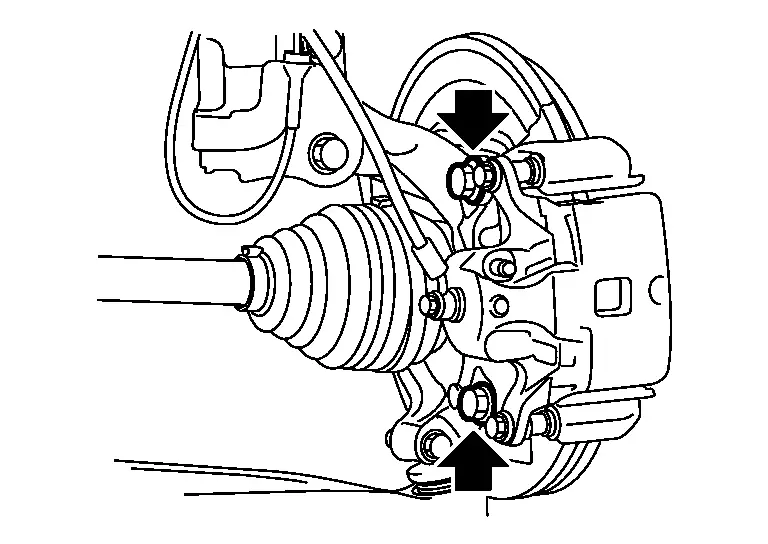

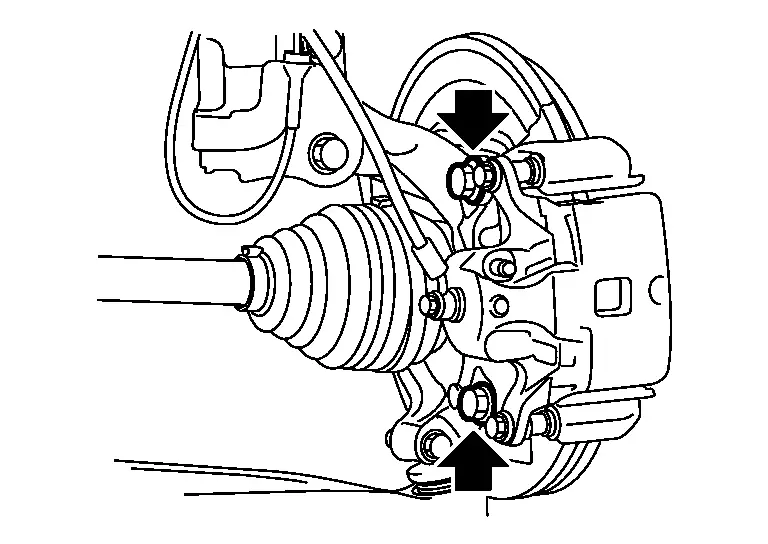

Fix sliding pin with spanner wrench (commercial tool) (A) and remove sliding pin bolt.

Remove cylinder body  from torque member, and hang cylinder body with suitable wire (A) to prevent brake hose for stretching.

from torque member, and hang cylinder body with suitable wire (A) to prevent brake hose for stretching.

Remove brake pads, shims and shim covers from torque member.

CAUTION:

-

When removing pad retainer

from torque member

from torque member  , never deform pad retainer.

, never deform pad retainer.

-

Never damage piston boots.

-

Never drop brake pads, shims and shim covers.

-

Distinguish each position of the removed brake pads.

Perform inspection after removal. Refer to Inspection.

INSTALLATION

WARNING:

Remove dust covering brake caliper assembly and brake pad with a dust collector. Never splatter the dust with an air blow gun.

CAUTION:

-

Never depress the brake pedal while removing the brake pads because the piston may pop out.

-

Never adhere brake fluid to disc rotor.

-

If the brake fluid or grease adheres to disc rotor, quickly wipe it off.

Install pad retainers  to torque members

to torque members  if pad retainers are removed before.

if pad retainers are removed before.

CAUTION:

-

Securely assemble pad retainers not to be lifted up from torque member.

-

Never deform pad retainers.

Install inner shim and inner shim cover to inner pad.

CAUTION:

When replacing brake pad, must always be together with shim.

Install outer cover to outer pad.

CAUTION:

When replacing brake pad, must always be together with shim.

Install brake pad to torque member.

CAUTION:

Never deform pad retainer.

Install cylinder body to torque member.

CAUTION:

-

Never damage piston boot.

-

When installing cylinder body with new one, check brake fluid level in reservoir tank because brake fluid returns to reservoir tank by pressing piston in.

NOTE:

NOTE:

When returning piston, use disc brake piston tool (commercial tool) to press piston easily.

Install sliding pin bolt  to cylinder body and tighten them to the specified torque.

to cylinder body and tighten them to the specified torque.

Must be performed additional service when removing and replacing brake pad and rear brake caliper. Refer to Description.

Depress the brake pedal several times to check that no drag feel is present for the rear disc brake. Refer to Inspection.

Install tires. Refer to Removal and Installation.

Perform inspection after installation. Refer to Inspection.

REAR BRAKE PAD : Inspection

INSPECTION AFTER REMOVAL

-

Replace the shims and shim covers if rust is excessively attached.

-

Eliminate rust on the pad and the torque member. Replace them if rust is excessively attached.

INSPECTION AFTER INSTALLATION

-

When replacing rear brake pad or when returning piston of rear brake caliper, perform the following procedure.

-

Adjust initial position. Refer to Work Procedure.

-

Must be performed additional service when removing and replacing rear brake pad and rear brake caliper. Refer to Description.

-

-

Check a drag of rear disc brake, if any drag is felt, follow the procedure described below.

-

Must be performed additional service when removing and replacing rear brake pad and rear Refer to Description.

-

Depress the brake pedal several times.

-

Check a drag of rear disc brake again. If any drag is felt, disassemble the cylinder body and replace if necessary. Refer to Removal and Installation.

-

-

If brake pads are replaced or ground, or if braking force is felt strange, perform break-in work. Refer to Periodic Maintenance Operation.

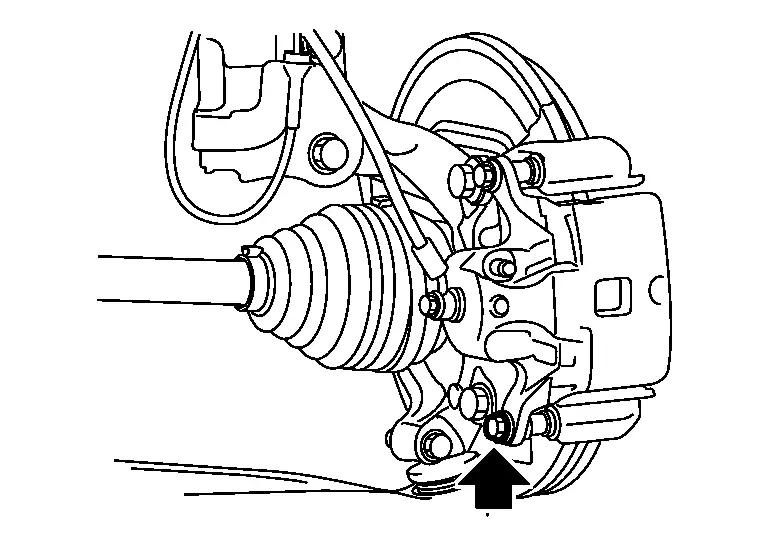

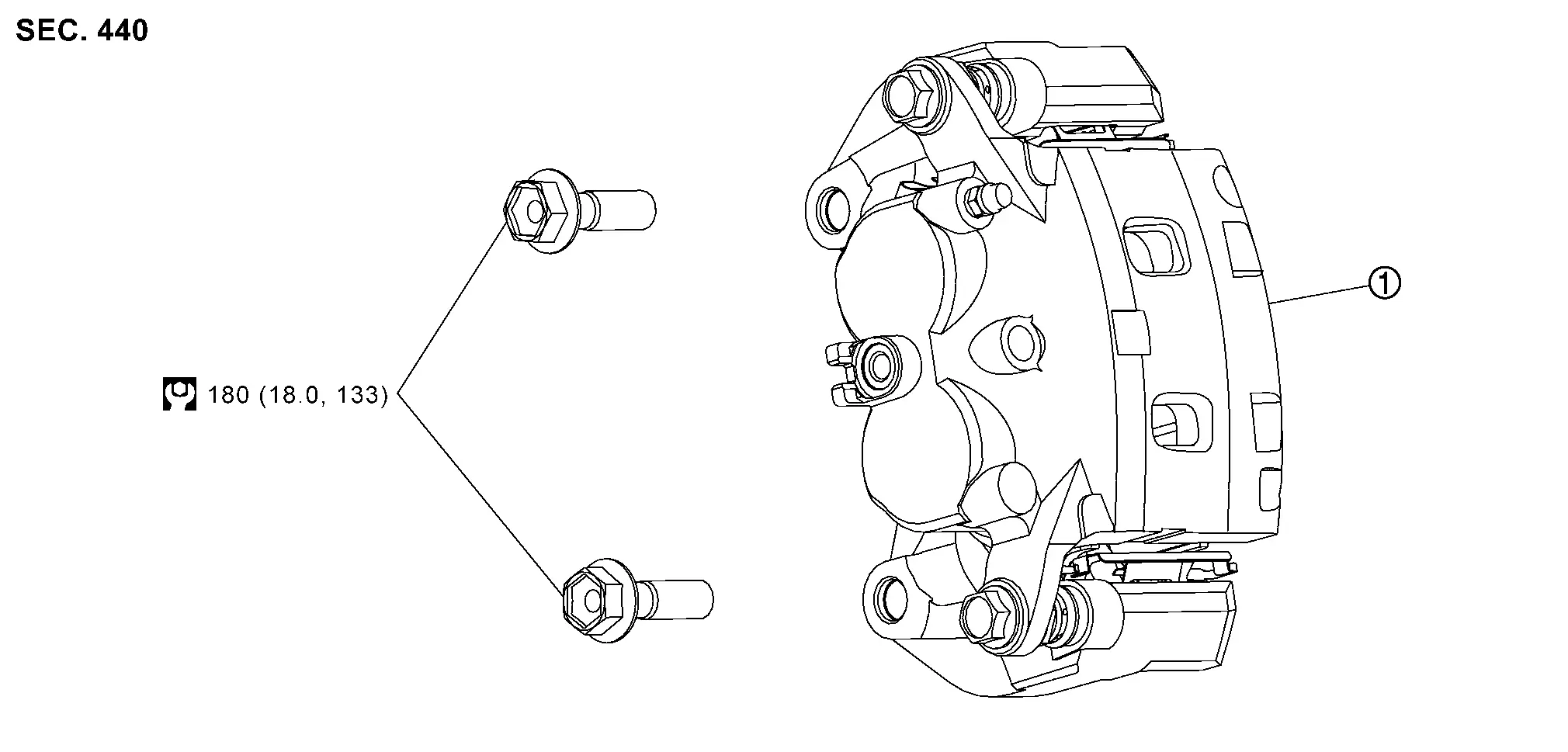

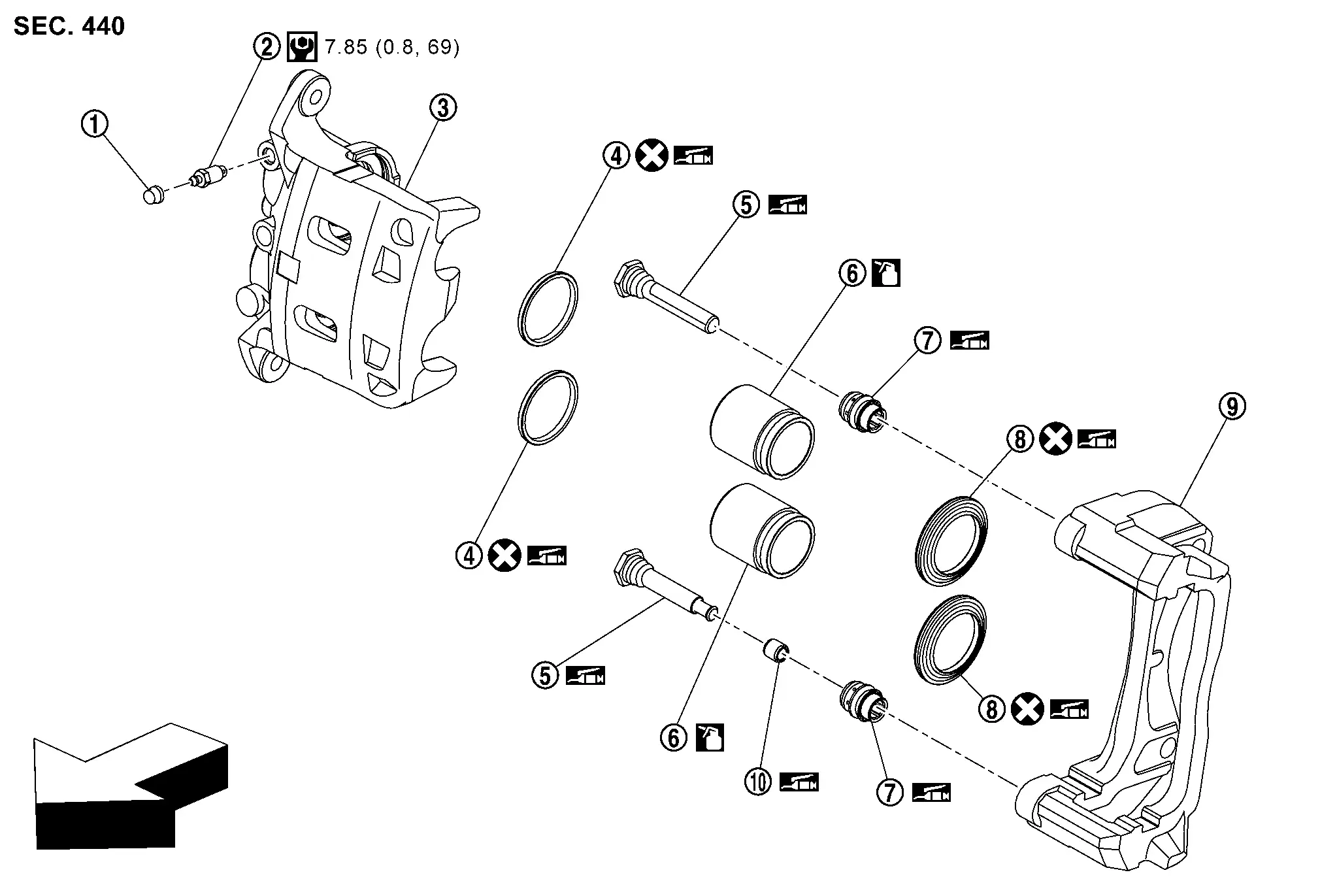

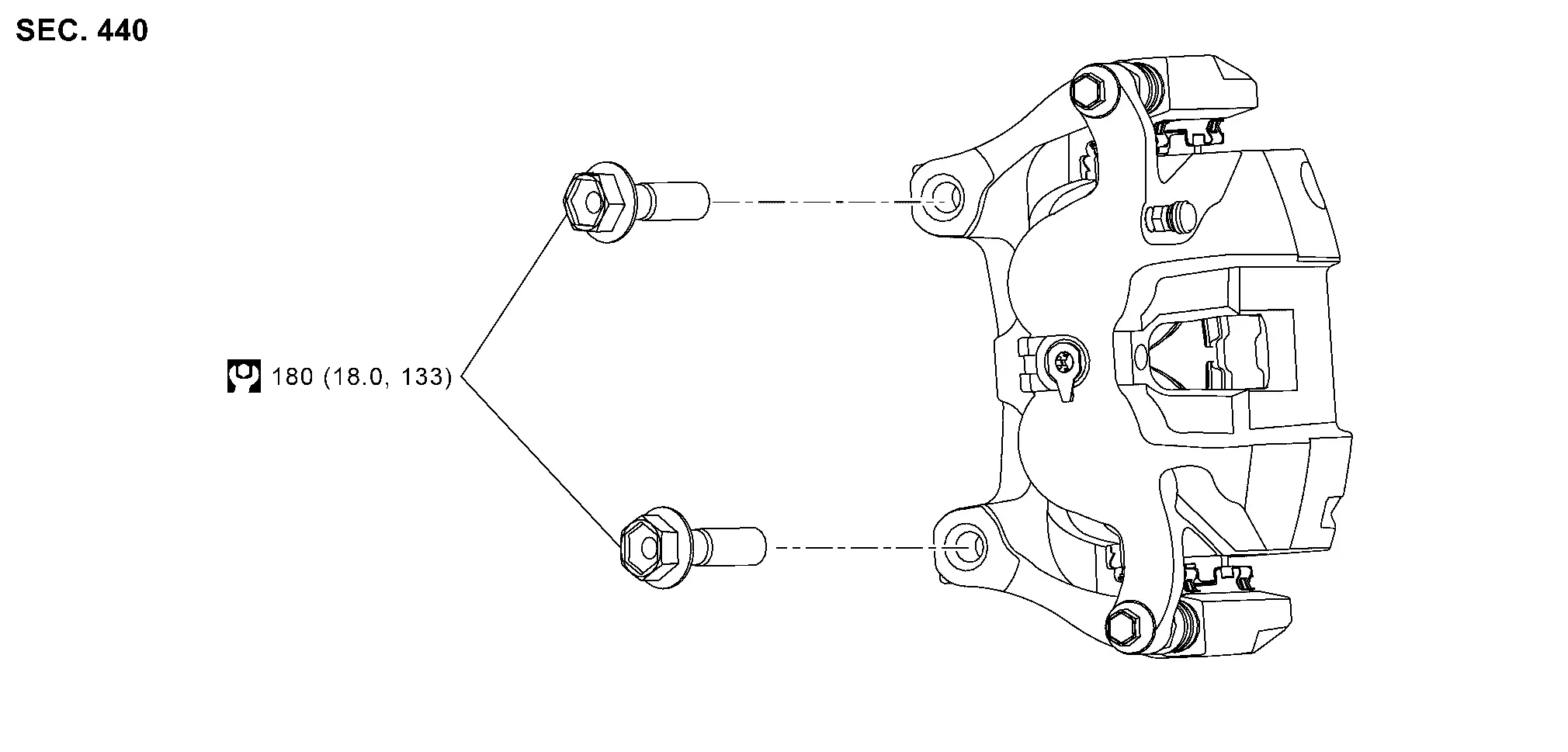

Rear Brake Caliper Assembly Nissan Ariya 2026

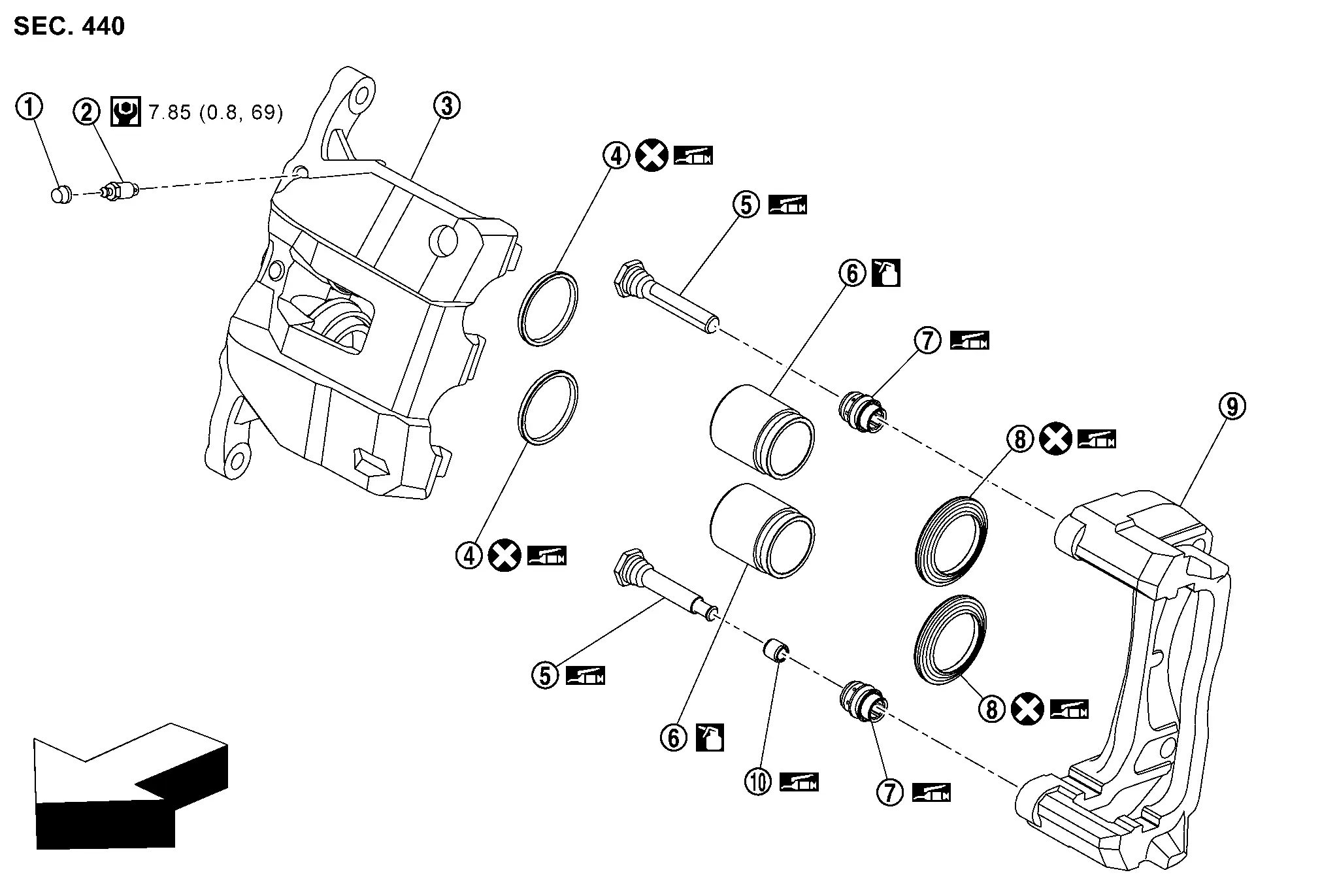

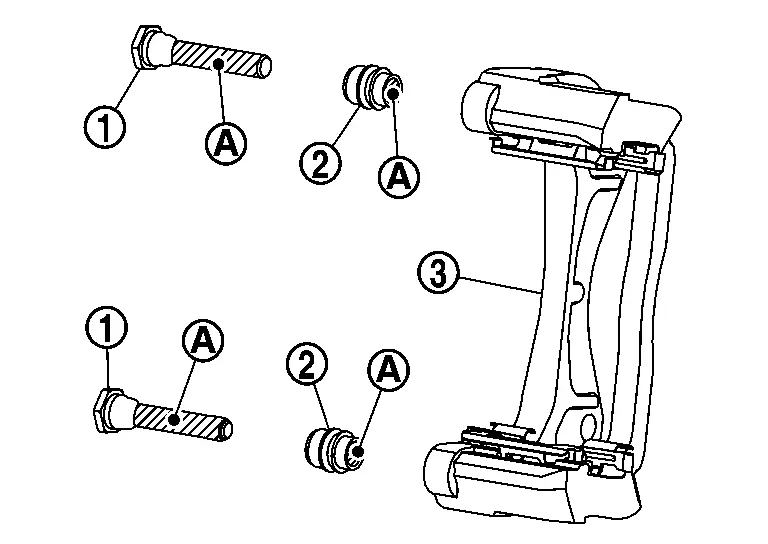

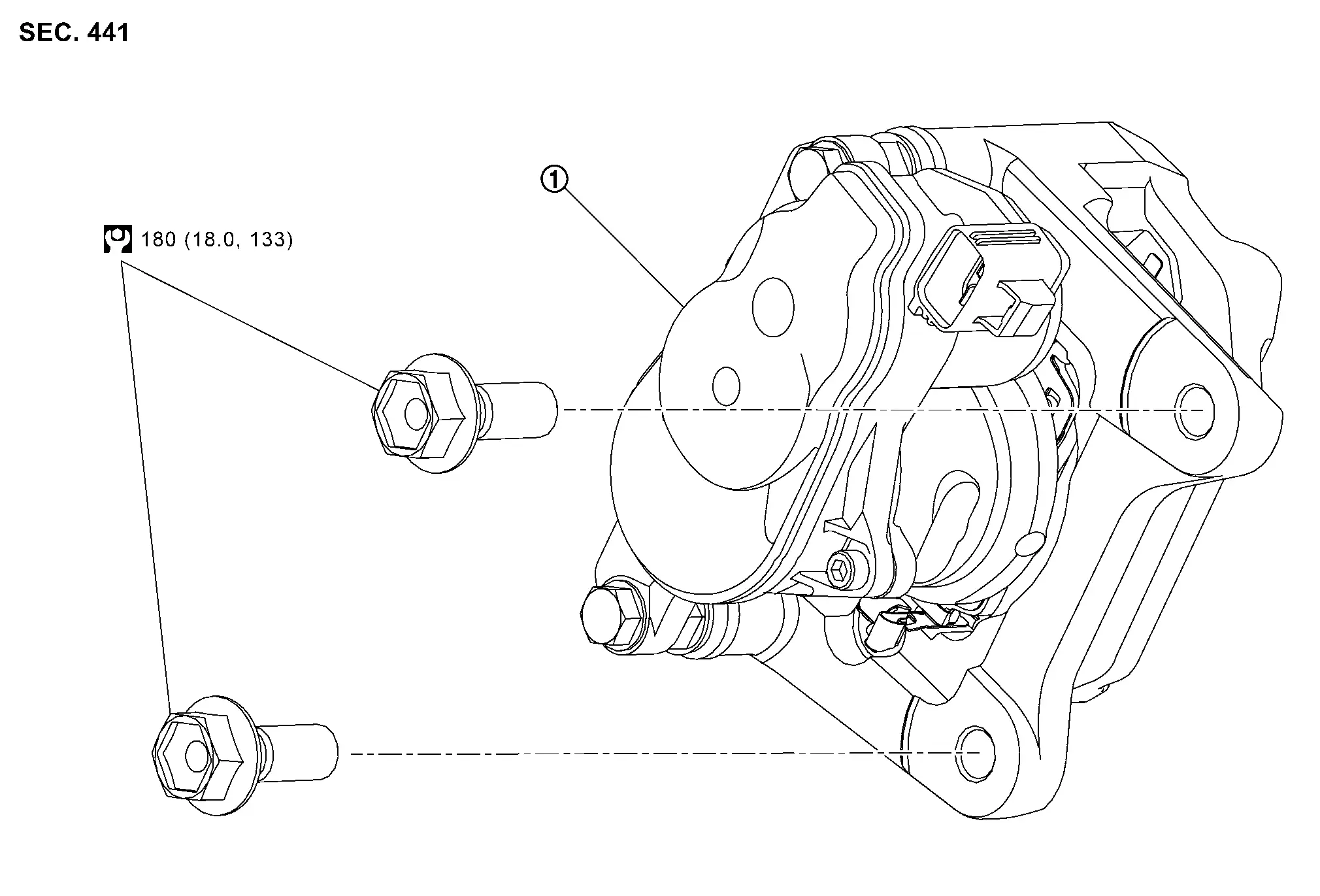

REAR BRAKE CALIPER ASSEMBLY : Exploded View

REMOVAL

|

Brake caliper assembly | ||||

|

: N·m (kg-m, ft-lb) | ||||

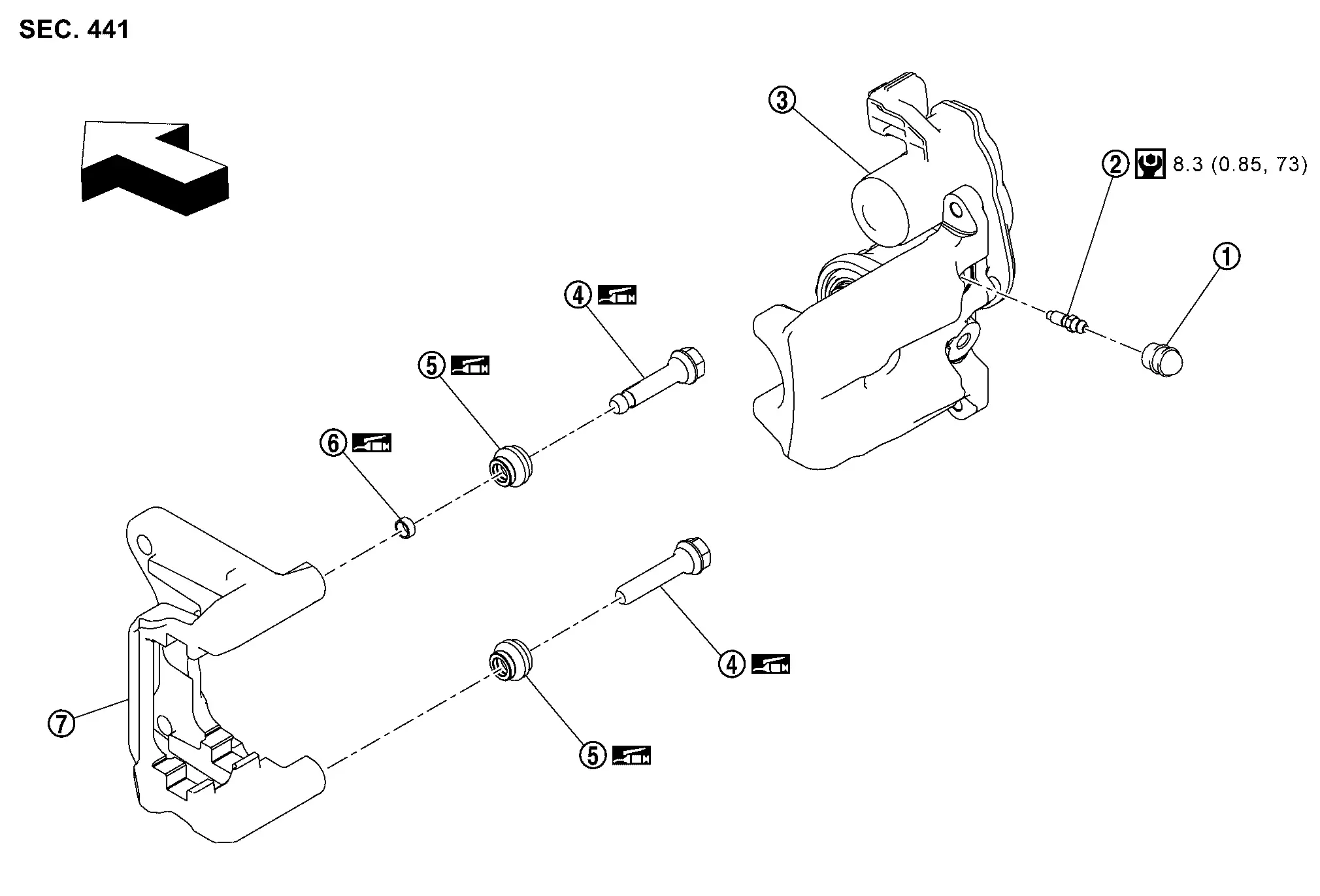

DISASSEMBLY

|

Cap |  |

Bleeder valve |  |

Cylinder body |

|

Sliding pin |  |

Sliding pin boot |  |

Bushing |

|

Torque member | ||||

|

: Nissan Ariya Vehicle front | ||||

|

: N·m (kg-m, in-lb) | ||||

|

: NISSAN rubber grease. | ||||

REAR BRAKE CALIPER ASSEMBLY : Removal & Installation

REMOVAL

WARNING:

Remove dust covering brake caliper assembly and brake pad with a dust collector. Never splatter the dust with an air blow gun.

CAUTION:

-

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off immediately and wash with water if it gets on a painted surface. For brake component parts, never wash them with water.

-

Never drop removed parts.

-

Never adhere brake fluid to disc rotor.

-

If the brake fluid or grease adheres to disc rotor and cylinder body, quickly wipe it off.

Release parking brake.

Must be performed additional service when removing and replacing brake pad or rear brake caliper. Refer to Description.

Remove tires. Refer to Removal and Installation.

Fix disc rotor using wheel nut.

Drain brake fluid. Refer to Draining.

Separate brake hose from brake caliper assembly. Refer to Removal and Installation.

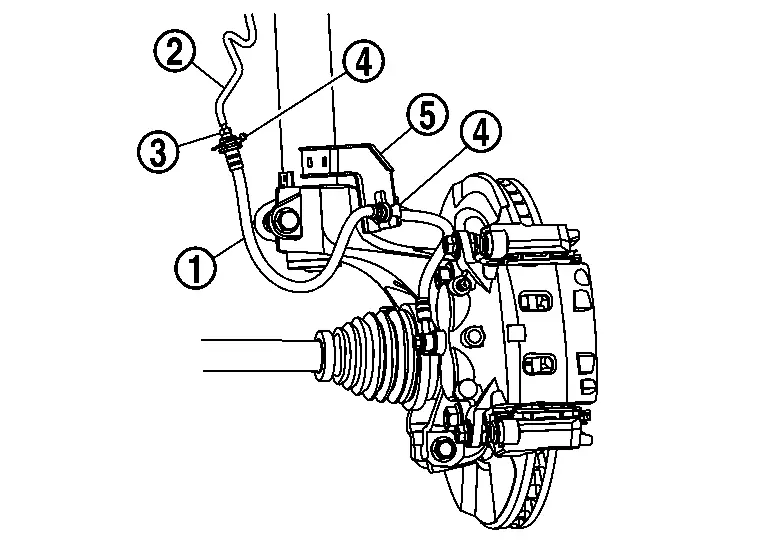

Remove parking brake actuator harness connector  and bracket mounting bolt

and bracket mounting bolt  .

.

Remove torque member mounting bolt  and then remove brake caliper assembly.

and then remove brake caliper assembly.

When remove disc rotor. Refer to Removal and Installation.

INSTALLATION

WARNING:

Remove dust covering brake caliper assembly and brake pad with a dust collector. Never splatter the dust with an air blow gun.

CAUTION:

-

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off immediately and wash with water if it gets on a painted surface. For brake component parts, never wash them with water.

-

Never depress brake pedal during removal and installation of brake hose because brake fluid may scatter.

-

Never adhere brake fluid to disc rotor.

-

If the brake fluid or grease adheres to disc rotor and cylinder body, quickly wipe it off.

Install disc rotor. Refer to Removal and Installation.

Install brake caliper assembly to axle housing and then tighten torque member mounting bolts  to the specified torque.

to the specified torque.

CAUTION:

Never spill or splash any grease and moisture on the brake caliper assembly mounting face, threads, mounting bolts and washers. Wipe out any grease and moisture.

Install brake hose and copper washers to brake caliper assembly. Refer to Removal and Installation.

CAUTION:

Never reuse copper washer.

Install parking brake actuator harness connector  and bracket mounting bolt

and bracket mounting bolt  .

.

Perform air bleeding. Refer to Bleeding.

Check drag of rear disc brake. If any drag is felt. Refer to Inspection.

Install tires. Refer to Removal and Installation.

Perform inspection after installation. Refer to Inspection.

REAR BRAKE CALIPER ASSEMBLY : Disassembly & Assembly

DISASSEMBLY

CAUTION:

Never drop parts.

NOTE:

NOTE:

Never remove the torque member, brake pad and pad retainer when disassembling cylinder body.

Remove sliding pin bolt, and then remove cylinder body from torque member. Refer to Removal and Installation.

CAUTION:

Fix brake pad with suitable tape to prevent brake pad from dropping.

Remove sliding pins and sliding pin boots from torque member.

Remove bushing  from sliding pin

from sliding pin  .

.

Remove bleeder valve and cap.

Perform inspection after disassembly. Refer to Inspection.

ASSEMBLY

Install bleeder valve and cap.

Apply rubber grease to mating faces  between sliding pin bolt

between sliding pin bolt  and bushing

and bushing  , and install bushing to sliding pin.

, and install bushing to sliding pin.

Apply Nissan rubber grease to mating faces  between sliding pins

between sliding pins  and sliding pin boots

and sliding pin boots  , and then install sliding pins and sliding pin boots to torque member

, and then install sliding pins and sliding pin boots to torque member  .

.

Install cylinder body to torque member and tighten sliding pin bolts to the specified torque. Refer to Exploded View

Perform inspection after installation. Refer to Inspection.

REAR BRAKE CALIPER ASSEMBLY : Inspection

INSPECTION AFTER DISASSEMBLY

Check the following items and replace if necessary.

Cylinder Body

Check cylinder inner wall for rust, wear, cracks or damage.

CAUTION:

Always clean with new brake fluid. Never clean with mineral oil such as gasoline and diesel fuel.

Torque Member

Check torque member for rust, wear, cracks or damage.

Piston

Check piston for rust, wear, cracks or damage.

CAUTION:

Piston sliding surface is plated. Never polish with sandpaper.

Sliding Pin, Sliding Pin Boot and Bushing

Check sliding pins, sliding pin boots and bushing for rust, wear, cracks or damage.

INSPECTION AFTER INSTALLATION

-

When replacing rear brake caliper or when returning piston of rear brake caliper, perform the following procedure.

-

Adjust initial position. Refer to Work Procedure

. -

Must be performed additional service when removing and replacing rear brake pad and rear brake caliper. Refer to Description.

-

-

Check drag of rear disc brake. If any drag is felt, follow the procedure described below.

-

Performed additional service when removing and replacing rear brake pad and rear brake caliper. Refer to. Work Procedure.

-

Depress the brake pedal several times.

-

Check drag of rear disc brake again. When any drag is felt, replace cylinder body. Refer to Removal and Installation.

-

-

If brake pads are replaced or ground, or if braking force is felt strange, perform break-in work. Refer to Periodic Maintenance Operation.

Nissan Ariya (FE0) 2023-2026 Service & Repair Manual

Removal and Installation

- Brake Pedal

- Front Brake Piping

- Rear Brake Piping

- Brake Power Supply Backup Unit

- Electrically-Driven Intelligent Brake Unit

- Warning Buzzer

- Front Brake Pad

- Front Brake Caliper Assembly

- Rear Brake Pad

- Rear Brake Caliper Assembly

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image