Nissan Ariya: Component Parts /circuit Diagnosis

- Power Supply and Ground Circuit (li-Ion Battery Controller)

- Cell Controller Communication Circuit

- Cell Voltage Inspection

- Cell Voltage Circuit

- Module Temperature Sensor

- Module

- Interlock Detection Switch (service Plug)

- Battery Current Sensor Circuit

- Battery Pack Water Temperature Sensor Circuit

- Battery Coolant Heater (ptc)

- High Voltage Fuse

- Li-Ion Battery Insulation Resistance Loss Inspection. 2wd

Power Supply and Ground Circuit (li-Ion Battery Controller) Nissan Ariya: FE0

Diagnosis Procedure

WARNING:

Since hybrid vehicles and electric Nissan Ariya vehicles contain a high voltage battery, there is the risk of electric shock, electric leakage, or similar accidents if the high voltage component and Nissan Ariya vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

Since hybrid vehicles and electric Nissan Ariya vehicles contain a high voltage battery, there is the risk of electric shock, electric leakage, or similar accidents if the high voltage component and Nissan Ariya vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

WARNING:

-

Be sure to remove the service plug in order to disconnect the high voltage circuits before performing inspection or maintenance of high voltage system harnesses and parts.

-

The removed service plug must always be carried in a pocket of the responsible worker or placed in the tool box during the procedure to prevent the plug from being connected by mistake.

-

Be sure to wear insulating protective equipment consisting of glove, shoes, face shield and glasses before beginning work on the high voltage system.

-

Never allow workers other than the responsible person to touch the Nissan Ariya vehicle containing high voltage parts. To keep others from touching the high voltage parts, these parts must be covered with an insulating sheet except when using them.

-

Refer to HIGH VOLTAGE PRECAUTIONS : Precautions.

CAUTION:

Never bring the vehicle into the READY status with the service plug removed unless otherwise instructed in the Service Manual. A malfunction may occur if this is not observed.

CHECK FUSE

Check the following fuse

| Power supply | Fuse No. |

|---|---|

| Main switch ON power supply (12V main relay power supply) | 102 |

Is inspection result normal?

YES>>GO TO 2.

NO>>Replace the fuse after repairing the circuit that caused blown fuse.

PRECONDITIONING-1

-

Turn power switch OFF.

-

Remove the service plug. Refer to HOW TO DISCONNECT HIGH VOLTAGE : Precautions.

>>

GO TO 3.

CHECK LI-ION BATTERY GROUND CIRCUIT

-

Disconnect Li-ion battery Nissan Ariya vehicle communication harness connector.

-

Check the continuity between Li-ion battery vehicle communication harness connector and ground.

+ − Continuity Li-ion battery Connector Terminal E9 6 Ground Exist 13 20

Is inspection result normal?

YES>>GO TO 4.

NO>>Check and repair ground circuit. Refer to Wiring Diagram.

CHECK 12V BATTERY MAIN RELAY POWER SUPPLY

-

Connect 12V battery negative terminal.

-

Check the voltage between Li-ion battery Nissan Ariya vehicle communication harness connector and 12V main relay harness connector.

+ − Voltage Li-ion battery Connector Terminal E9 11 Ground 9 – 16 V

Is inspection result normal?

YES>>GO TO 6.

NO>>GO TO 5.

CHECK 12V MAIN RELAY POWER SUPPLY

Check continuity between Li-ion battery Nissan Ariya vehicle communication harness connector and 12V main relay harness connector.

| + | − | ||

|---|---|---|---|

| Li-ion battery | 12V main relay | ||

| Connector | Terminal | Connector | Terminal |

| E9 | 11 | E106 | 5 |

Is inspection result normal?

YES>>Check 12V main relay. Refer to Diagnosis Procedure.

NO>>Repair and replace malfunction parts.

PRECONDITIONING-2

WARNING:

Be sure to disconnect the high voltage. Refer to HOW TO DISCONNECT HIGH VOLTAGE : Precautions.

-

Turn power switch OFF.

-

Disconnect 12V battery negative terminal.

-

Remove Li-ion battery from Nissan Ariya vehicle. Refer to Removal & Installation.

-

Remove battery pack upper case. Refer to Removal & Installation.

>>

GO TO 7.

CHECK CONNECTOR CONNECTION CONDITION

Check the connection of LBC harness connectors.

NOTE:

NOTE:

Pull the connector first then push the connector to check connection.

Is the inspection result normal?

YES>>GO TO 8.

NO>>Repair harness connector connection.

CHECK CONTINUITY BETWEEN LI-ION BATTERY AND LBC

-

Remove LBC. Refer to Removal & Installation.

-

Check continuity between Li-ion battery Nissan Ariya vehicle communication harness connector and LBC harness connector.

Li-ion battery LBC Continuity Connector Terminal Connector Terminal Z305 12 Z313 4 Exist 6 10 13 11 20 12 -

Check harnesses for short to ground and short to lines

Is the inspection result normal?

YES>>INSPECTION END

NO>>Repair or replace Li-ion battery Nissan Ariya vehicle communication harness.

Cell Controller Communication Circuit Nissan Ariya 2023

Diagnosis Procedure

WARNING:

Since hybrid vehicles and electric Nissan Ariya vehicles contain a high voltage battery, there is the risk of electric shock, electric leakage, or similar accidents if the high voltage component and Nissan Ariya vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

Since hybrid vehicles and electric Nissan Ariya vehicles contain a high voltage battery, there is the risk of electric shock, electric leakage, or similar accidents if the high voltage component and Nissan Ariya vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

WARNING:

-

Be sure to remove the service plug in order to disconnect the high voltage circuits before performing inspection or maintenance of high voltage system harnesses and parts.

-

The removed service plug must always be carried in a pocket of the responsible worker or placed in the tool box during the procedure to prevent the plug from being connected by mistake.

-

Be sure to wear insulating protective equipment consisting of glove, shoes, face shield and glasses before beginning work on the high voltage system.

-

Never allow workers other than the responsible person to touch the Nissan Ariya vehicle containing high voltage parts. To keep others from touching the high voltage parts, these parts must be covered with an insulating sheet except when using them.

-

Refer to HIGH VOLTAGE PRECAUTIONS : Precautions.

CAUTION:

Never bring the vehicle into the READY status with the service plug removed unless otherwise instructed in the Service Manual. A malfunction may occur if this is not observed.

PRECONDITIONING

WARNING:

Perform to disconnect the high voltage and check an residual voltage.

-

Disconnect the high voltage. Refer to HOW TO DISCONNECT HIGH VOLTAGE : Precautions.

-

Check voltage of high voltage circuit. Refer to CHECK VOLTAGE IN HIGH VOLTAGE CIRCUIT : Precautions.

-

Remove Li-ion battery from Nissan Ariya vehicle. Refer to Removal & Installation.

-

Remove battery pack upper case. Refer to Removal & Installation.

>>

GO TO 2.

CHECK CONNECTOR CONNECTION CONDITION

Check the connection condition of LBC and each cell controller harness connectors.

NOTE:

NOTE:

Pull connector first then push connector to check connection. Since if connector is pressed first, connector may be locked, malfunction cannot be found.

Is the inspection result normal?

YES>>GO TO 3.

NO>>Repair harness connector connection.

CHECK CONTINUITY OF CELL CONTROLLER COMMUNICATION CIRCUIT HARNESS.

-

Remove LBC and each cell controller harness connector.

-

Check resistance value between LBC harness connector and each cell controller harness connector.

LBC Cell controller No.1 Resistance value Connector Terminal Connector Terminal Z369 2 Z365 24 0 Ω approx. 1 23 6 18 5 17 Cell controller No.1 Cell controller No.2 Resistance value Connector Terminal Connector Terminal Z365 22 Z364 24 0 Ω approx. 21 23 32 18 31 17 Cell controller No.2 Cell controller No.3 Resistance value Connector Terminal Connector Terminal Z364 22 Z361 24 0 Ω approx. 21 23 32 18 31 17 Cell controller No.3 Cell controller No.4 Resistance value Connector Terminal Connector Terminal Z361 22 Z360 24 0 Ω approx. 21 23 32 18 31 17 Cell controller No.4 Cell controller No.5 Resistance value Connector Terminal Connector Terminal Z360 22 Z376 24 0 Ω approx. 21 23 32 18 31 17 Cell controller No.5 Cell controller No.6 Resistance value Connector Terminal Connector Terminal Z376 22 Z375 24 0 Ω approx. 21 23 32 18 31 17 Cell controller No.6 Cell controller No.7 Resistance value Connector Terminal Connector Terminal Z375 22 Z372 24 0 Ω approx. 21 23 32 18 31 17 Cell controller No.7 Cell controller No.8 Resistance value Connector Terminal Connector Terminal Z372 22 Z370 24 0 Ω approx. 21 23 32 18 31 17

Is the inspection result normal?

YES>>INSPECTION END

NO>>Repair or replace harness.

Cell Voltage Inspection Nissan Ariya 1st generation

Diagnosis Procedure

CHECK CELL VOLTAGE WITH DATA MONITOR

With CONSULT

With CONSULT

-

Power switch ON.

-

Select “Data Monitor” of “HIGH VOLTAGE BATTERY”.

-

Record “Maximum cell voltage”.

NOTE:

NOTE:

When the procedure is reached to replace the malfunction module, the module voltage adjustment is required. At that time, the maximum cell voltage is also required.

-

Select “Cell voltage 01 - 96”.

-

Check abnormal voltage of any cell by comparing each monitored value.

NOTE:

NOTE:

If power switch cannot be turned ON, the cell voltage is confirmed by recorded "FFD".

Is there any abnormal cell?

YES>>GO TO 2.

NO>>DIAGNOSIS END

CHECK PATTERN OF ABNORMAL CELL

With CONSULT

With CONSULT

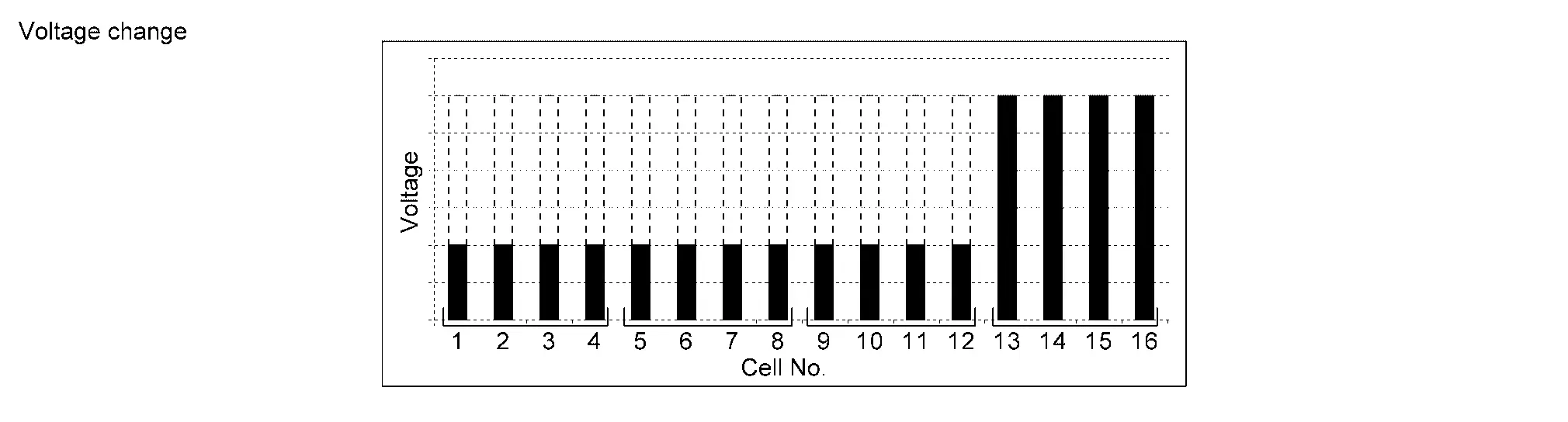

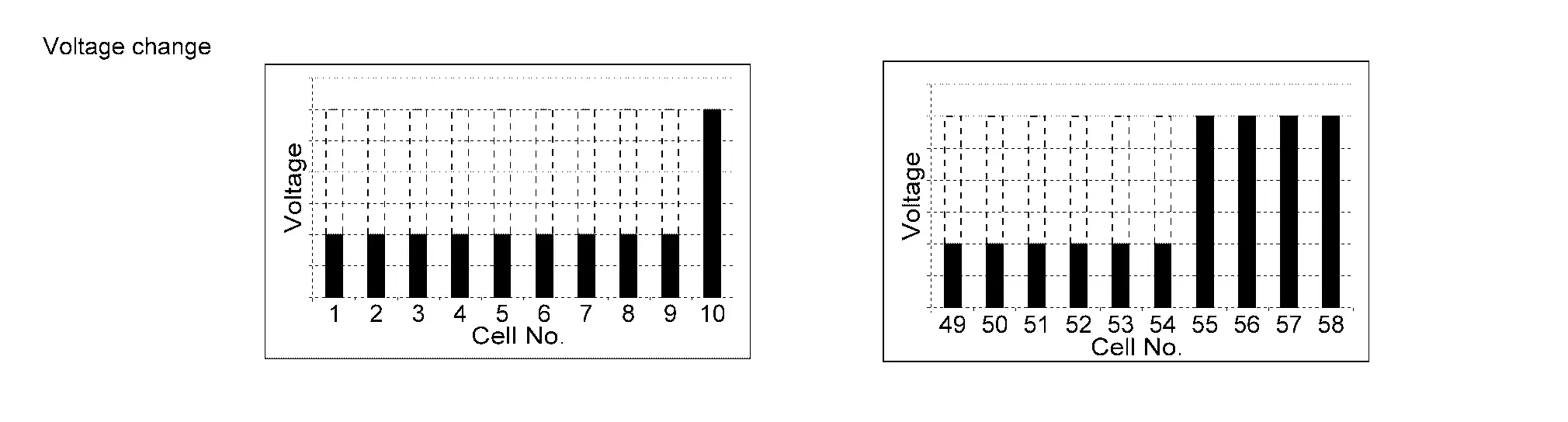

Check with CONSULT, if the voltage fluctuation pattern of abnormal cells applies to any one of the following conditions.

NOTE:

NOTE:

For the comparison of ASIC, cell voltage, and module stack, Refer to Component Description.

-

In comparison with the cell controller (ASIC), the voltage of consecutive 12 cell or 13 cell is almost the same and drops.

-

In comparison with the module, the voltage of consecutive 9 cell or 6 cell is almost the same and drops.

-

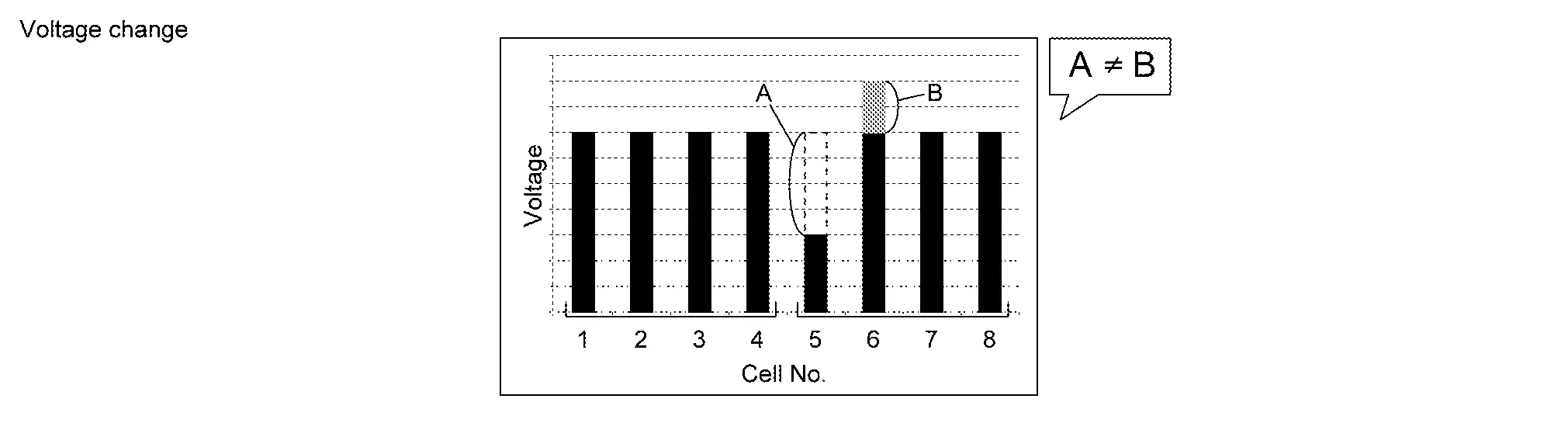

The potential difference between two adjacent cells fluctuates unsymmetrically.

-

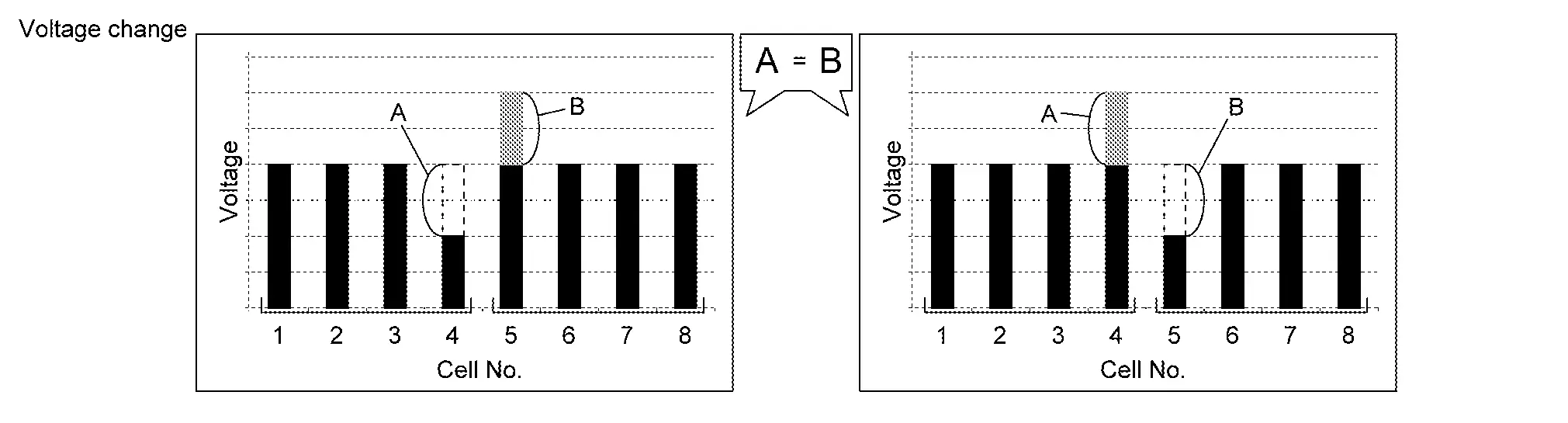

The potential difference between two adjacent cells fluctuates symmetrically.

Does the abnormal cell voltage fluctuation pattern apply to any one of the above conditions?

YES-1>>-

In comparison with the cell controller (ASIC), the voltage of consecutive 12 cell or 13 cell is almost the same and drops.

Possible malfunction parts: Cell controller internal malfunction (ASIC circuit). Replace cell controller. Refer to Removal & Installation.

YES-2>>-

In comparison with the module, the voltage of consecutive 9 cell or 6 cell is almost the same and drops.

Possible malfunction parts: Module or cell voltage circuit (Harness connector).GO TO 3.

YES-3>>-

The potential difference between two adjacent cells fluctuates unsymmetrically.

-

The potential difference between two adjacent cells fluctuates symmetrically.

Possible malfunction parts: Cell voltage circuit (Harness connector) or cell controller. GO TO 4.

NO>>-

Does not apply to any one of them.

Possible malfunction parts: Cell, module, cell voltage circuit (Harness connector) or cell controller. GO TO 5.

CHECK CELL VOLTAGE CIRCUIT-1

Check cell voltage circuit (Harness connector) connected to abnormal cells. Refer to Diagnosis Procedure.

Is the inspection result normal?

YES>>Replace corresponding module.

-

Refer to Disassembly & Assembly.

-

Refer to Disassembly & Assembly.

Repair or replace malfunctioning parts.

CHECK CELL VOLTAGE CIRCUIT-2

Check cell voltage circuit (Harness connector) connected to abnormal cells. Refer to Diagnosis Procedure.

Is the inspection result normal?

YES>>Replace corresponding cell controller. Refer to Removal & Installation.

NO>>Repair or replace malfunctioning parts.

CHECK CELL VOLTAGE CIRCUIT-3

Check cell voltage circuit (Harness connector) connected to abnormal cells. Refer to Diagnosis Procedure.

Is the inspection result normal?

YES>>GO TO 6.

NO>>Repair or replace malfunctioning parts.

CHECK MODULE VOLTAGE

Check voltage of module corresponding to abnormal cell number. Refer to Component Inspection.

Is the inspection result normal?

YES>>Replace corresponding cell controller. Refer to Removal & Installation.

NO>>GO TO 7.

MODULE REPLACED HISTORY CONFIRMATION

Confirm the latest replacing history of an abnormal module.

Was the module changed?

YES>>Replace corresponding module and cell controller.

-

Module:

-

Refer to Disassembly & Assembly.

-

Refer to Disassembly & Assembly.

-

-

Cell controller: Refer to Removal & Installation.

Replace corresponding module.

-

Refer to Disassembly & Assembly.

-

Refer to Disassembly & Assembly.

Cell Voltage Circuit Nissan Ariya 2023

Diagnosis Procedure

WARNING:

Since hybrid vehicles and electric Nissan Ariya vehicles contain a high voltage battery, there is the risk of electric shock, electric leakage, or similar accidents if the high voltage component and Nissan Ariya vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

Since hybrid vehicles and electric Nissan Ariya vehicles contain a high voltage battery, there is the risk of electric shock, electric leakage, or similar accidents if the high voltage component and Nissan Ariya vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

WARNING:

-

Be sure to remove the service plug in order to disconnect the high voltage circuits before performing inspection or maintenance of high voltage system harnesses and parts.

-

The removed service plug must always be carried in a pocket of the responsible worker or placed in the tool box during the procedure to prevent the plug from being connected by mistake.

-

Be sure to wear insulating protective equipment consisting of glove, shoes, face shield and glasses before beginning work on the high voltage system.

-

Never allow workers other than the responsible person to touch the Nissan Ariya vehicle containing high voltage parts. To keep others from touching the high voltage parts, these parts must be covered with an insulating sheet except when using them.

-

Refer to HIGH VOLTAGE PRECAUTIONS : Precautions.

CAUTION:

Never bring the vehicle into the READY status with the service plug removed unless otherwise instructed in the Service Manual. A malfunction may occur if this is not observed.

PRECONDITIONING-1

WARNING:

Be sure to disconnect the high voltage and check residual voltage before work starts.

-

Disconnect the high voltage. Refer to HOW TO DISCONNECT HIGH VOLTAGE : Precautions.

-

Check voltage of high voltage circuit. Refer to CHECK VOLTAGE IN HIGH VOLTAGE CIRCUIT : Precautions.

-

Remove Li-ion battery. Refer to Removal & Installation.

-

Remove battery pack upper case. Refer to Removal & Installation.

>>

GO TO 2.

CHECK CONNECTOR CONNECTION CONDITION

Check the connection of LBC harness connectors and each module stack harness connector.

NOTE:

NOTE:

Pull the connector first then push the connector to confirm a connection. Since id connector is pressed first, connector may be locked, malfunction cannot be found.

Is the inspection result normal?

YES>>GO TO 3.

NO>>Repair harness connector connection.

CHECK TOTAL CELL VOLTAGE DETECTION HARNESS CONTINUITY

-

Disconnect all harness connectors of LBC, each cell controller, and each module stack.

-

Check resistance value between LBC harness connector, module No.1 (MD1) harness connector and cell controller harness connector.

LBC Cell controller 1 Resistance Connector Terminal Connector Terminal Z369 40 Z365 19 Less than 700 mΩ Z366 15 41 Z365 19 Z366 15 LBC MD1 Resistance Connector Terminal Connector Terminal Z369 40 Z358

6 Less than 700 mΩ 41

Is the inspection result normal?

YES>>GO TO 4.

NO>>Repair harness connector connection.

CHECK CELL VOLTAGE DETECTION HARNESS CONTINUITY

-

Check resistance value between each cell controller harness connector and each module stack harness connector.

Module No. Cell No. Connector Terminal Cell controller No. Connector Terminal Resistance MD1 1 Z358 6 Cell controller No.1 Z366 15 Less than 700 mΩ 2 1 14 3 5 4 4 3 13 5 12 12 6 10 11 7 11 10 Module No. Cell No. Connector Terminal Cell controller No. Connector Terminal Resistance MD2 8 Z355 6 Cell controller No.1 Z366 9 Less than 700 mΩ 9 1 3 10 5 8 11 13 2 12 4 7 13 12 Cell controller No.2 Z363 15 14 15 14 Module No. Cell No. Connector Terminal Cell controller No. Connector Terminal Resistance MD3 15 Z352 6 Cell controller No.2 Z363 4 Less than 700 mΩ 16 1 13 17 5 12 18 13 11 19 4 10 20 12 9 21 15 3 Module No. Cell No. Connector Terminal Cell controller No. Connector Terminal Resistance MD4 22 Z349 6 Cell controller No.2 Z352 8 Less than 700 mΩ 23 1 2 24 5 7 25 13 1 Cell controller No.3 Z362 15 26 4 14 27 12 4 28 15 13 Module No. Cell No. Connector Terminal Cell controller No. Connector Terminal Resistance MD5 29 Z314 6 Cell controller No.3 Z362 12 Less than 700 mΩ 30 1 11 31 16 10 32 4 9 33 14 3 Module No. Cell No. Connector Terminal Cell controller No. Connector Terminal Resistance MD6 34 Z321 6 Cell controller No.3 Z362 8 Less than 700 mΩ 35 1 2 36 16 7 37 4 1 Cell controller No.4 Z359 15 38 14 14 Module No. Cell No. Connector Terminal Cell controller No. Connector Terminal Resistance MD7 39 Z320 6 Cell controller No.4 Z359 4 Less than 700 mΩ 40 1 13 41 16 12 42 4 11 43 14 10 Module No. Cell No. Connector Terminal Cell controller No. Connector Terminal Resistance MD8 44 Z319 6 Cell controller No.4 Z359 9 Less than 700 mΩ 45 1 3 46 16 8 47 4 2 48 14 7 49 9 1 Module No. Cell No. Connector Terminal Cell controller No. Connector Terminal Resistance MD9 50 Z325 6 Cell controller No.5 Z377 15 Less than 700 mΩ 51 1 14 52 16 4 53 4 13 54 14 12 Module No. Cell No. Connector Terminal Cell controller No. Connector Terminal Resistance MD10 55 Z324 6 Cell controller No.5 Z377 11 Less than 700 mΩ 56 1 10 57 6 9 58 4 3 59 14 8 Module No. Cell No. Connector Terminal Cell controller No. Connector Terminal Resistance MD11 60 Z323 6 Cell controller No.5 Z377 2 Less than 700 mΩ 61 1 7 62 16 1 Cell controller No.6 Z374 15 63 4 14 64 14 4 Module No. Cell No. Connector Terminal Cell controller No. Connector Terminal Resistance MD12 65 Z322 6 Cell controller No.6 Z374 13 Less than 700 mΩ 66 1 12 67 16 11 68 4 10 69 14 9 Module No. Cell No. Connector Terminal Cell controller No. Connector Terminal Resistance MD13 70 Z318 6 Cell controller No.6 Z374 3 Less than 700 mΩ 71 1 8 72 5 2 73 13 7 74 4 1 Cell controller No.7 Z373 15 75 12 14 76 15 4 Module No. Cell No. Connector Terminal Cell controller No. Connector Terminal Resistance MD14 77 Z317 6 Cell controller No.7 Z373 13 Less than 700 mΩ 78 1 12 79 5 11 80 13 10 81 4 9 82 12 3 83 15 8 Module No. Cell No. Connector Terminal Cell controller No. Connector Terminal Resistance MD15 84 Z316 6 Cell controller No.7 Z373 2 Less than 700 mΩ 85 1 7 86 5 1 Cell controller No.8 Z371 15 87 13 14 88 4 4 89 12 13 90 15 12 Module No. Cell No. Connector Terminal Cell controller No. Connector Terminal Resistance MD16 91 Z315 6 Cell controller No.8 Z371 11 Less than 700 mΩ 92 1 10 93 5 9 94 13 3 95 4 8 96 12 2 97 15 7 98 8 1

Is the inspection result normal?

YES>>INSPECTION END

NO>>Repair harness connector connection.

Module Temperature Sensor Nissan Ariya: FE0

Diagnosis Procedure

WARNING:

Since hybrid vehicles and electric Nissan Ariya vehicles contain a high voltage battery, there is the risk of electric shock, electric leakage, or similar accidents if the high voltage component and Nissan Ariya vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

Since hybrid vehicles and electric Nissan Ariya vehicles contain a high voltage battery, there is the risk of electric shock, electric leakage, or similar accidents if the high voltage component and Nissan Ariya vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

WARNING:

-

Be sure to remove the service plug in order to disconnect the high voltage circuits before performing inspection or maintenance of high voltage system harnesses and parts.

-

The removed service plug must always be carried in a pocket of the responsible worker or placed in the tool box during the procedure to prevent the plug from being connected by mistake.

-

Be sure to wear insulating protective equipment consisting of glove, shoes, face shield and glasses before beginning work on the high voltage system.

-

Never allow workers other than the responsible person to touch the Nissan Ariya vehicle containing high voltage parts. To keep others from touching the high voltage parts, these parts must be covered with an insulating sheet except when using them.

-

Refer to HIGH VOLTAGE PRECAUTIONS : Precautions.

CAUTION:

Never bring the vehicle into the READY status with the service plug removed unless otherwise instructed in the Service Manual. A malfunction may occur if this is not observed.

PRECONDITIONING-1

WARNING:

Be sure to disconnect the high voltage and check residual voltage before work starts.

-

Disconnect the high voltage. Refer to HOW TO DISCONNECT HIGH VOLTAGE : Precautions.

-

Check voltage of high voltage circuit. Refer to CHECK VOLTAGE IN HIGH VOLTAGE CIRCUIT : Precautions.

-

Remove Li-ion battery. Refer to Removal & Installation.

-

Remove battery pack upper case. Refer to Removal & Installation.

>>

GO TO 2.

CHECK CONNECTOR CONNECTION CONDITION

Check the connection of each cell controller harness connectors and each module stack harness connector.

NOTE:

NOTE:

Pull the connector first then push the connector to confirm a connection. Since id connector is pressed first, connector may be locked, malfunction cannot be found.

Is the inspection result normal?

YES>>GO TO 3.

NO>>Repair harness connector connection.

CHECK MODULE TEMPERATURE SENSOR

-

Disconnect each cell controller harness connector.

-

Check module temperature sensor. Refer to Component Inspection.

Is the inspection result normal?

YES>>GO TO 4.

NO>>Replace malfunction module.

CHECK CONTINUITY BETWEEN MODULE TEMPERATURE SENSOR AND LBC

-

Disconnect connector of corresponding module.

-

Check continuity between module harness connector and cell controller harness connector.

MD1 Cell controller No.1 Resistance Connector Terminal Connector Terminal Z358 10 Z366 16 0 Ω approx. 3 5 MD2 Cell controller No.1 Resistance Connector Terminal Connector Terminal Z355 10 Z366 16 0 Ω approx. 3 6 MD3 Cell controller No.2 Resistance Connector Terminal Connector Terminal Z352 10 Z363 16 0 Ω approx. 3 5 MD4 Cell controller No.2 Resistance Connector Terminal Connector Terminal Z349 10 Z363 16 0 Ω approx. 3 6 MD5 Cell controller No.3 Resistance Connector Terminal Connector Terminal Z314 12 Z362 16 0 Ω approx. 11 5 MD6 Cell controller No.3 Resistance Connector Terminal Connector Terminal Z321 12 Z362 16 0 Ω approx. 11 6 MD7 Cell controller No.4 Resistance Connector Terminal Connector Terminal Z320 12 Z359 16 0 Ω approx. 11 5 MD8 Cell controller No.4 Resistance Connector Terminal Connector Terminal Z319 12 Z359 16 0 Ω approx. 11 6 MD9 Cell controller No.5 Resistance Connector Terminal Connector Terminal Z325 12 Z377 16 0 Ω approx. 11 5 MD10 Cell controller No.5 Resistance Connector Terminal Connector Terminal Z324 12 Z377 16 0 Ω approx. 11 6 MD11 Cell controller No.6 Resistance Connector Terminal Connector Terminal Z323 12 Z374 16 0 Ω approx. 11 5 MD12 Cell controller No.6 Resistance Connector Terminal Connector Terminal Z322 12 Z374 16 0 Ω approx. 11 6 MD13 Cell controller No.7 Resistance Connector Terminal Connector Terminal Z318 10 Z373 16 0 Ω approx. 3 5 MD14 Cell controller No.7 Resistance Connector Terminal Connector Terminal Z317 10 Z373 16 0 Ω approx. 3 6 MD15 Cell controller No.8 Resistance Connector Terminal Connector Terminal Z316 10 Z371 16 0 Ω approx. 3 5 MD16 Cell controller No.8 Resistance Connector Terminal Connector Terminal Z315 10 Z371 16 0 Ω approx. 3 6 -

Check harnesses for short to ground and short to lines.

Is the inspection result normal?

YES>>INSPECTION END

NO>>Replace or repair Li-ion batter Nissan Ariya vehicle communication harness.

Component Inspection

WARNING:

Since hybrid vehicles and electric Nissan Ariya vehicles contain a high voltage battery, there is the risk of electric shock, electric leakage, or similar accidents if the high voltage component and Nissan Ariya vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

Since hybrid vehicles and electric Nissan Ariya vehicles contain a high voltage battery, there is the risk of electric shock, electric leakage, or similar accidents if the high voltage component and Nissan Ariya vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

WARNING:

-

Be sure to remove the service plug in order to disconnect the high voltage circuits before performing inspection or maintenance of high voltage system harnesses and parts.

-

The removed service plug must always be carried in a pocket of the responsible worker or placed in the tool box during the procedure to prevent the plug from being connected by mistake.

-

Be sure to wear insulating protective equipment consisting of glove, shoes, face shield and glasses before beginning work on the high voltage system.

-

Never allow workers other than the responsible person to touch the Nissan Ariya vehicle containing high voltage parts. To keep others from touching the high voltage parts, these parts must be covered with an insulating sheet except when using them.

-

Refer to HIGH VOLTAGE PRECAUTIONS : Precautions.

CAUTION:

Never bring the vehicle into the READY status with the service plug removed unless otherwise instructed in the Service Manual. A malfunction may occur if this is not observed.

PRECONDITIONING-1

WARNING:

Be sure to disconnect the high voltage and check residual voltage before work starts.

-

Disconnect the high voltage. Refer to HOW TO DISCONNECT HIGH VOLTAGE : Precautions.

-

Check voltage of high voltage circuit. Refer to CHECK VOLTAGE IN HIGH VOLTAGE CIRCUIT : Precautions.

-

Remove Li-ion battery. Refer to Removal & Installation.

-

Remove battery pack upper case. Refer to Removal & Installation.

>>

GO TO 2.

CHECK MODULE TEMPERATURE SENSOR

-

Disconnect each cell controller harness connector.

-

Check resistance of module temperature sensor.

WARNING:

Never measure the cell voltage terminal by mistake.

2P7S Module Measurement Condition Resistance Terminal 10 3 10 °C 18 kΩ approx. 25 °C 10 kΩ approx. 40 °C 5.8 kΩ approx. 2P5S Module Measurement Condition Resistance Terminal 12 11 10 °C 18 kΩ approx. 25 °C 10 kΩ approx. 40 °C 5.8 kΩ approx.

Is the inspection result normal?

YES>>INSPECTION END

NO>>Replace corresponding module.

-

Refer to Disassembly & Assembly.

-

Refer to Disassembly & Assembly.

Module Nissan Ariya

Component Inspection

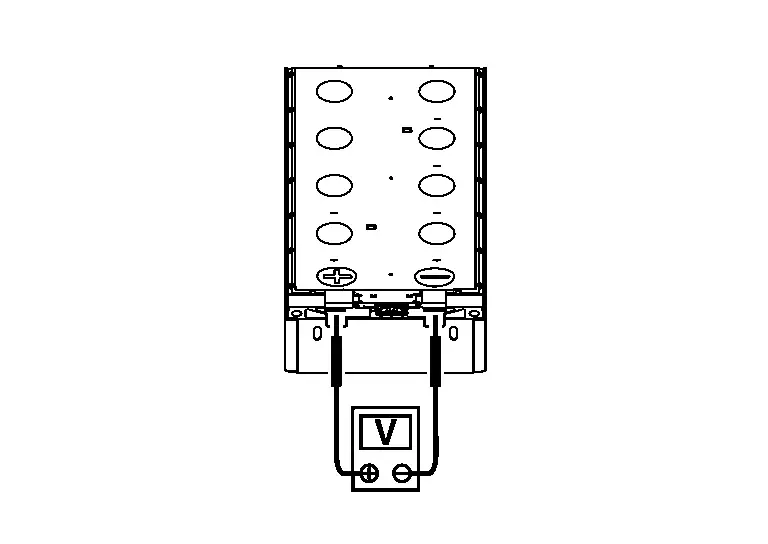

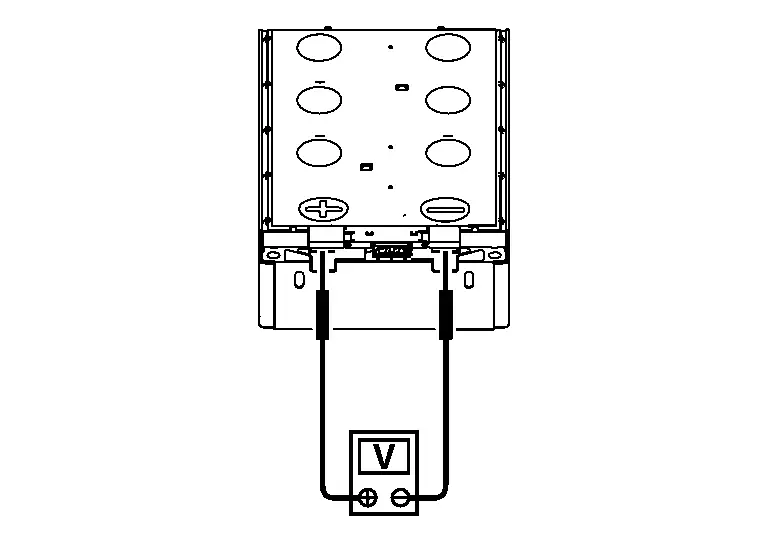

CHECK MODULE VOLTAGE

Check voltage of module.

-

2P7S (23 Parallel 7 Series)

Terminal Voltage + − Module Positive terminal Negative terminal 19.600 - 29.288 V -

2P5S (2 Parallel 5 Series)

Terminal Voltage + − Module Positive terminal Negative terminal 14.000 - 20.920 V

Is the inspection result normal?

YES>>INSPECTION END

NO>>Replace module.

Interlock Detection Switch (service Plug) Nissan Ariya: FE0

Diagnosis Procedure

WARNING:

Since hybrid vehicles and electric Nissan Ariya vehicles contain a high voltage battery, there is the risk of electric shock, electric leakage, or similar accidents if the high voltage component and Nissan Ariya vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

Since hybrid vehicles and electric Nissan Ariya vehicles contain a high voltage battery, there is the risk of electric shock, electric leakage, or similar accidents if the high voltage component and Nissan Ariya vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

WARNING:

-

Be sure to remove the service plug in order to disconnect the high voltage circuits before performing inspection or maintenance of high voltage system harnesses and parts.

-

The removed service plug must always be carried in a pocket of the responsible worker or placed in the tool box during the procedure to prevent the plug from being connected by mistake.

-

Be sure to wear insulating protective equipment consisting of glove, shoes, face shield and glasses before beginning work on the high voltage system.

-

Never allow workers other than the responsible person to touch the Nissan Ariya vehicle containing high voltage parts. To keep others from touching the high voltage parts, these parts must be covered with an insulating sheet except when using them.

-

Refer to HIGH VOLTAGE PRECAUTIONS : Precautions.

CAUTION:

Never bring the vehicle into the READY status with the service plug removed unless otherwise instructed in the Service Manual. A malfunction may occur if this is not observed.

CHECK INSTALLATION CONDITION OF SERVICE PLUG

Check service plug installation condition. Refer to HOW TO DISCONNECT HIGH VOLTAGE : Precautions.

Is the inspection result normal?

YES>>GO TO 2.

NO>>Install service plug properly.

CHECK INTERLOCK DETECTING SWITCH (SERVICE PLUG)

Check interlock detecting switch (Service plug). Refer to Component Inspection.

Is the inspection result normal?

YES>>GO TO 3.

NO>>Replace service plug.

CHECK INSTALLATION CONDITION OF HIGH-VOLTAGE HARNESS CONNECTOR

WARNING:

Be sure to disconnect the high voltage. Refer to HOW TO DISCONNECT HIGH VOLTAGE : Precautions.

Check the connection status of high-voltage harness connector (Front) for locking and interlocking.

Is the inspection result normal?

YES>>GO TO 4.

NO>>Connect high-voltage harness connector (front) harness connector properly.

CHECK INTERLOCK DETECTING SWITCH [HIGH VOLTAGE HARNESS CONNECTOR (FRONT)]

Check interlock detecting switch [(High-voltage harness connector(Front)]. Refer to Component Inspection.

Is the inspection result normal?

YES>>GO TO 5.

NO>>Replace Li-ion battery high-voltage harness.

REMOVE LI-ION BATTERY

-

Remove Li-ion battery. Refer to Removal & Installation.

-

Remove battery pack upper case. Refer to Removal & Installation.

>>

GO TO 6.

CHECK CONNECTOR CONNECTION CONDITION

Check connection status of LBC harness connector, interlock detecting switch (Service plug) harness connector and interlock detecting switch [High voltage harness connector (Front)] harness connector.

NOTE:

NOTE:

Pull the connector first then push the connector to confirm a connection. Since id connector is pressed first, connector may be locked, malfunction cannot be found.

Is the inspection result normal?

YES>>GO TO 7.

NO>>Repair harness connector connection.

CHECK INTERLOCK DETECTING CIRCUIT CONTINUITY

-

Remove LBC harness connector, interlock detecting switch (Service plug) harness connector and interlock detecting switch [High voltage harness connector (Front)] harness connector.

-

Check continuity between LBC harness connector and interlock detecting switch (Service plug) harness connector.

LBC Interlock detecting switch

(Service plug)Continuity Connector Terminal Connector Terminal Z368 21 Z338 1 Exist -

Check harness for short to ground and short to lines.

-

Check continuity between interlock detecting switch (Service plug) harness connector and interlock detecting switch [high voltage harness connector (front)] harness connector.

Interlock detecting switch

(Service plug)Interlock detecting switch

[High voltage harness connector (Front)]Continuity Connector Terminal Connector Terminal Z337 1 Z307 1 Exist -

Check harness for short to ground and short to lines.

-

Check continuity between interlock detecting switch [High voltage harness connector (Front)] and LBC harness connector.

Interlock detecting switch

[High voltage harness connector (Front)]LBC Continuity Connector Terminal Connector Terminal Z307 2 Z368 21 Exist -

Check harness for short to ground and short to lines.

YES>>

GO TO 8.

NO>>Repair or replace Li-ion battery Nissan Ariya vehicle communication harness.

CHECK HIGH VOLTAGE HARNESS CONNECTOR (FRONT)

-

Check continuity between high voltage harness connector and interlock detecting switch (High voltage harness) harness connector.

High voltage harness connector (Front) Interlock detecting switch

[High voltage harness connector (Front)]Continuity Connector Terminal Connector Terminal Z345 2 Z307 2 Exist 1 1 -

Check harness for short to ground and short to lines.

YES>>

INSPECTION END

NO>>Replace high voltage harness connector. Refer to Disassembly & Assembly.

Component Inspection

WARNING:

Since hybrid vehicles and electric Nissan Ariya vehicles contain a high voltage battery, there is the risk of electric shock, electric leakage, or similar accidents if the high voltage component and Nissan Ariya vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

Since hybrid vehicles and electric Nissan Ariya vehicles contain a high voltage battery, there is the risk of electric shock, electric leakage, or similar accidents if the high voltage component and Nissan Ariya vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

WARNING:

-

Be sure to remove the service plug in order to disconnect the high voltage circuits before performing inspection or maintenance of high voltage system harnesses and parts.

-

The removed service plug must always be carried in a pocket of the responsible worker or placed in the tool box during the procedure to prevent the plug from being connected by mistake.

-

Be sure to wear insulating protective equipment consisting of glove, shoes, face shield and glasses before beginning work on the high voltage system.

-

Never allow workers other than the responsible person to touch the Nissan Ariya vehicle containing high voltage parts. To keep others from touching the high voltage parts, these parts must be covered with an insulating sheet except when using them.

-

Refer to HIGH VOLTAGE PRECAUTIONS : Precautions.

CAUTION:

Never bring the vehicle into the READY status with the service plug removed unless otherwise instructed in the Service Manual. A malfunction may occur if this is not observed.

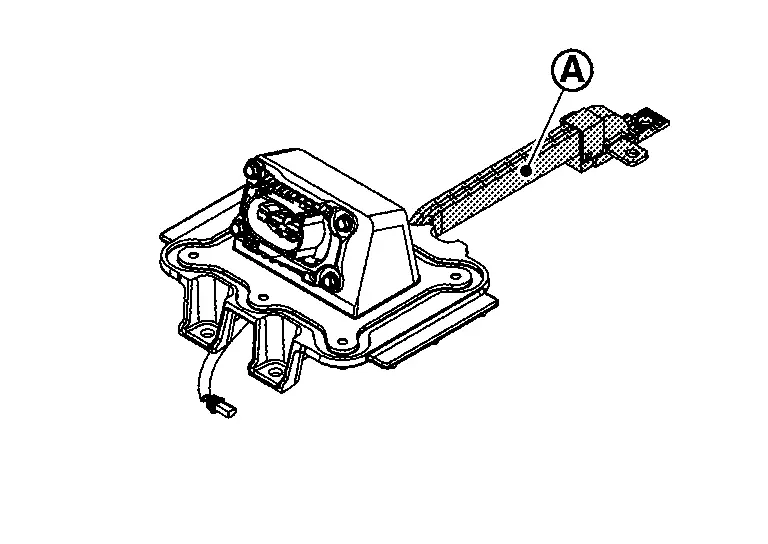

SERVICE PLUG REMOVING

-

Remove the service plug. Refer to HOW TO DISCONNECT HIGH VOLTAGE : Precautions.

>>

GO TO 2.

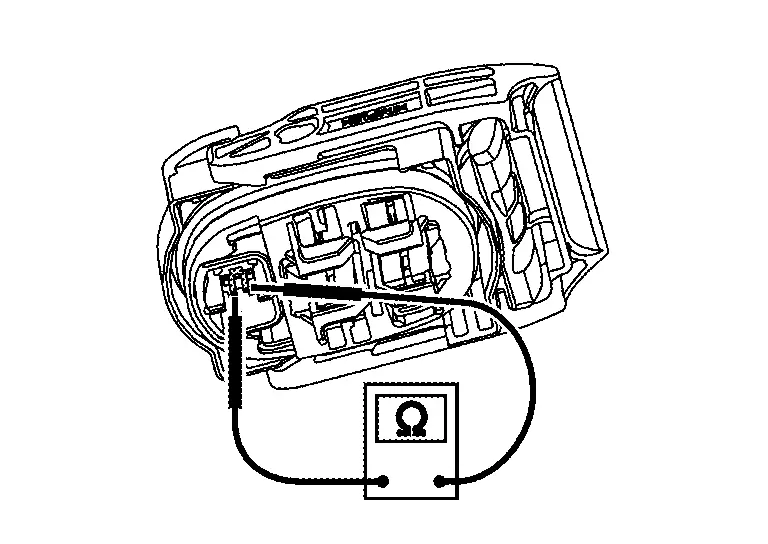

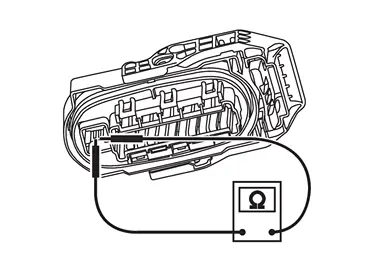

CHECK INTERLOCK DETECTING SWITCH (SERVICE PLUG)

-

Check visually that the terminals are not a corrosion, a bend, a break or a damage.

-

Check the continuity between terminals.

TYPE A

TYPE B

| Value: | 0 Ω approx. |

Is the inspection result normal?

YES>>INSPECTION END

NO>>Replace service plug.

Battery Current Sensor Circuit Nissan Ariya SUV

Diagnosis Procedure

WARNING:

Since hybrid vehicles and electric Nissan Ariya vehicles contain a high voltage battery, there is the risk of electric shock, electric leakage, or similar accidents if the high voltage component and Nissan Ariya vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

Since hybrid vehicles and electric Nissan Ariya vehicles contain a high voltage battery, there is the risk of electric shock, electric leakage, or similar accidents if the high voltage component and Nissan Ariya vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

WARNING:

-

Be sure to remove the service plug in order to disconnect the high voltage circuits before performing inspection or maintenance of high voltage system harnesses and parts.

-

The removed service plug must always be carried in a pocket of the responsible worker or placed in the tool box during the procedure to prevent the plug from being connected by mistake.

-

Be sure to wear insulating protective equipment consisting of glove, shoes, face shield and glasses before beginning work on the high voltage system.

-

Never allow workers other than the responsible person to touch the Nissan Ariya vehicle containing high voltage parts. To keep others from touching the high voltage parts, these parts must be covered with an insulating sheet except when using them.

-

Refer to HIGH VOLTAGE PRECAUTIONS : Precautions.

CAUTION:

Never bring the vehicle into the READY status with the service plug removed unless otherwise instructed in the Service Manual. A malfunction may occur if this is not observed.

PRECONDITIONING-1

WARNING:

Be sure to disconnect the high voltage and check residual voltage before work starts.

-

Disconnect the high voltage. Refer to HOW TO DISCONNECT HIGH VOLTAGE : Precautions.

-

Check voltage of high voltage circuit. Refer to CHECK VOLTAGE IN HIGH VOLTAGE CIRCUIT : Precautions.

-

Remove Li-ion battery. Refer to Removal & Installation.

-

Remove battery pack upper case. Refer to Removal & Installation.

>>

GO TO 2.

CHECK CONNECTOR CONNECTION CONDITION

Check the connection status of the LBC harness connector and junction box harness connectors.

NOTE:

NOTE:

Pull the connector first then push the connector to confirm a connection. Since if connector is pressed first, connector may be locked, malfunction cannot be found.

Is the inspection result normal?

YES>>GO TO 3.

NO>>Repair harness connector connection.

CHECK CONTINUITY BETWEEN BATTERY CURRENT SENSOR (BATTERY JUNCTION BOX) AND LBC HARNESS CONNECTOR

-

Remove LBC harness connector and battery junction box harness connector.

-

Check continuity LBC harness connector and battery junction box harness connector.

Battery junction box LBC Continuity Connector Terminal Connector Terminal Z313 11 Z368 17 Exist 12 18 13 Z367 9 14 3 -

Check harness for short to ground and short to lines.

Is inspection result normal?

YES>>Replace battery junction box. Refer to Disassembly & Assembly.

NO>>Repair or replace Li-ion battery Nissan Ariya vehicle communication harness.

Battery Pack Water Temperature Sensor Circuit Nissan Ariya: FE0

Diagnosis Procedure

WARNING:

Since hybrid vehicles and electric Nissan Ariya vehicles contain a high voltage battery, there is the risk of electric shock, electric leakage, or similar accidents if the high voltage component and Nissan Ariya vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

Since hybrid vehicles and electric Nissan Ariya vehicles contain a high voltage battery, there is the risk of electric shock, electric leakage, or similar accidents if the high voltage component and Nissan Ariya vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

WARNING:

-

Be sure to remove the service plug in order to disconnect the high voltage circuits before performing inspection or maintenance of high voltage system harnesses and parts.

-

The removed service plug must always be carried in a pocket of the responsible worker or placed in the tool box during the procedure to prevent the plug from being connected by mistake.

-

Be sure to wear insulating protective equipment consisting of glove, shoes, face shield and glasses before beginning work on the high voltage system.

-

Never allow workers other than the responsible person to touch the Nissan Ariya vehicle containing high voltage parts. To keep others from touching the high voltage parts, these parts must be covered with an insulating sheet except when using them.

-

Refer to HIGH VOLTAGE PRECAUTIONS : Precautions.

CAUTION:

Never bring the vehicle into the READY status with the service plug removed unless otherwise instructed in the Service Manual. A malfunction may occur if this is not observed.

PRECONDITIONING-1

WARNING:

Be sure to disconnect the high voltage and check residual voltage before work starts.

-

Disconnect the high voltage. Refer to HOW TO DISCONNECT HIGH VOLTAGE : Precautions.

-

Check voltage of high voltage circuit. Refer to CHECK VOLTAGE IN HIGH VOLTAGE CIRCUIT : Precautions.

-

Remove Li-ion battery. Refer to Removal & Installation.

-

Remove battery pack upper case. Refer to Removal & Installation.

>>

GO TO 2.

CHECK CONNECTOR CONNECTION CONDITION

Check the connection status of the LBC harness connector and battery pack water temperature sensor harness connector.

NOTE:

NOTE:

Pull the connector first then push the connector to confirm a connection. Since if connector is pressed first, connector may be locked, malfunction cannot be found.

Is the inspection result normal?

YES>>GO TO 3.

NO>>Repair harness connector connection.

CHECK BATTERY PACK WATER TEMPERATURE SENSOR

-

Disconnect battery pack water temperature sensor harness connector.

-

Check battery pack water temperature sensor. Refer to Component Inspection.

Is the inspection result normal?

YES>>GO TO 4.

NO>>Replace battery pack water temperature sensor.

CHECK CONTINUITY BETWEEN BATTERY PACK WATER TEMPERATURE SENSOR AND LBC

-

Remove LBC connector.

-

Check continuity between battery pack water temperature sensor harness connector and LBC harness connector.

Battery pack water temperature sensor LBC Continuity Connector Terminal Connector Terminal Z311 1 Z368 23 Exist 2 24 -

Check harness for short to ground and short to lines.

Is inspection result normal?

YES>>INSPECTION END

NO>>Repair or replace Li-ion battery Nissan Ariya vehicle communication harness.

Component Inspection

WARNING:

Since hybrid vehicles and electric Nissan Ariya vehicles contain a high voltage battery, there is the risk of electric shock, electric leakage, or similar accidents if the high voltage component and Nissan Ariya vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

Since hybrid vehicles and electric Nissan Ariya vehicles contain a high voltage battery, there is the risk of electric shock, electric leakage, or similar accidents if the high voltage component and Nissan Ariya vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

WARNING:

-

Be sure to remove the service plug in order to disconnect the high voltage circuits before performing inspection or maintenance of high voltage system harnesses and parts.

-

The removed service plug must always be carried in a pocket of the responsible worker or placed in the tool box during the procedure to prevent the plug from being connected by mistake.

-

Be sure to wear insulating protective equipment consisting of glove, shoes, face shield and glasses before beginning work on the high voltage system.

-

Never allow workers other than the responsible person to touch the Nissan Ariya vehicle containing high voltage parts. To keep others from touching the high voltage parts, these parts must be covered with an insulating sheet except when using them.

-

Refer to HIGH VOLTAGE PRECAUTIONS : Precautions.

CAUTION:

Never bring the vehicle into the READY status with the service plug removed unless otherwise instructed in the Service Manual. A malfunction may occur if this is not observed.

PRECONDITIONING

WARNING:

Be sure to disconnect the high voltage and check residual voltage before work starts.

-

Disconnect the high voltage. Refer to HOW TO DISCONNECT HIGH VOLTAGE : Precautions.

-

Check voltage of high voltage circuit. Refer to CHECK VOLTAGE IN HIGH VOLTAGE CIRCUIT : Precautions.

-

Remove Li-ion battery. Refer to Removal & Installation.

-

Remove battery pack upper case. Refer to Removal & Installation.

>>

GO TO 2.

CHECK BATTERY PACK WATER TEMPERATURE SENSOR

-

Disconnect battery pack water temperature sensor harness connector.

-

Check resistance of battery pack water temperature sensor.

Battery pack water temperature sensor Condition Resistance Terminal 1 2 25 °C 3960 Ω - 4040 Ω

Is the inspection result normal?

YES>>INSPECTION END

NO>>Replace battery pack water temperature sensor.

Battery Coolant Heater (ptc) Nissan Ariya 2023

Diagnosis Procedure

WARNING:

Since hybrid vehicles and electric Nissan Ariya vehicles contain a high voltage battery, there is the risk of electric shock, electric leakage, or similar accidents if the high voltage component and Nissan Ariya vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

Since hybrid vehicles and electric Nissan Ariya vehicles contain a high voltage battery, there is the risk of electric shock, electric leakage, or similar accidents if the high voltage component and Nissan Ariya vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

WARNING:

-

Be sure to remove the service plug in order to disconnect the high voltage circuits before performing inspection or maintenance of high voltage system harnesses and parts.

-

The removed service plug must always be carried in a pocket of the responsible worker or placed in the tool box during the procedure to prevent the plug from being connected by mistake.

-

Be sure to wear insulating protective equipment consisting of glove, shoes, face shield and glasses before beginning work on the high voltage system.

-

Never allow workers other than the responsible person to touch the Nissan Ariya vehicle containing high voltage parts. To keep others from touching the high voltage parts, these parts must be covered with an insulating sheet except when using them.

-

Refer to HIGH VOLTAGE PRECAUTIONS : Precautions.

CAUTION:

Never bring the vehicle into the READY status with the service plug removed unless otherwise instructed in the Service Manual. A malfunction may occur if this is not observed.

PRECONDITIONING-1

WARNING:

Be sure to disconnect the high voltage and check residual voltage before work starts.

-

Disconnect the high voltage. Refer to HOW TO DISCONNECT HIGH VOLTAGE : Precautions.

-

Check voltage of high voltage circuit. Refer to CHECK VOLTAGE IN HIGH VOLTAGE CIRCUIT : Precautions.

>>

GO TO 2.

CHECK CONTINUITY BATTERY PTC Nissan Ariya Vehicle COMMUNICATION CIRCUIT

-

Remove vehicle communication harness connector and vehicle communication harness connector (Battery PTC) connector.

-

Check continuity between Nissan Ariya vehicle communication harness connector and vehicle communication harness connector (Battery PTC) and vehicle communication harness connector (Battery PTC).

Nissan Ariya Vehicle communication harness connector Vehicle communication harness connector

(Battery PTC)Continuity Connector Terminal Connector Terminal Z305 17 Z301 17 Exist 27 15 30 23 -

Check harness for short to ground and short to lines.

Is inspection result normal?

YES>>-

When checking only battery PTC Nissan Ariya vehicle communication: INSPECTION END

-

When also checking battery high voltage circuit: GO TO 5.

GO TO 3.

PRECONDITIONING-2

WARNING:

Be sure to disconnect the high voltage and check residual voltage before work starts.

-

Remove Li-ion battery from Nissan Ariya vehicle. Refer to Removal & Installation.

-

Remove battery pack upper case. Refer to Removal & Installation.

>>

GO TO 4.

CHECK CONNECTOR CONNECTING CONDITION

Check connection status of intermediate connector (Z302).

NOTE:

NOTE:

Pull connector first then push connector to check connection. Since if connector is pressed first, connector may be locked, malfunction cannot be found.

Is the inspection result normal?

YES>>Repair replace Li-ion battery Nissan Ariya vehicle communication harness.

NO>>Repair harness connector connection.

PRECONDITIONING-3

WARNING:

Be sure to disconnect the high voltage and check residual voltage before work starts.

-

Remove Li-ion battery from Nissan Ariya vehicle. Refer to Removal & Installation.

-

Remove battery pack upper case. Refer to Removal & Installation.

>>

GO TO 6.

CHECK CONNECTOR CONNECTING CONDITION

Check connection status of the junction box connector (Z308 and Z309), and intermediate connector (Z330 and Z328).

NOTE:

NOTE:

Pull connector first then push connector to check connection. Since if connector is pressed first, connector may be locked, malfunction cannot be found.

Is the inspection result normal?

YES>>GO TO 7.

NO>>Repair harness connector connection.

CHECK BATTERY PTC FUSE

Check battery PTC fuse. Refer to Component Inspection.

Is the inspection result normal?

YES>>GO TO 8.

NO>>Replace junction box.

CHECK CONTINUITY BETWEEN HARNESS CONNECTORS OF JUNCTION BOX AND BATTERY PTC.

-

Remove harness connectors of junction box and battery PTC.

-

Check continuity between harness connectors of junction box and battery PTC.

Junction box Battery PTC Continuity Connector Terminal Connector Terminal Z309 P12 Z348 N 0Ω approx. Z308 P11 P

Is the inspection result normal?

YES>>INSPECTION END

NO>>Replace high voltage harness battery PTC.

High Voltage Fuse Nissan Ariya first Gen

Component Inspection

WARNING:

Since hybrid vehicles and electric Nissan Ariya vehicles contain a high voltage battery, there is the risk of electric shock, electric leakage, or similar accidents if the high voltage component and Nissan Ariya vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

Since hybrid vehicles and electric Nissan Ariya vehicles contain a high voltage battery, there is the risk of electric shock, electric leakage, or similar accidents if the high voltage component and Nissan Ariya vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

WARNING:

-

Be sure to remove the service plug in order to disconnect the high voltage circuits before performing inspection or maintenance of high voltage system harnesses and parts.

-

The removed service plug must always be carried in a pocket of the responsible worker or placed in the tool box during the procedure to prevent the plug from being connected by mistake.

-

Be sure to wear insulating protective equipment consisting of glove, shoes, face shield and glasses before beginning work on the high voltage system.

-

Never allow workers other than the responsible person to touch the Nissan Ariya vehicle containing high voltage parts. To keep others from touching the high voltage parts, these parts must be covered with an insulating sheet except when using them.

-

Refer to HIGH VOLTAGE PRECAUTIONS : Precautions.

CAUTION:

Never bring the vehicle into the READY status with the service plug removed unless otherwise instructed in the Service Manual. A malfunction may occur if this is not observed.

REMOVE BATTERY PACK

WARNING:

Disconnect the high voltage. Refer to HOW TO DISCONNECT HIGH VOLTAGE : Precautions.

-

Remove Li-ion battery from Nissan Ariya vehicle. Refer to Removal & Installation.

-

Remove battery pack upper case. Refer to Removal & Installation.

-

Remove junction box cover.

>>

GO TO 2.

CHECK HIGH VOLTAGE FUSE (MAIN)

-

Check continuity of high voltage fuse (Main).

-

High voltage fuse (Main)

Value: 0 Ω approx. -

High voltage fuse (Quick charge)

Value: 0 Ω approx. -

PTC fuse

Value: 0 Ω approx.

-

Is the inspection result normal?

YES>>INSPECTION END

NO>>Replace junction box.

Li-Ion Battery Insulation Resistance Loss Inspection. 2wd Nissan Ariya 1st generation

Diagnosis Procedure

WARNING:

-

Be sure to remove the service plug in order to disconnect the high voltage circuits before performing inspection or maintenance of high voltage system harnesses and parts.

-

The removed service plug must always be carried in a pocket of the responsible worker or placed in the tool box during the procedure to prevent the plug from being connected by mistake.

-

Be sure to wear insulating protective equipment consisting of glove, shoes, face shield and glasses before beginning work on the high voltage system.

-

Never allow workers other than the responsible person to touch the Nissan Ariya vehicle containing high voltage parts. To keep others from touching the high voltage parts, these parts must be covered with an insulating sheet except when using them.

-

Refer to PRECAUTIONS FOR HIGH VOLTAGE : Precautions.

CAUTION:

Never bring the vehicle into the READY status with the service plug removed unless otherwise instructed in the Service Manual. A malfunction may occur if this is not observed.

NOTE:

NOTE:

To check a stable value, have time enough after putting a probe.

CAUTION:

-

The following diagnosis procedure must be performed when “P1BA2-49” are detected and Li-ion battery is judged that its insulation resistance is dropping.

-

Be sure to perform procedure till the last. And write down a memo about the malfunctioning parts. Insulation resistance may be lost in some parts.

CHECK MAXIMUM CELL VOLTAGE

With CONSULT

With CONSULT

-

Power switch ON.

-

Select “Data Monitor” of “HIGH VOLTAGE BATTERY”.

-

Record “Maximum cell voltage”.

NOTE:

NOTE:

When procedure for replacing malfunction module is required, “MAXIMUM CELL VOLTAGE” is used.

>>

GO TO 2.

PRECONDITIONING

WARNING:

Be sure to perform the high voltage disconnection and voltage check in high voltage circuit before inspection.

-

Disconnect the high voltage. Refer to HOW TO DISCONNECT HIGH VOLTAGE : Precautions.

-

Check voltage in high voltage circuit. Refer to CHECK VOLTAGE IN HIGH VOLTAGE CIRCUIT : Precautions.

-

Remove Li-ion battery. Refer to Removal & Installation.

-

Remove battery pack upper case. Refer to Removal & Installation.

-

Remove LBC. Refer to Removal & Installation.

>>

GO TO 3.

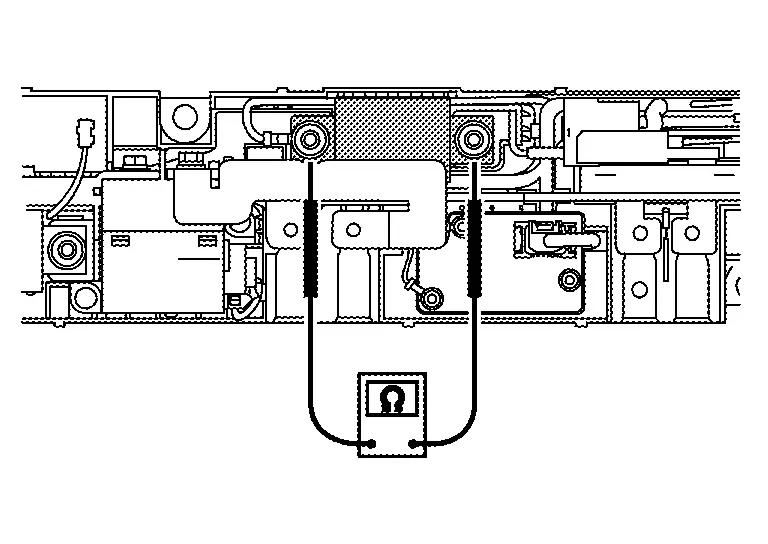

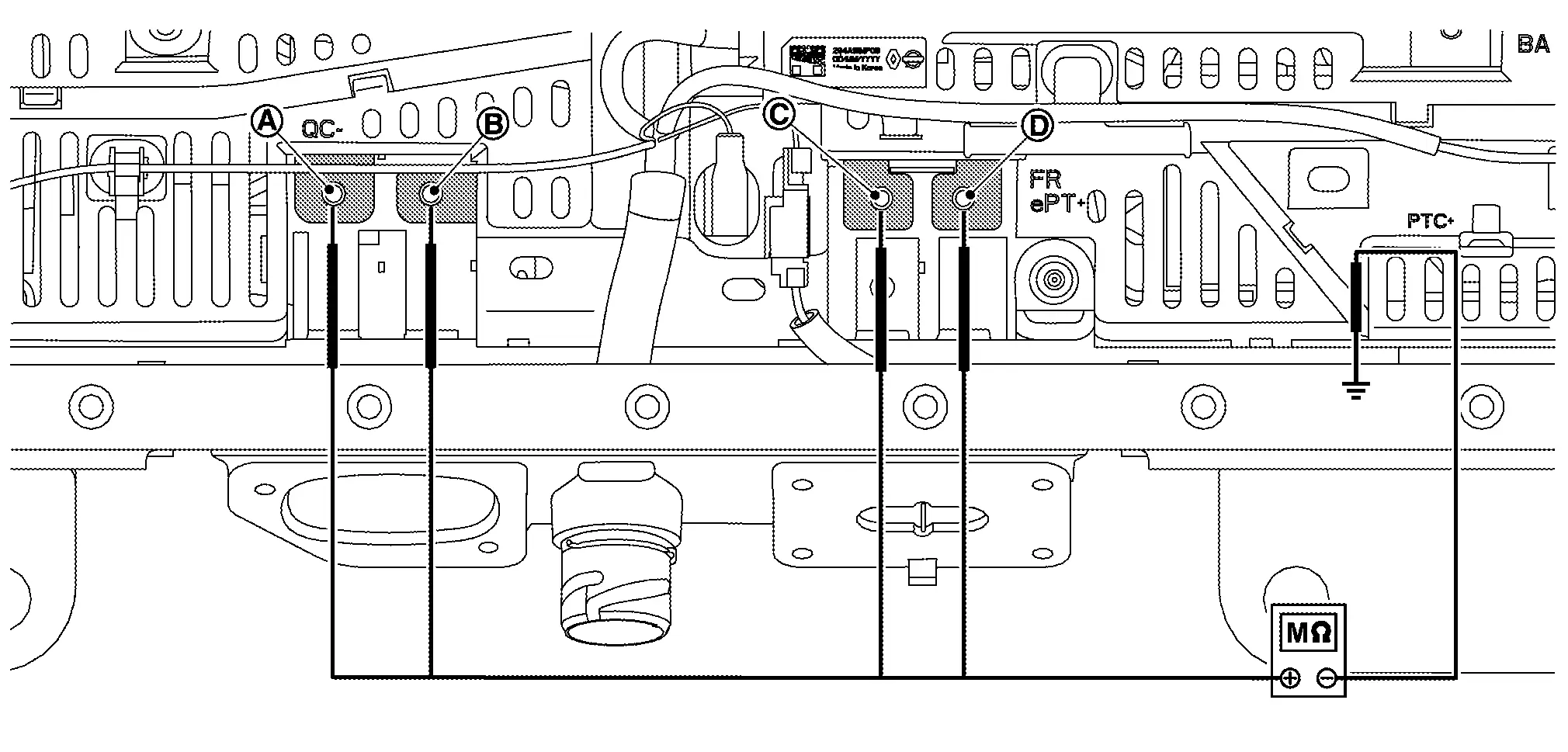

CHECK INSULATION RESISTANCE OF HIGH-VOLTAGE CONNECTOR (FRONT) AND HIGH-VOLTAGE CONNECTOR (QUICK CHARGE)

Using insulation resistance tester, measure insulation resistance between terminals of high-voltage connector (front) and high voltage connector (quick charge).

| Probe | Resistance | |

|---|---|---|

| + | − | |

High-voltage connector (Front) terminal |

Battery pack lower case | 1000 MΩ or more |

High-voltage connector (Front) terminal |

||

High-voltage connector (Quick charge) terminal |

||

High-voltage connector (Quick charge) terminal |

||

WARNING:

Unlike the ordinary tester, the insulation resistance tester applies 500 V when measuring.

If used incorrectly, there is the danger of electric shock. If used in the Nissan Ariya vehicle 12 V system, there is the danger of damage to electronic devices. Read the insulation resistance tester instruction manual carefully and be sure to work safely.

CAUTION:

-

Be sure to set the insulation resistance tester to 500 V when performing this test.

-

Using a setting higher than 500 V can result in damage to the component being inspected.

-

When probe is pot on the battery lower case, put it on the part that is not corroded or soiled.

Is the inspection result normal?

YES>>GO TO 6.

NO>>GO TO 4.

CHECK BUS BAR BETWEEN HIGH VOLTAGE CONNECTOR AND JUNCTION BOX.

-

Remove high voltage connector (front) and high voltage connector (quick charge).

-

Remove each connector of junction box.

-

Remove the following bus bar.

-

Bus bar (Bus bar 1) between high voltage connector (Front) and junction box.

-

Bus bar (Bus bar 20) between high voltage connector (Quick charge) and junction box.

-

-

Check that each bus bar shield have no scratches and cracks.

Is the inspection result normal?

YES>>GO TO 5.

NO>>Take note about replaced malfunction parts. Then GO TO 5.

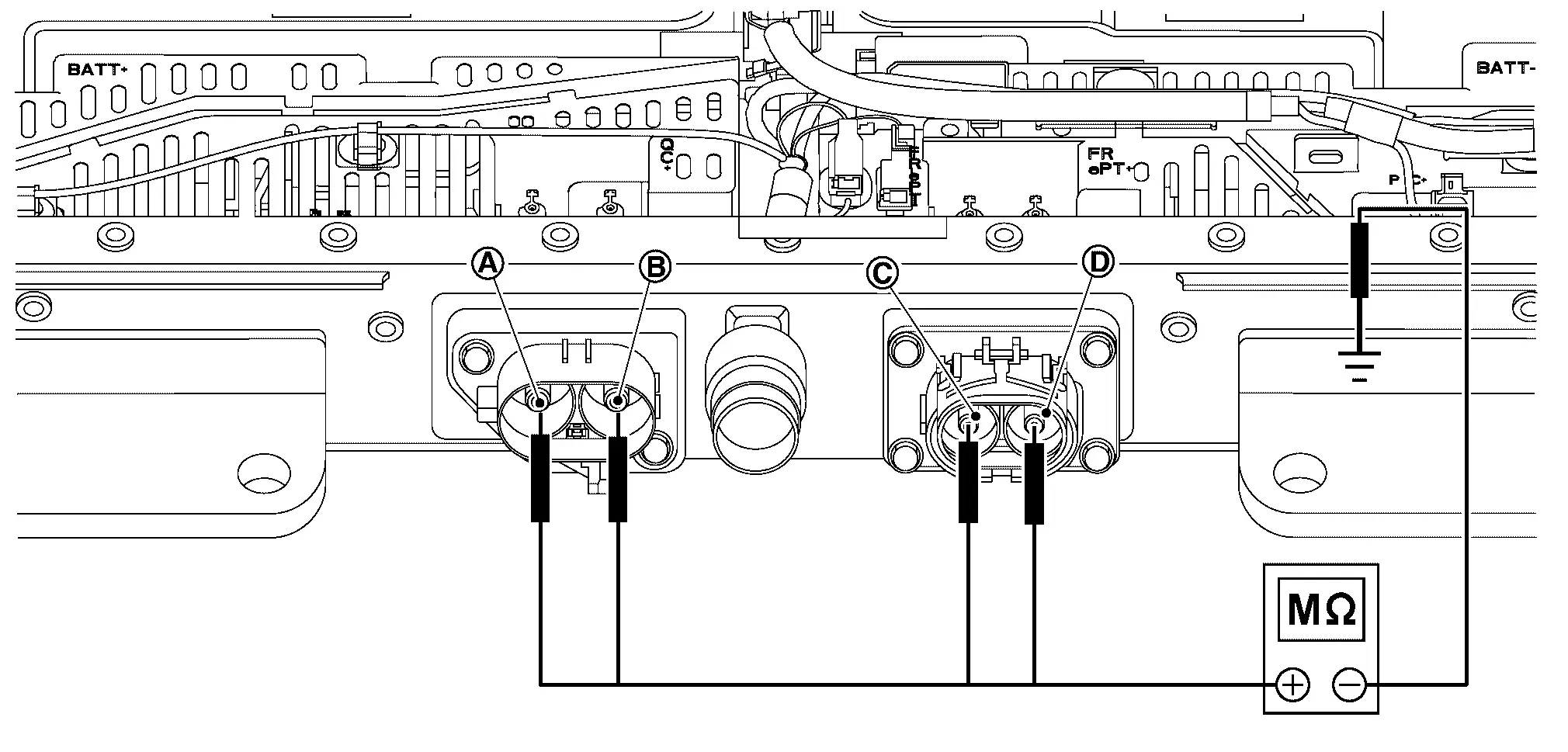

BATTERY JUNCTION BOX INSULATION RESISTANCE-1

-

Remove high voltage connector (Front) and high voltage connector (Quick charge).

-

Remove each connector of junction box.

-

Using insulation resistance tester, measure insulation resistance between battery junction box terminals and battery pack ground.

Probe Resistance + − Battery junction box terminals (P1)

Battery pack lower case 1000 MΩ or more Battery junction box terminals (P3)

Battery junction box terminals (P5)

Battery junction box terminals (P6)

WARNING:

Unlike the ordinary tester, the insulation resistance tester applies 500 V when measuring. If used incorrectly, there is the danger of electric shock. If used in the Nissan Ariya vehicle 12 V system, there is the danger of damage to electronic devices. Read the insulation resistance tester instruction manual carefully and be sure to work safely.

CAUTION:

-

Be sure to set the insulation resistance tester to 500 V when performing this test.

-

Using a setting higher than 500 V can result in damage to the component being inspected.

-

When probe is pot on the battery lower case, put it on the part that is not corroded or soiled.

-

Is the inspection result normal?

YES>>Take note about replacement of high voltage connector (Front) and high voltage connector (Quick charge) Then GO TO 6.

NO>>Take note about malfunction parts. Then GO TO 6.

CHECK INSULATION RESISTANCE OF HIGH VOLTAGE CONNECTOR (BATTERY PTC CONNECTOR)

Using insulation resistance tester, measure insulation resistance between high-voltage connector (Battery PTC) terminals and battery pack ground (battery pack lower case).

| Probe | Resistance | |

|---|---|---|

| + | − | |

High-voltage connector (Battery PTC) terminal |

Battery pack lower case | 1000 MΩ or more |

High-voltage connector (Battery PTC) terminal |

||

WARNING:

Unlike the ordinary tester, the insulation resistance tester applies 500 V when measuring. If used incorrectly, there is the danger of electric shock. If used in the Nissan Ariya vehicle 12V system, there is the danger of damage to electronic devices. Read the insulation resistance tester instruction manual carefully and be sure to work safely.

CAUTION:

-

Be sure to set the insulation resistance tester to 500 V when performing this test.

-

Using a setting higher than 500 V can result in damage to the component being inspected.

-

When probe is pot on the battery lower case, put it on the part that is not corroded or soiled.

Is the inspection result normal?

YES>>GO TO 8.

NO>>GO TO 7.

CHECK INSULATION RESISTANCE BETWEEN HARNESSES OF BATTERY PTC AND JUNCTION BOX

-

Remove battery PTC connector of junction box.

-

Using insulation resistance tester, measure insulation resistance between battery PTC harness and battery pack lower case.

Probe Resistance + − High-voltage connector (Battery PTC) terminal

Battery pack lower case 1000 MΩ or more High-voltage connector (Battery PTC) terminal

WARNING:

Unlike the ordinary tester, the insulation resistance tester applies 500 V when measuring. If used incorrectly, there is the danger of electric shock. If used in the Nissan Ariya vehicle 12 V system, there is the danger of damage to electronic devices. Read the insulation resistance tester instruction manual carefully and be sure to work safely.

CAUTION:

-

Be sure to set the insulation resistance tester to 500 V when performing this test.

-

Using a setting higher than 500 V can result in damage to the component being inspected.

-

When probe is pot on the battery lower case, put it on the part that is not corroded or soiled.

Is the inspection result normal?

YES>>Record replacement of high voltage connector (Battery PTC) Then GO TO 8.

NO>>Record replacement of harnesses between battery PTC and junction box. Then GO TO 8.

CHECK BUS BAR BETWEEN JUNCTION BOX AND MODULE

-

Remove the following parts.

-

Bus bar (bas bar2) between junction box and module No.1.

-

Bus bar (bas bar19) between junction box and module No.12.

-

-

Check that each bus bar shield have no scratches and cracks.

Is the inspection result normal?

YES>>GO TO 9.

NO>>Record replacement of malfunction parts. Then GO TO 9.

CHECK INSULATION RESISTANCE OF BATTERY JUNCTION BOX

Using insulation resistance tester, measure insulation resistance between battery junction box and battery pack lower case.

| Probe | Resistance | |

|---|---|---|

| + | − | |

Battery junction box terminals (P2) |

Battery pack lower case | 1000 MΩ or more |

Battery junction box terminals (P4) |

||

WARNING:

Unlike the ordinary tester, the insulation resistance tester applies 500 V when measuring. If used incorrectly, there is the danger of electric shock. If used in the Nissan Ariya vehicle 12V system, there is the danger of damage to electronic devices. Read the insulation resistance tester instruction manual carefully and be sure to work safely.

CAUTION:

-

Be sure to set the insulation resistance tester to 500 V when performing this test.

-

Using a setting higher than 500 V can result in damage to the component being inspected.

-

When probe is pot on the battery lower case, put it on the part that is not corroded or soiled.

Is the inspection result normal?

YES>>GO TO 10.

NO>>Record replacement of junction box. Then GO TO 10.

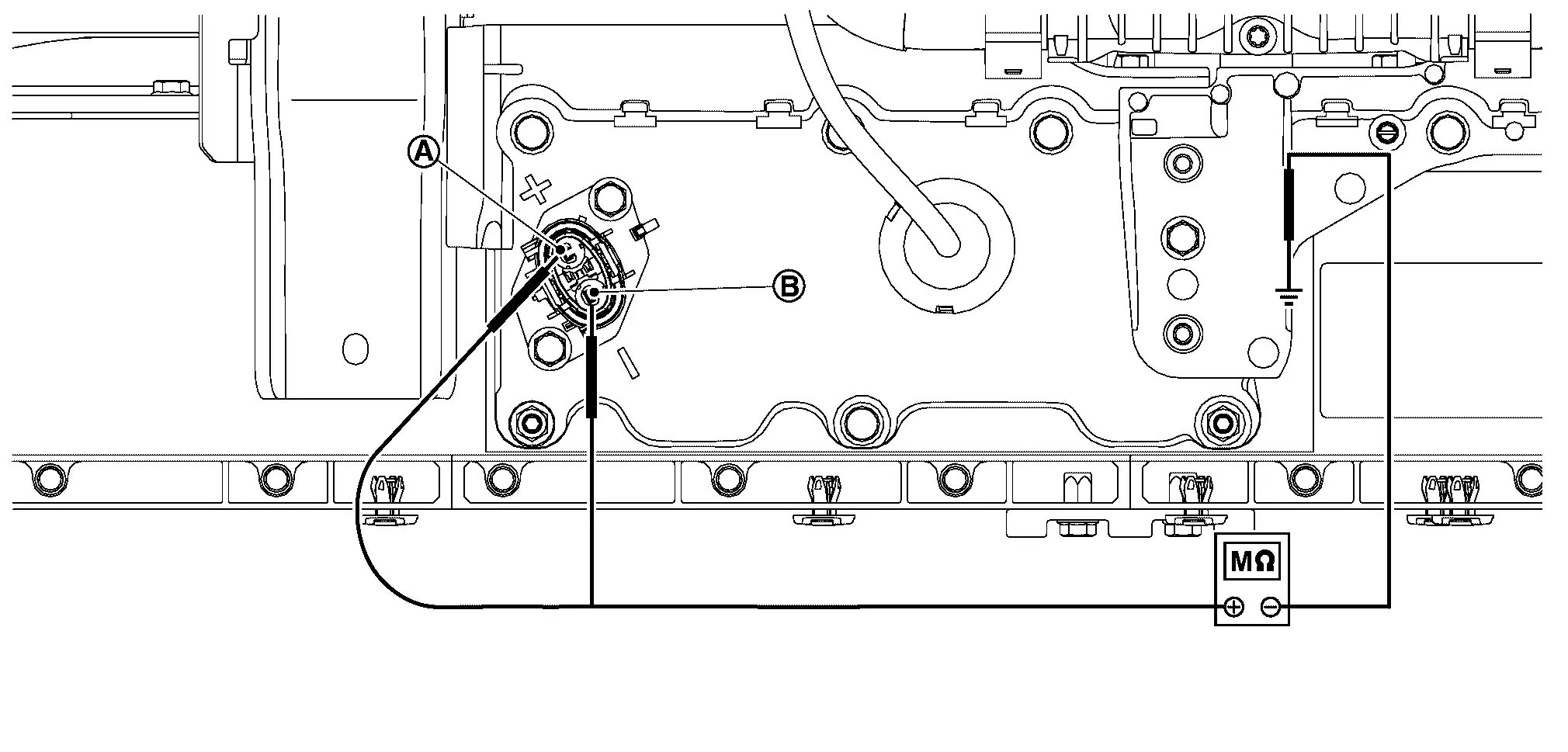

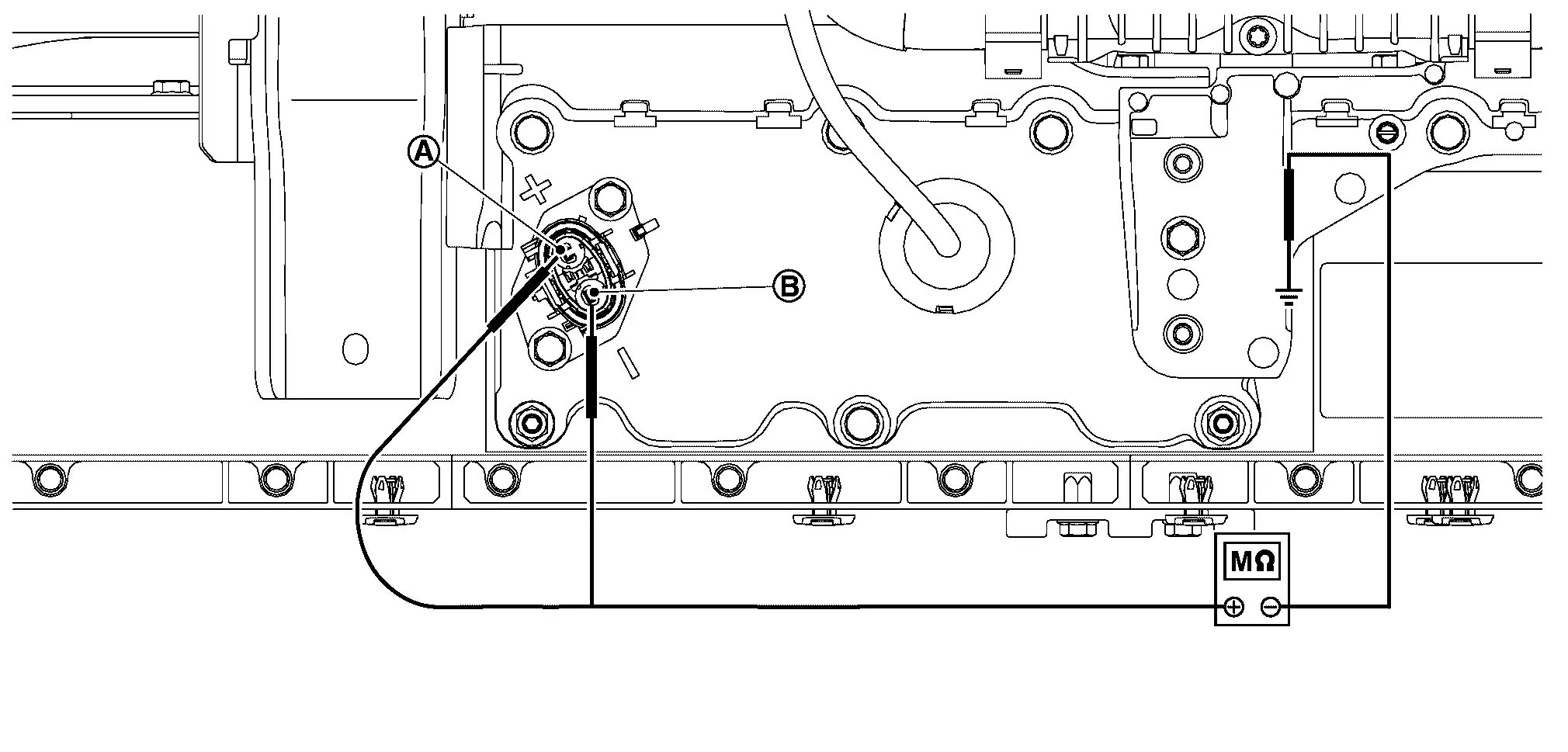

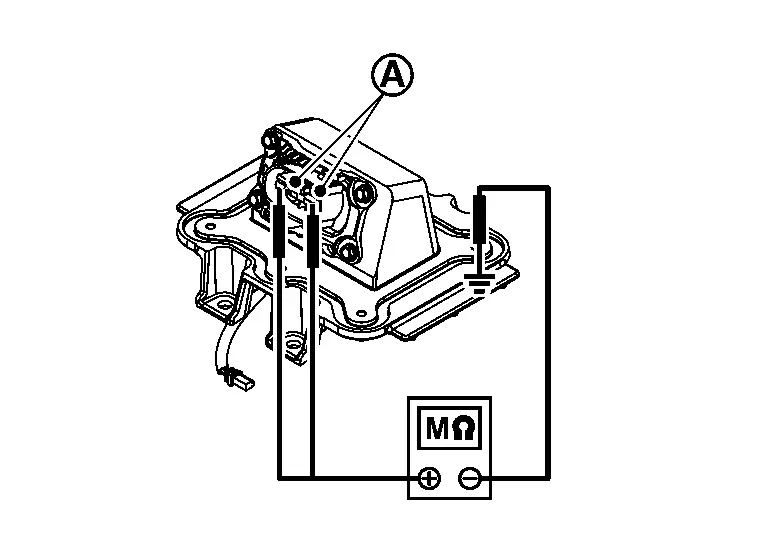

CHECK INSULATION RESISTANCE OF SERVICE PLUG SWITCH

-

Remove service plug switch bracket together with bus bar.

-

Remove bus bar

from service plug.

from service plug.

-

Check that each bus bar shield have no scratches and cracks.

-

Using insulation resistance tester, measure insulation resistance between service plug switch terminal

and service plug switch bracket.

and service plug switch bracket.

WARNING:

Unlike the ordinary tester, the insulation resistance tester applies 500 V when measuring. If used incorrectly, there is the danger of electric shock. If used in the Nissan Ariya vehicle 12 V system, there is the danger of damage to electronic devices. Read the insulation resistance tester instruction manual carefully and be sure to work safely.

CAUTION:

-

Be sure to set the insulation resistance tester to 500 V when performing this test.

-

Using a setting higher than 500 V can result in damage to the component being inspected.

-

When probe is pot on the battery lower case, put it on the part that is not corroded or soiled.

NOTE:

NOTE:

Check service plug switch and service plug switch bracket as an assembly.

+ − Resistance Service plug switch terminals Service plug switch bracket. 1000 MΩ or more -

Is the inspection result normal?

YES>>GO TO 12.

NO>>Record replacement of malfunction parts. Then GO TO 12.

CHECK EACH BUS BAR (2ND FLOOR)

-

Remove the following bus bars.

-

Bus bar (Bus bar 9) between module No.6 and module No.7

-

Bus bar (Bus bar 10) between module No.7 and module No.8

-

Bus bar (Bus bar 14) between module No.10 and module No.9

-

Bus bar (Bus bar 15) between module No.11 and module No.10

-

-

Check that each bus bar shield have no scratches and cracks.

Is the inspection result normal?

YES>>GO TO 12.

NO>>Record replacement of malfunction parts. Then GO TO 12.

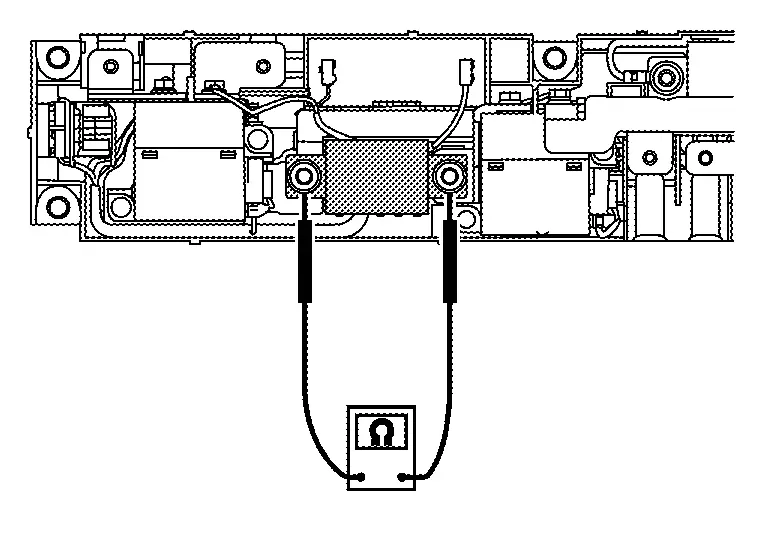

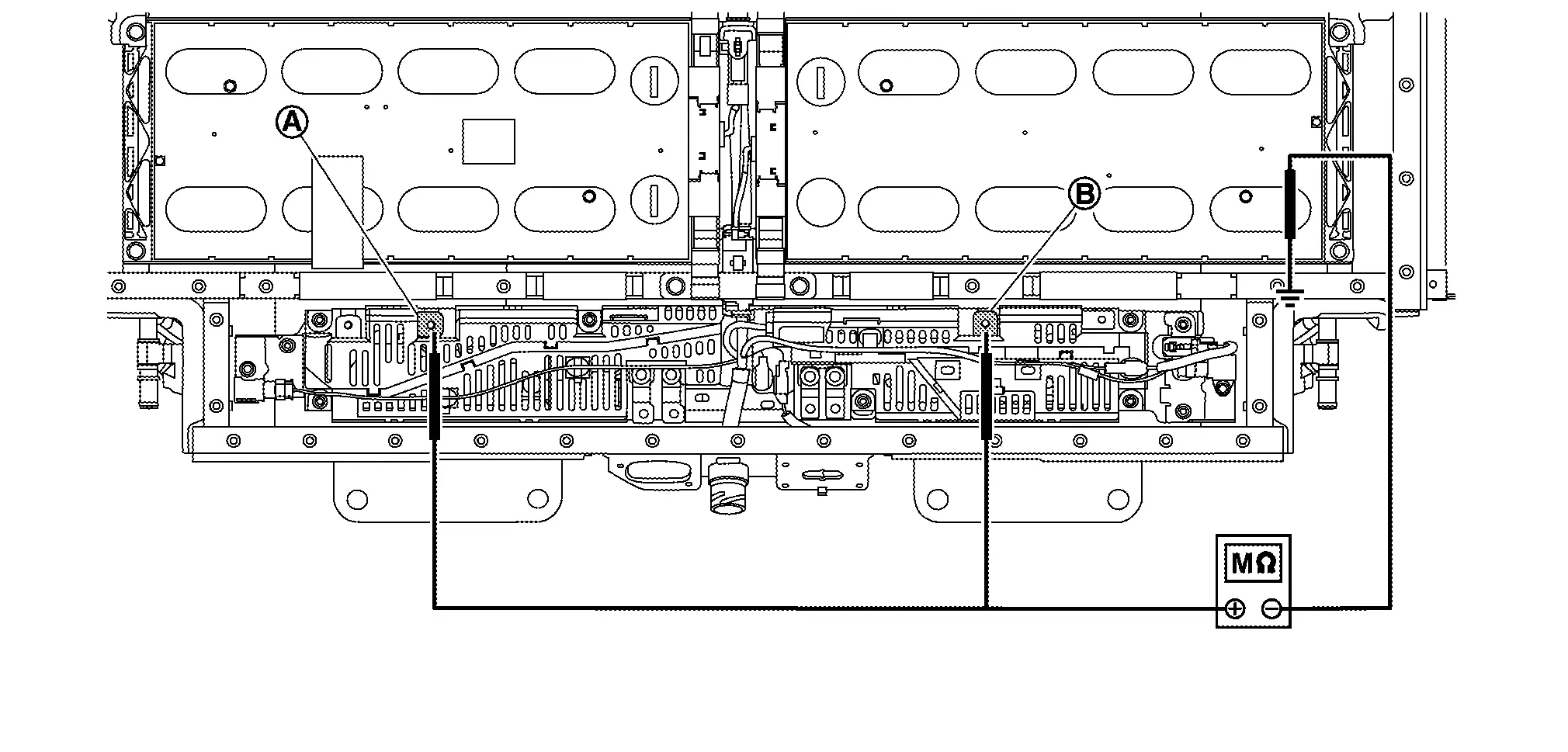

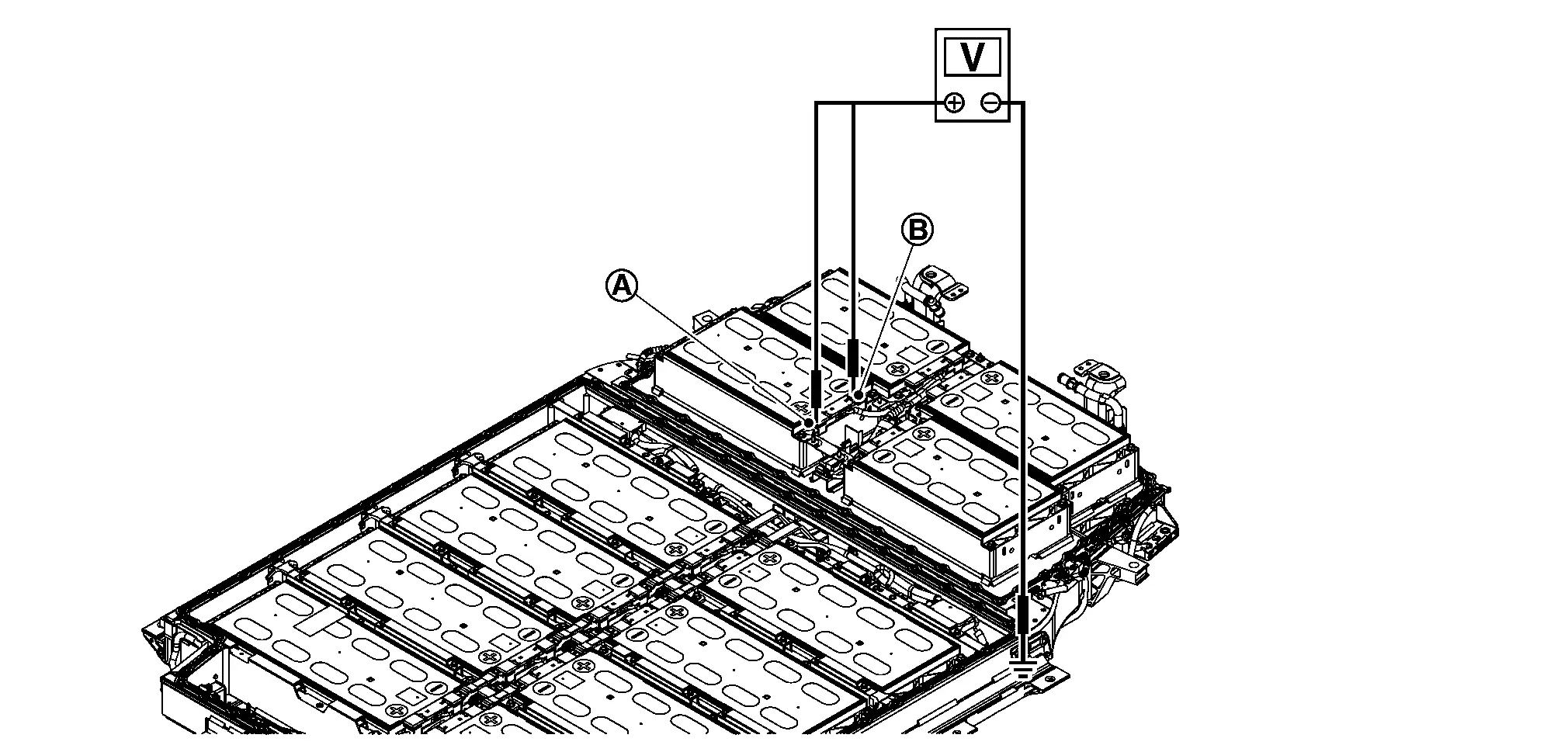

CHECK INSULATION VOLTAGE OF MODULE (2ND FLOOR)

-

Disconnect cell voltage detecting connector of each module.

-

Measure voltage between positive and negative terminal of each module and battery lower case ground.

NOTE:

NOTE:

The figure shows module No. 10 as an example. Measure voltage of each module in the same procedure.

Probe Resistance + − Module positive terminal

Battery pack lower case 0 V approx. Module negative terminal

Is the inspection result normal?

YES>>GO TO 13.

NO>>GO TO 17.

REMOVE BATTERY PACK 2ND FLOOR

Remove the battery pack 2nd floor.

>>

GO TO 14.

CHECK EACH BUS BAR (1ST FLOOR)

-

Remove the following bus bars.

-

Bus bar (Bus bar 3) between module No.1 and module No.2

-

Bus bar (Bus bar 4) between module No.2 and module No.3

-

Bus bar (Bus bar 5) between module No.3 and module No.4

-

Bus bar (Bus bar 6) between module No.4 and module No.5

-

Bus bar (Bus bar 7) between module No.5 and module No.6

-

Bus bar (Bus bar 8) between module No.6/11 and module No.7/10

-

Bus bar (Bus bar 16) between module No.11 and module No.12

-

Bus bar (Bus bar 17) between module No.12 and module No.13

-

Bus bar (Bus bar 18) between module No.13 and module No.14

-

Bus bar (Bus bar 19) between module No.14 and module No.15

-

Bus bar (Bus bar 20) between module No.15 and module No.16

-

-

Check that each bus bar shield have no scratches and cracks.

Is the inspection result normal?

YES>>GO TO 15.

NO>>Record replacement of malfunction parts. Then GO TO 15.

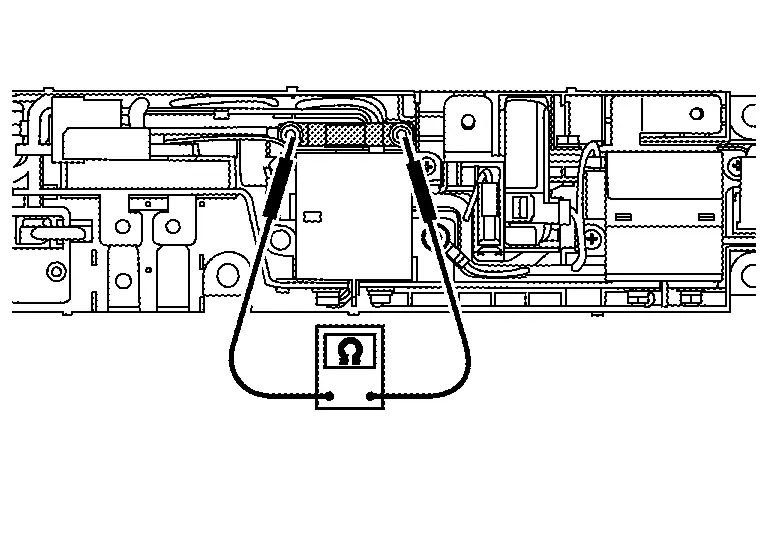

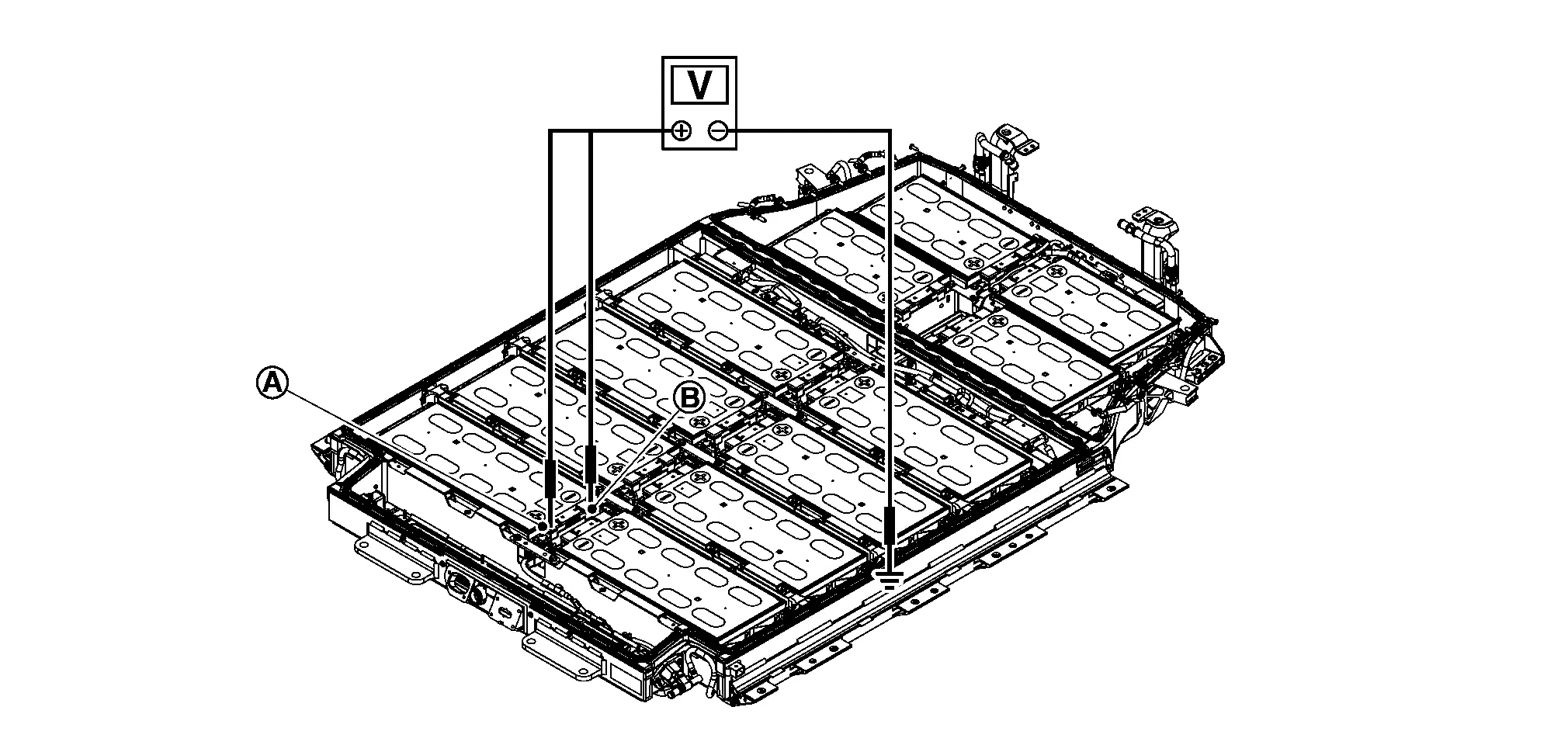

CHECK INSULATION VOLTAGE OF MODULE (1ST FLOOR)

-

Disconnect cell voltage detecting connector of each module.

-

Measure voltage between positive and negative terminal of each module and battery lower case ground.

NOTE:

NOTE:

The figure shows module No. 16 as an example. Measure voltage of each module in the same procedure.

Probe Resistance + − Module positive terminal

Battery pack lower case 0 V approx. Module negative terminal

Is the inspection result normal?

YES>>GO TO 16.

NO>>GO TO 17.

CHECK RESULT CONFIRMATION

Confirm malfunction parts written or record by check.

Is there malfunction parts?

YES>>Replace all parts written down or recorded.

NO>>Replace LBC.

MODULE APPEARANCE CHECK

-

Remove the module that has malfunction at voltage leak check from battery pack lower case.

-

Check the module for any of the following abnormalities by comparing its appearance with other normal modules.

-

There are dents or deformation on the module surface.

-

Liquid adheres to the module surface.

-

Module emits a strong organic solvent-like odor and continues.

-

>>

Record replacement of malfunction module and GO TO 16.

Nissan Ariya (FE0) 2023-2026 Service & Repair Manual

Component Parts /circuit Diagnosis

- Power Supply and Ground Circuit (li-Ion Battery Controller)

- Cell Controller Communication Circuit

- Cell Voltage Inspection

- Cell Voltage Circuit

- Module Temperature Sensor

- Module

- Interlock Detection Switch (service Plug)

- Battery Current Sensor Circuit

- Battery Pack Water Temperature Sensor Circuit

- Battery Coolant Heater (ptc)

- High Voltage Fuse

- Li-Ion Battery Insulation Resistance Loss Inspection. 2wd

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image