Nissan Ariya: Disassembly and Assembly

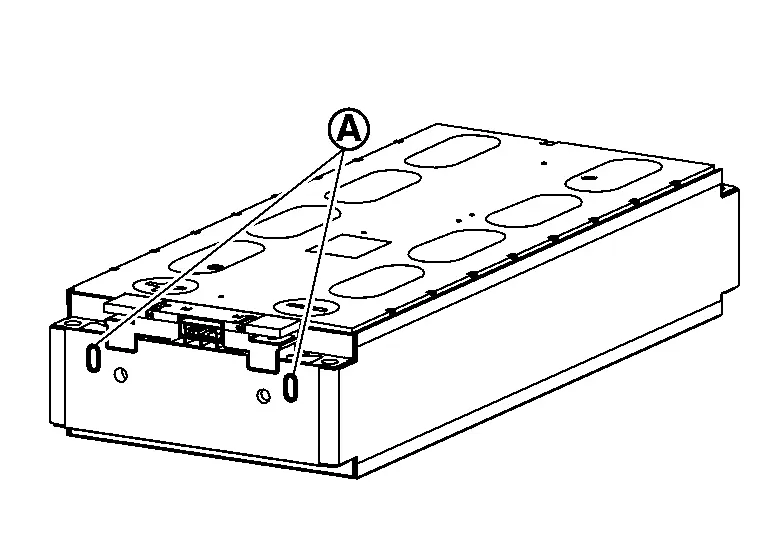

- Li-Ion Battery Heater. 2wd

- Battery Pack Upper Case

- Battery Pack Lower Case. 2wd

- Service Plug Bracket

- Li-Ion Battery Controller

- Busbar. 2wd

- Battery Junction Box and Battery Harness

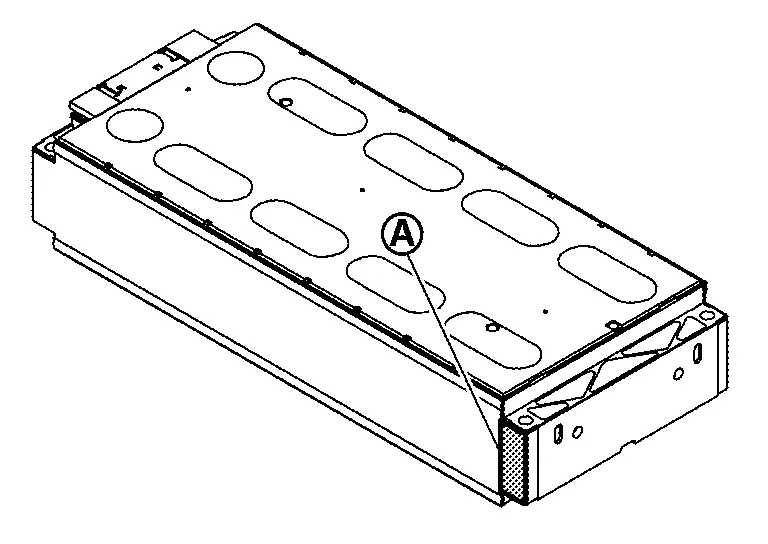

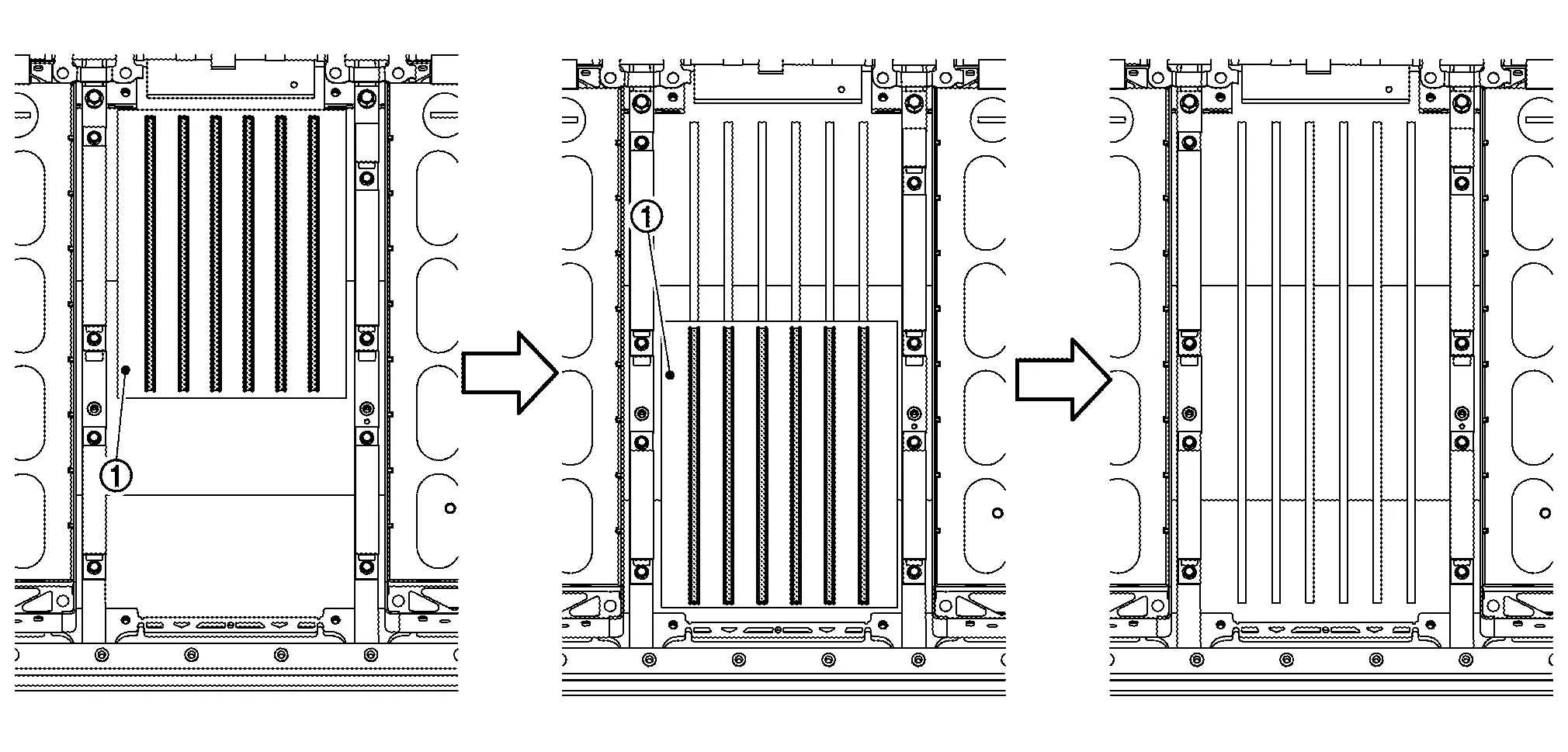

- Front Module Stack

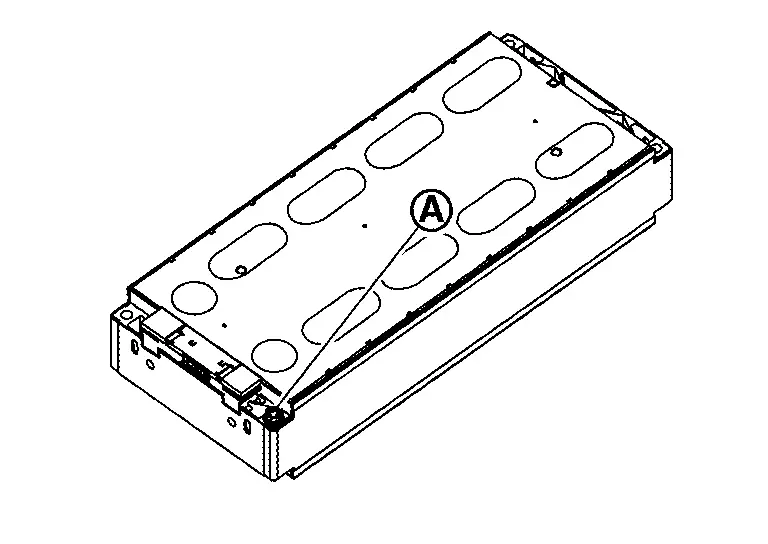

- Rear Module Stack

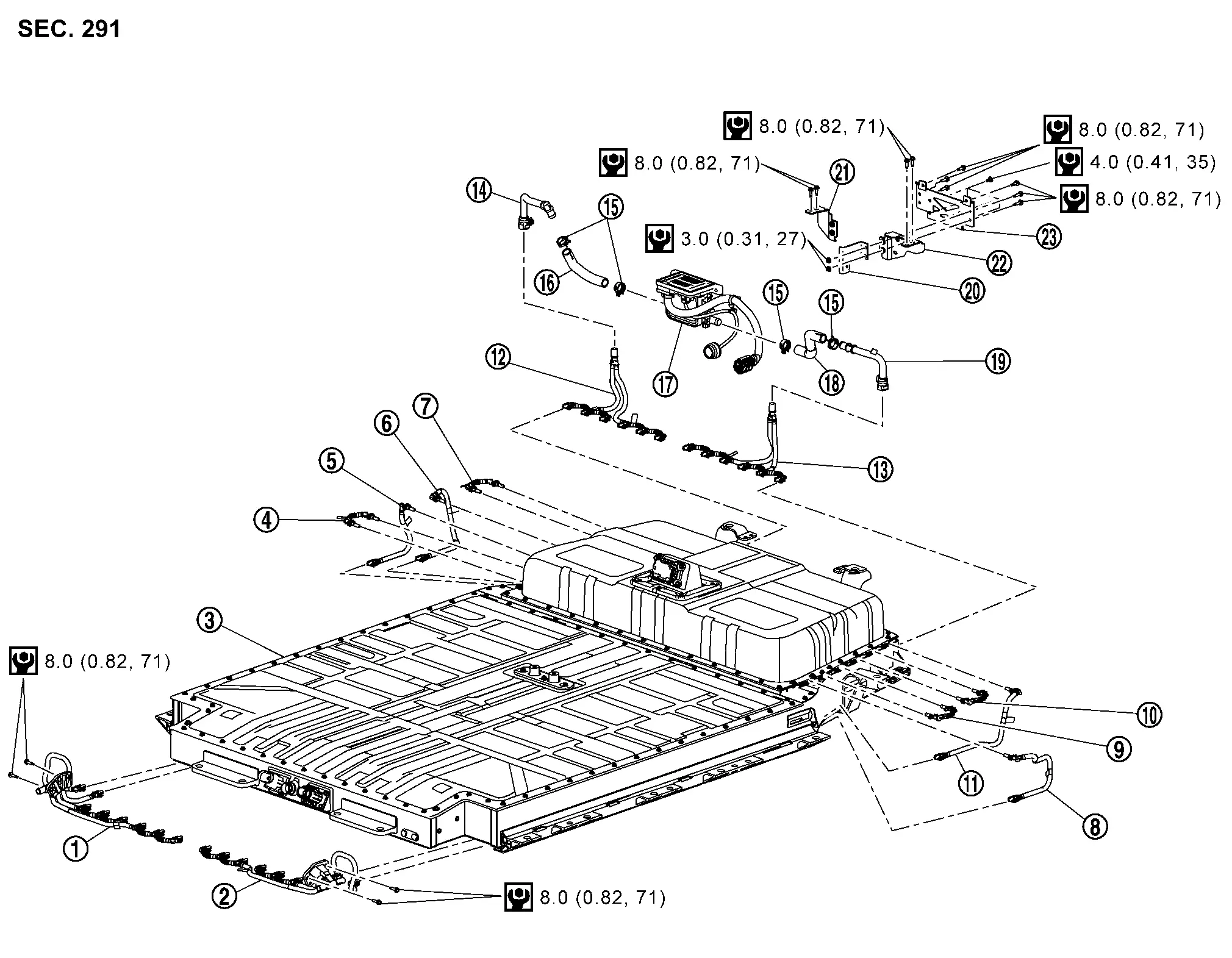

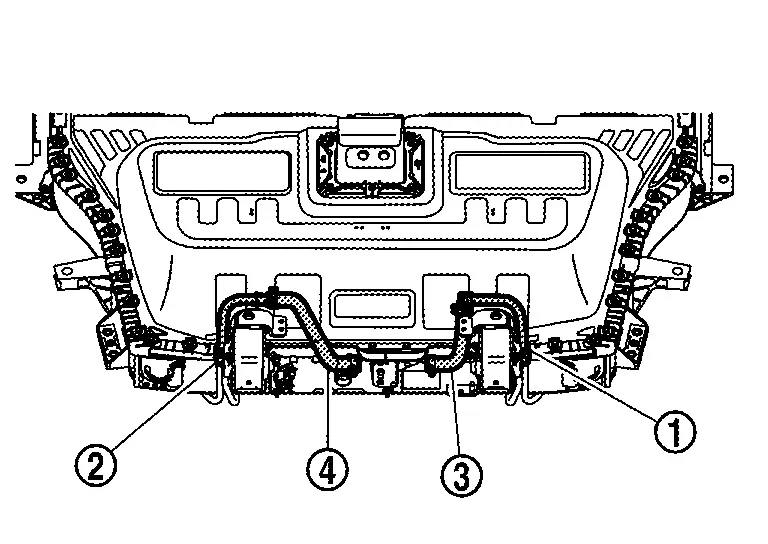

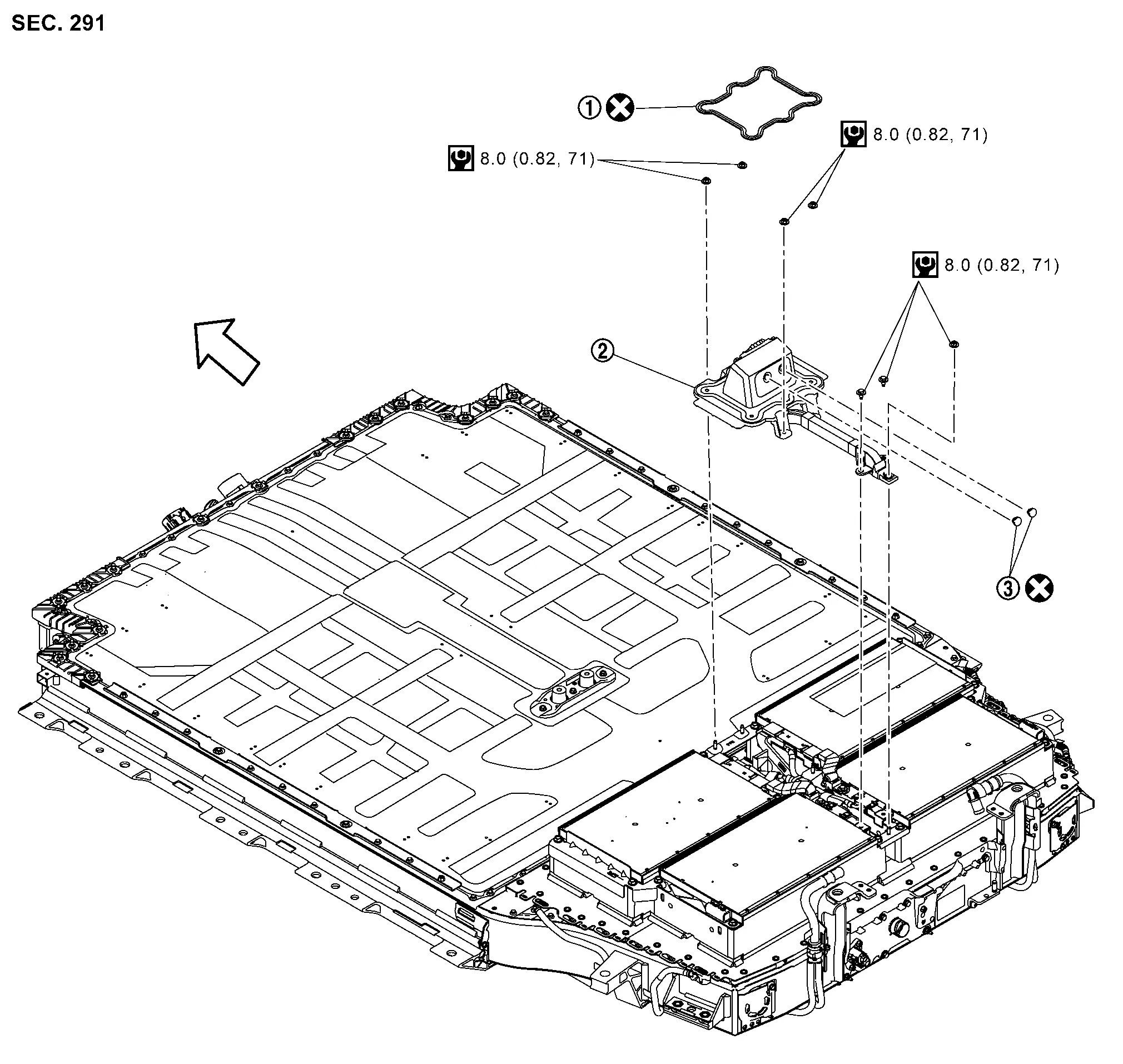

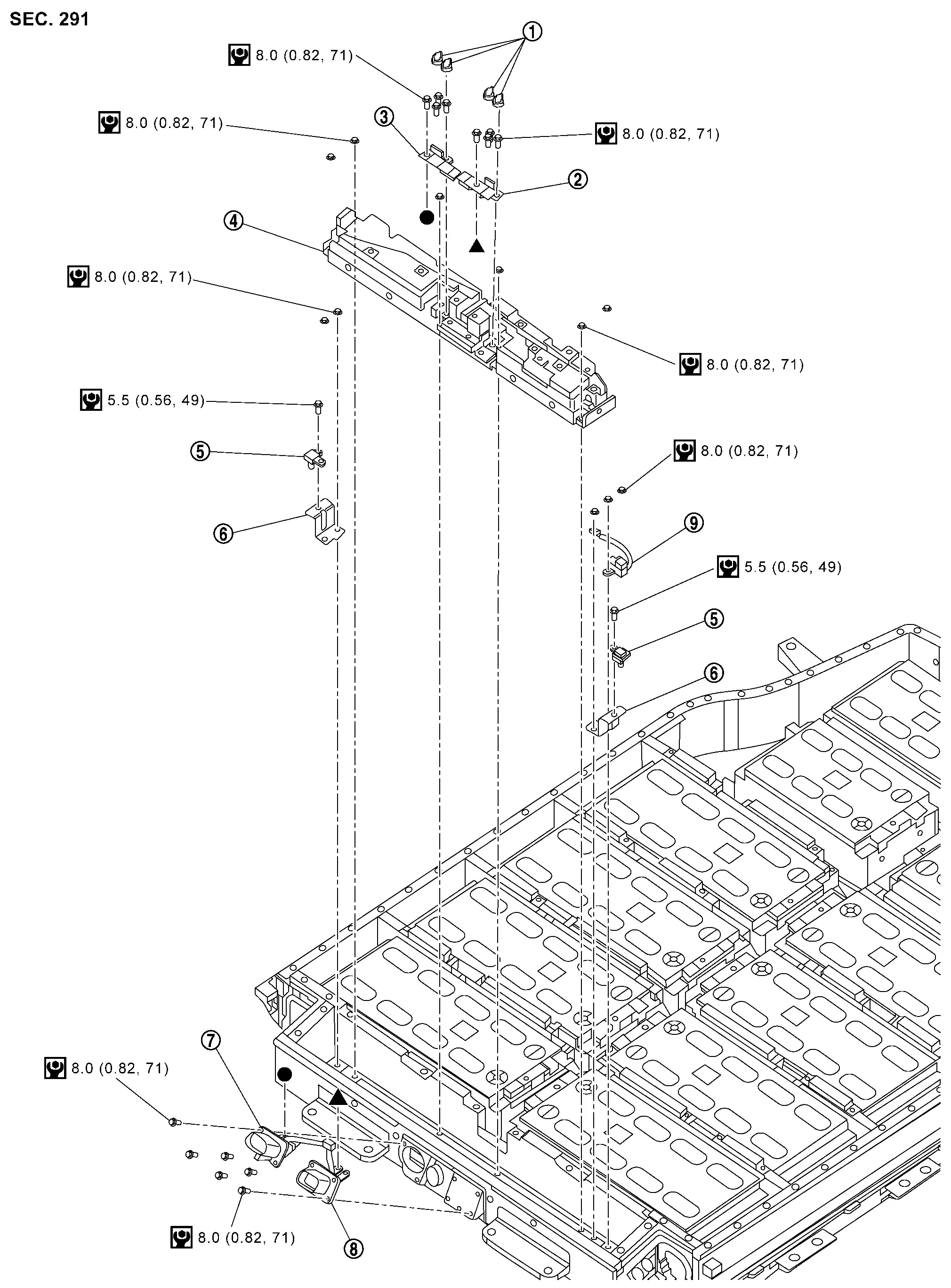

Li-Ion Battery Heater. 2wd Nissan Ariya 2026

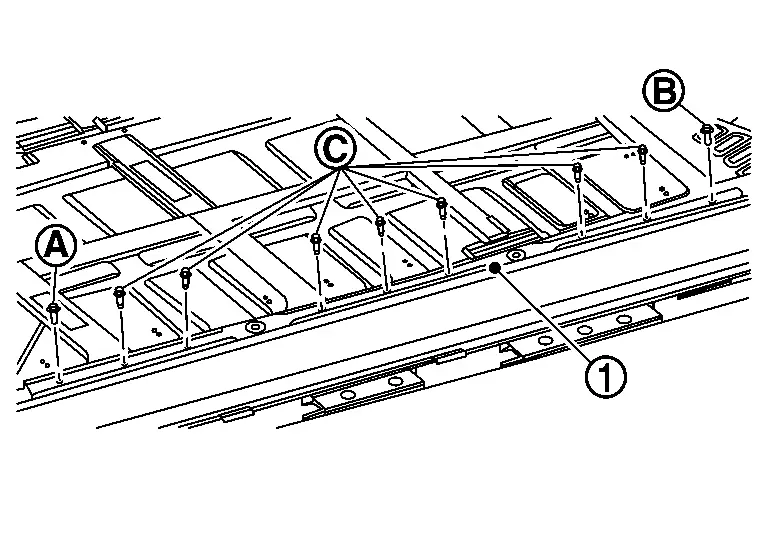

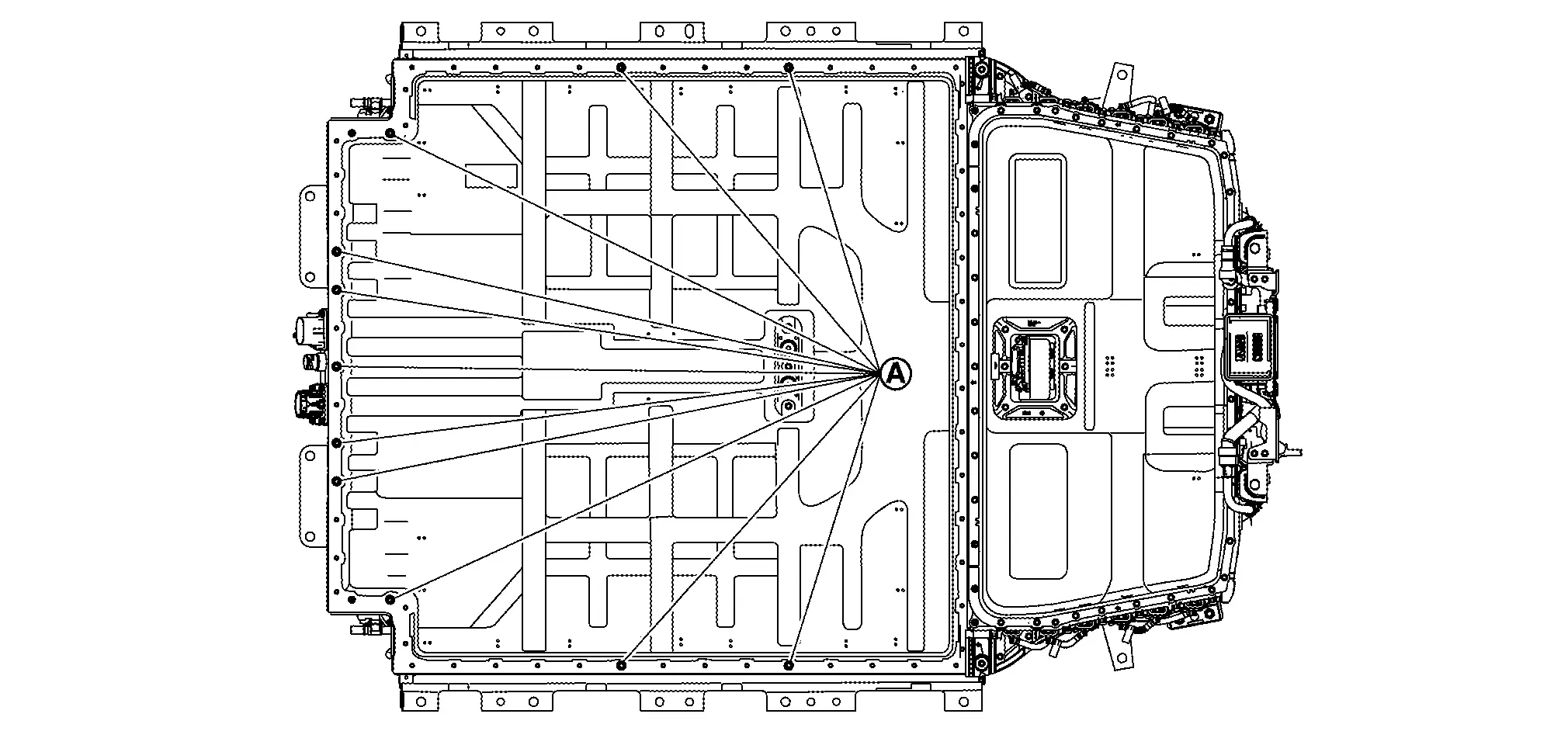

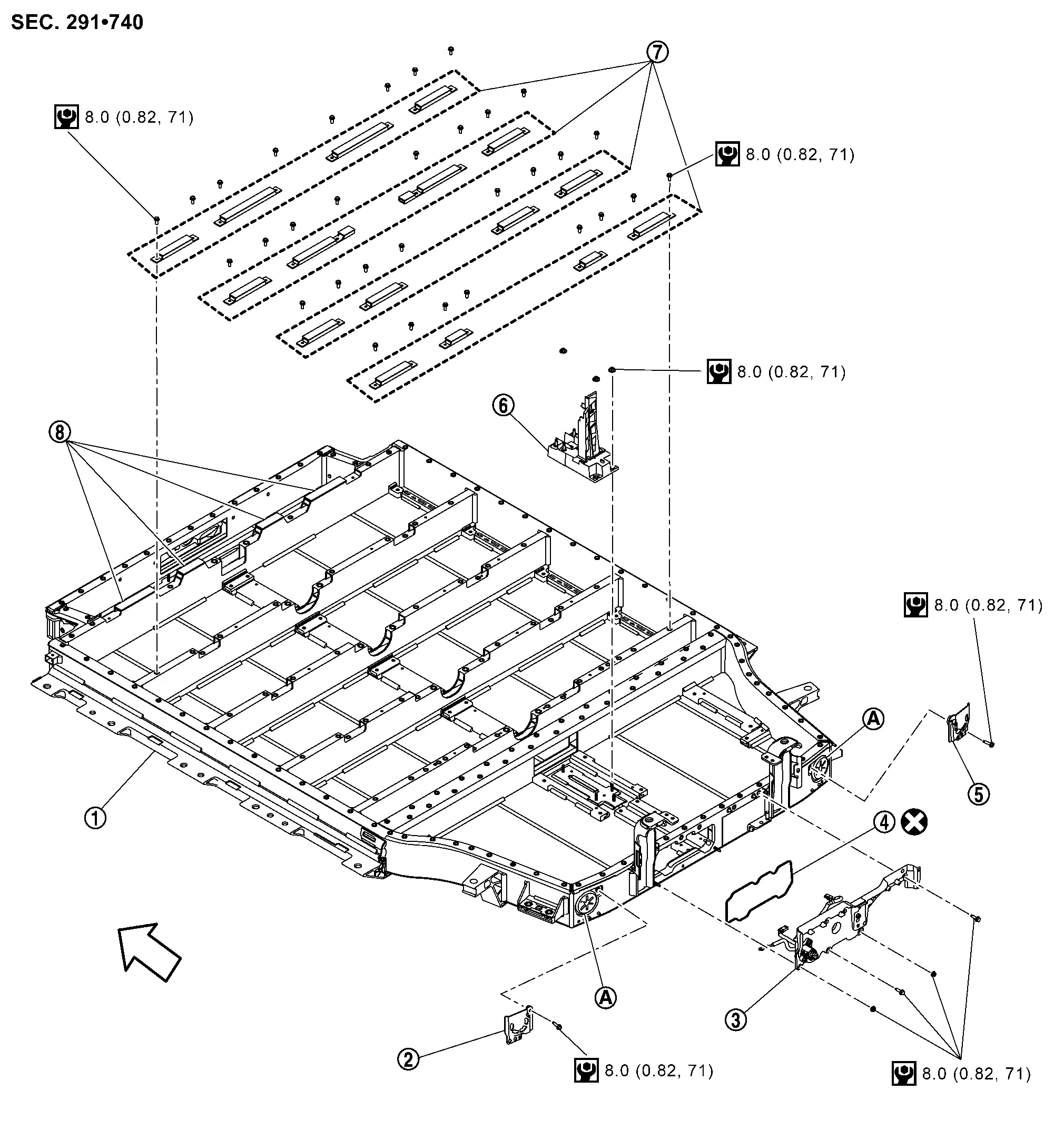

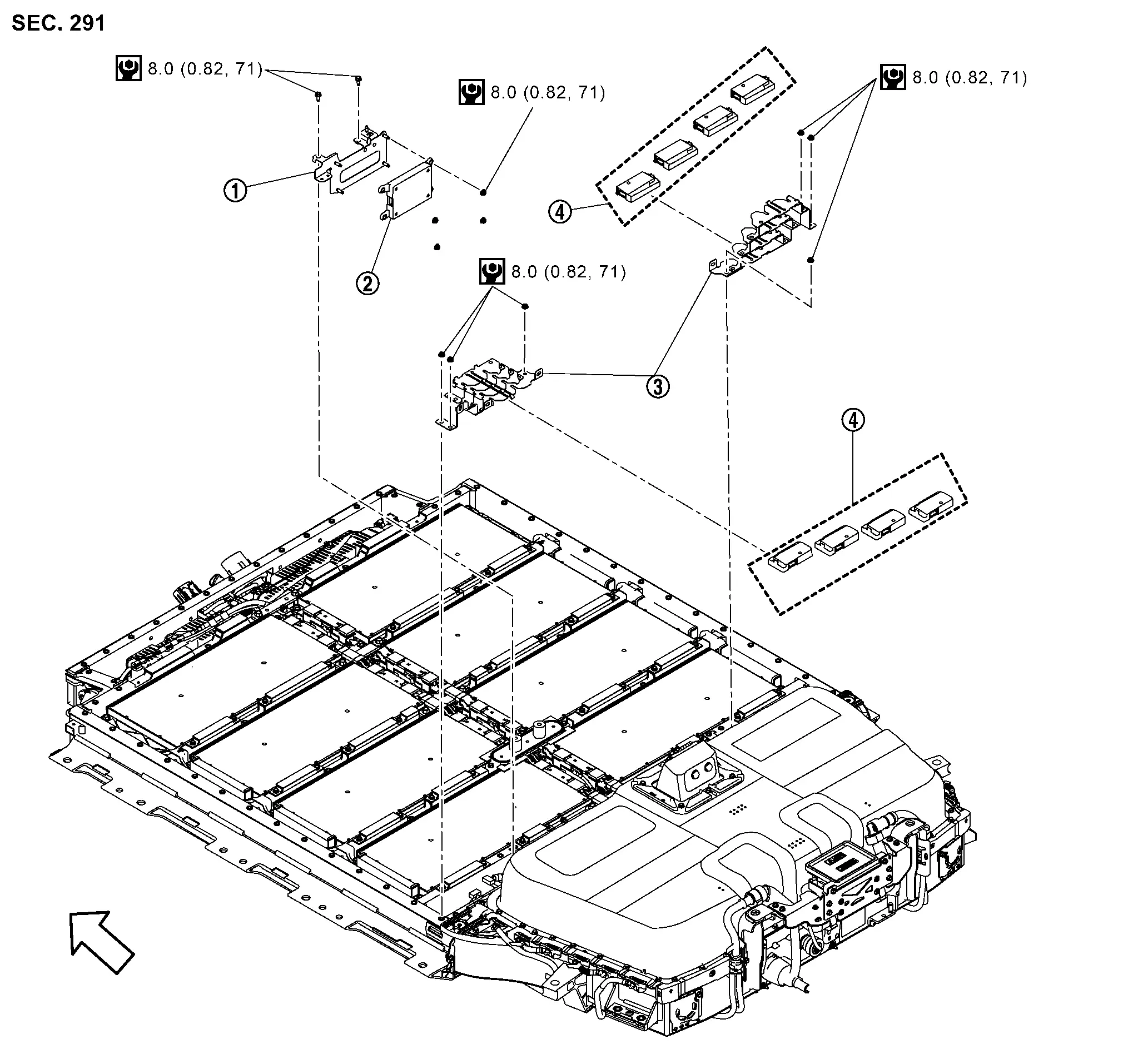

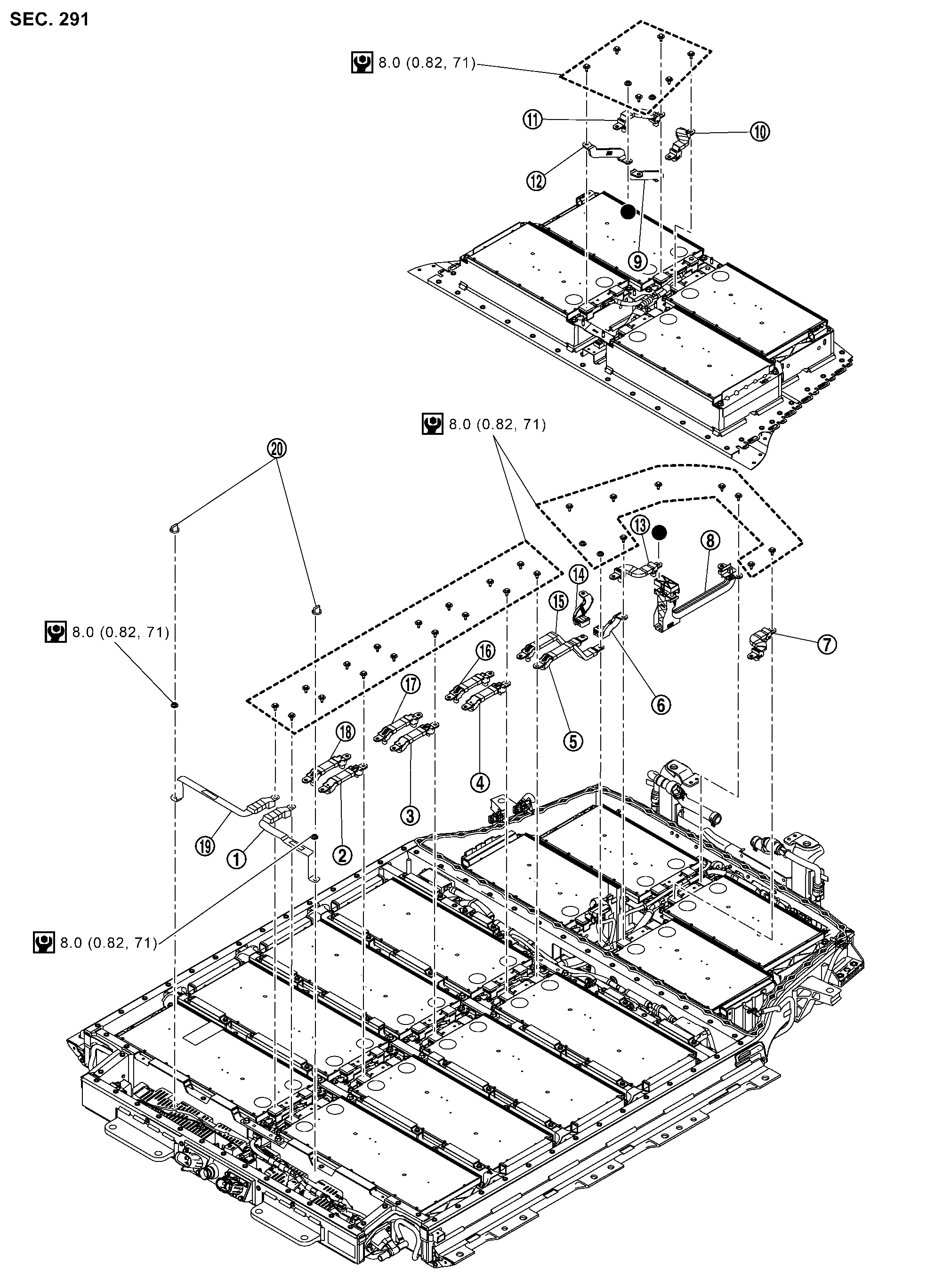

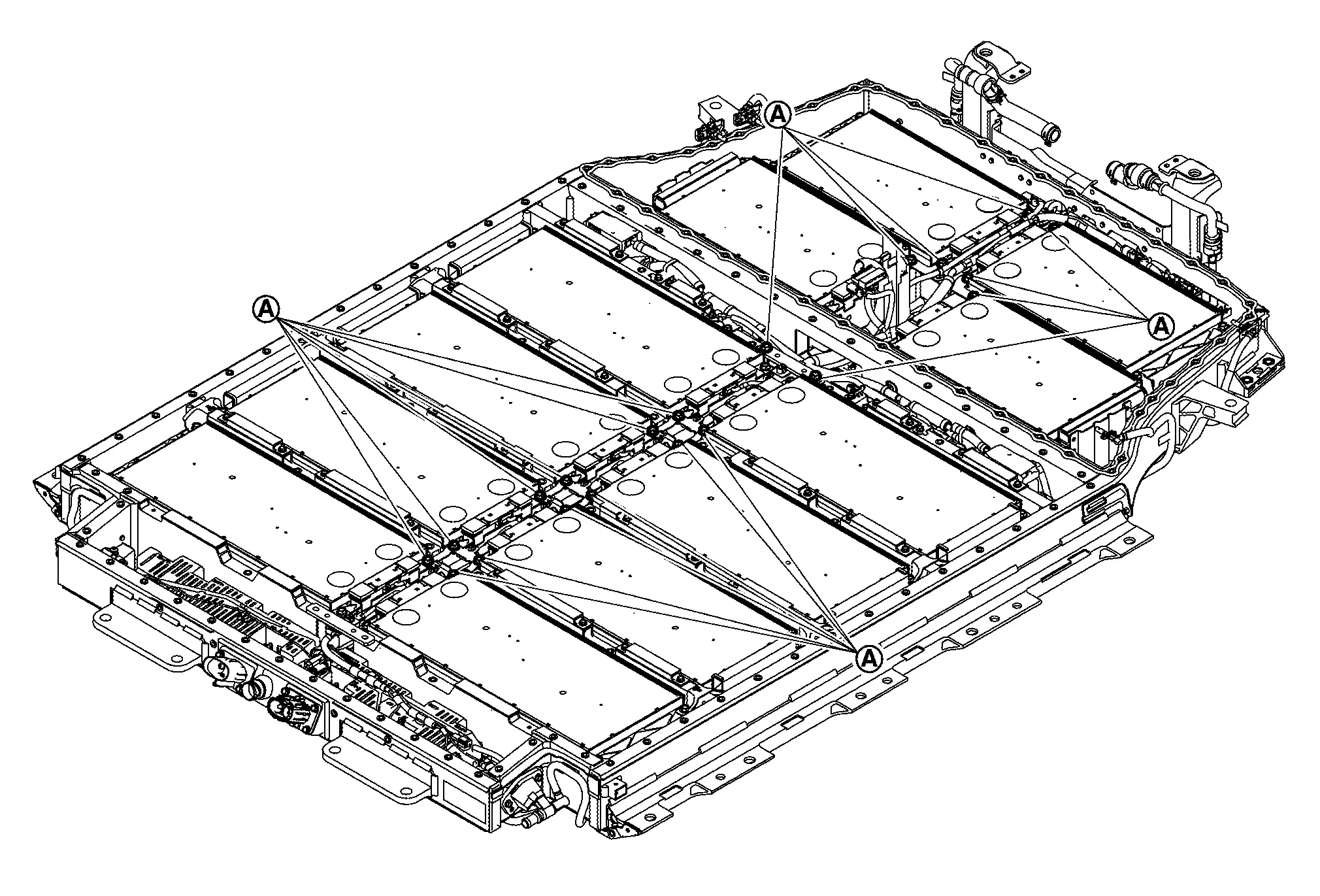

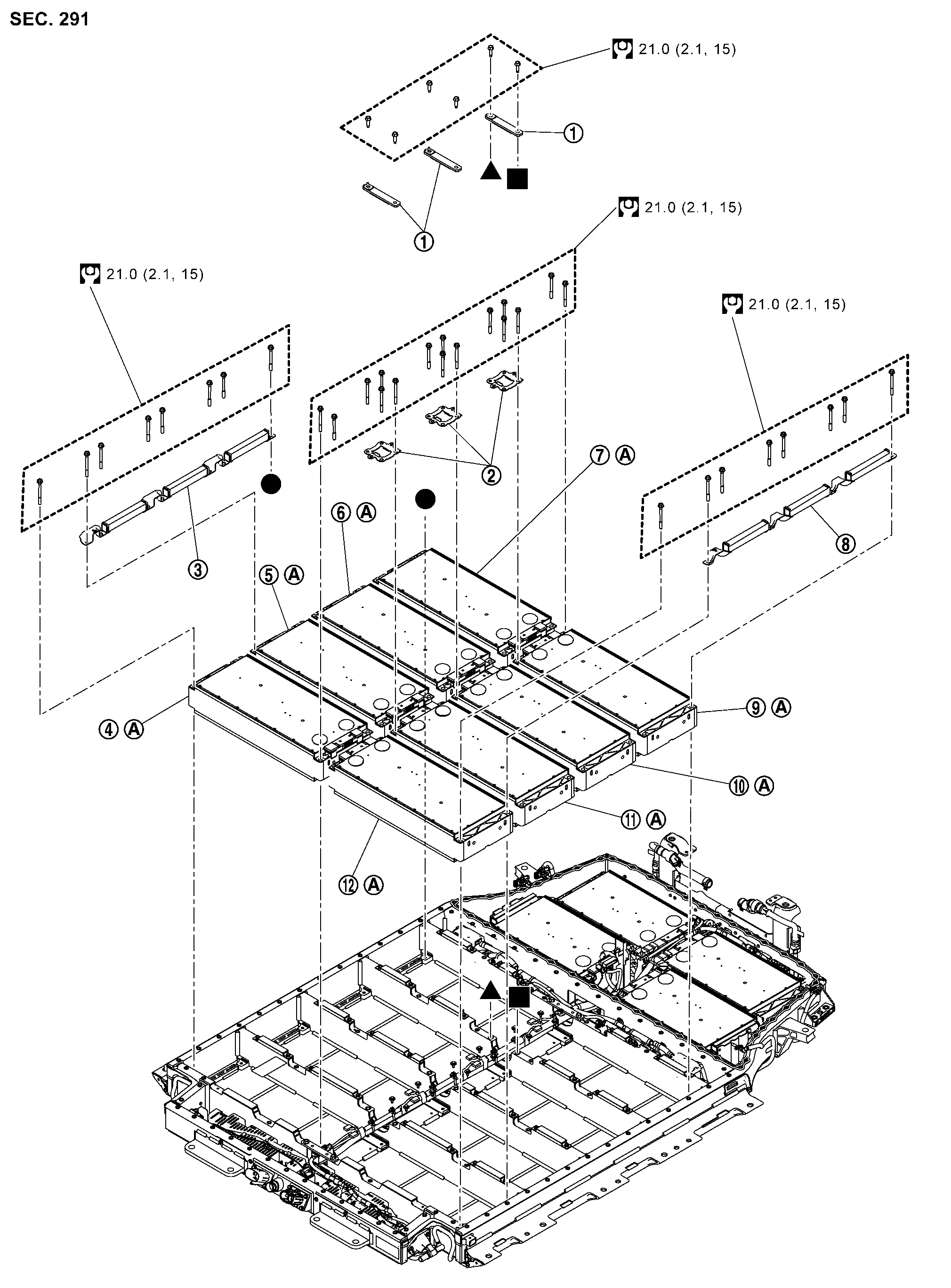

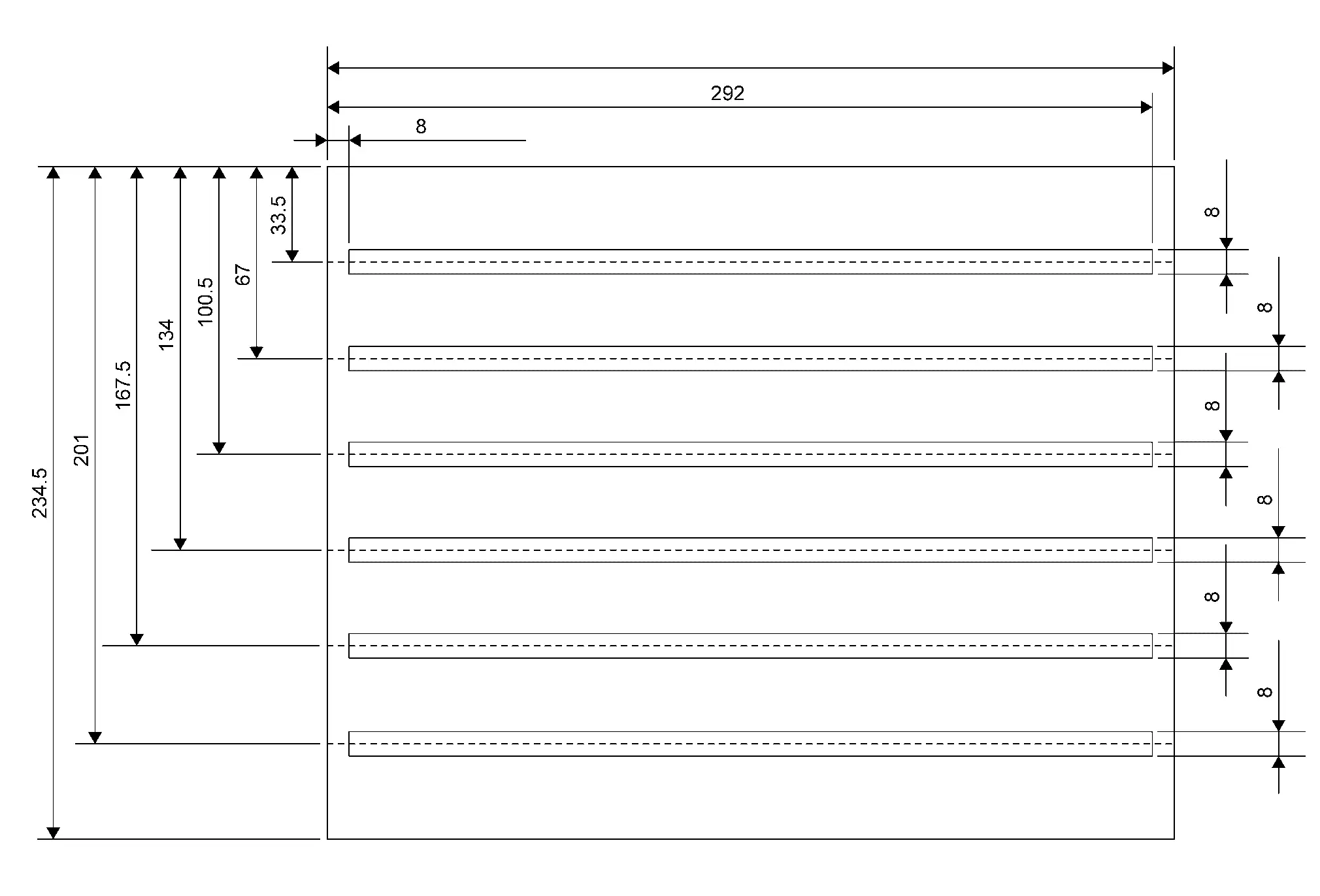

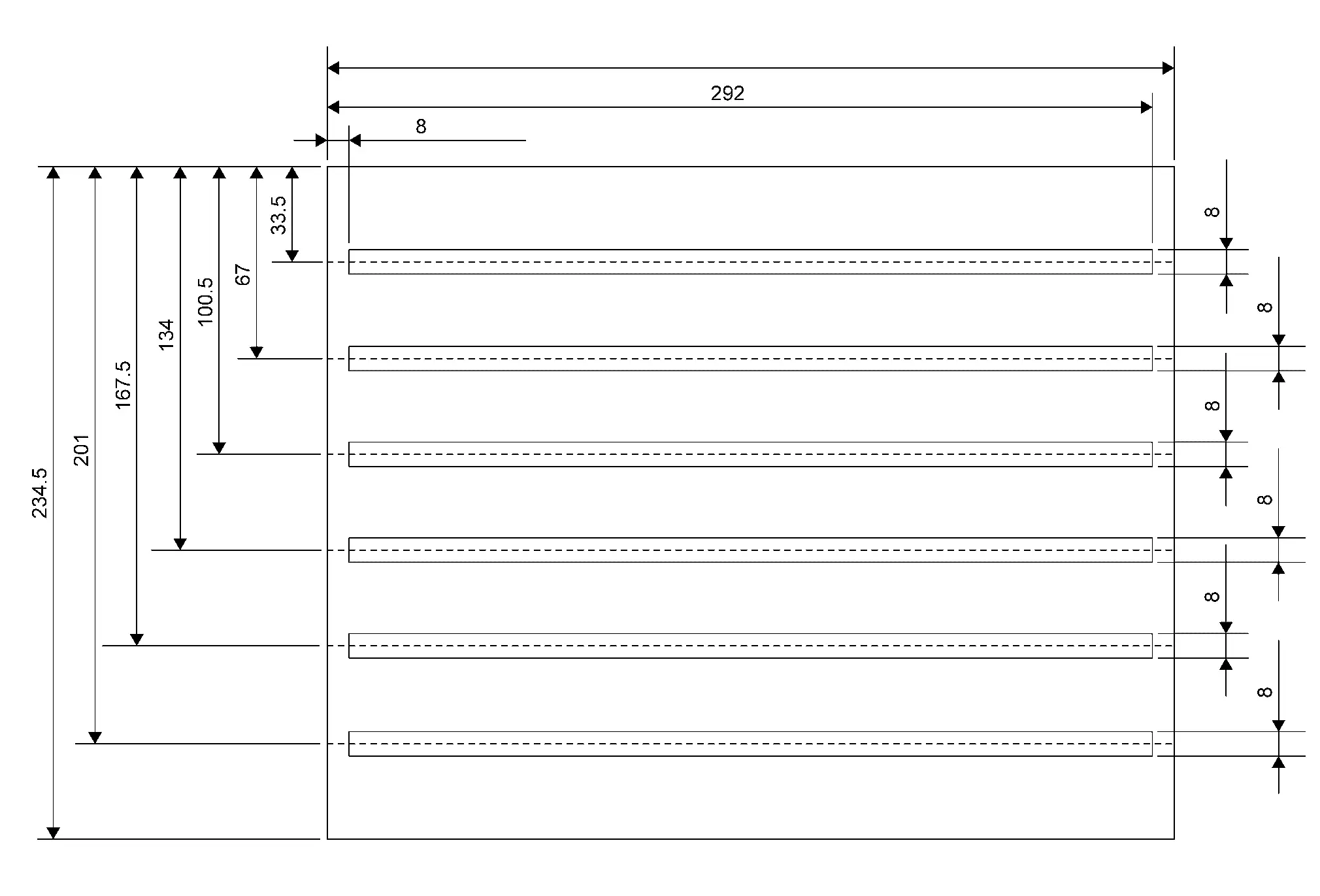

Exploded View

|

Li-ion battery cooler tube (front right) |  |

Li-ion battery cooler tube (front left) |  |

Li-ion battery |

|

Li-ion battery cooler tube 1 (right) |  |

Li-ion battery cooler tube 2 (right) |  |

Li-ion battery cooler tube 3 (right) |

|

Li-ion battery cooler tube 4 (right) |  |

Li-ion battery cooler tube 5 (left) |  |

Li-ion battery cooler tube 6 (left) |

|

Li-ion battery cooler tube 7 (left) |  |

Li-ion battery cooler tube 8 (left) |  |

Li-ion battery cooler tube (rear right) |

|

Li-ion battery cooler tube (rear left) |  |

Li-ion battery cooler tube (rear right) upper |  |

Clamp |

|

Li-ion battery cooler hose (right) |  |

Battery heater |  |

Li-ion battery cooler hose (left) |

|

Li-ion battery cooler tube (rear left) upper |  |

Battery heater bracket 1 |  |

Battery heater bracket 3 |

|

Battery heater bracket 2 |  |

Battery heater bracket 4 | ||

|

: N·m (kg-m, in-lb) | ||||

|

: N·m (kg-m, ft-lb) |

Disassembly & Assembly

DANGER: Because hybrid vehicles and electric vehicles contain a high voltage battery, there is a risk of electric shock, electric leakage, or similar accidents if the Nissan Ariya vehicle is handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

Because hybrid vehicles and electric vehicles contain a high voltage battery, there is a risk of electric shock, electric leakage, or similar accidents if the Nissan Ariya vehicle is handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

WARNING:

-

Be sure to remove the service plug in order to shut off the high voltage circuits before performing inspection or maintenance of high voltage system harnesses and parts.

-

Be sure to put the removed service plug in pocket and carry it or store it in a tool box or other container so that another person does not accidentally connect it while work is in progress.

-

Be sure to put on insulating protective gear before beginning work on the high voltage system.

-

Clearly identify the persons responsible for high voltage work and ensure that other persons do not touch the Nissan Ariya vehicle. When not working, cover high voltage components with an anti-static cover sheet or similar item to prevent contact with other persons.

-

Refer to PRECAUTIONS FOR HIGH VOLTAGE : Precautions.

CAUTION:

There is the possibility of a malfunction occurring if the vehicle is changed to READY status while the service plug is removed. Therefore do not change the Nissan Ariya vehicle to READY status unless instructed to do so in the Service Manual.

WARNING:

Prepare for work on the high-voltage system. Refer to HOW TO DISCONNECT HIGH VOLTAGE : Precautions.

DISASSEMBLY

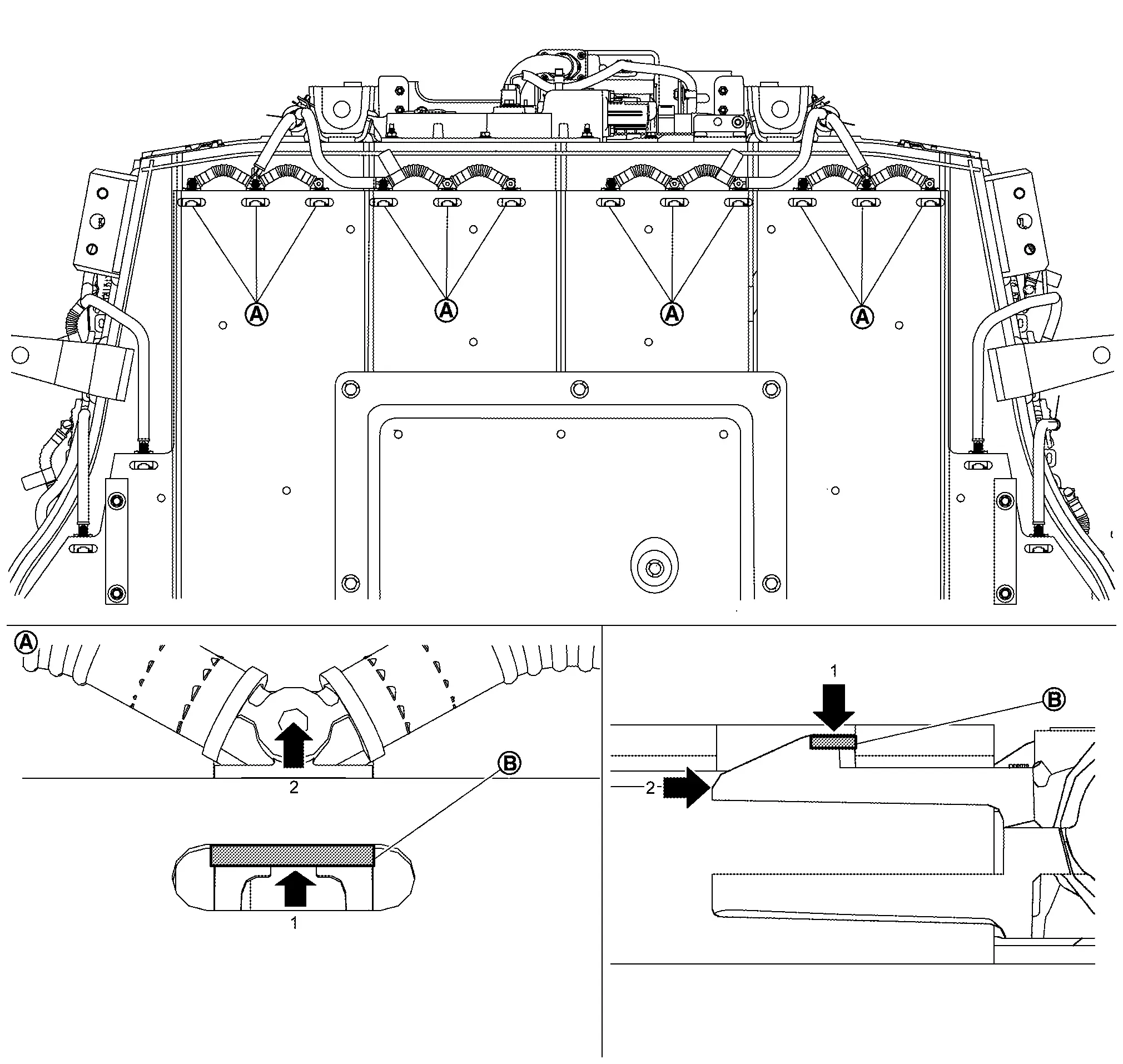

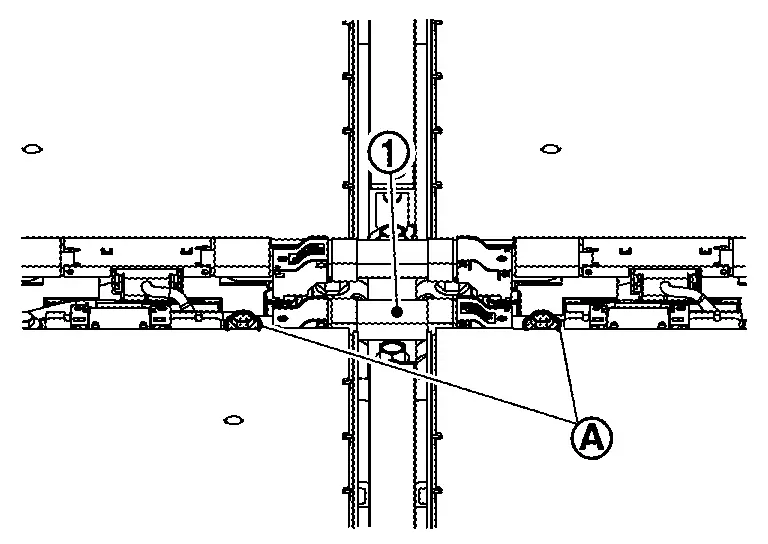

LI-ION BATTERY COOLER TUBE (FRONT)

CAUTION:

If LI-ion battery cooler tube (front) is removed from Li-ion battery, since Li-ion battery cooler tube (front) cannot be reused, replacement is required.

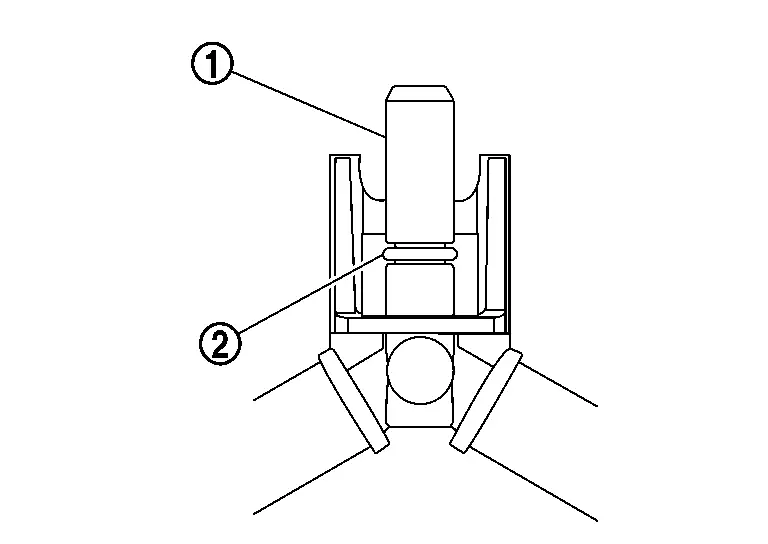

If necessary, remove Li-ion battery cooler tubes (front right and front left).

-

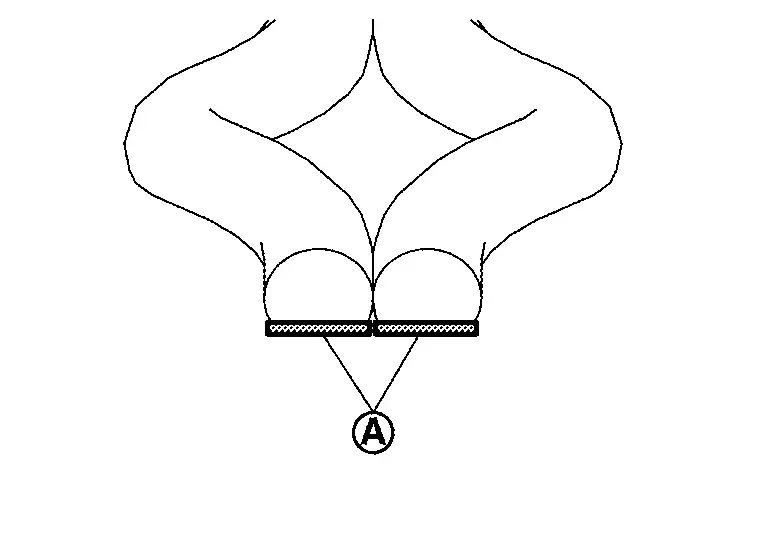

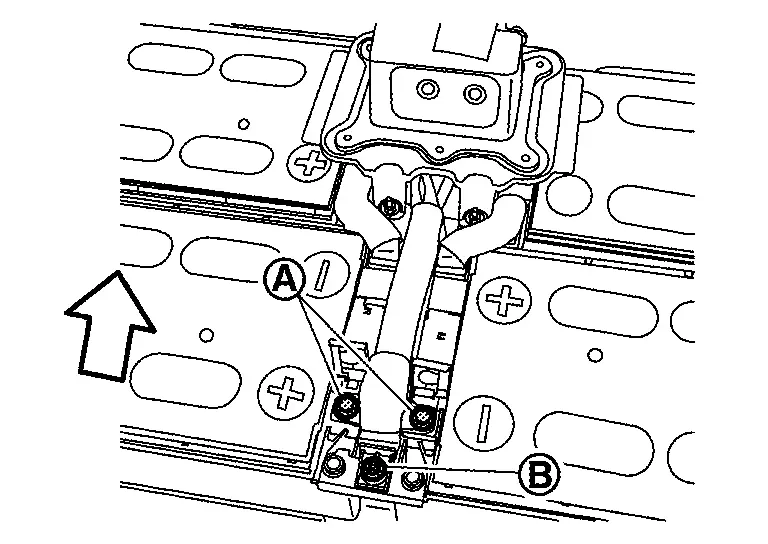

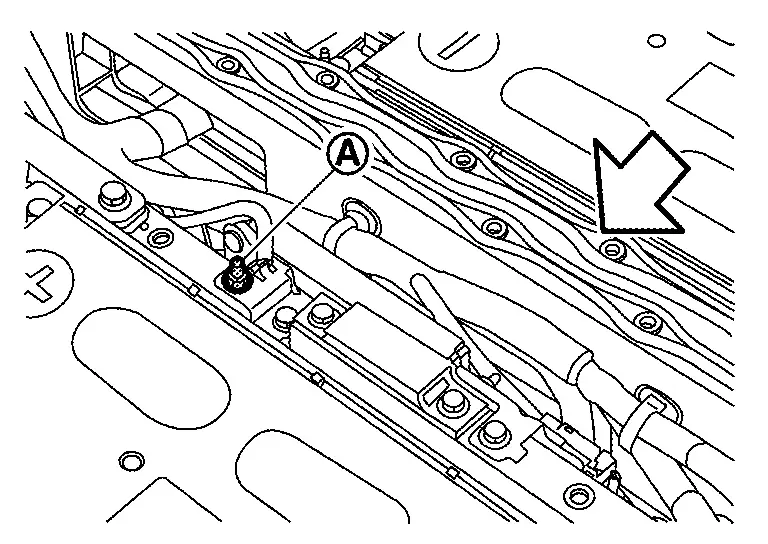

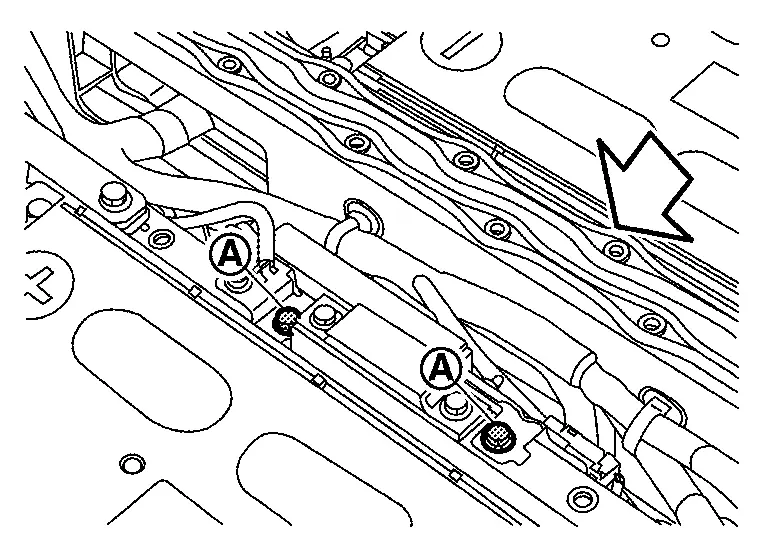

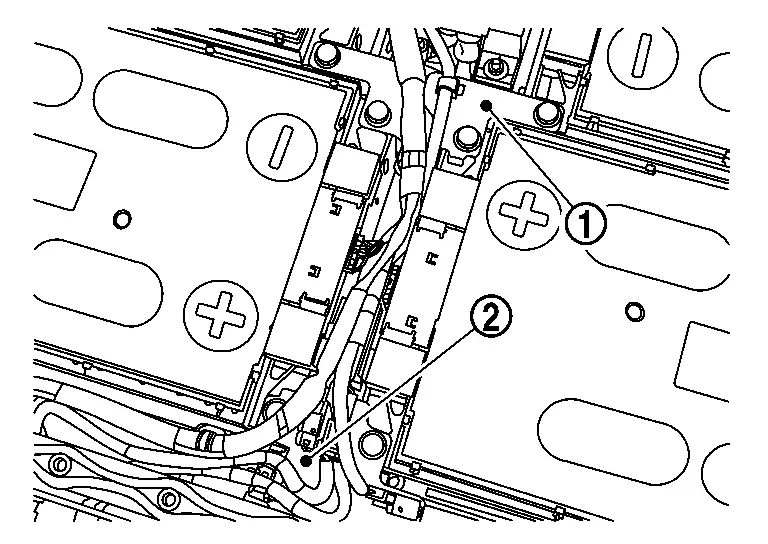

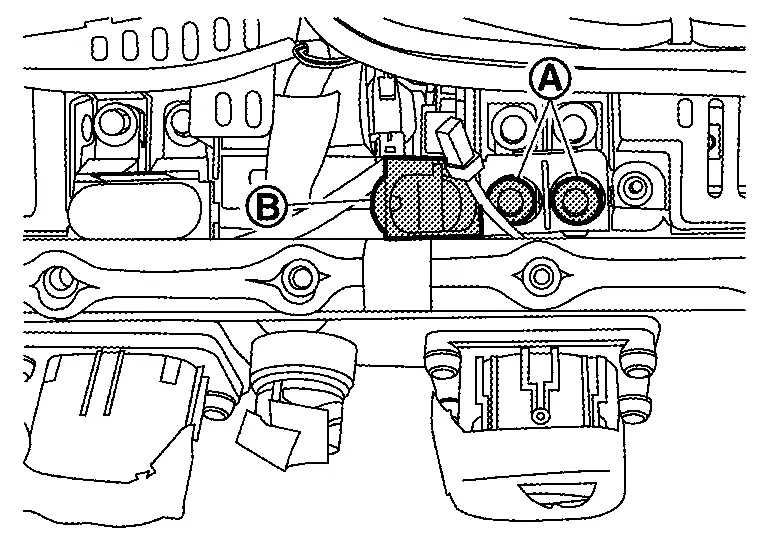

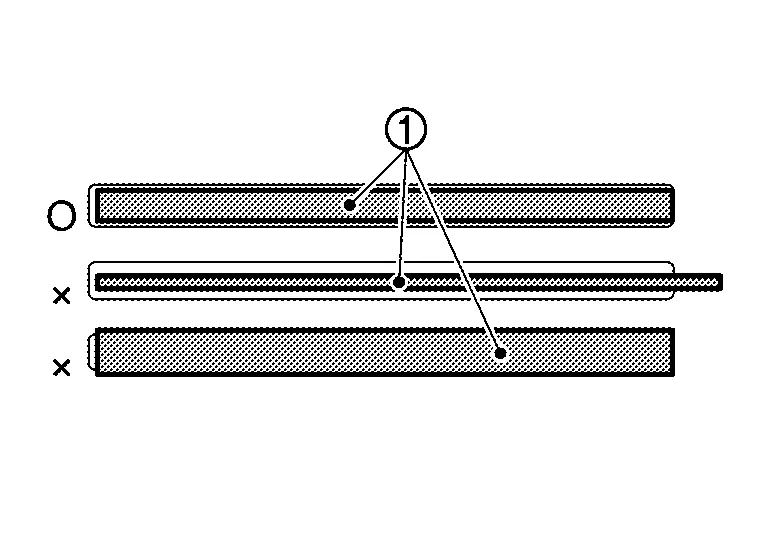

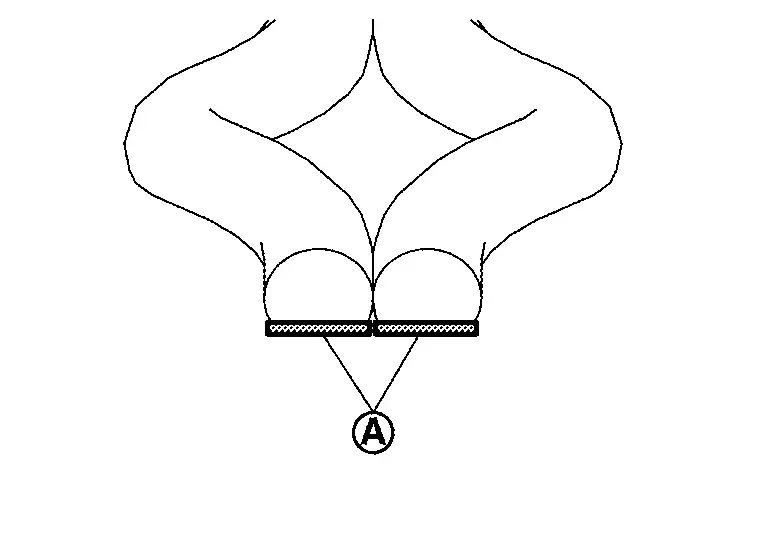

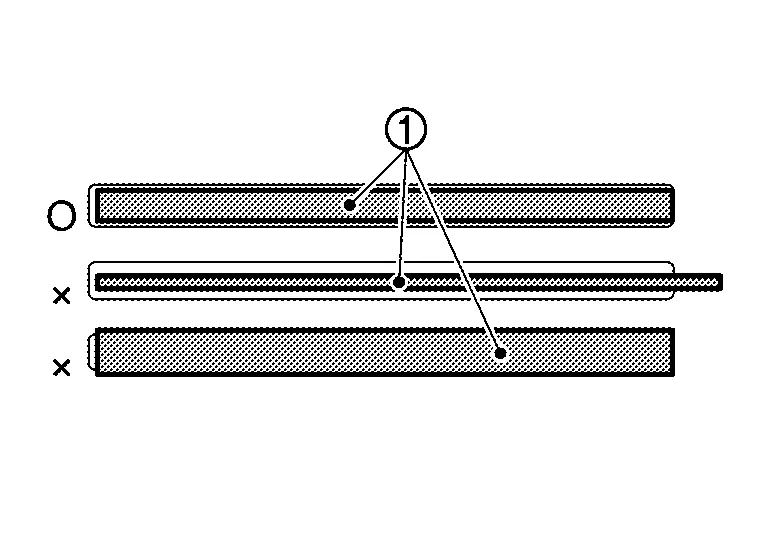

Push claws

of connector on Li-ion battery cooler tubes (front right and front left)

of connector on Li-ion battery cooler tubes (front right and front left)  and remove from the Li-ion battery until all connectors are half-locked.

and remove from the Li-ion battery until all connectors are half-locked.CAUTION:

Li-ion battery cooler tubes (front right and front left) can be removed individually one by one and does not need to be removed together.

-

Remove mounting bolts of Li-ion battery cooler tubes (front right

and front left

and front left  ).

).CAUTION:

Li-ion battery cooler tubes (front right and front left) can be removed individually one by one and does not need to be removed together.

-

Remove Li-ion battery cooler tubes (front right and front left) from Li-ion battery.

CAUTION:

-

Li-ion battery cooler tubes (front right and front left) can be removed individually one by one and does not need to be removed together.

-

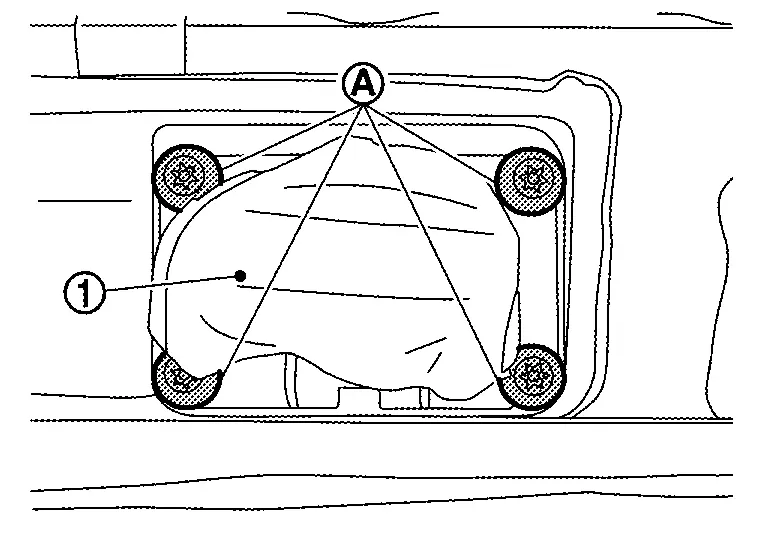

If the collar

and O-ring

and O-ring  at the end of connector remain in the Li-ion battery while removing Li-ion battery cooler tubes (front right and front left) from Li-ion battery, take them out.

at the end of connector remain in the Li-ion battery while removing Li-ion battery cooler tubes (front right and front left) from Li-ion battery, take them out.

-

LI-ION BATTERY COOLER TUBE (REAR)

CAUTION:

If LI-ion battery cooler tube (rear) is removed from Li-ion battery, since Li-ion battery cooler tube (rear) cannot be reused, replacement is required.

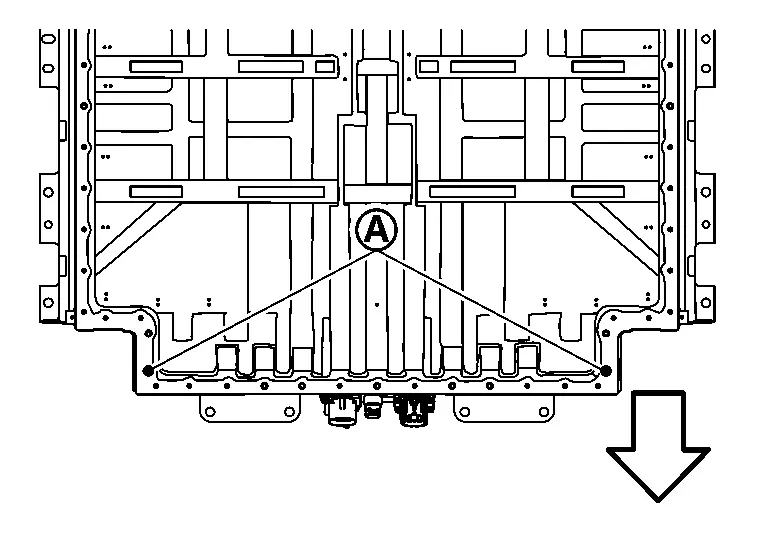

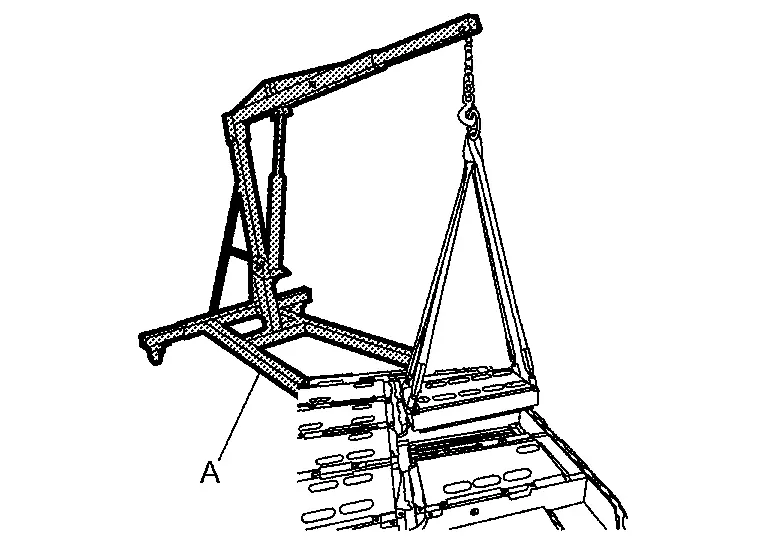

Remove Li-ion battery. Refer to Removal & Installation.

If necessary, remove Li-ion battery cooler tubes (rear right and rear left).

-

Remove Li-ion battery cooler tubes (rear right and rear left) from Li-ion battery cooler tube (rear right and rear left) uppers, respectively.

CAUTION:

Li-ion battery cooler tubes (rear right and rear left) can be removed individually one by one and does not need to be removed together.

-

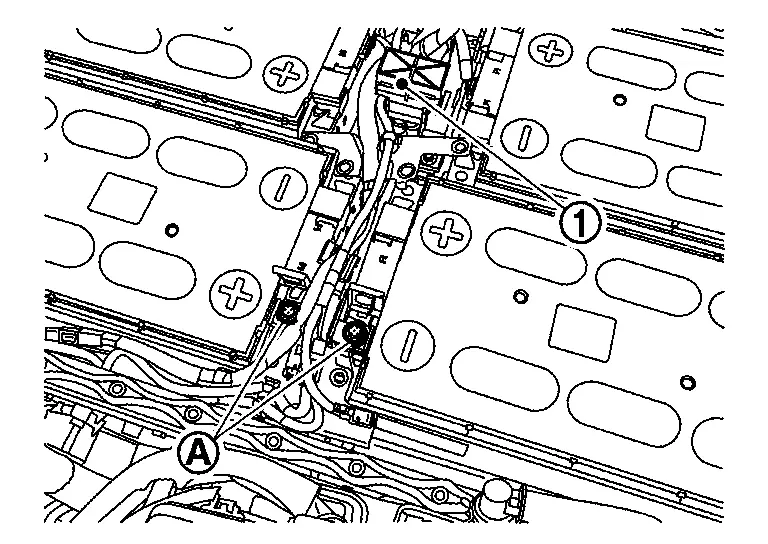

Push claws

of connector on Li-ion battery cooler tubes (rear right and rear left)

of connector on Li-ion battery cooler tubes (rear right and rear left)  and remove from Li-ion battery until all connectors are half-locked.

and remove from Li-ion battery until all connectors are half-locked.CAUTION:

Li-ion battery cooler tubes (rear right and rear left) can be removed individually one by one and does not need to be removed together.

-

Remove Li-ion battery cooler tubes (rear right and rear left) from Li-ion battery.

CAUTION:

-

Li-ion battery cooler tubes (rear right and rear left) can be removed individually one by one and does not need to be removed together.

-

If the collar

and O-ring

and O-ring  at the end of connector remain in the Li-ion battery while removing Li-ion battery cooler tubes (rear right and rear left) from Li-ion battery, take them out.

at the end of connector remain in the Li-ion battery while removing Li-ion battery cooler tubes (rear right and rear left) from Li-ion battery, take them out.

-

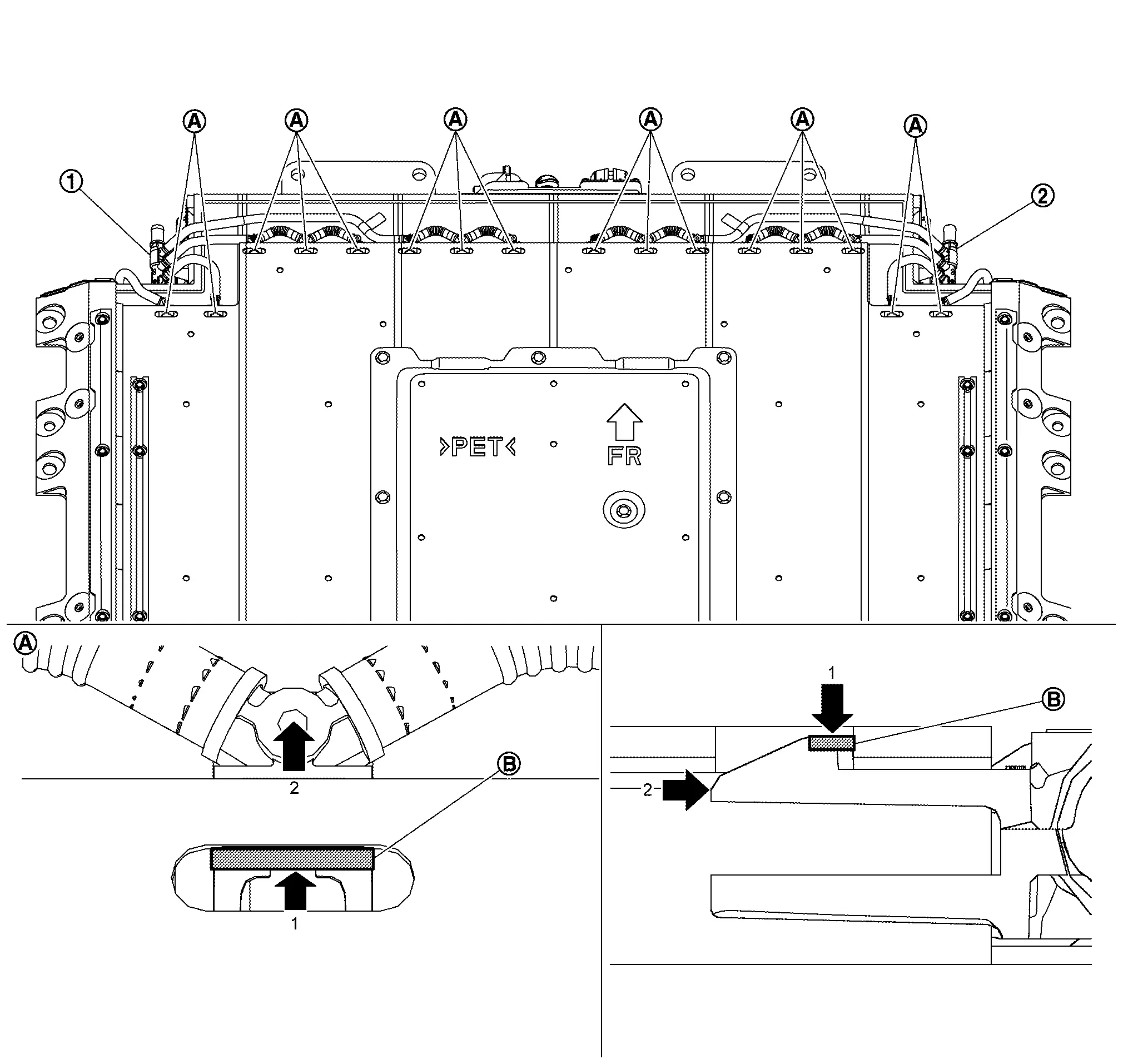

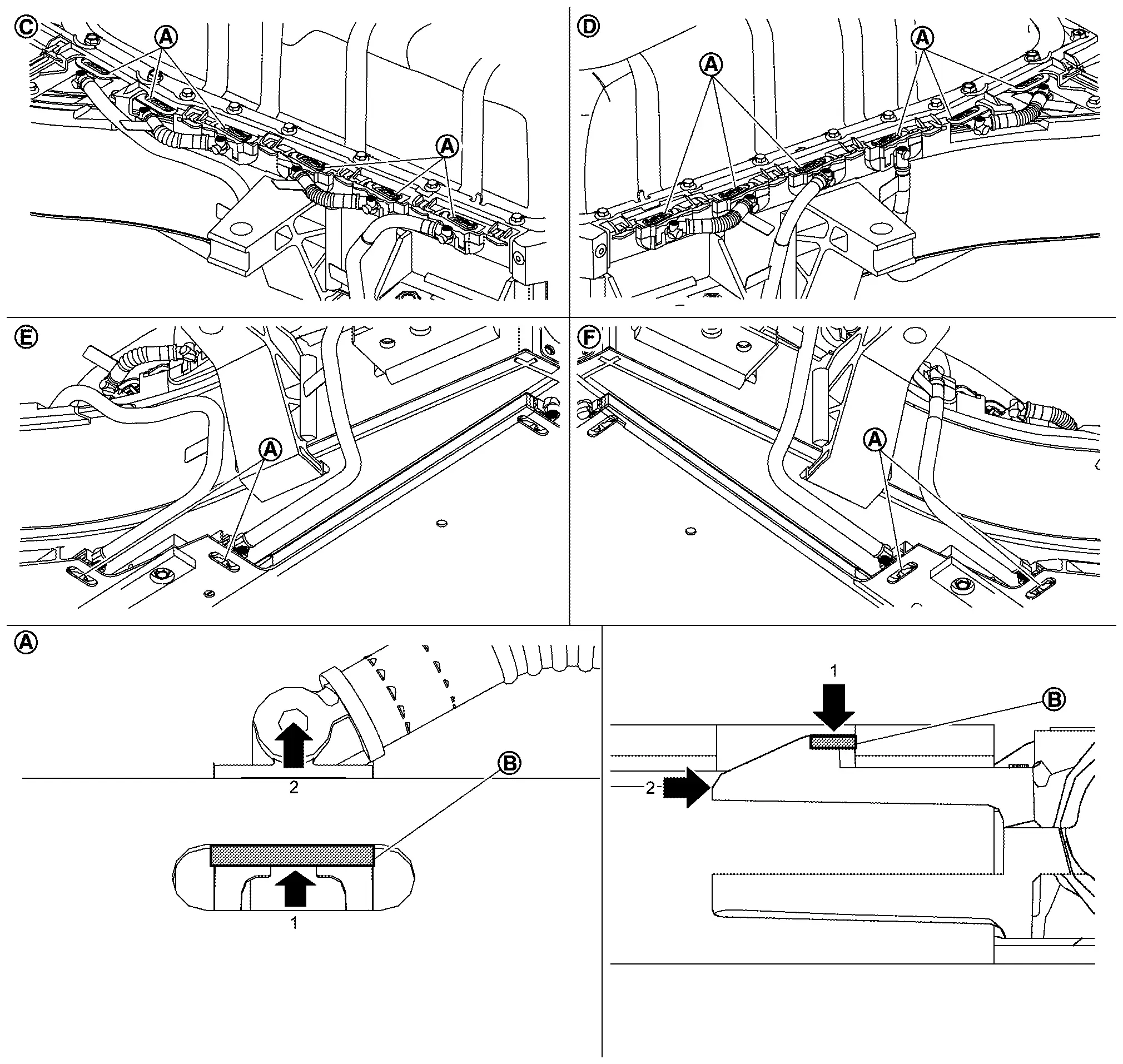

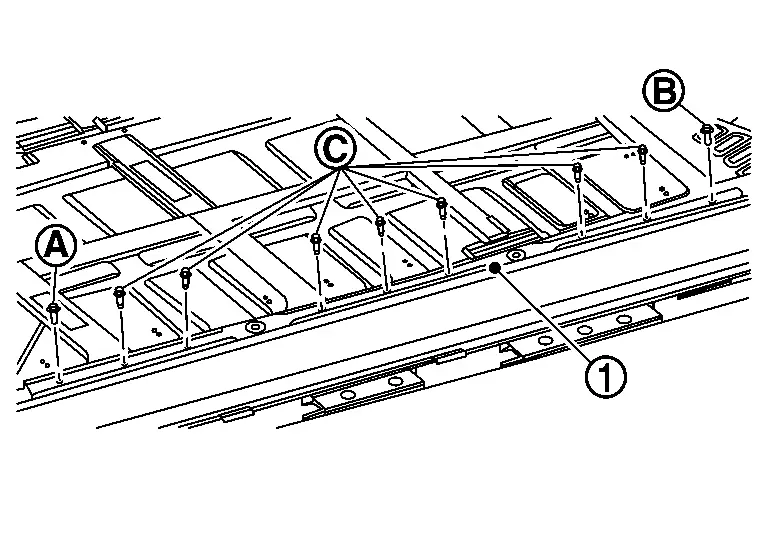

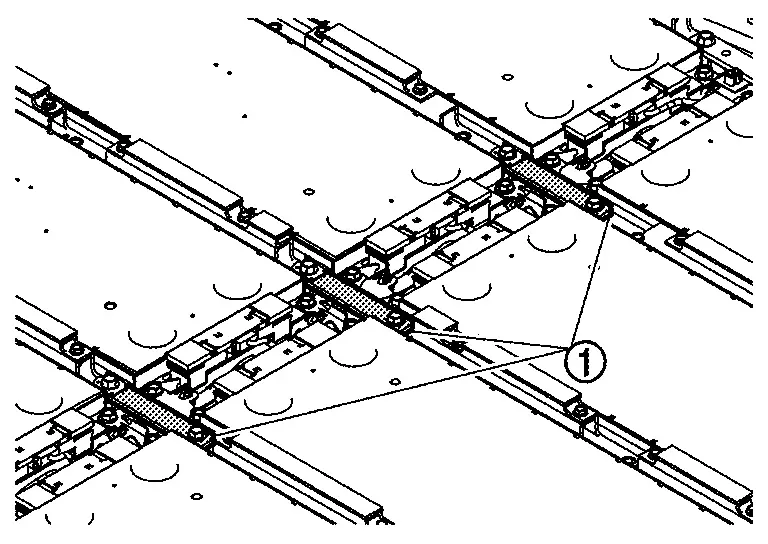

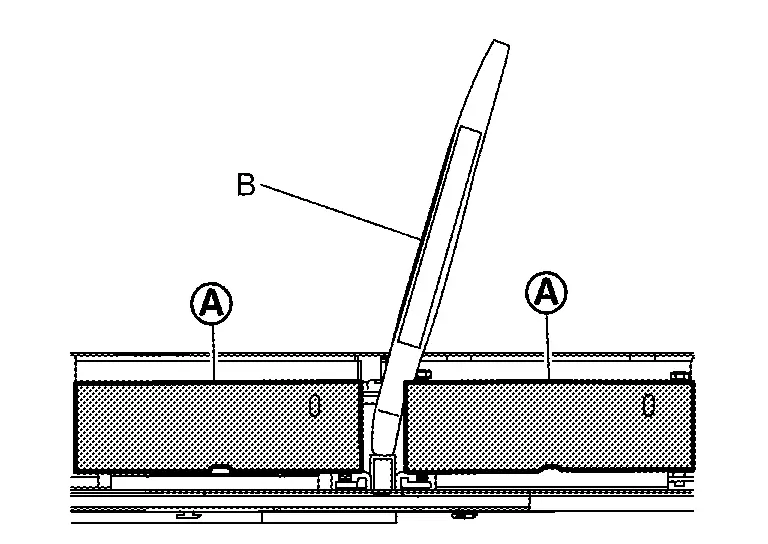

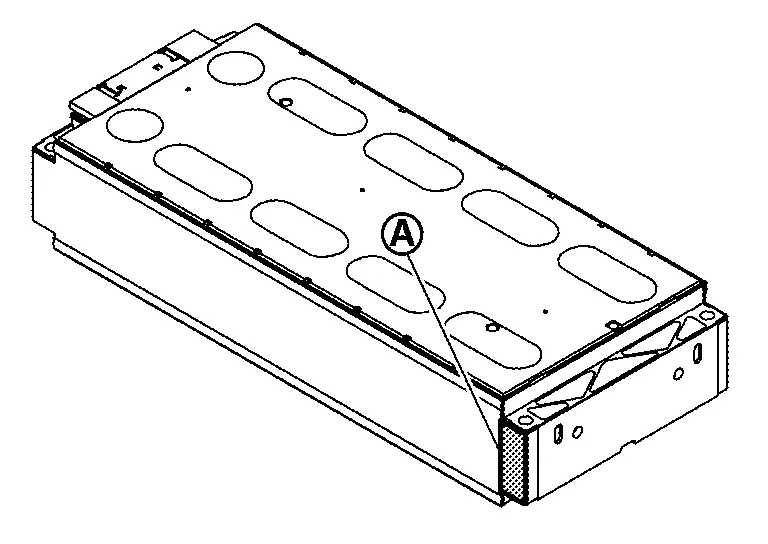

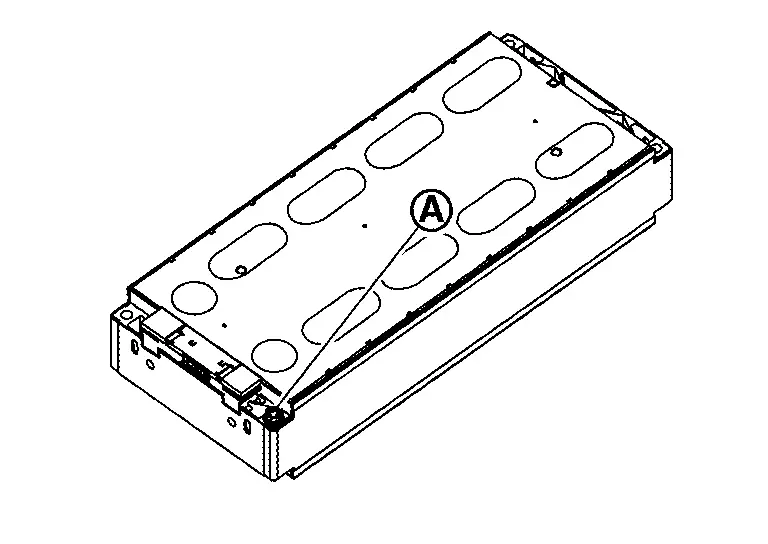

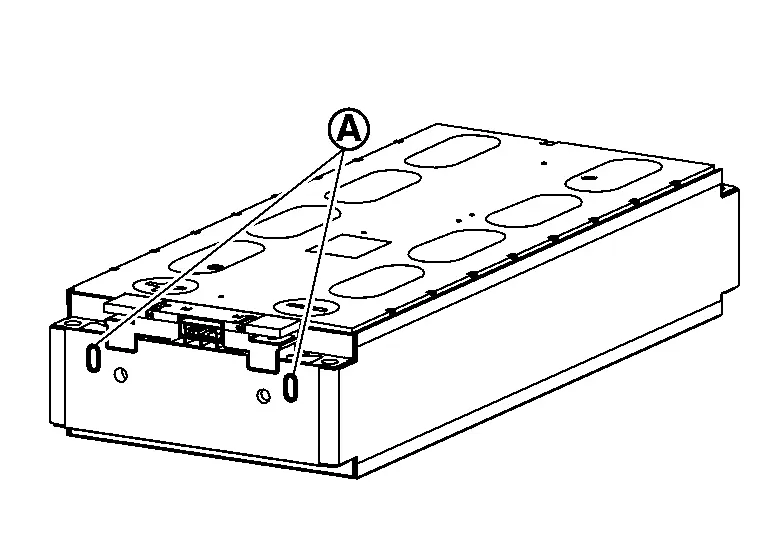

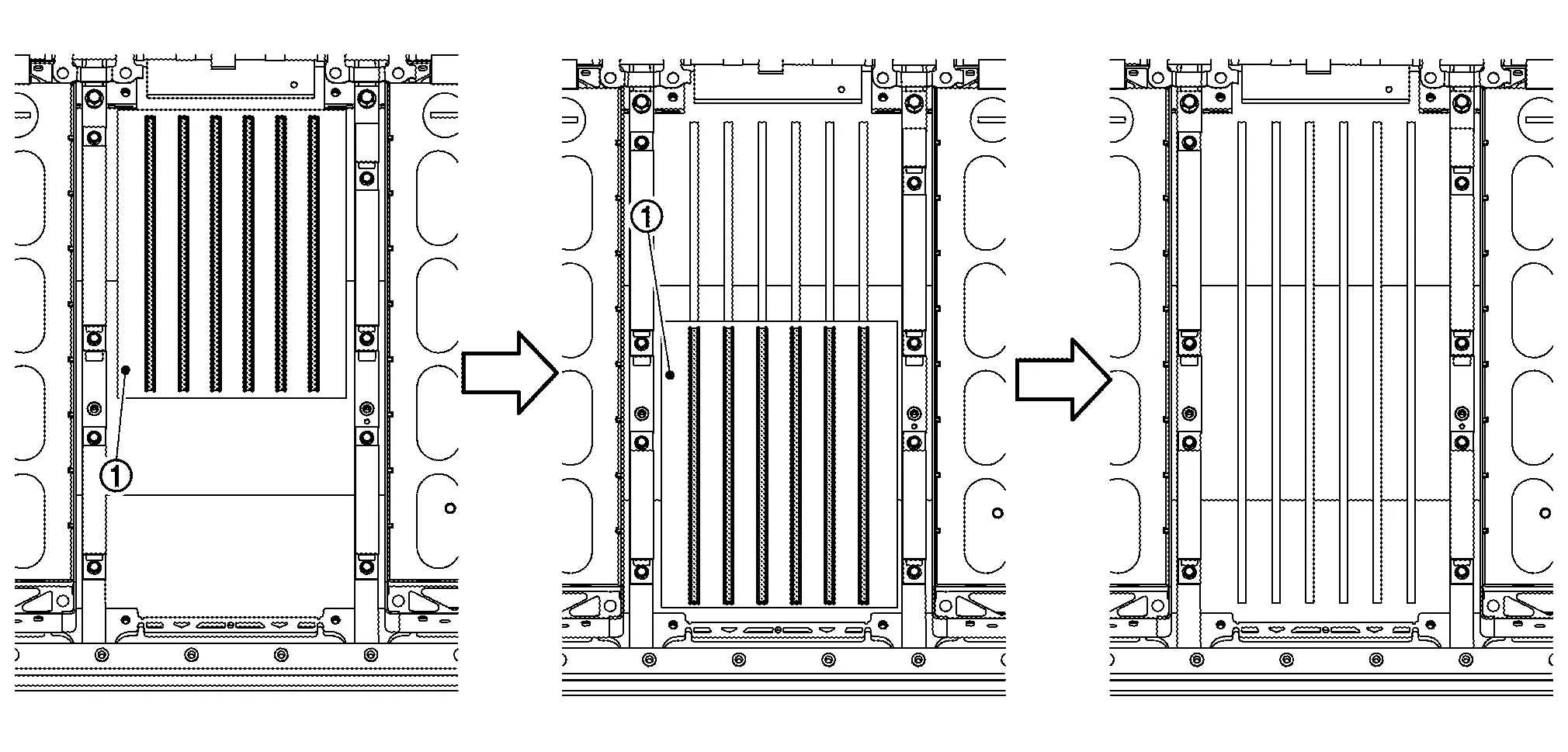

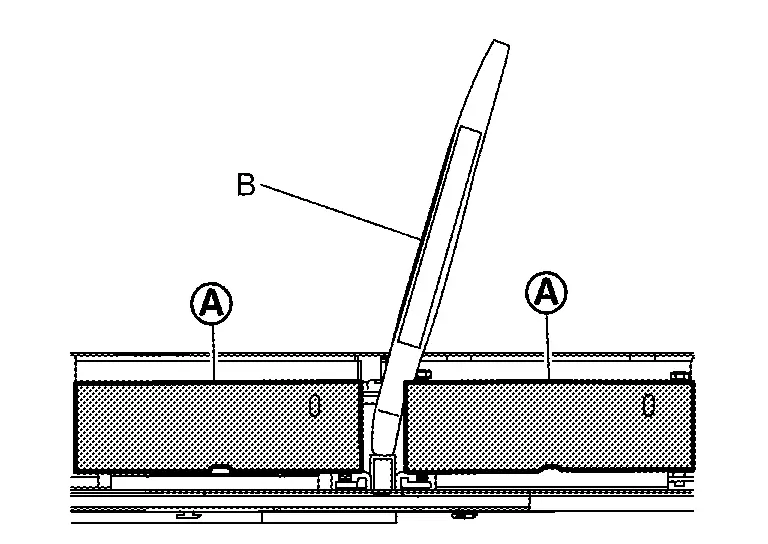

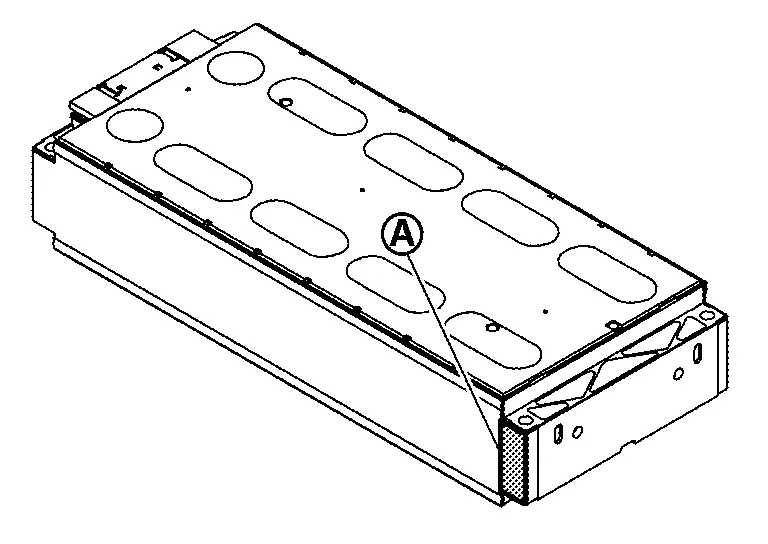

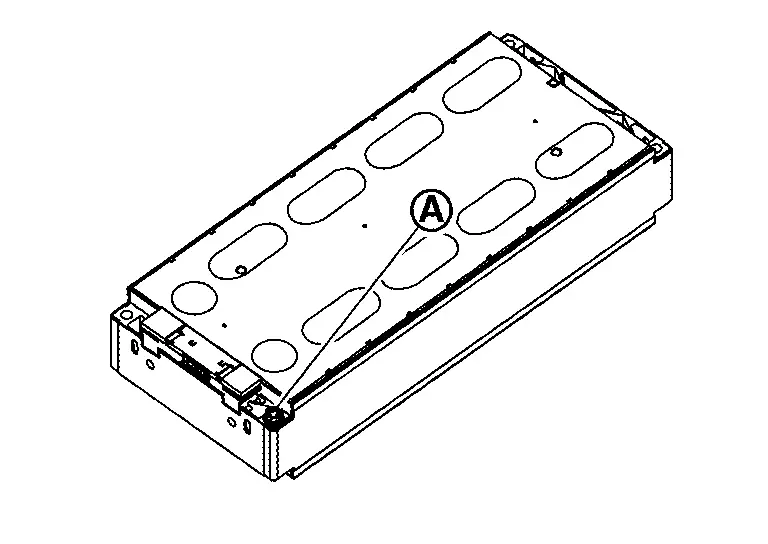

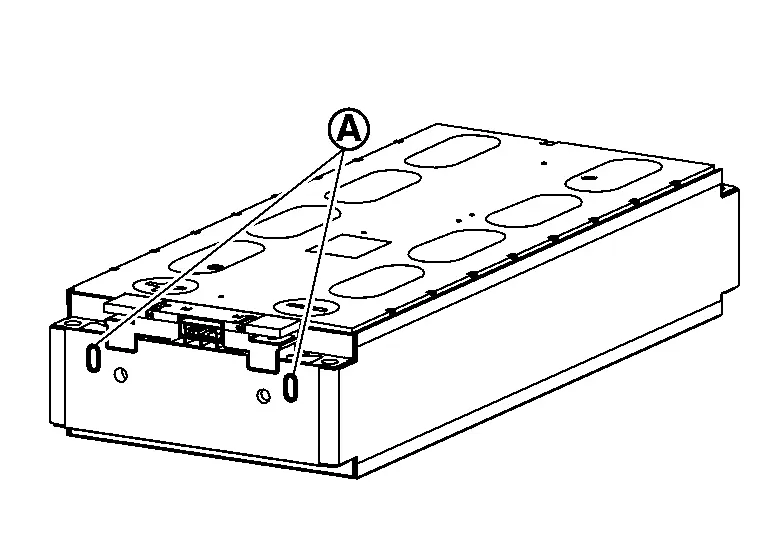

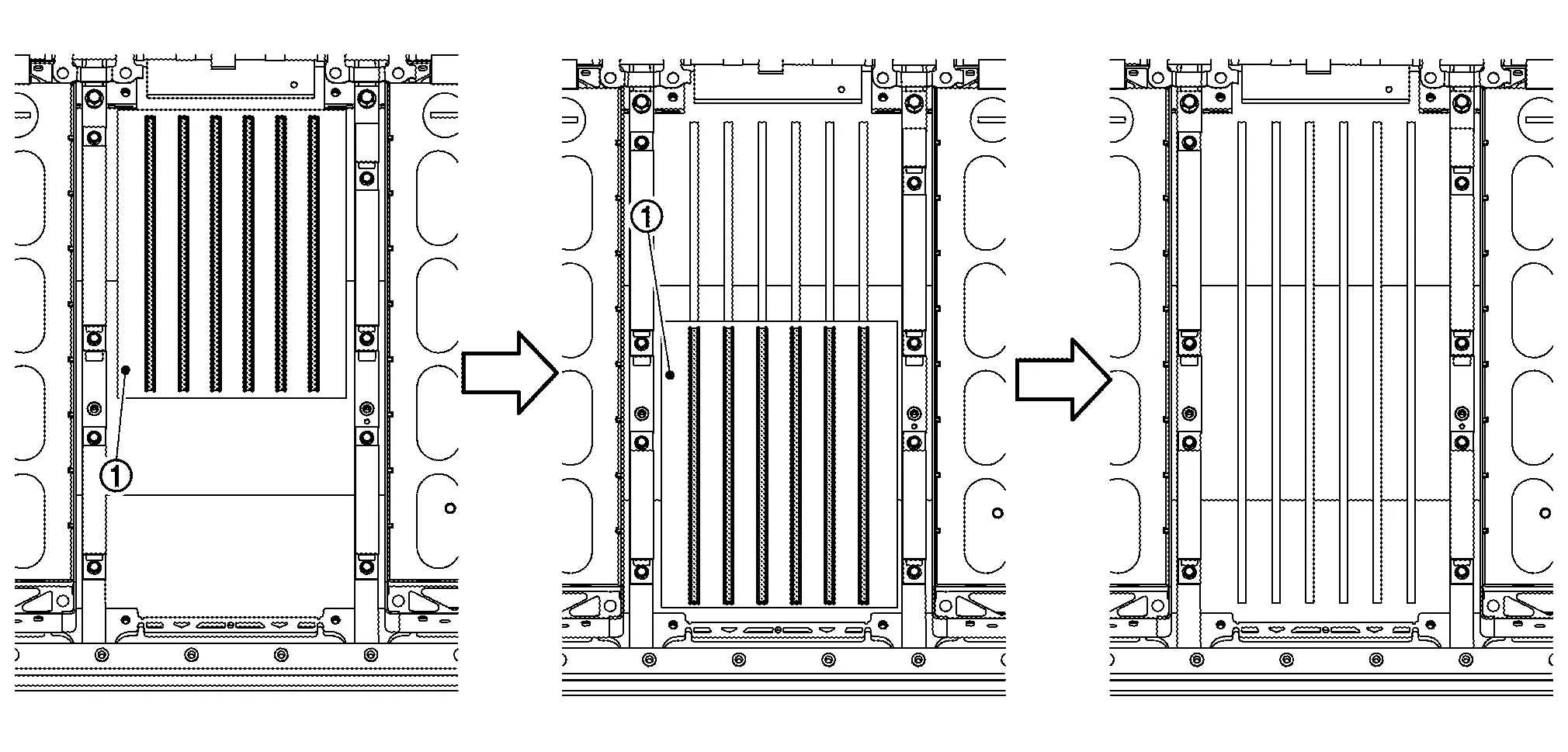

LI-ION BATTERY COOLER 1-4 (RIGHT), LI-ION BATTERY COOLER 5-8 (LEFT)

CAUTION:

Do not reuse the Li-ion battery cooler tube 1-4 (right) and Li-ion battery cooler tube 5-8 (left) when it was removed from the battery pack.

Remove Li-ion battery. Refer to Removal & Installation.

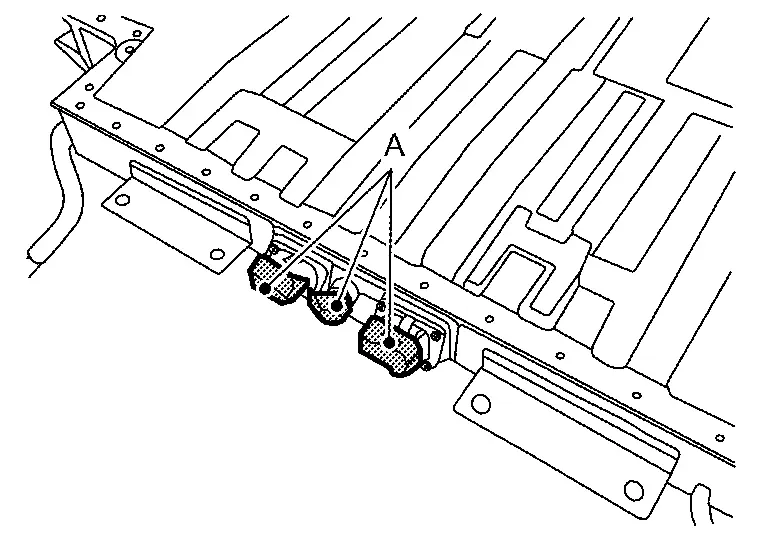

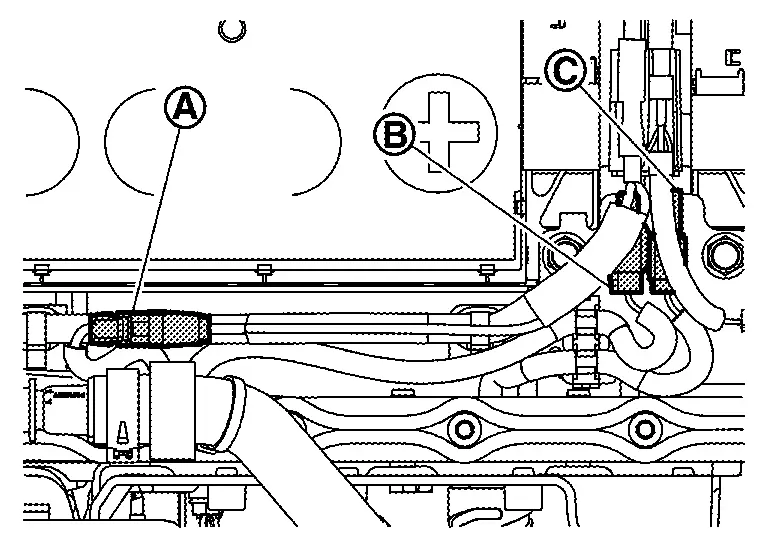

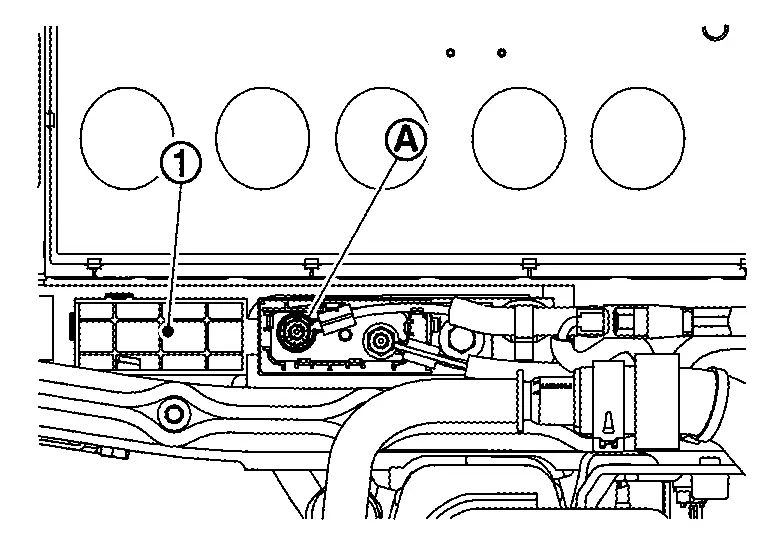

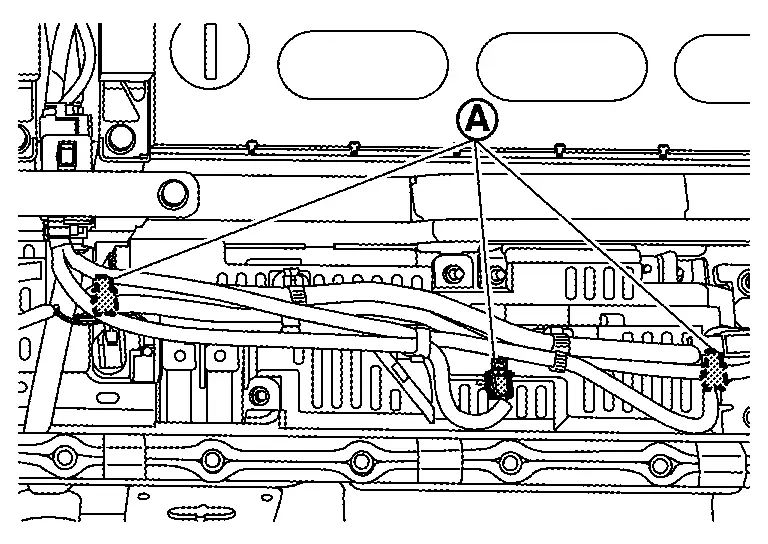

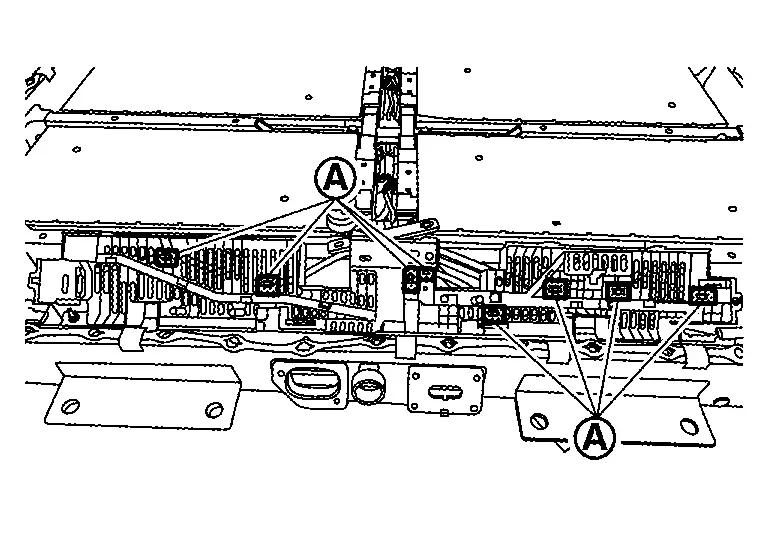

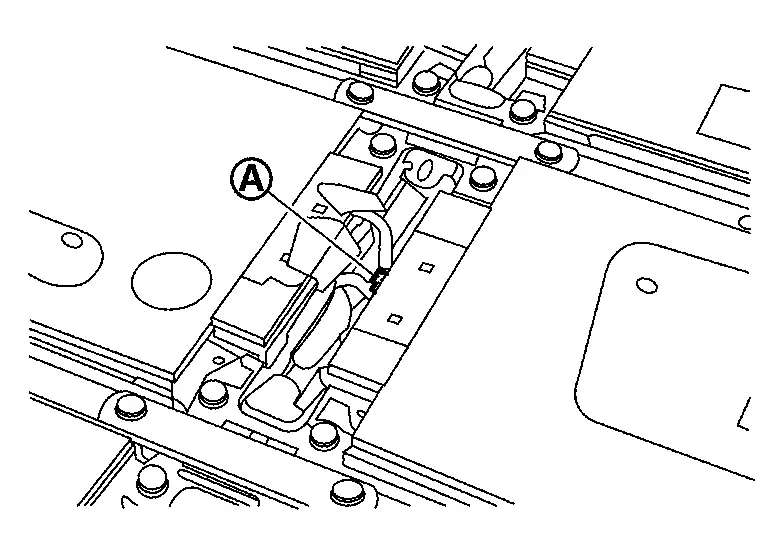

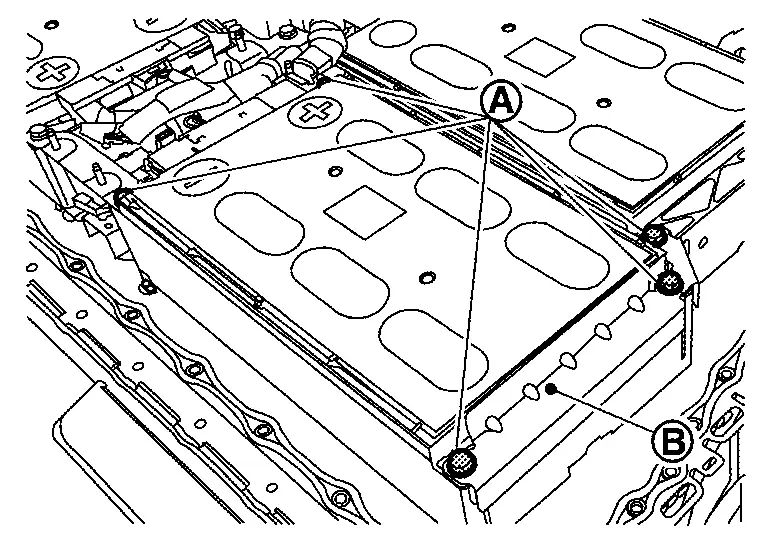

Remove Li-ion battery cooler tube 1-4 (right) and Li-ion battery cooler tube 5-8 (left).Push claws  of connector

of connector  on Li-ion battery cooler tubes and then remove from the Li-ion battery until all connectors are half-locked.

on Li-ion battery cooler tubes and then remove from the Li-ion battery until all connectors are half-locked.

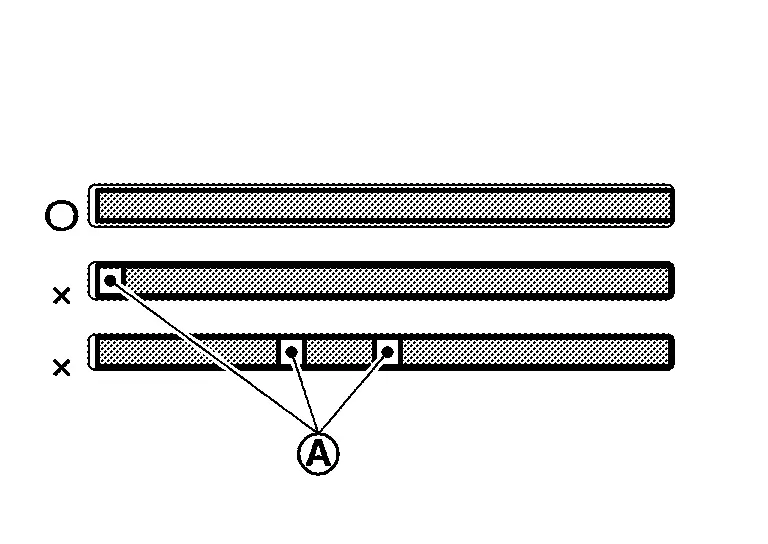

|

Left side |

|

Right side |

|

Left bottom |

|

Right bottom |

Cooler tubes from Li-ion battery.

CAUTION:

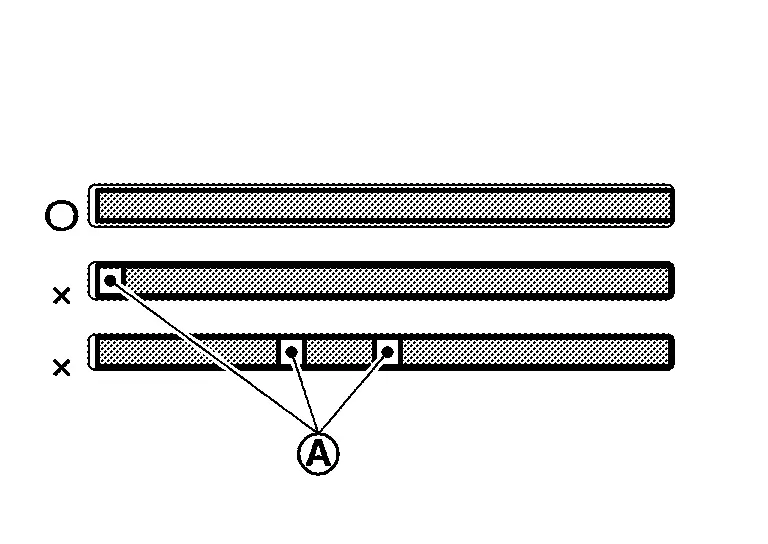

If the collar  and O-ring

and O-ring  at the end of connector remain in the Li-ion battery while removing Li-ion battery cooler tubes (front right and front left) from Li-ion battery, take them out.

at the end of connector remain in the Li-ion battery while removing Li-ion battery cooler tubes (front right and front left) from Li-ion battery, take them out.

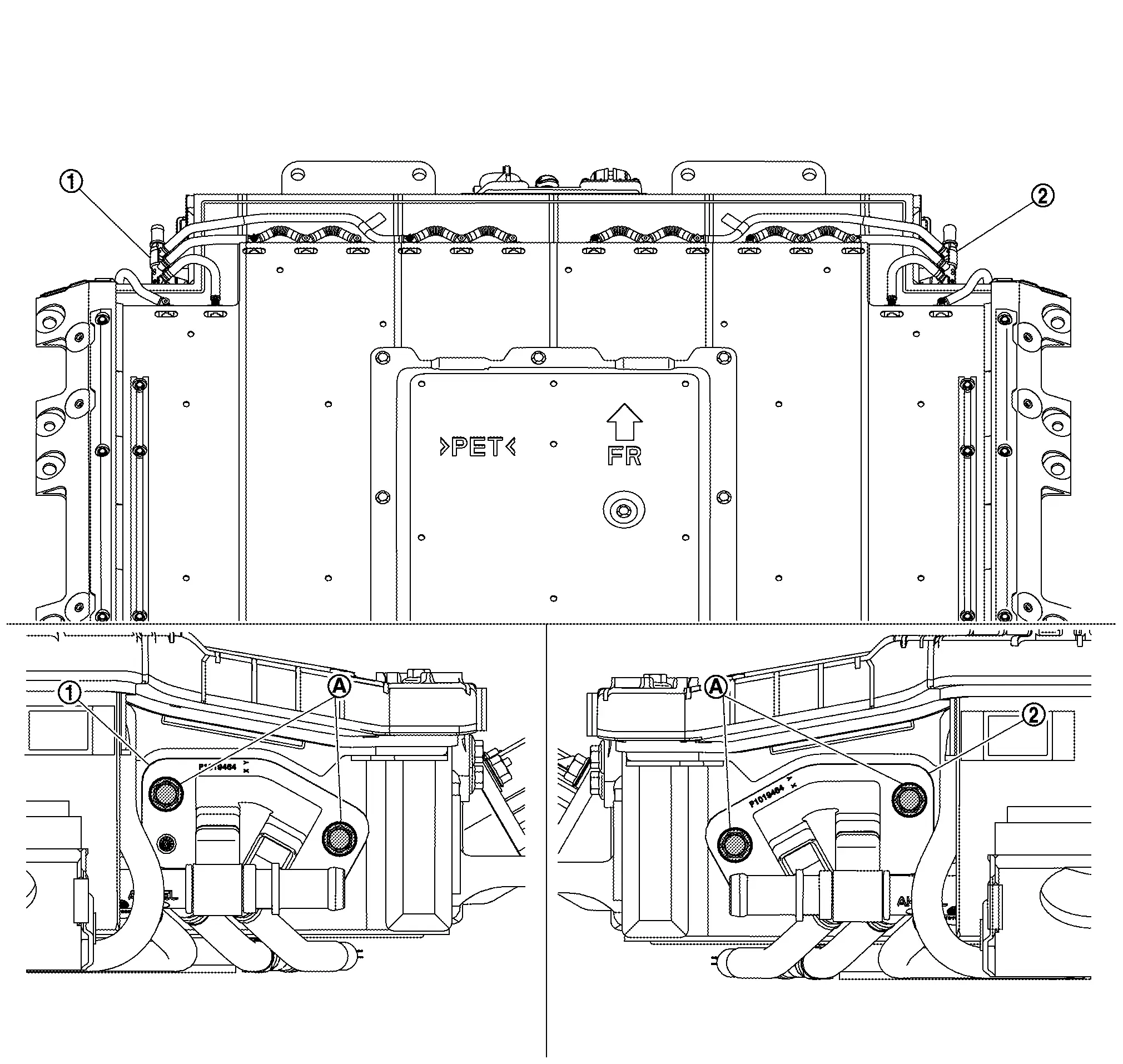

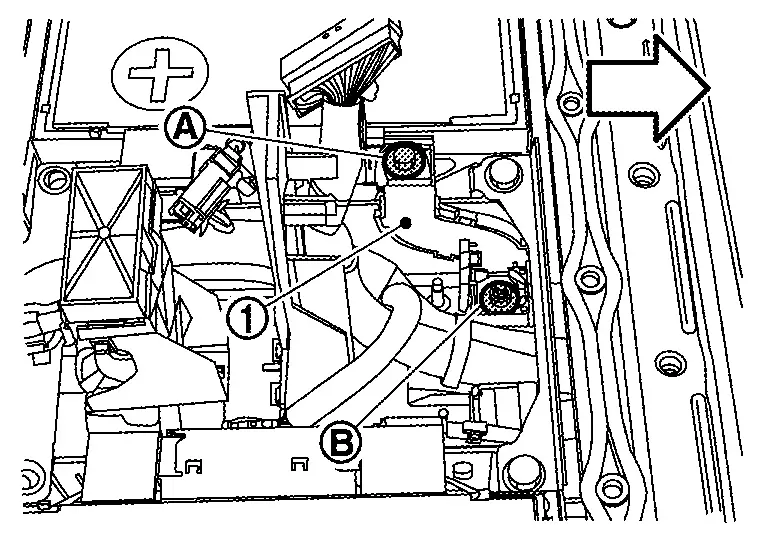

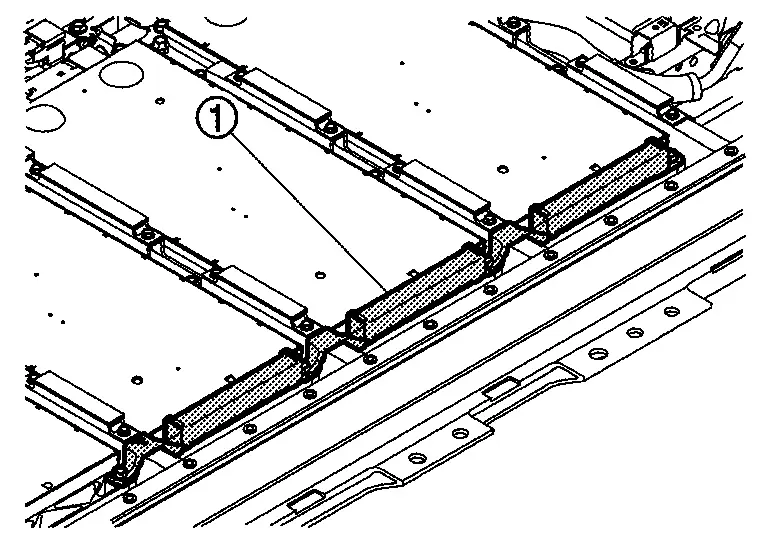

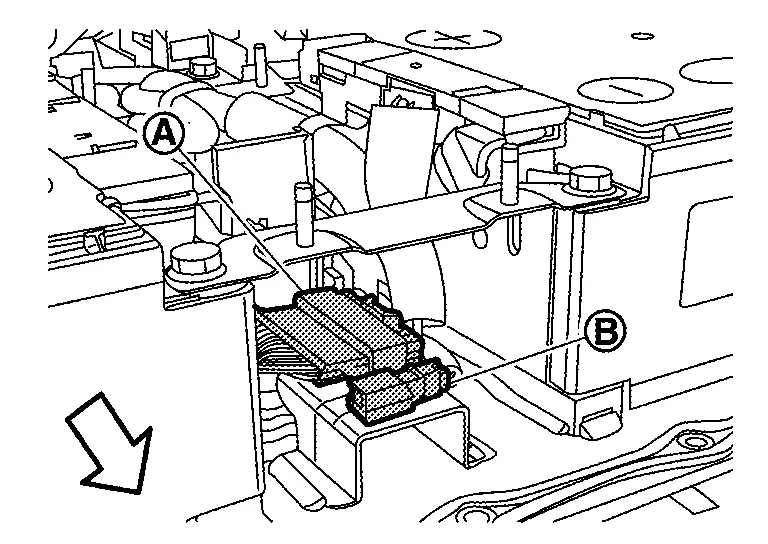

BATTERY HEATER

If necessary, remove Li-ion battery. Refer to Removal & Installation.

CAUTION:

Do not reuse the Li-ion battery cooler tube 1-4 (right) and Li-ion battery cooler tube 5-8 (left) when it was removed from the battery pack.

-

Remove Li-ion battery. Refer to Removal & Installation.

-

Remove Li-ion battery cooler tube 1-4 (right) and Li-ion battery cooler tube 5-8 (left).

CAUTION:

If the collar and O-ring at the end of connector remain in the Li-ion battery while removing Li-ion battery cooler tubes (front right and front left) from Li-ion battery, take them out.

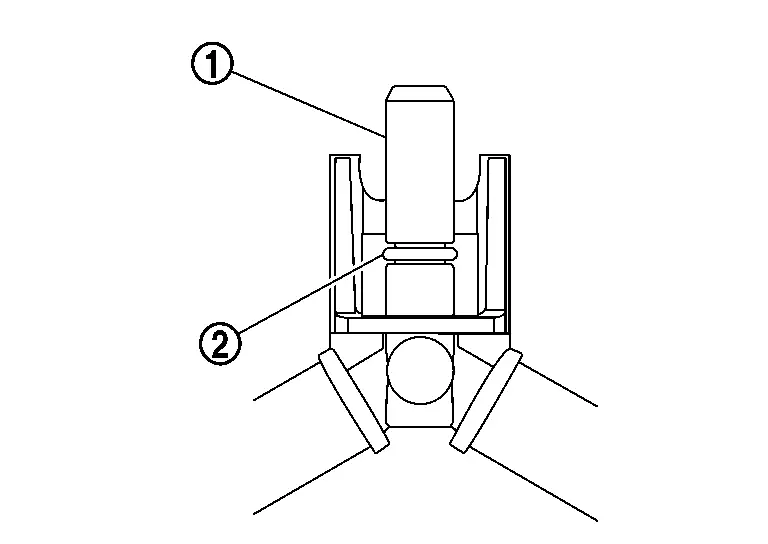

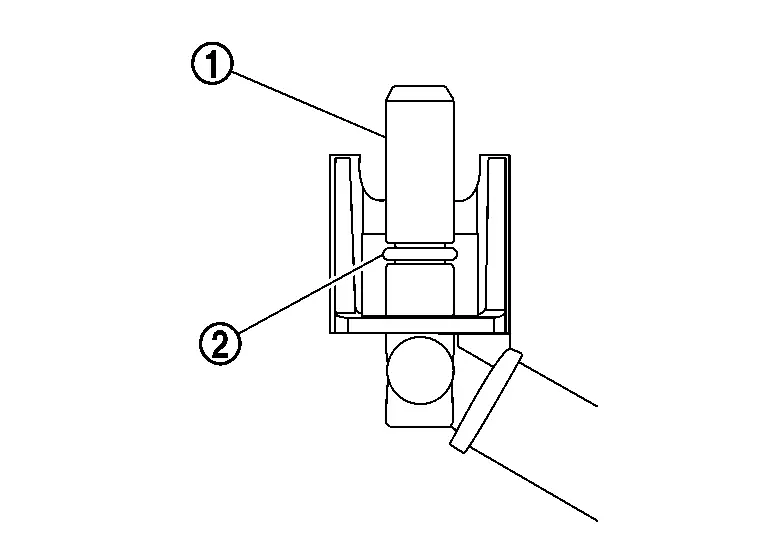

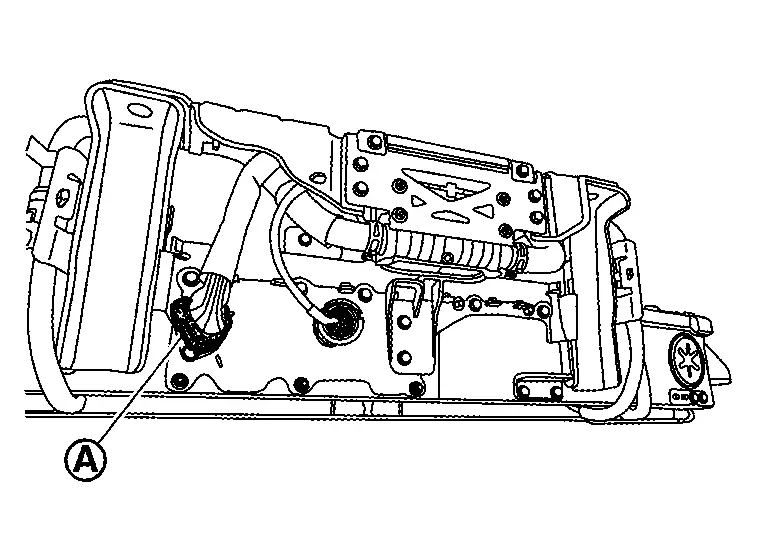

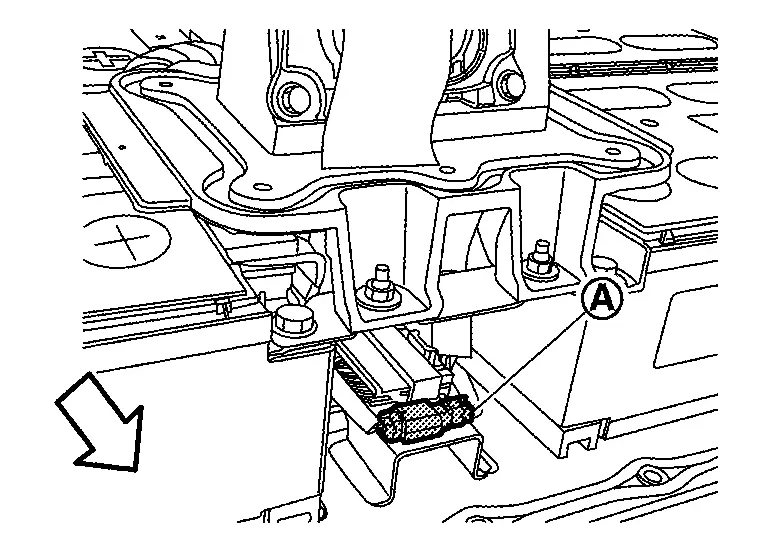

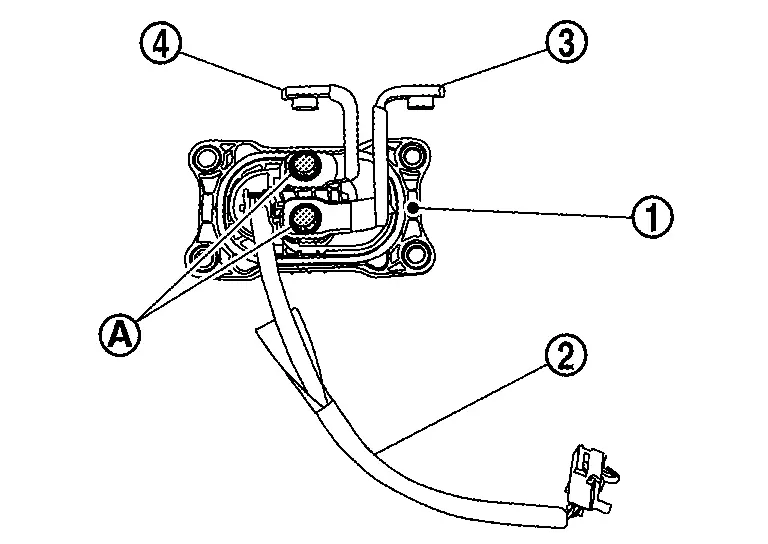

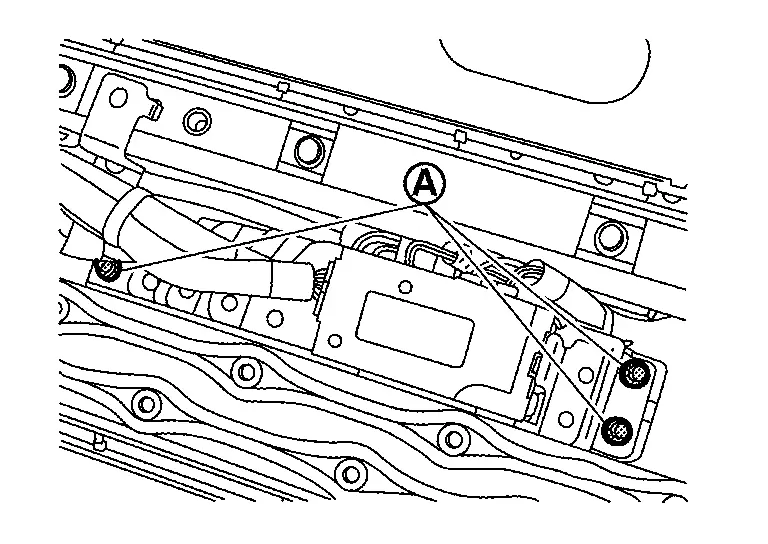

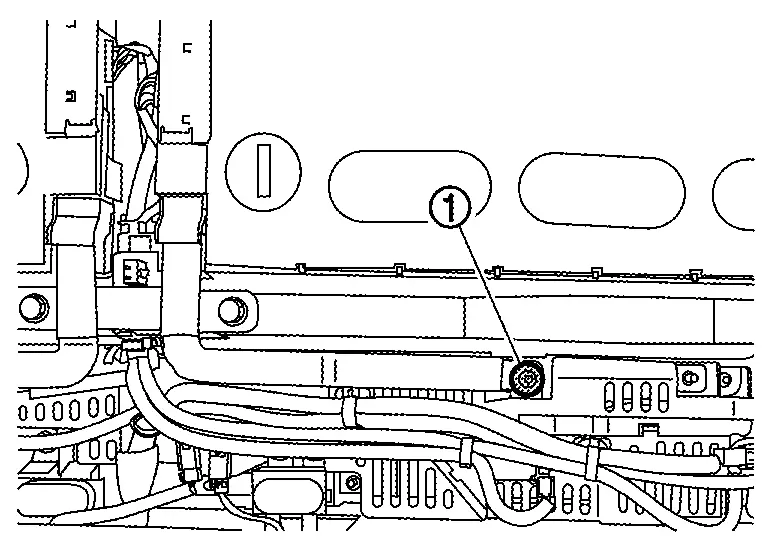

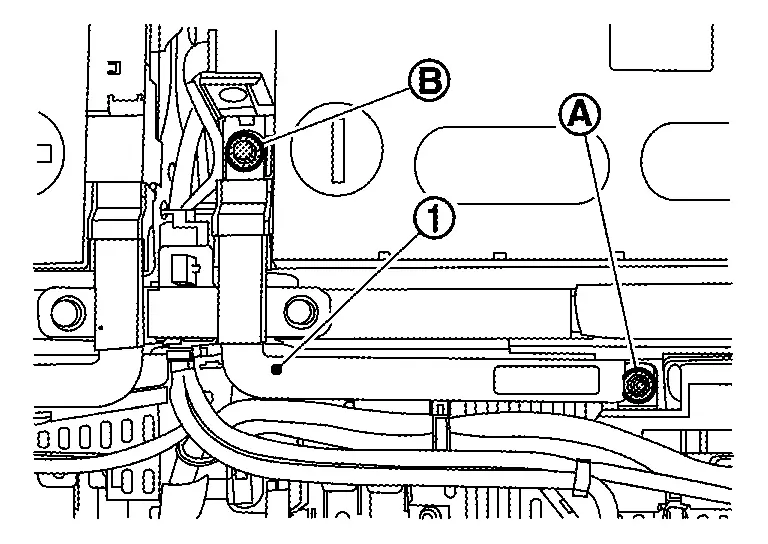

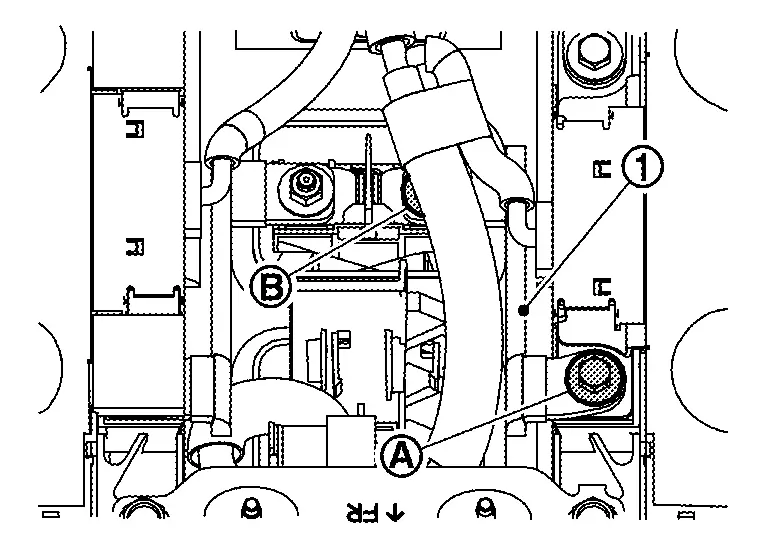

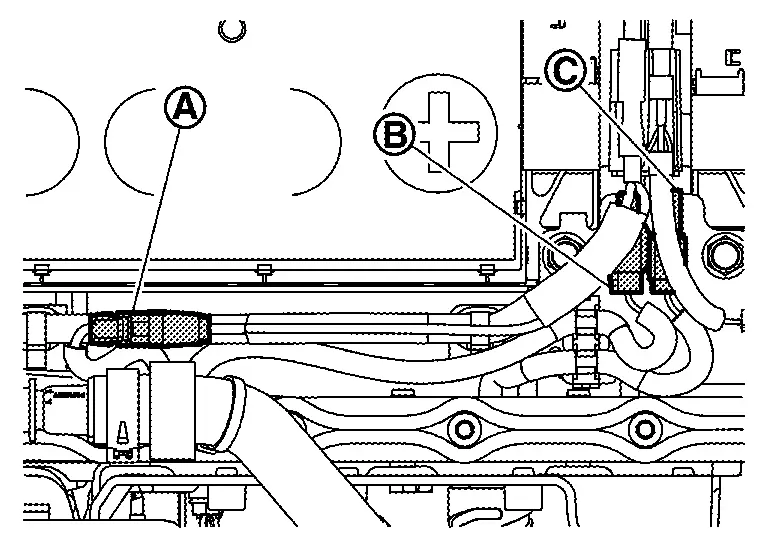

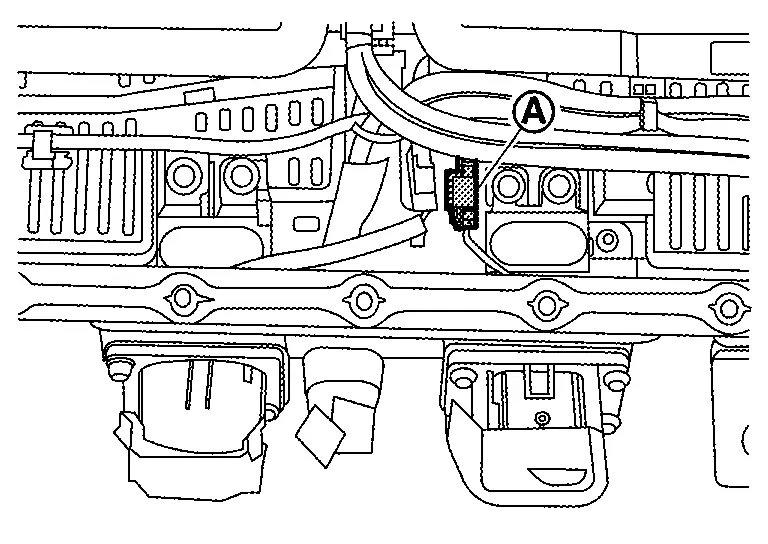

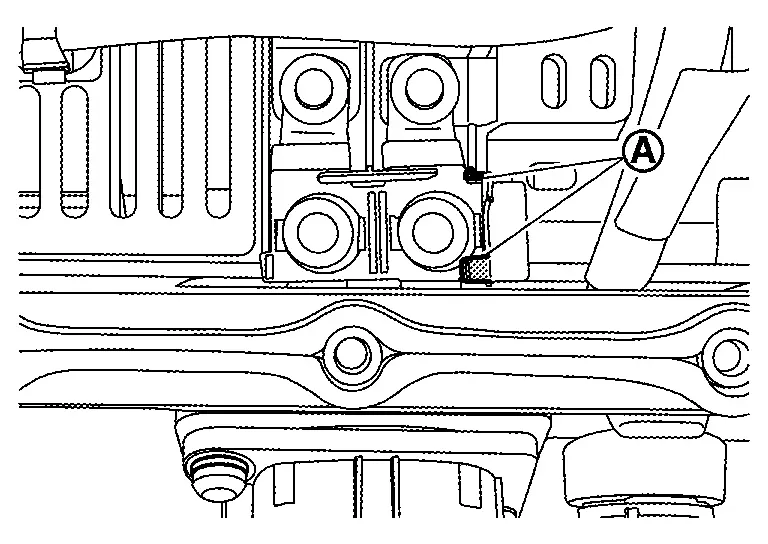

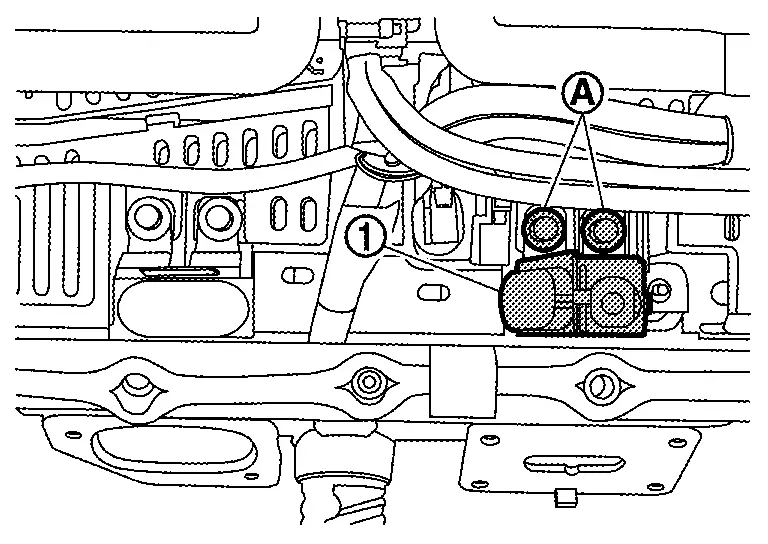

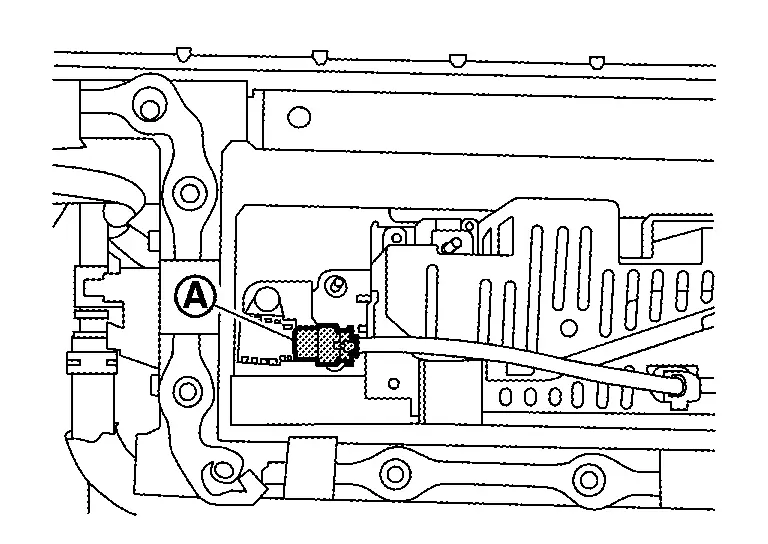

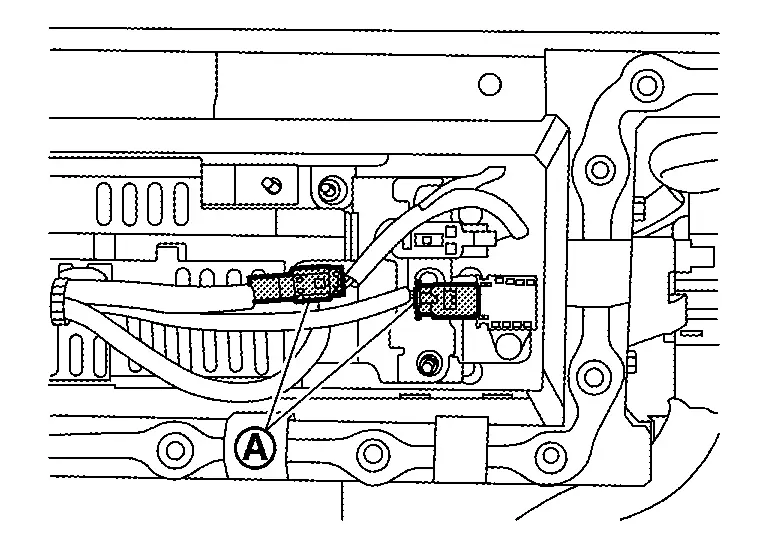

Remove high voltage harness connector  .

.

-

There is the danger of electric shock caused by contact with the terminals. Be sure to wear insulated protective gear.

There is the danger of electric shock caused by contact with the terminals. Be sure to wear insulated protective gear.

-

Because there is the danger of electric shock, immediately insulate disconnected high voltage connectors and terminals with insulating tape.

Because there is the danger of electric shock, immediately insulate disconnected high voltage connectors and terminals with insulating tape.

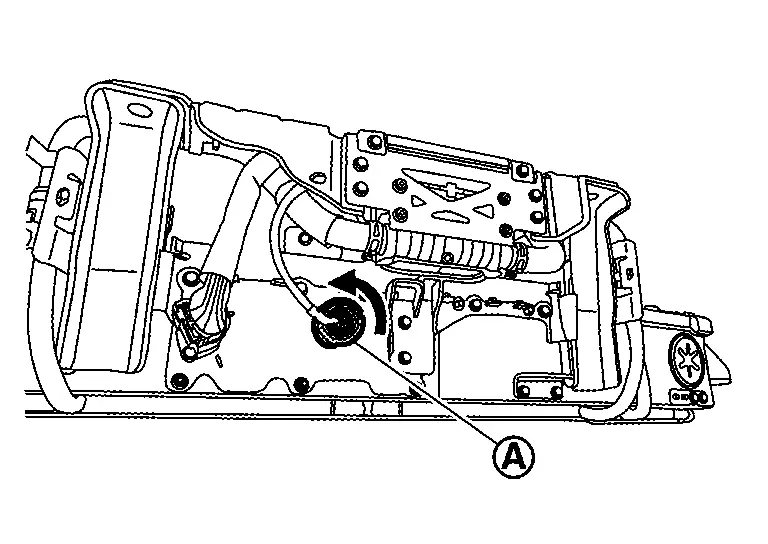

Remove harness connector  by turning in the direction of arrow.

by turning in the direction of arrow.

-

There is the danger of electric shock caused by contact with the terminals. Be sure to wear insulated protective gear.

There is the danger of electric shock caused by contact with the terminals. Be sure to wear insulated protective gear.

-

Because there is the danger of electric shock, immediately insulate disconnected high voltage connectors and terminals with insulating tape.

Because there is the danger of electric shock, immediately insulate disconnected high voltage connectors and terminals with insulating tape.

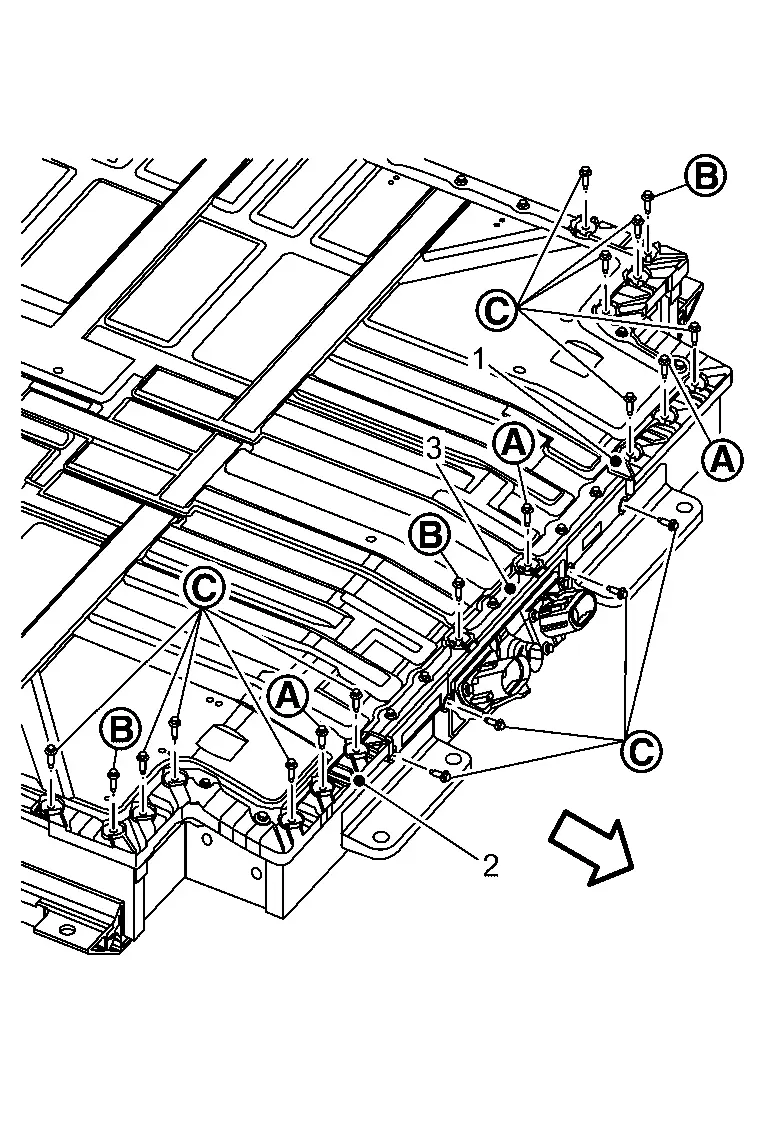

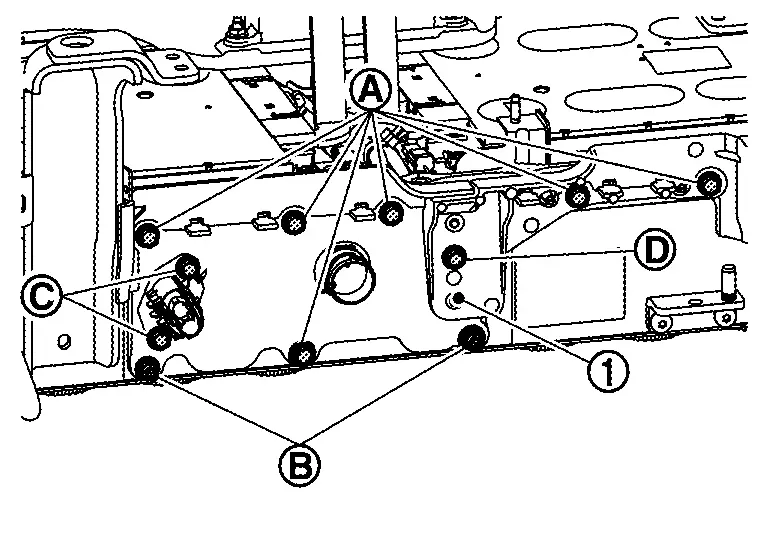

Remove battery heater bracket mounting bolts  .

.

-

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

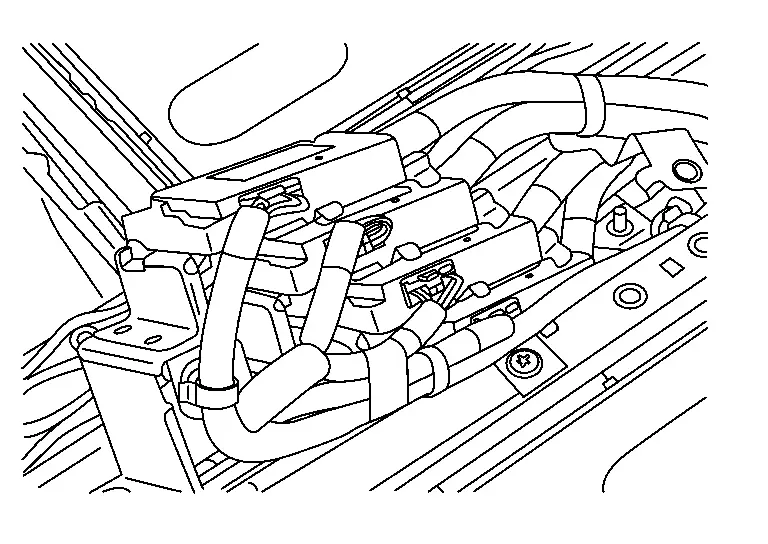

Remove battery heater sides only of Li-ion battery heater hose {left  and right

and right  }

}

|

:battery heater bracket 4 |

-

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

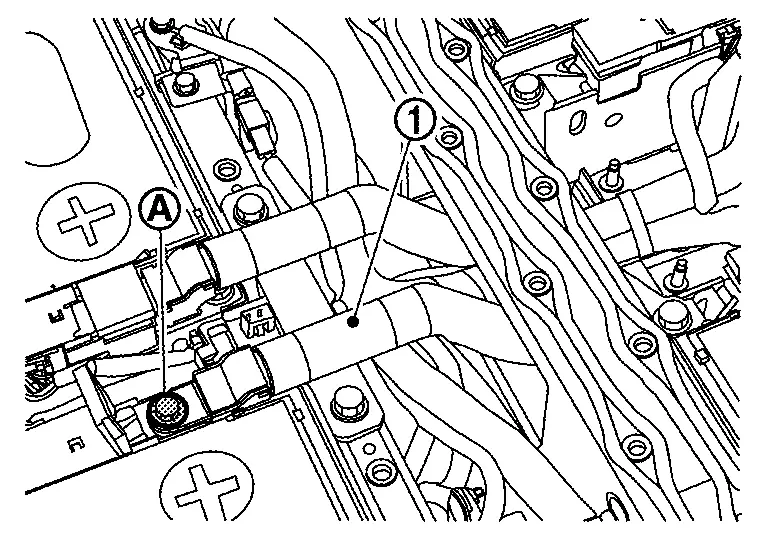

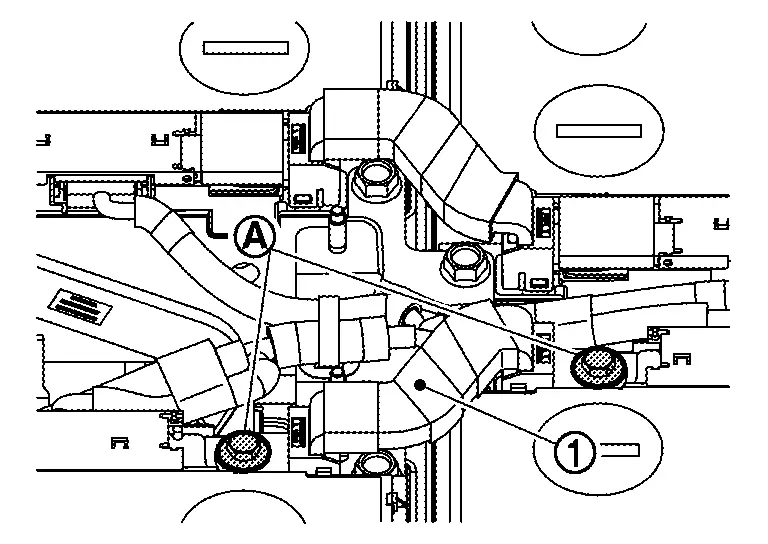

Remove battery heater bracket 1 mounting nuts  , and then remove battery heater bracket 1

, and then remove battery heater bracket 1  from battery heater bracket 2

from battery heater bracket 2  .

.

-

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

Remove harness clamp parts

-

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

Remove mounting bolts  of battery heater brackets 2 and 3, and then remove battery heater brackets 2

of battery heater brackets 2 and 3, and then remove battery heater brackets 2  and 3

and 3  from battery heater bracket 4

from battery heater bracket 4  .

.

-

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

Remove mounting bolts  of battery heater bracket 4, and then remove battery heater bracket 4

of battery heater bracket 4, and then remove battery heater bracket 4  from battery heater

from battery heater  .

.

-

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

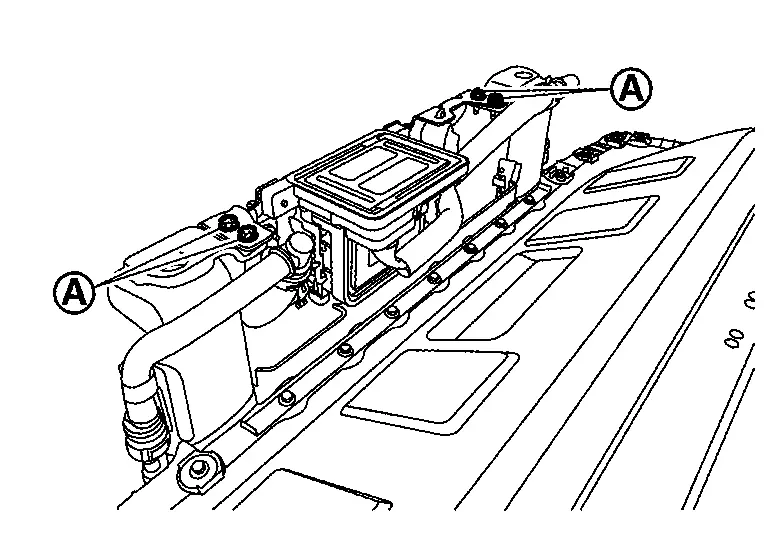

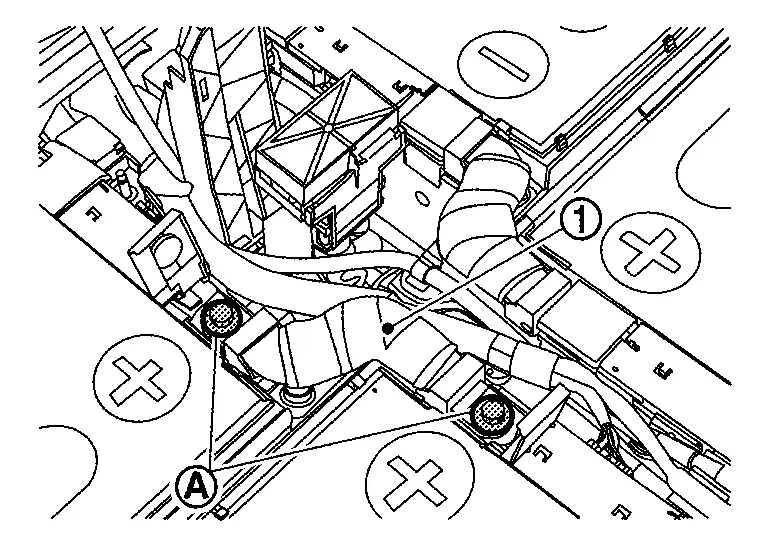

If necessary, remove Li-ion battery cooler tubes {rear right upper  and rear left upper

and rear left upper  } , and Li-ion battery cooler hoses {right

} , and Li-ion battery cooler hoses {right  and left

and left  }.

}.

-

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

ASSEMBLY

Assemble in the reverse order of disassembly, and pay attention to the following caution.

CAUTION:

After refilling coolant, perform leak check. Refer to COOLANT : Inspection.

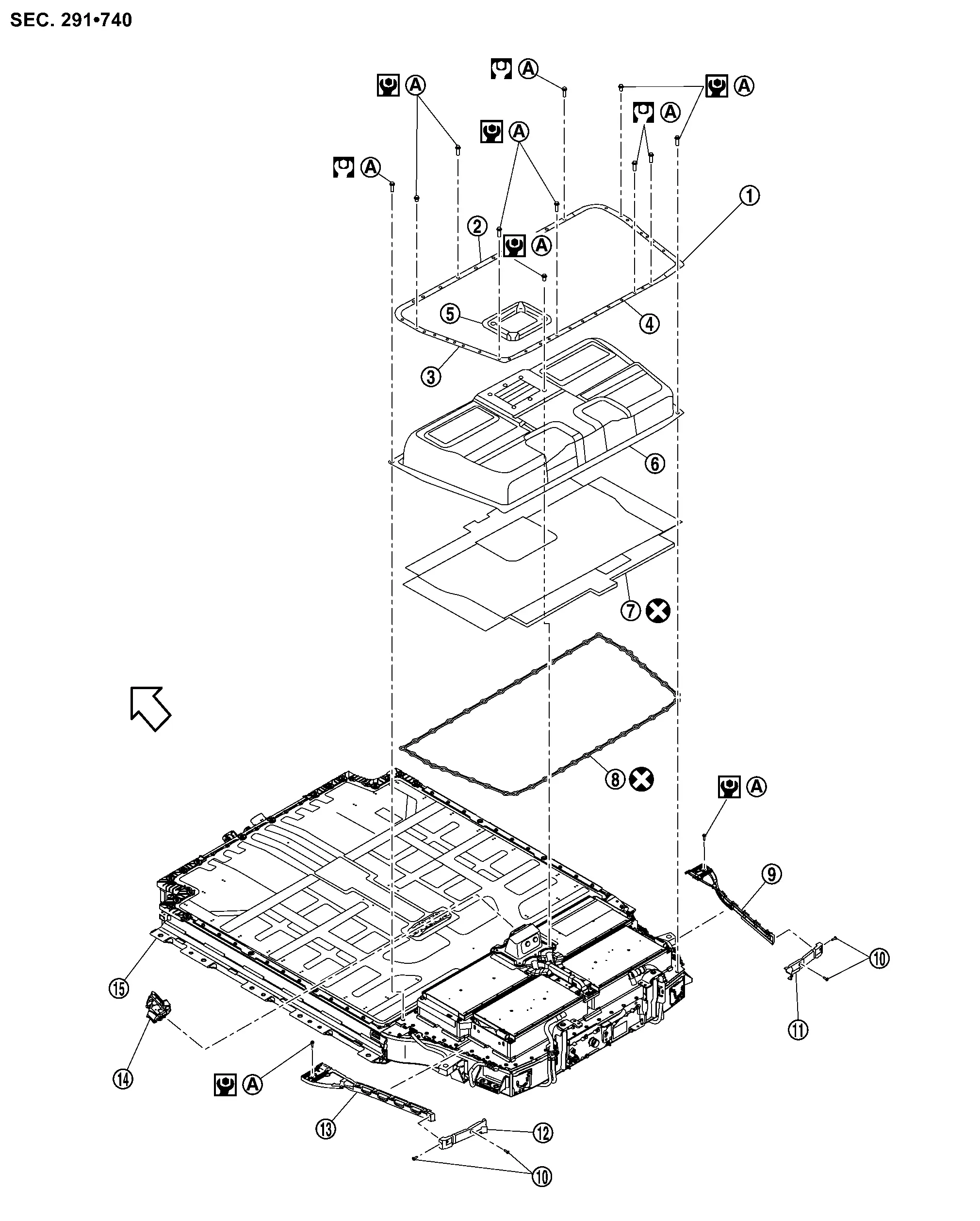

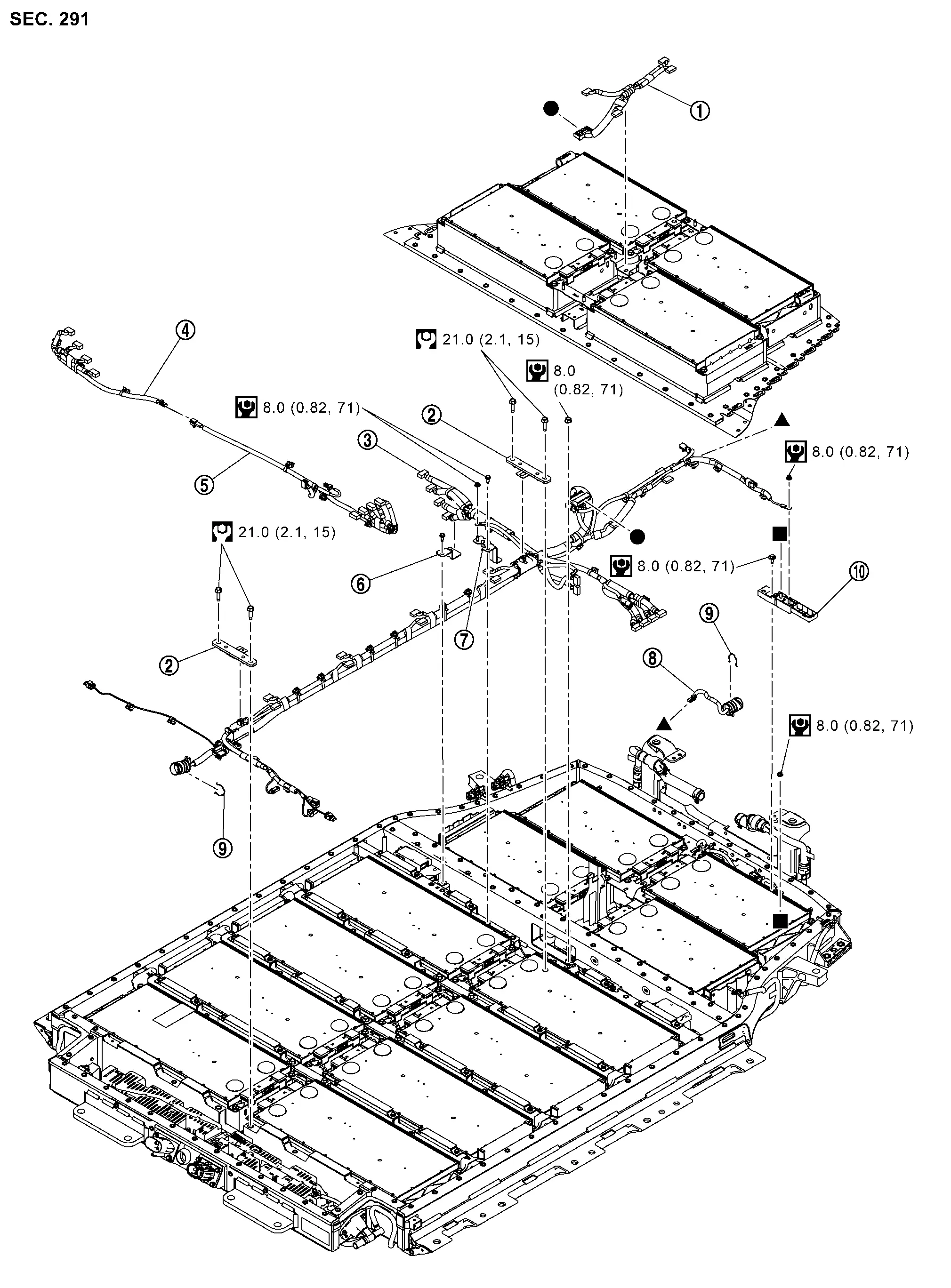

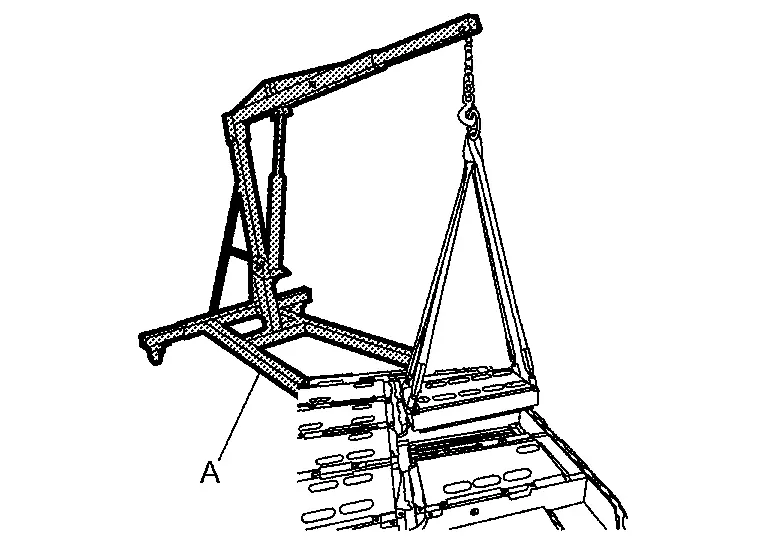

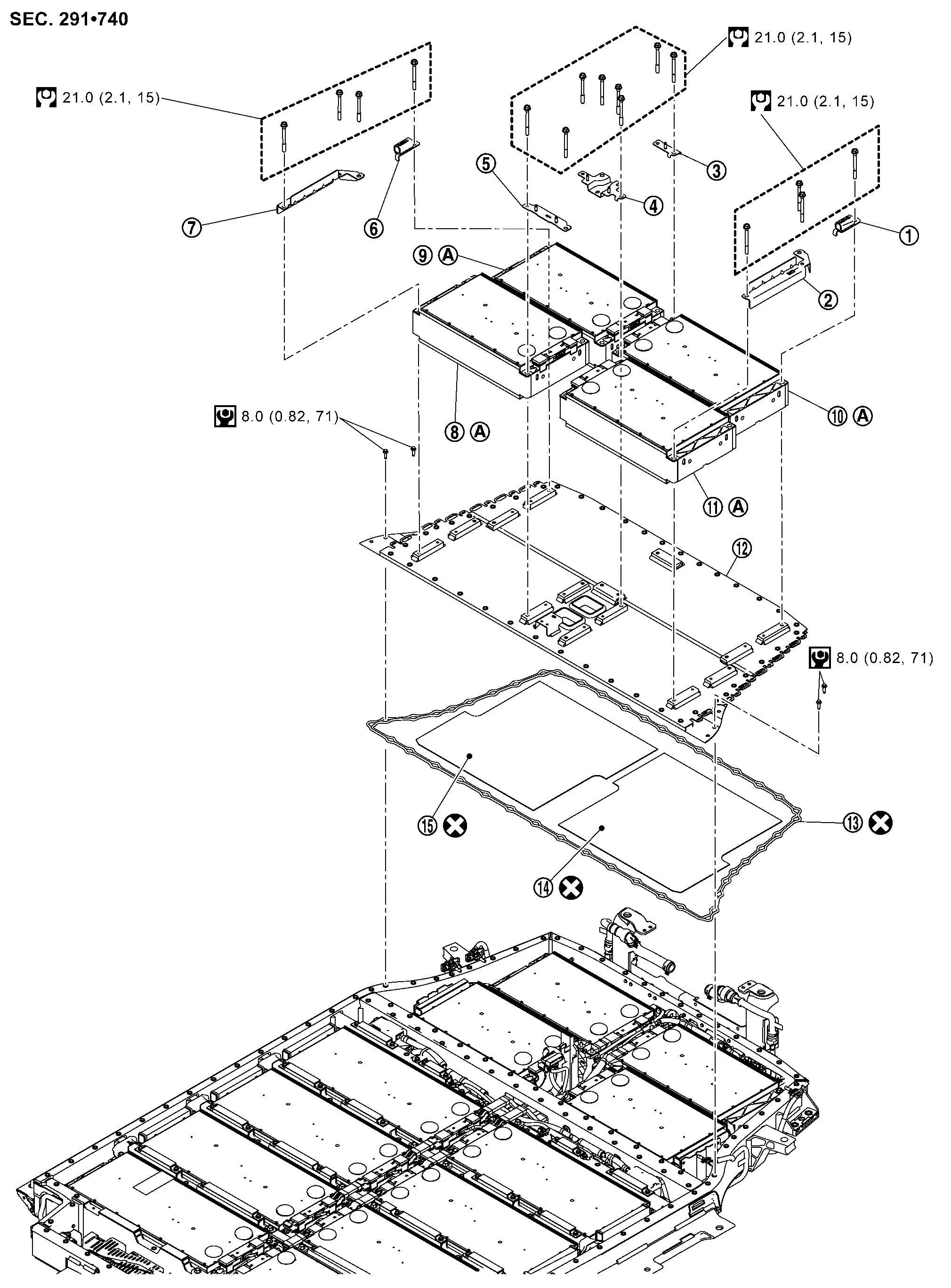

Battery Pack Upper Case Nissan Ariya

Exploded View

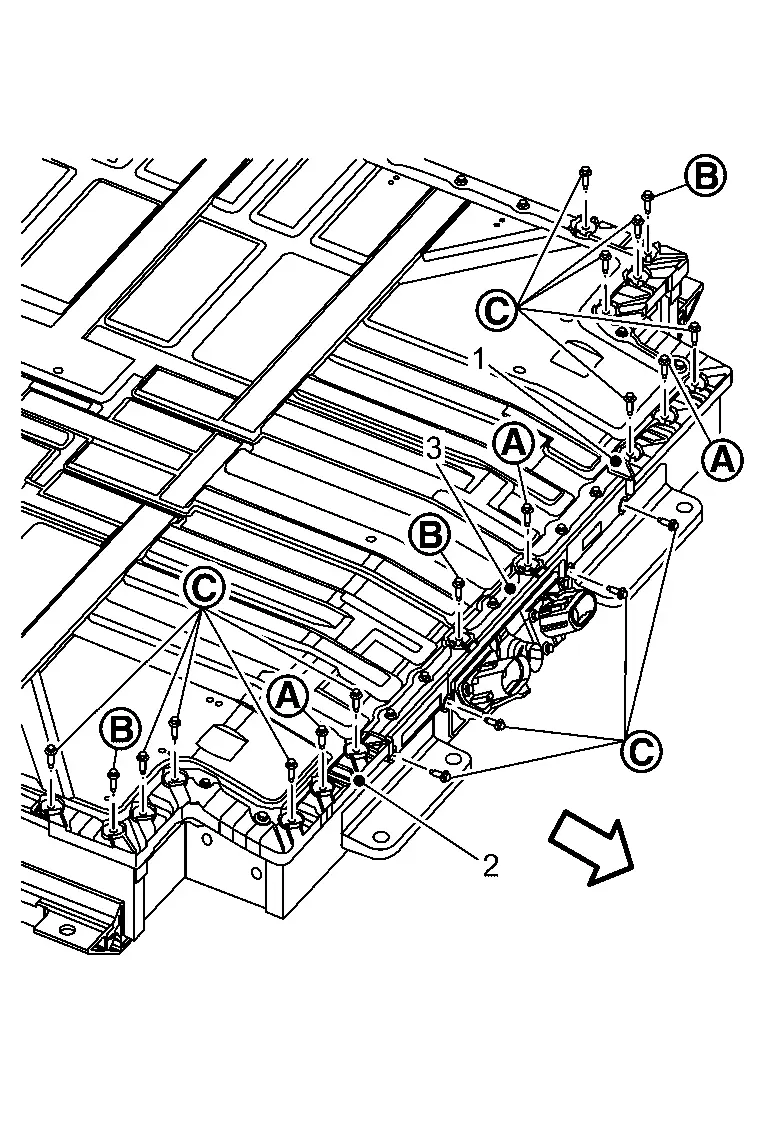

BATTERY PACK UPPER CASE REAR

|

Retainer (RH) |  |

Retainer (FR) |  |

Retainer (LH) |

|

Retainer (RR) |  |

Service plug retainer |  |

Battery pack upper case rear |

|

Insulator cover |  |

Seal |  |

Resin retainer |

|

Clip |  |

Resin retainer |  |

Resin retainer |

|

Resin retainer |  |

Service plug |  |

Battery pack lower case |

|

: Comply with the assembly procedure when tightening. Removal & Installation | ||||

|

: Nissan Ariya Vehicle front | ||||

|

: Always replace after every disassembly. | ||||

|

: N·m (kg-m, in-lb) | ||||

BATTERY PACK UPPER CASE FRONT

|

Resin retainer |  |

Resin retainer |  |

Resin retainer |

|

Retainer |  |

Retainer |  |

Retainer |

|

Battery pack upper case front |  |

Seal |  |

Seal |

|

Bracket |  |

Battery pack lower case | ||

|

: Comply with the assembly procedure when tightening. Removal & Installation | ||||

|

: Nissan Ariya Vehicle front | ||||

|

: Always replace after every disassembly. | ||||

|

: N·m (kg-m, in-lb) | ||||

, , , , , , , , , , , , , , : Indicates that the part is connected at points with same symbol in actual Nissan Ariya vehicle. : Indicates that the part is connected at points with same symbol in actual Nissan Ariya vehicle. |

|||||

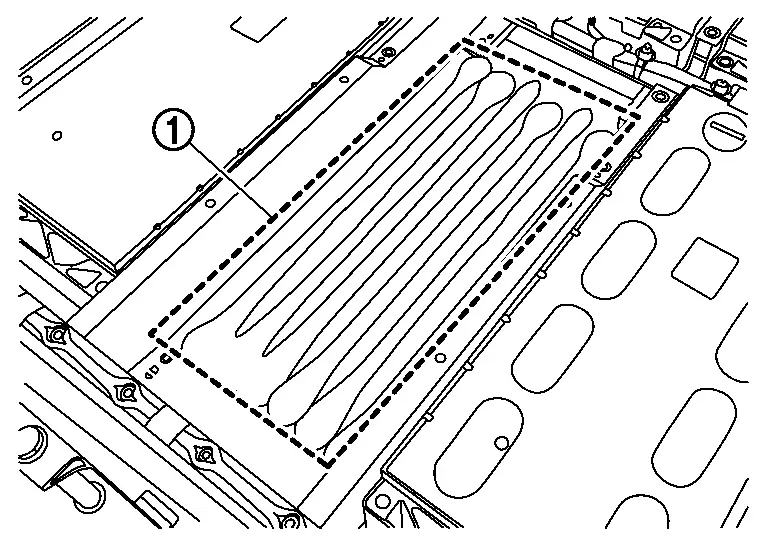

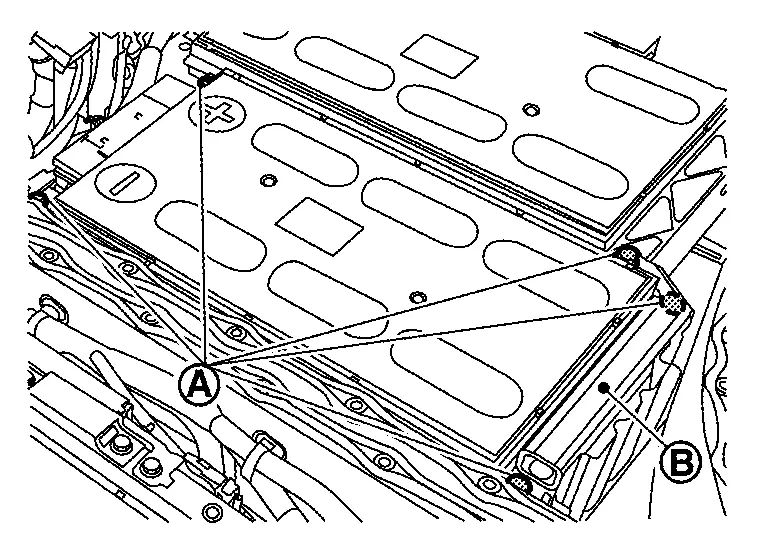

Heat shield sheet

|

Battery pack upper case |  |

Heat shield sheet |  |

Heat shield sheet |

|

Heat shield sheet |  |

Heat shield sheet |  |

Heat shield sheet |

|

: Nissan Ariya Vehicle front | ||||

|

: Always replace after every disassembly |

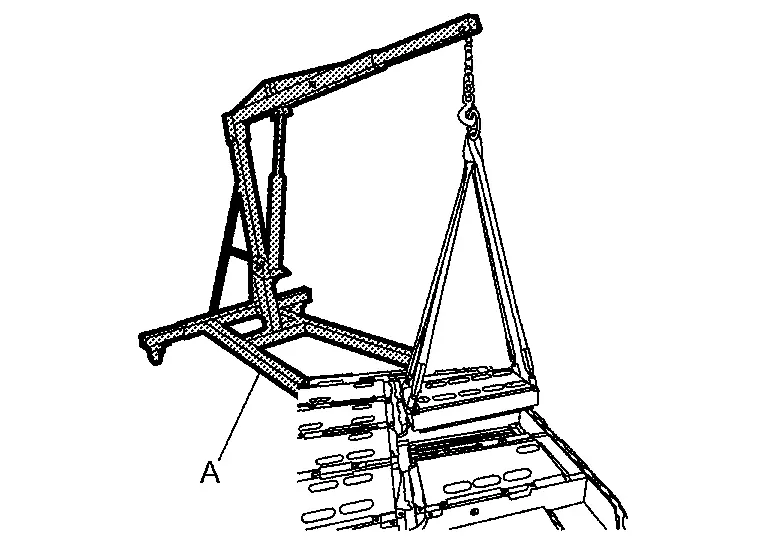

Removal & Installation

DANGER: Since hybrid vehicles and electric vehicles contain a high voltage battery, there is the risk of electric shock, electric leakage, or similar accidents if the high voltage component and Nissan Ariya vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

Since hybrid vehicles and electric vehicles contain a high voltage battery, there is the risk of electric shock, electric leakage, or similar accidents if the high voltage component and Nissan Ariya vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

WARNING:

-

Be sure to remove the service plug in order to shut off the high voltage circuits before performing inspection or maintenance of high voltage system harnesses and parts.

-

Be sure to put the removed service plug in pocket and carry it or store it in a tool box or other container so that another person does not accidentally connect it while work is in progress.

-

Be sure to put on insulating protective gear before beginning work on the high voltage system.

-

Clearly identify the persons responsible for high voltage work and ensure that other persons do not touch the Nissan Ariya vehicle. When not working, cover high voltage components with an anti-static cover sheet or similar item to prevent contact with other persons. Refer to HIGH VOLTAGE PRECAUTIONS : Precautions.

-

If the battery pack is to be disassembled, be sure to remove the Li-ion battery controller for preventing electric shock, fire, and damage to parts.

CAUTION:

There is the possibility of a malfunction occurring if the vehicle is changed to READY status while the service plug is removed. Therefore do not change the Nissan Ariya vehicle to READY status unless instructed to do so in the Service Manual.

ENVIRONMENT FOR LI-ION BATTERY DISASSEMBLY WORK

Must be an indoor environment.

-

The environment must utilize a shutter or other means to shut out the outside environment and prevent rain, snow, dust, or other substances from entering.

-

The environment must not cause the intrusion of sweat during work, or cause condensation to occur due to high temperature or humidity.

Metal powder, grease, and other foreign substances must not enter.

-

The indoor environment must also prevent metal powder, grease, and other foreign substances from entering due to maintenance performed on other Nissan Ariya vehicles and other sources during disassembly work.

-

During disassembly without internal work, temporarily close the battery pack upper case or cover it with an insulating cover.

The floor must be dry.

-

The floor must not be wet as a result of factors such as Nissan Ariya vehicle entry during rain or snow.

Work space

-

The work space must be approximately the size of one entire Nissan Ariya vehicle.

-

Take appropriate countermeasures so that persons other than the operator do not enter the work space, such as by placing signs indicating that disassembly work is in progress.

Standard fire fighting equipment

-

Always place a standard fire fighting equipment in the disassembly work area.

-

Depending on type of fire (Nissan Ariya vehicle or battery) use standard fire fighting equipment (water or extinguisher).

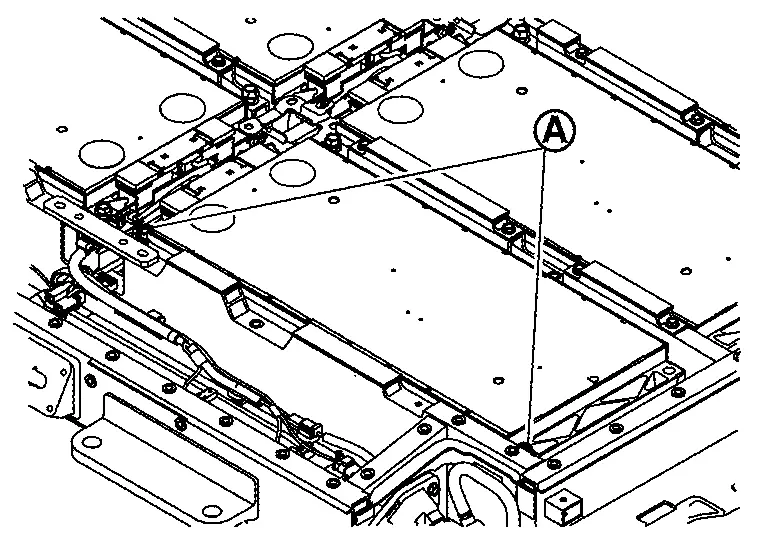

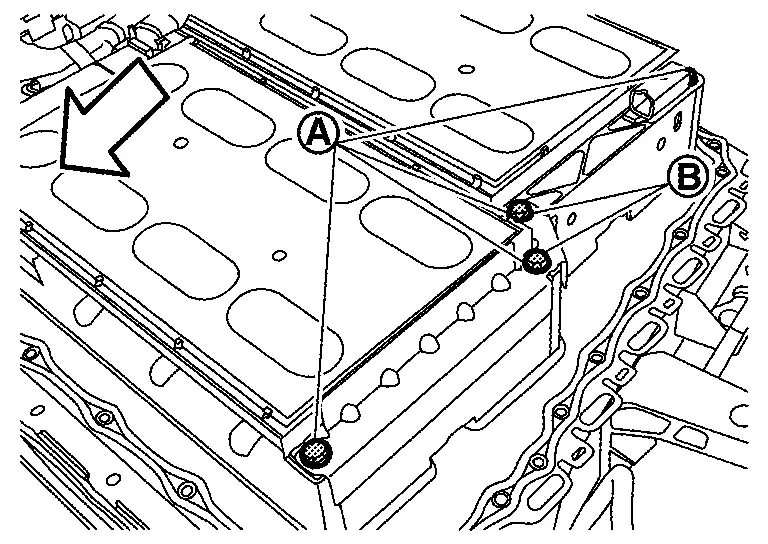

BATTERY PACK UPPER CASE REAR

REMOVAL

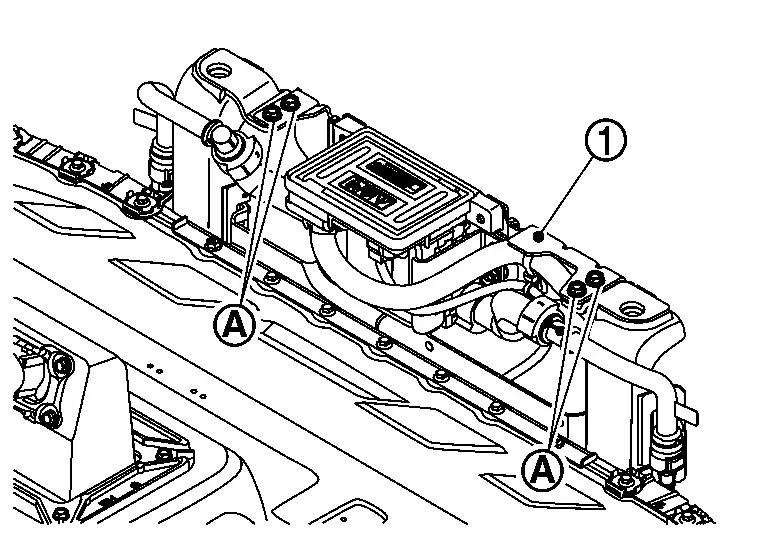

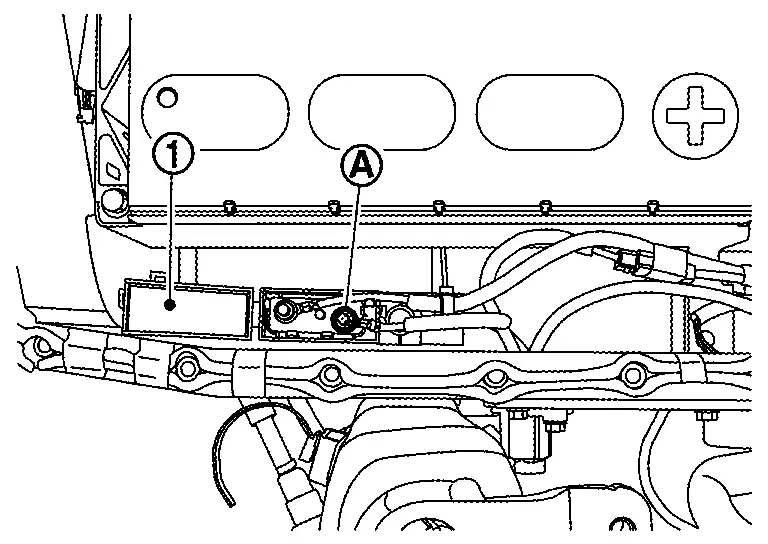

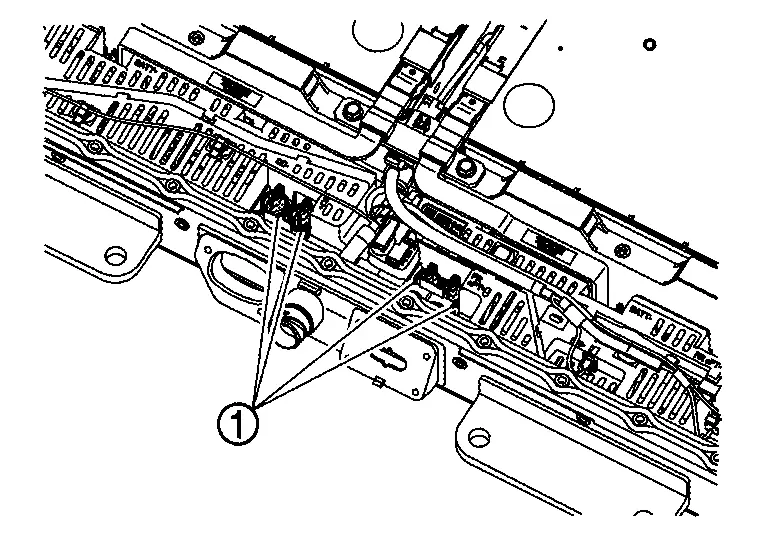

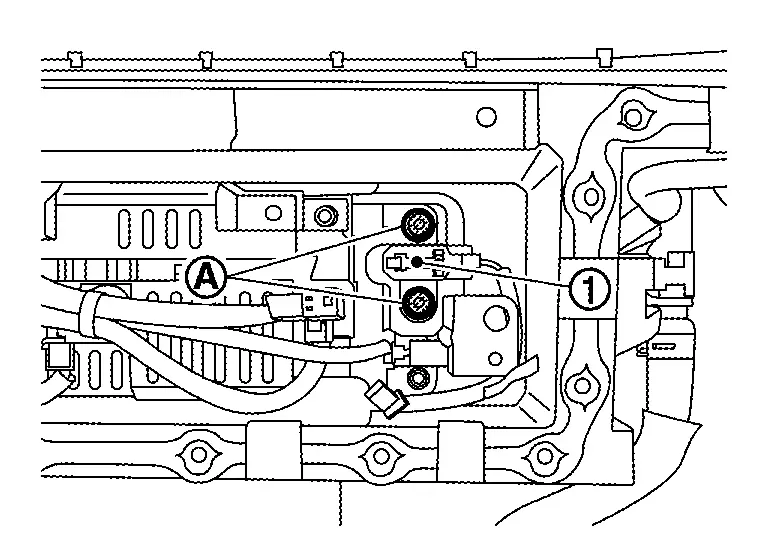

Remove tightening bolts  of battery heater bracket

of battery heater bracket  from battery pack lower case.

from battery pack lower case.

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

Remove Li-ion battery cooler tube from battery pack upper floor assembly. Refer to Disassembly & Assembly.

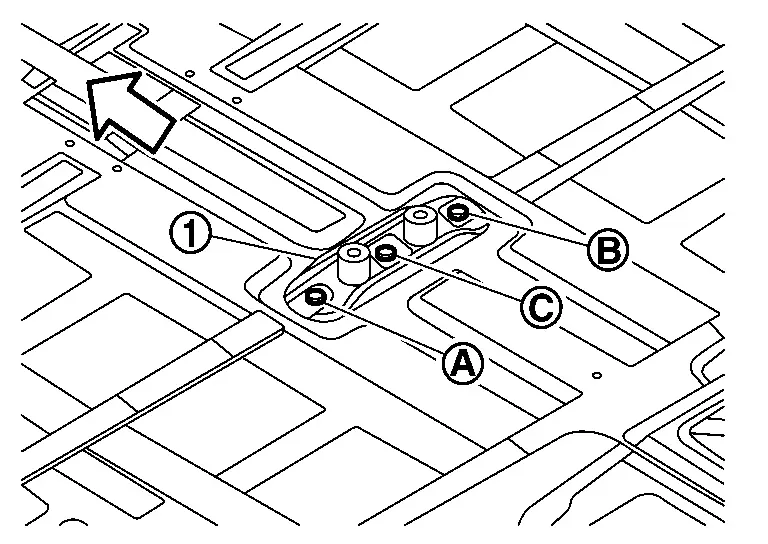

Remove service plug retainer .

.

|

: Battery front |

NOTE:

NOTE:

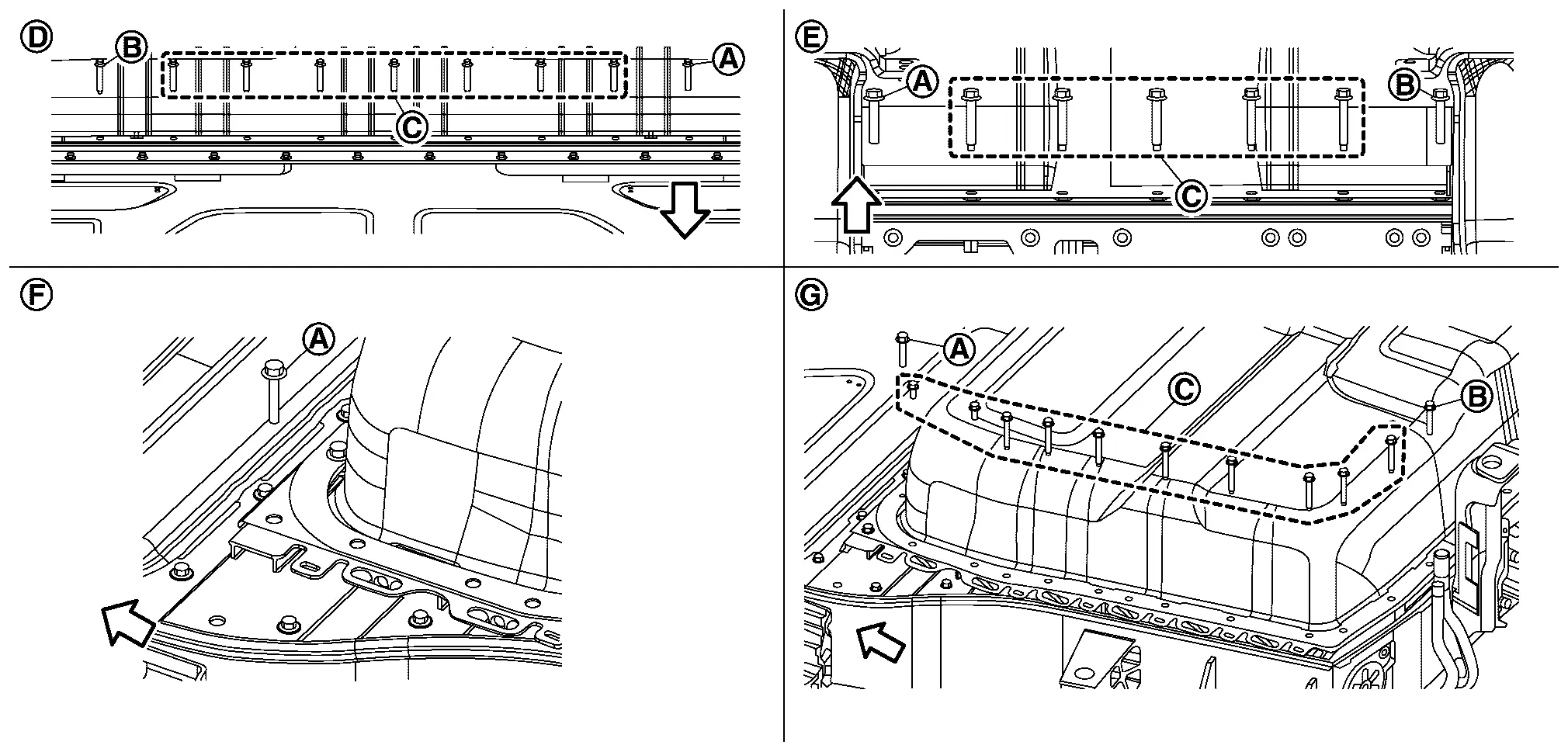

Remove bolts in the order of  →

→ →

→ .

.

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

Remove left and right retainers.

NOTE:

NOTE:

-

The figure shows the left side.

-

Remove bolts for each retainer in the order of

→

→ →

→ .

.

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

Remove left and right resin retainer.

Remove each bolt and for each retainer (FR, RR, LH and RH).

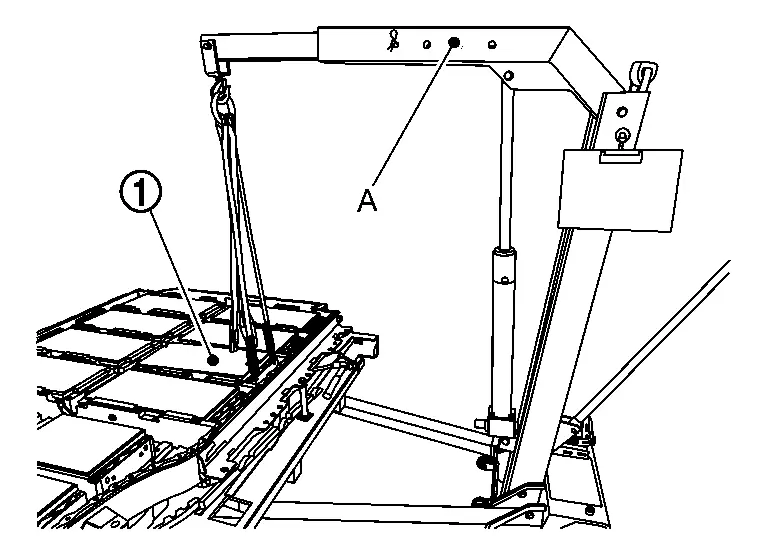

Hold both sides of the battery pack upper case to remove it.

Remove insulator cover.

Remove the seal from battery pack upper floor assembly.

Remove the seal from service plug bracket.

INSTALLATION

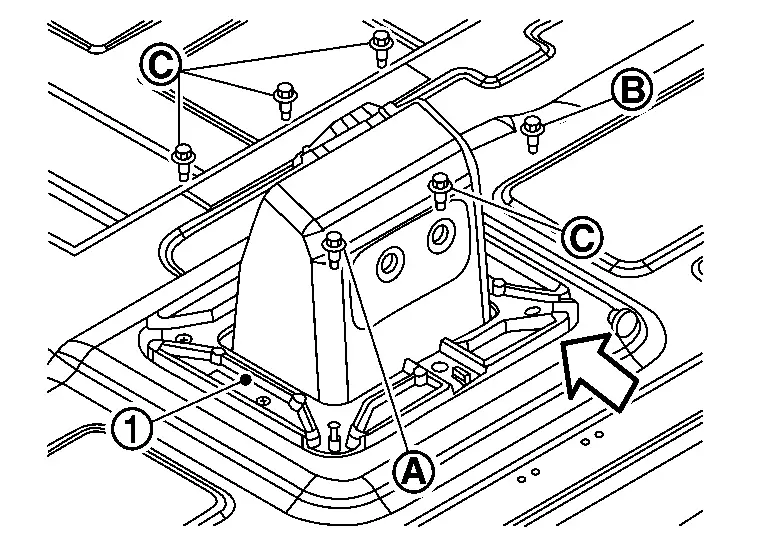

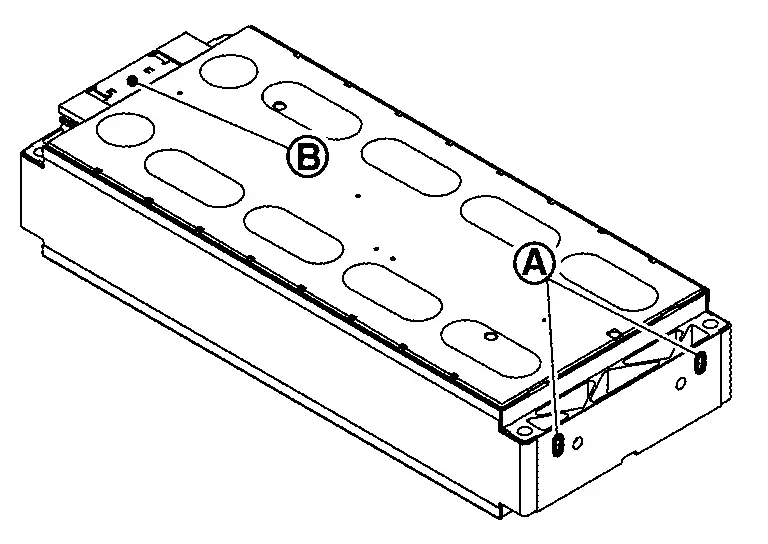

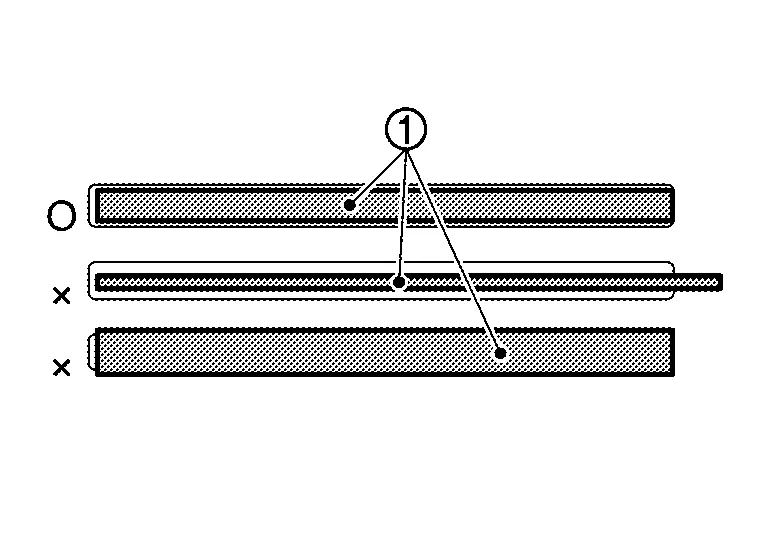

Check that heat shield sheet is still stuck back of battery upper case.

-

When the sheet is peeled or battery pack upper case rear is replaced, stick new heat shield sheet according to the following procedure.

CAUTION:

Work on carton box to prevent the warmed heat from escaping.

-

For the battery pack upper case rear, warm the surface where the heat shield sheet are stuck for at least 5 minutes so that the entire surface is at least 15 ℃ (59 °F).

-

Remove the release paper from the heat shield sheet, and then heat the side stuck to battery pack upper case rear for at least 1 minute so that its temperature is 15 ℃ (59 °F) or higher.

-

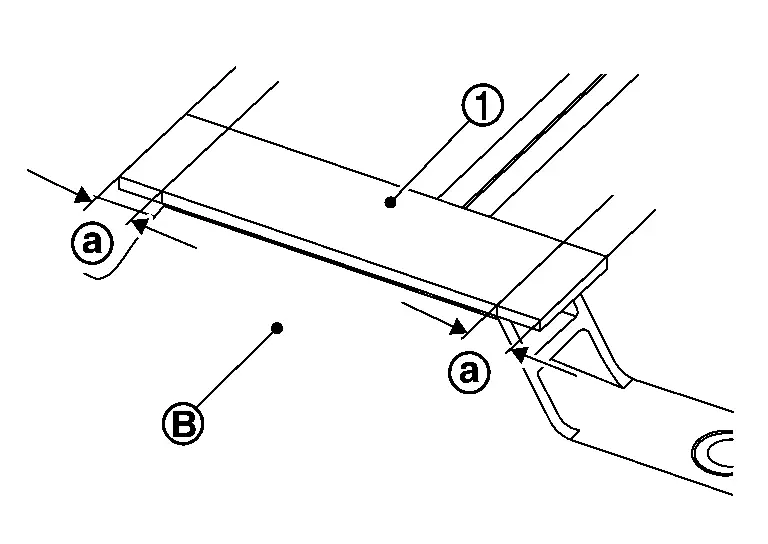

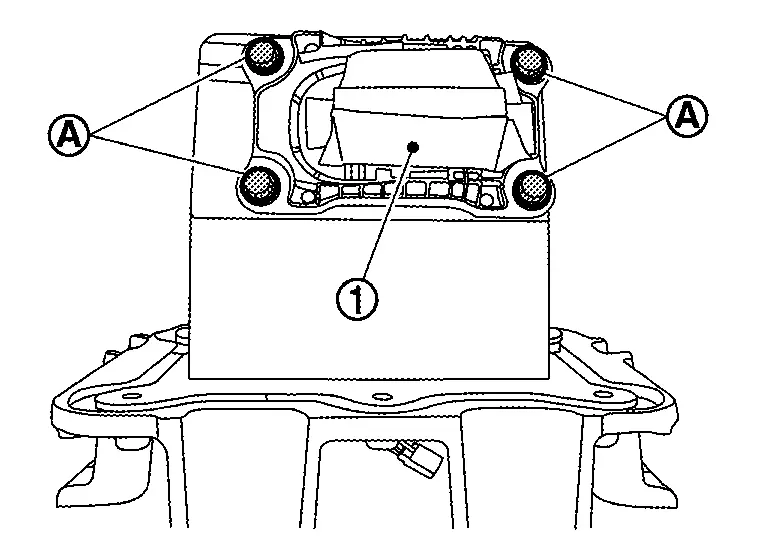

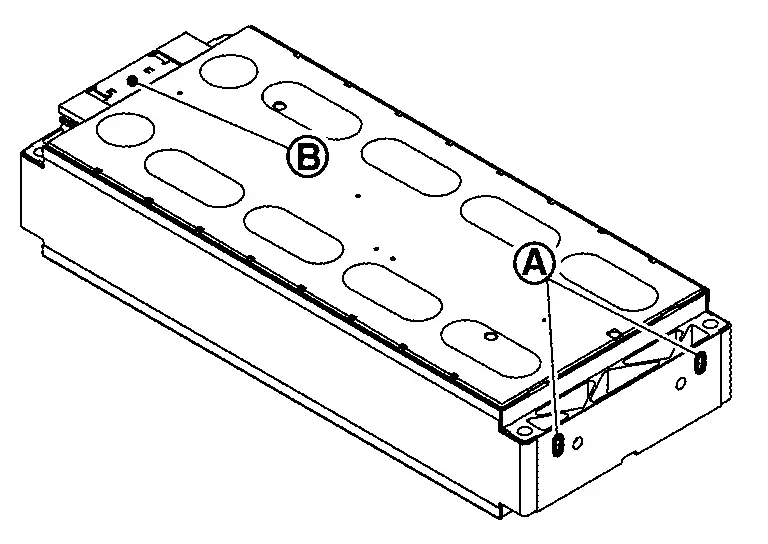

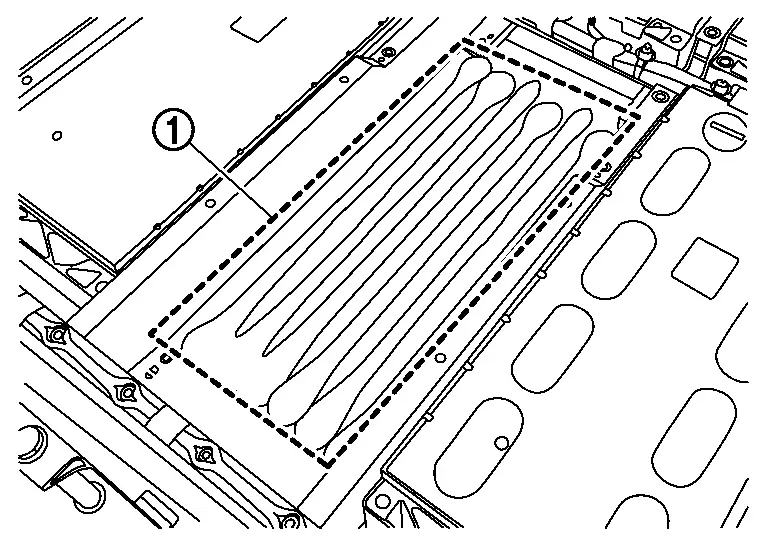

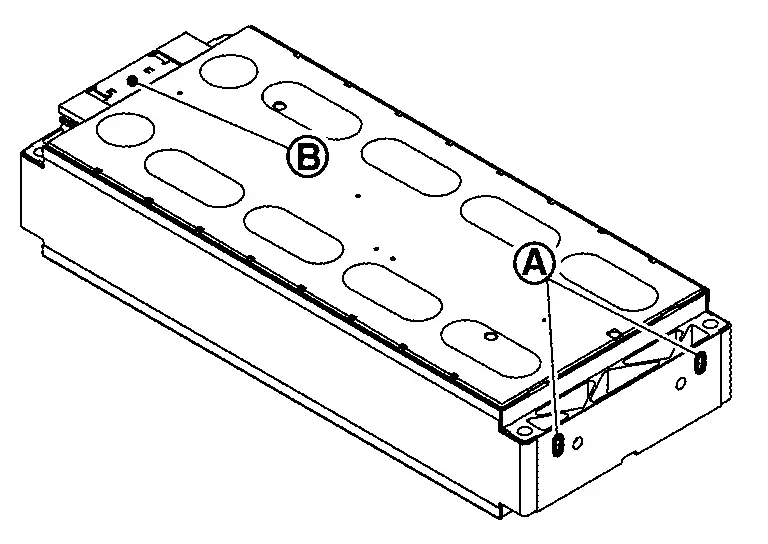

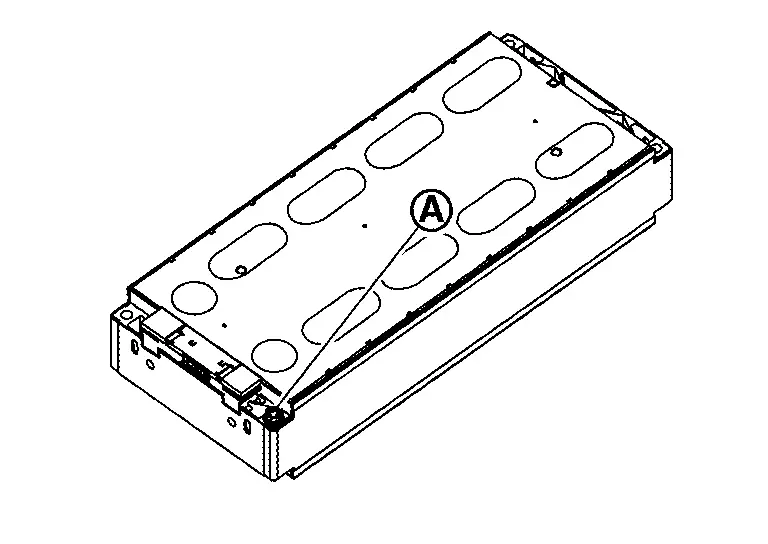

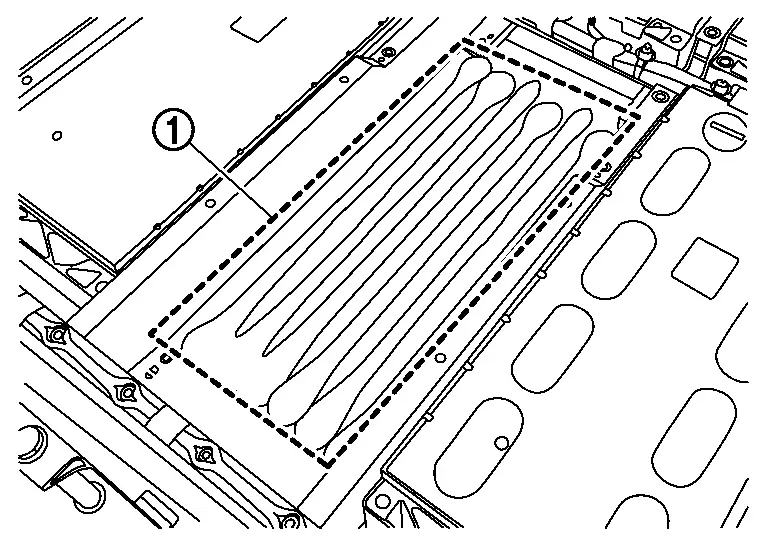

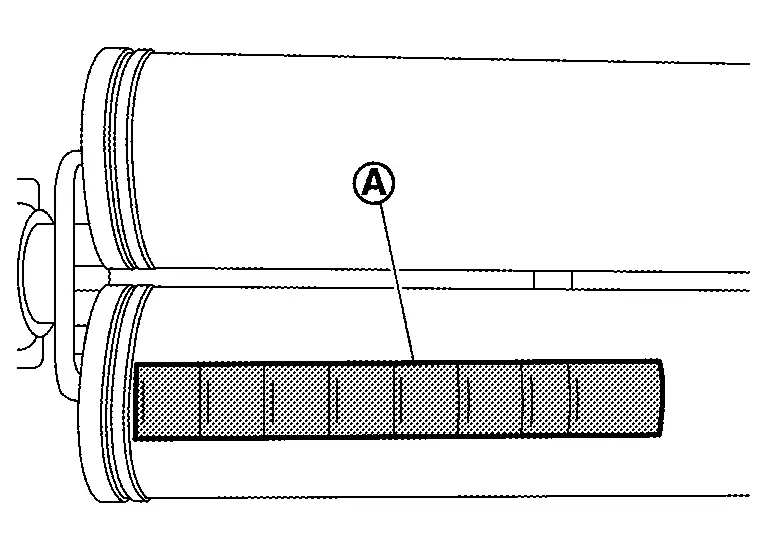

Stick the heat shield sheet

to the battery pack upper case rear as shown in the figure.

to the battery pack upper case rear as shown in the figure.

Position mark (Projection)

NOTE:

NOTE:

-

Stick the heat shield sheet that hides the inner position mark where two position marks are lined up.

-

Part

does not have any problem even if it gets wrinkled when sticking the heat shield sheet.

does not have any problem even if it gets wrinkled when sticking the heat shield sheet.

Install seal to battery pack upper floor assembly.

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

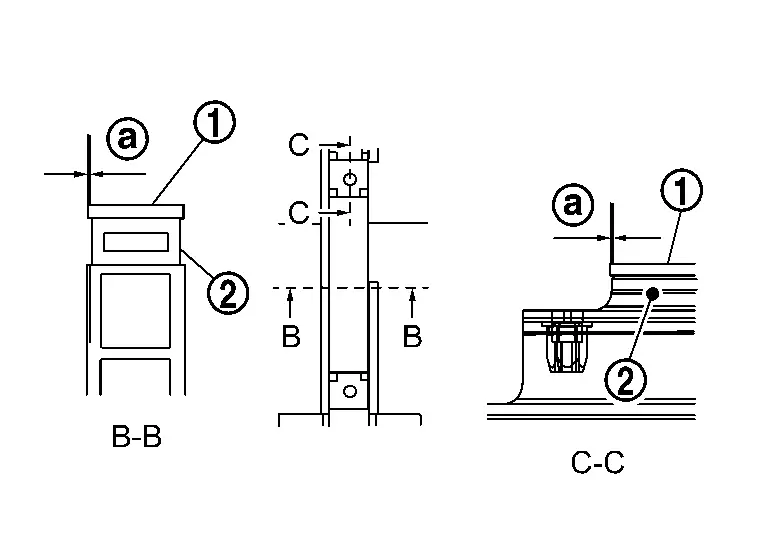

CAUTION:

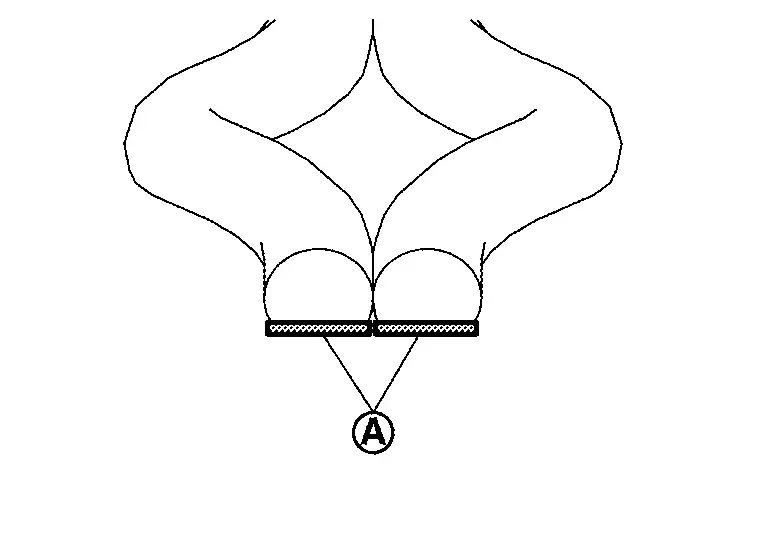

The flat side  of seal faces battery pack lower case.

of seal faces battery pack lower case.

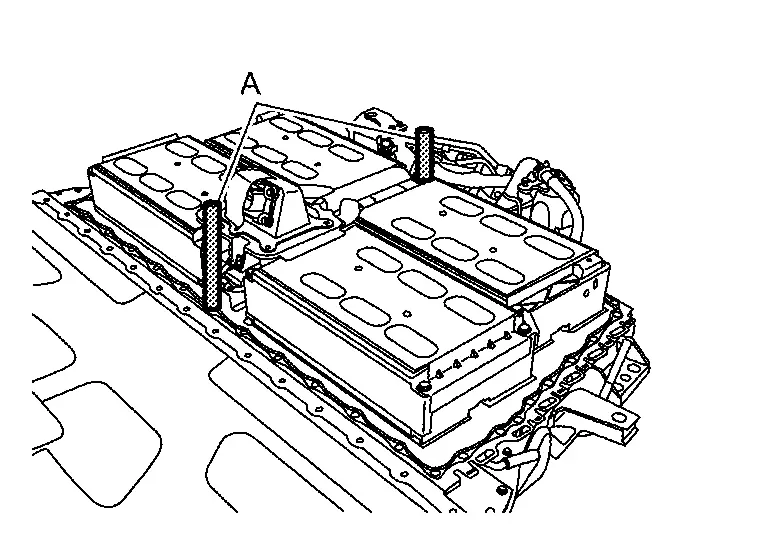

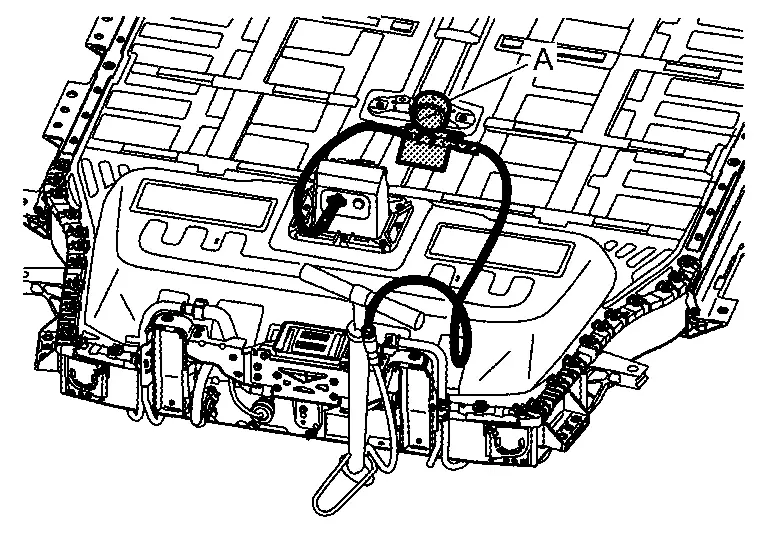

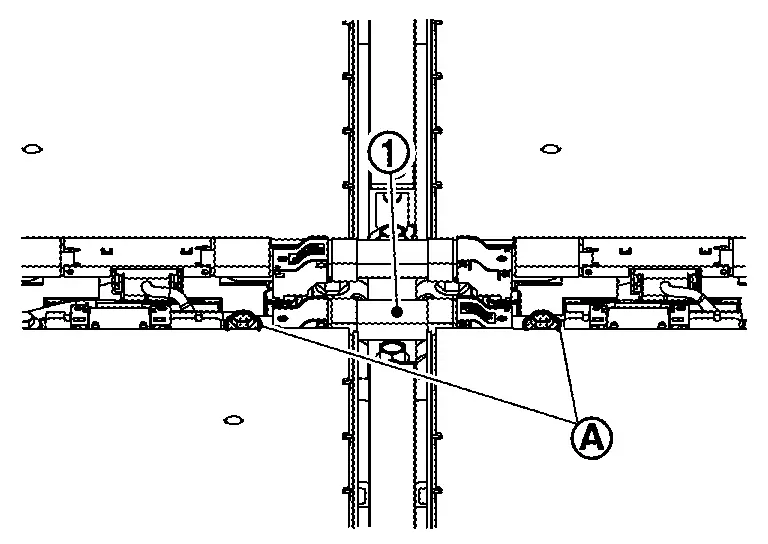

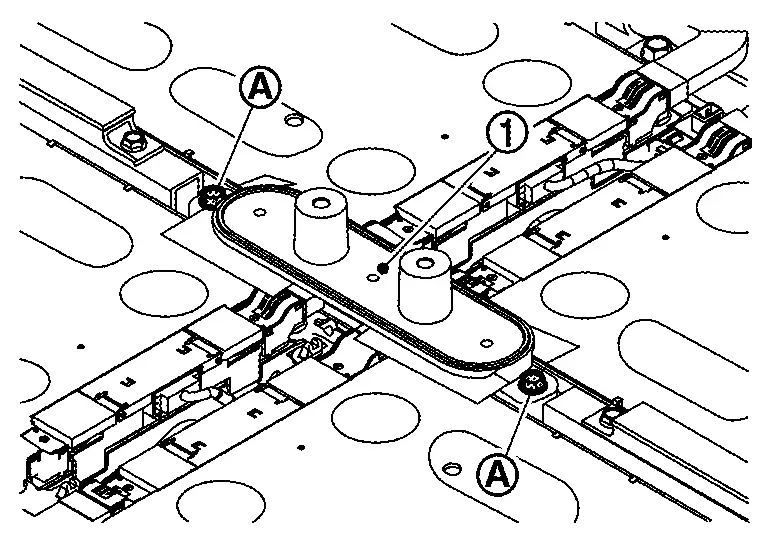

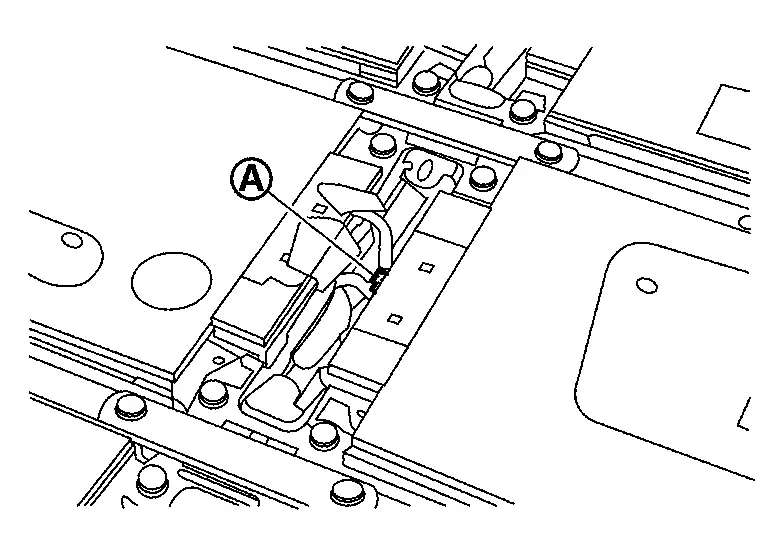

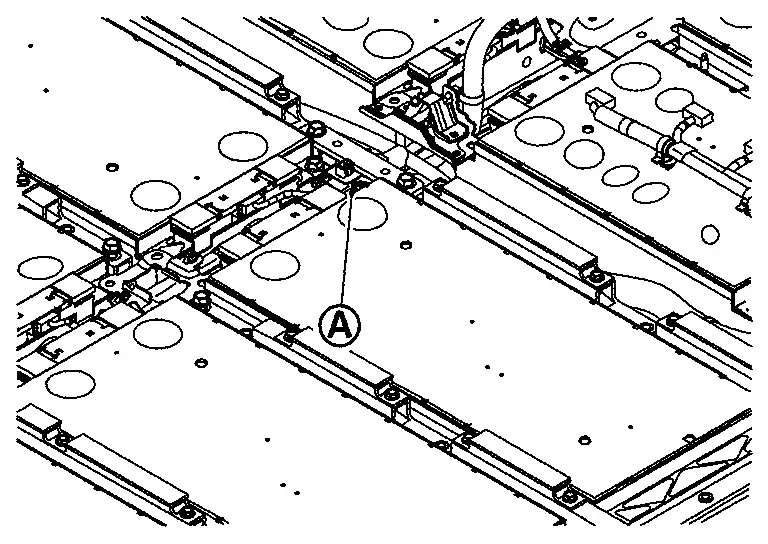

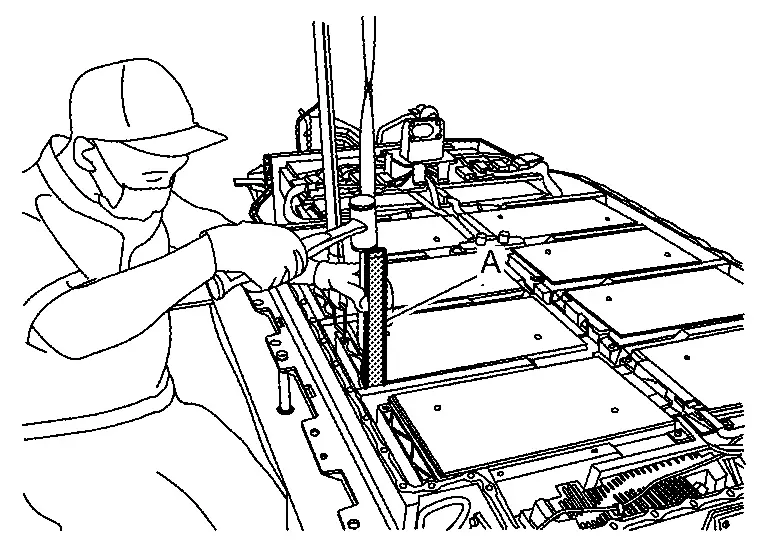

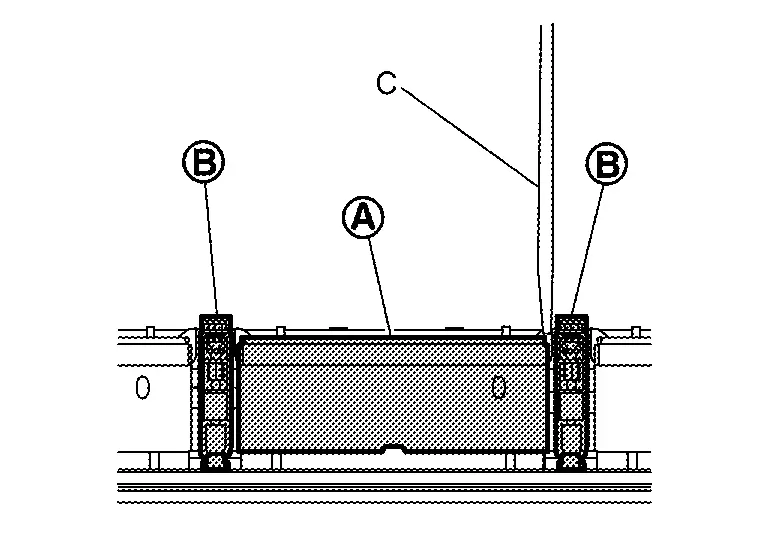

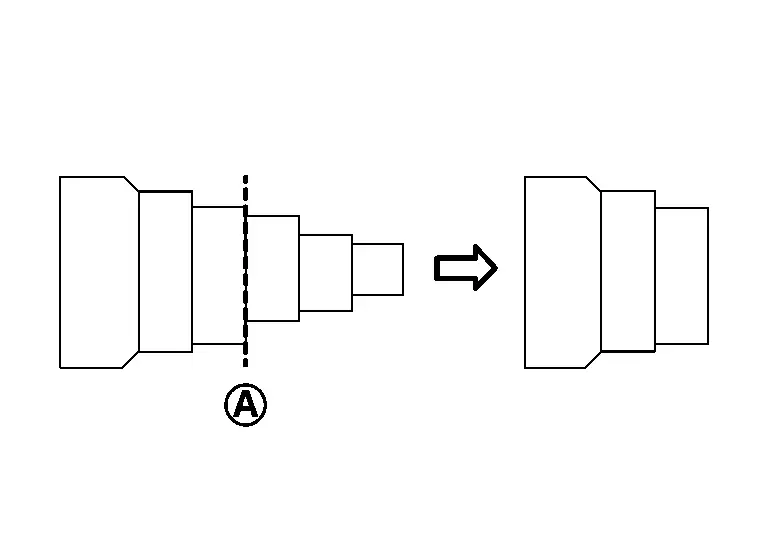

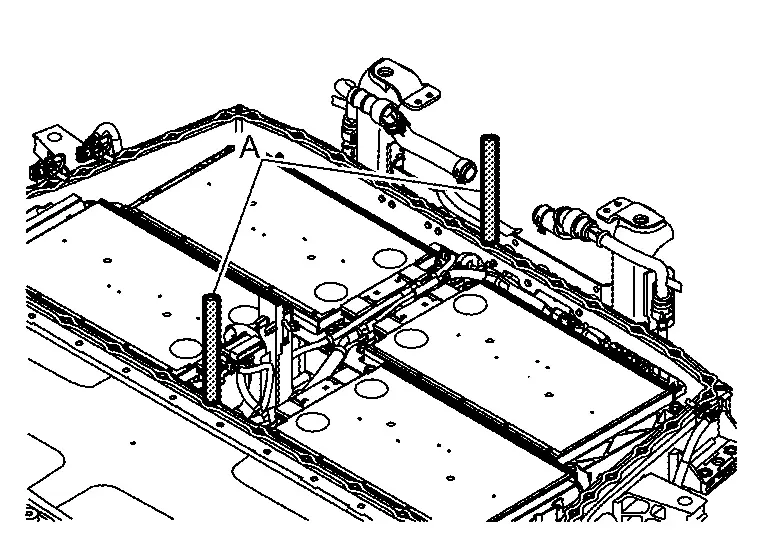

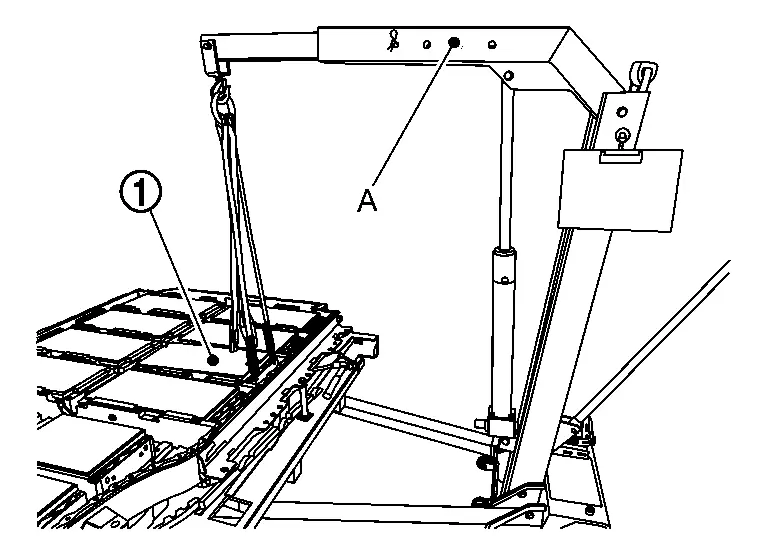

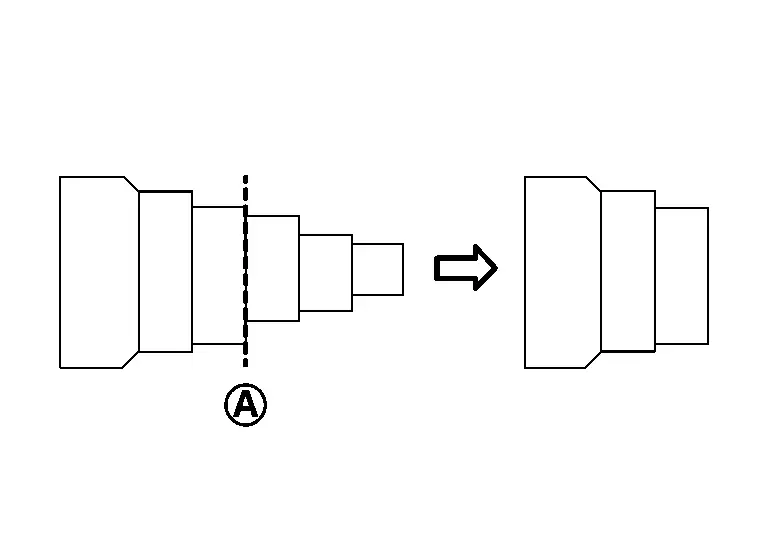

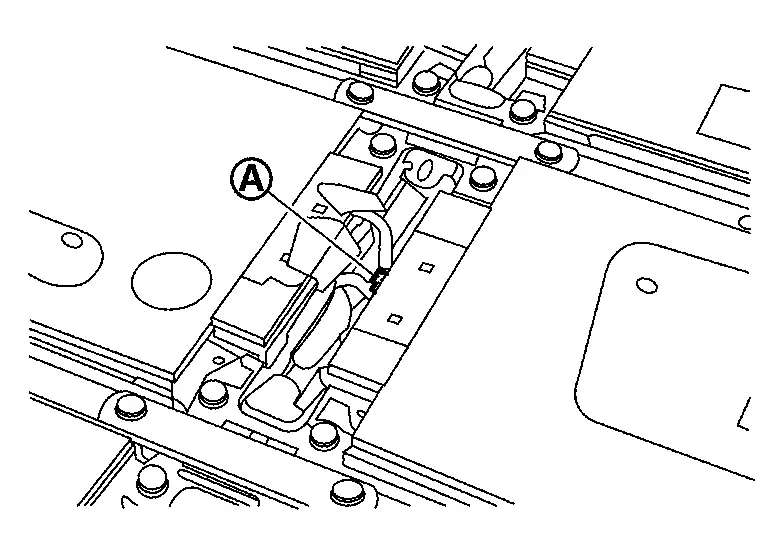

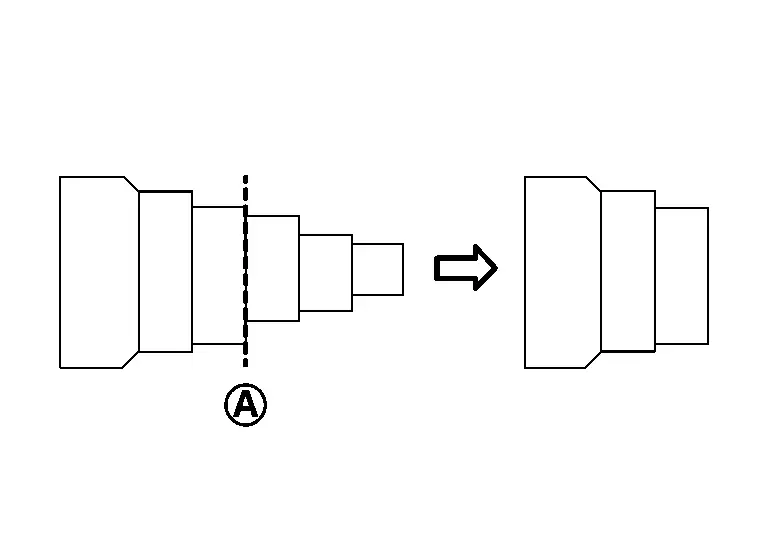

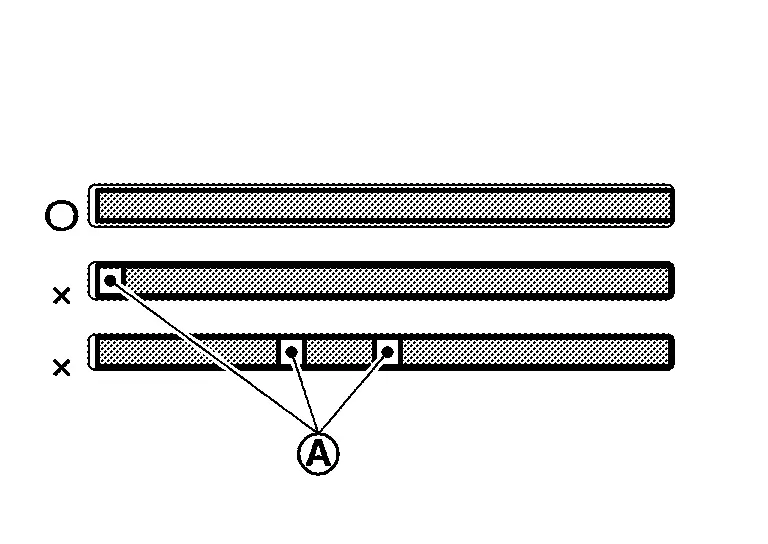

Install guide pin [SST: KV99119600 (J-53348)] (A) to the center of battery pack upper floor assembly.

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

Install insulator cover

CAUTION:

Hold the base sheet (clear) part of the insulator cover, and do not hold the form (white) and EPT sealer (black).

Install the seal of service plug bracket.

Hold both sides of the battery pack upper case to install it.

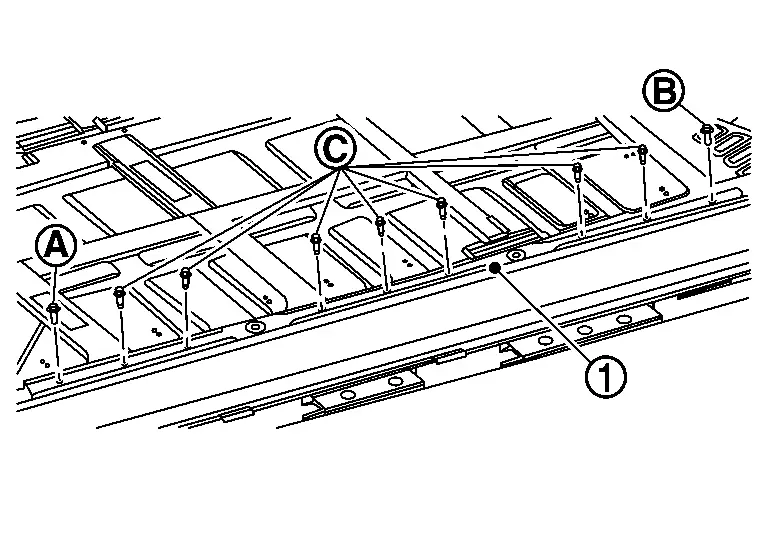

Install each bolt and for each retainer (FR, RR, LH and RH).

NOTE:

NOTE:

-

Tighten each retainer bolt in the order of

→

→ →

→ .

. ,

,

: 11.1 N.m (1.1kg-m, 8 ft-lb)

: 11.1 N.m (1.1kg-m, 8 ft-lb)

: 8.0 N.m (0.82 kg-m, 71 in-lb)

: 8.0 N.m (0.82 kg-m, 71 in-lb)

: Retainer (FR)

: Retainer (RR)

: Both side front

: Retainer (LH), Retainer (RH)

: Battery front

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

Install left and right resin retainer.

|

: Battery front |

|

: 8.0 N.m (0.82 kg-m, 71 in-lb) |

NOTE:

NOTE:

-

The figure shows the left side.

-

Tighten bolts in the order of

→

→ →

→ .

.

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

Install service plug retainer.

Install Li-ion battery cooler tube to battery pack upper floor assembly. Refer to Disassembly & Assembly.

Install battery heater bracket to battery pack lower case.

BATTERY PACK UPPER CASE FRONT

REMOVAL

Remove left and right retainers  .

.

NOTE:

NOTE:

-

The figure shows the left side.

-

Remove bolts for each retainer in the order of

→

→ →

→ .

.

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

Remove left and right resin retainers in the order of 3→2→1

|

: Battery front |

NOTE:

NOTE:

Remove bolts for each resin retainer in the order of  →

→ →

→ .

.

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

Remove retainer  .

.

|

: Battery front |

NOTE:

NOTE:

Remove bolts in the order of  →

→ →

→ .

.

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

Remove bolt  .

.

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

Remove bolt of backward on the battery pack upper case front.

Hold both sides of the battery pack upper case front to remove it.

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

Remove seal from battery pack lower case.

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

INSTALLATION

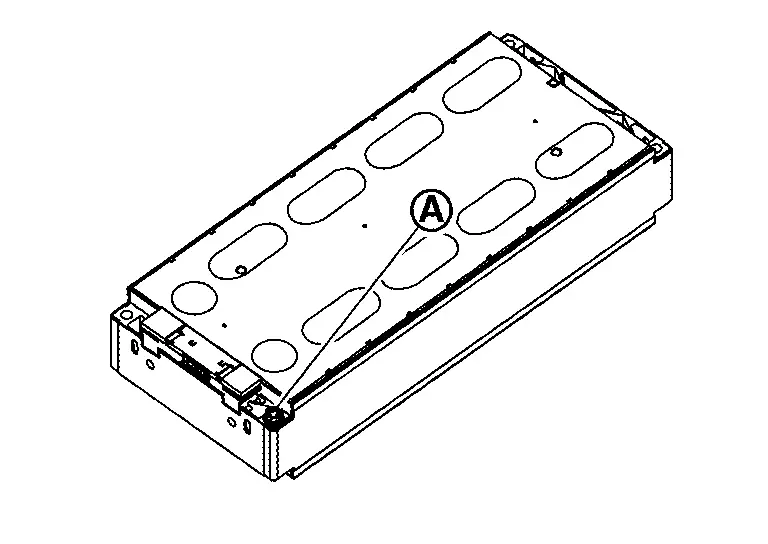

Check that heat shield sheet is still stuck back of battery upper case front.

-

When the sheet is peeled or battery pack upper case front is replaced, stick new heat shield sheet according to the following procedure.

CAUTION:

Work on carton box to prevent the warmed heat from escaping.

-

For the battery pack upper case front, warm the surface where the heat shield sheet are stuck for at least 5 minutes so that the entire surface is at least 15 ℃ (59 °F).

-

Remove the release paper from the heat shield sheet, and then heat the side stuck to battery pack upper case for at least 1 minute so that its temperature is 15 ℃ (59 °F)or higher.

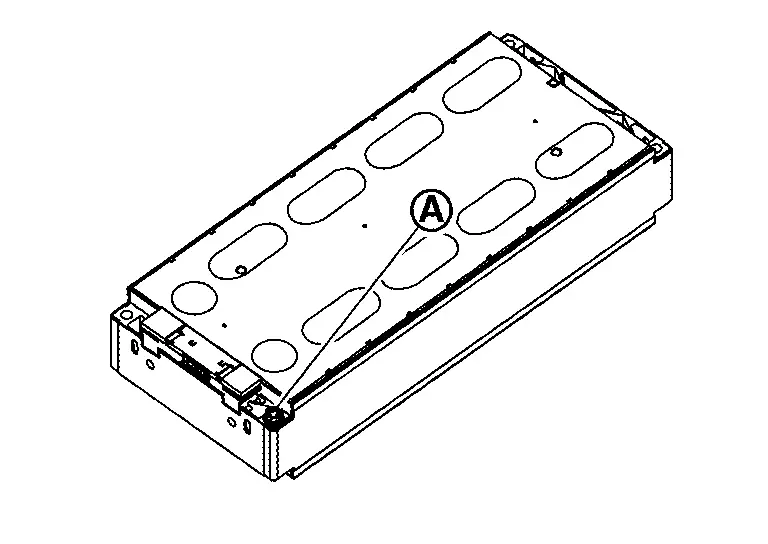

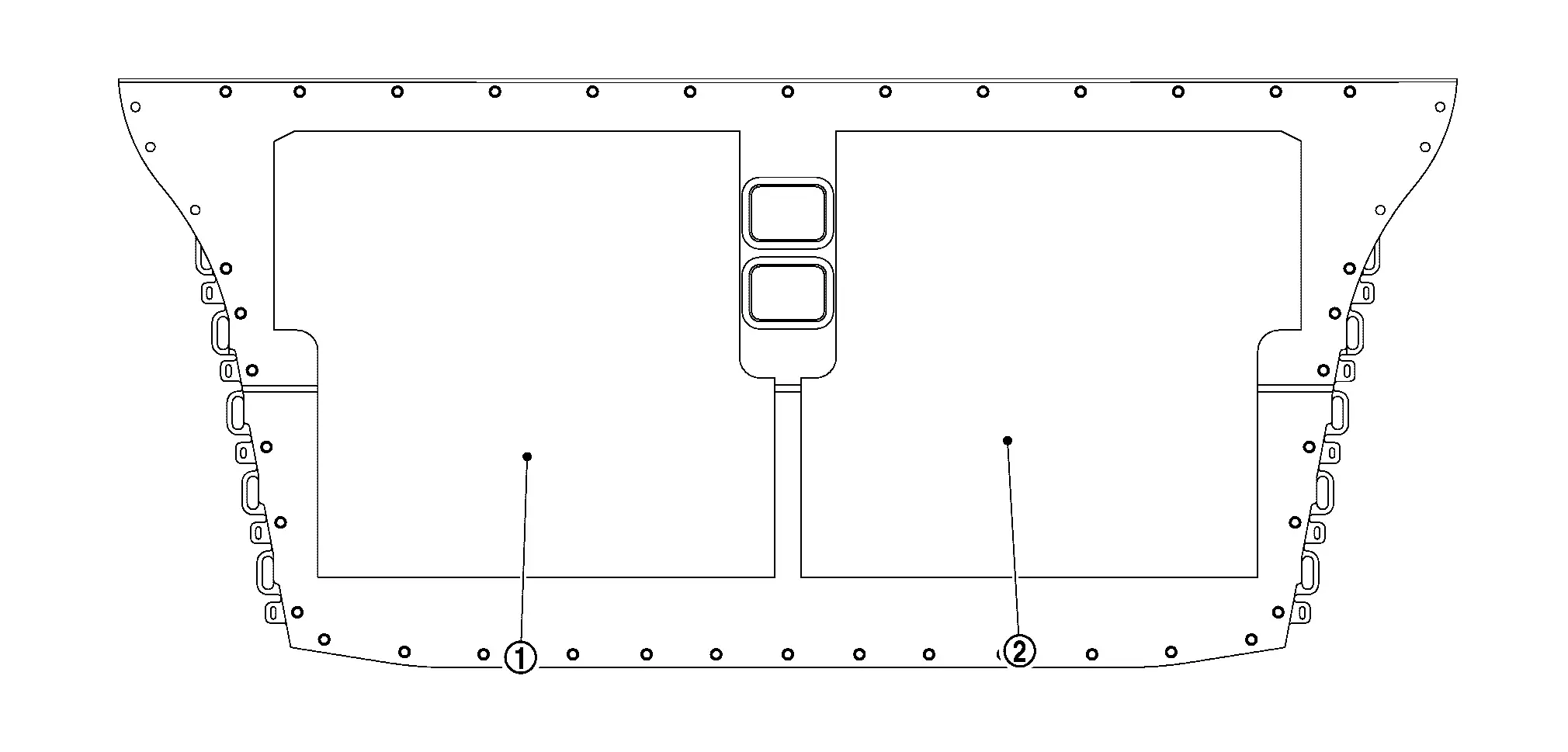

,

,  and

and  to the battery pack upper case front as shown in the figure.

to the battery pack upper case front as shown in the figure.

|

Position mark (Projection) |

NOTE:

NOTE:

Stick the heat shield sheet that hides the inner position mark where two position marks are lined up.

After sticking the heat shield sheet, press the whole by hands.Install seal to battery pack lower case.

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

CAUTION:

The flat side  of seal faces battery pack lower case.

of seal faces battery pack lower case.

Hold both sides of battery pack upper case front and install it.

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

Tighten bolts  .

.

|

: Battery front |

|

: 11.1 N.m (1.1 kg-m, 8 ft-lb) |

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

Install retainer  .

.

|

: Battery front |

|

: 8.0 N.m (0.82 kg-m, 71 in-lb) |

NOTE:

NOTE:

Tighten bolts in the order of  →

→ →

→ .

.

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

Tighten bolt .

.

|

: Battery front |

|

: 8.0 N.m (0.82 ㎏-m) |

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

Install resin retainers in the order of 1→2→3.

|

: Battery front |

|

: 8.0 N.m (0.82 kg-m, 71 in-lb) |

NOTE:

NOTE:

Tighten bolts of each resin retainer in the order of  →

→ →

→ .

.

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

Install left and right retainers  .

.

NOTE:

NOTE:

-

The figure shows the left side.

-

Tighten bolts for each retainer in the order of

→

→ →

→ .

. ,

,

: 11.1 N.m (1.1 kg-m, 8 ft-lb)

: 11.1 N.m (1.1 kg-m, 8 ft-lb)

: 8.0 N.m (0.82 kg-m, 71 in-lb)

: 8.0 N.m (0.82 kg-m, 71 in-lb)

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

Install bolt of backward on the battery pack upper case front.

: 8.0 N.m (0.82 kg-m, 71 in-lb) : 8.0 N.m (0.82 kg-m, 71 in-lb) |

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

Inspection

APPEARANCE CHECK

Check resin retainer  for damage.

for damage.

: Battery front

: Battery front

CAUTION:

When resin retainer is damaged, remove battery upper case and check that no water is entering in the case.

AIR LEAK INSPECTION

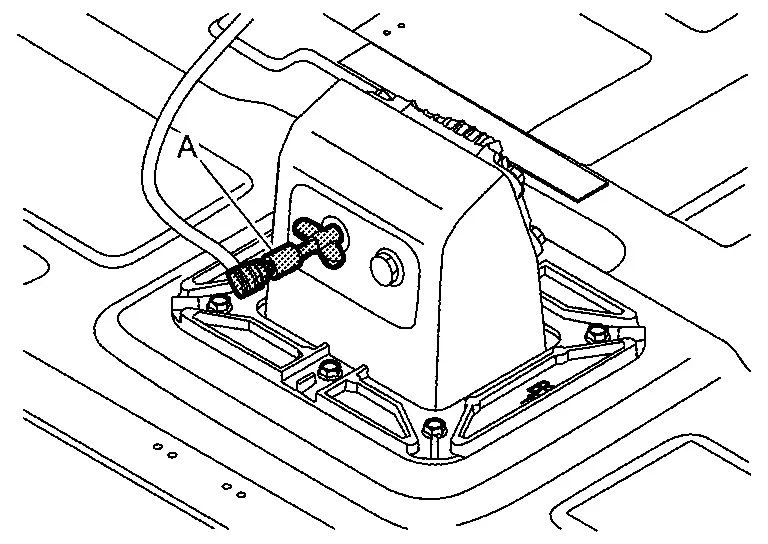

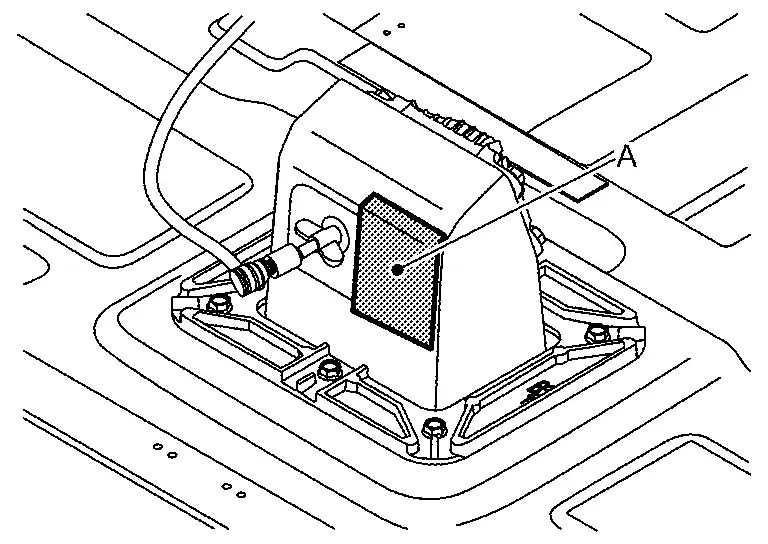

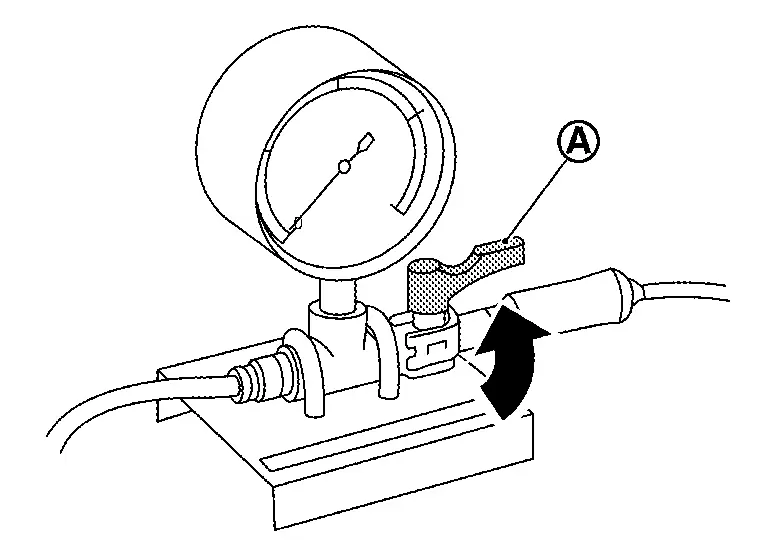

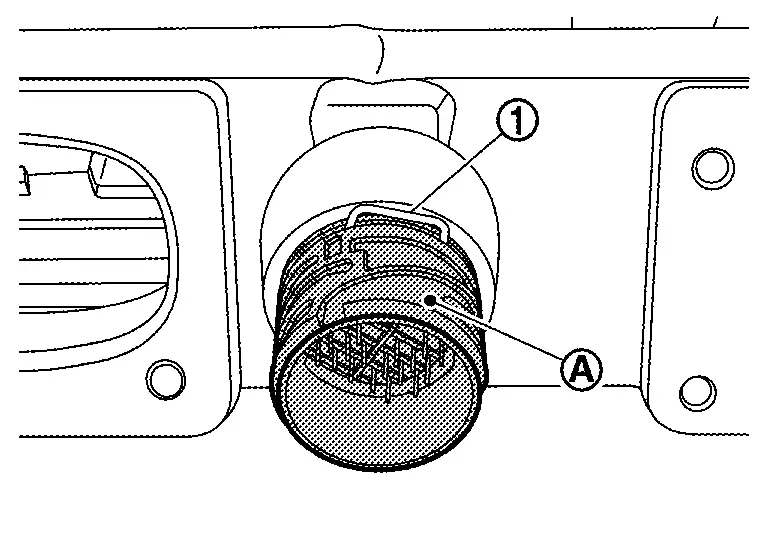

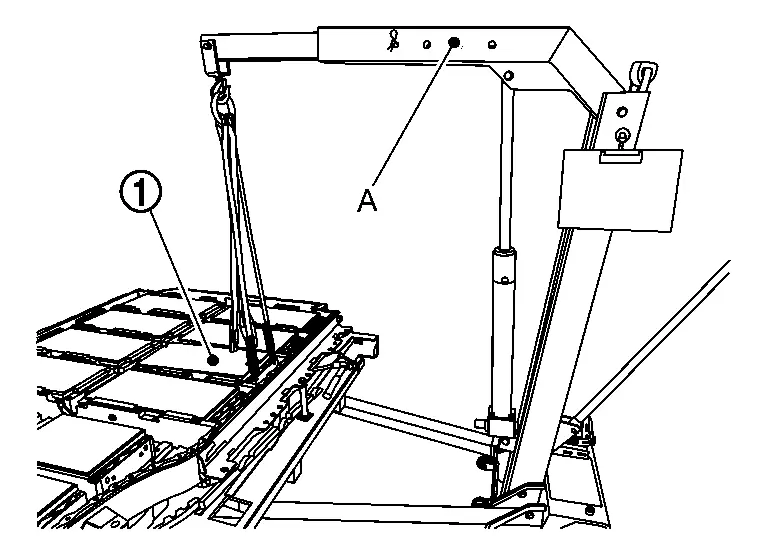

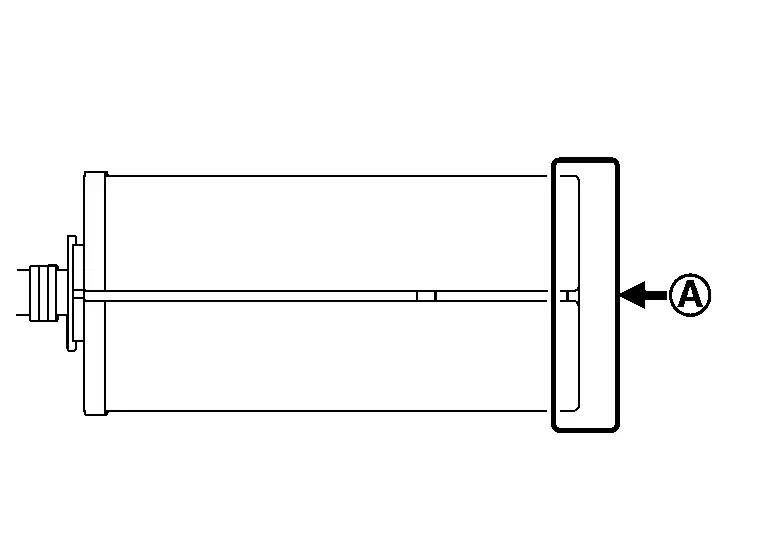

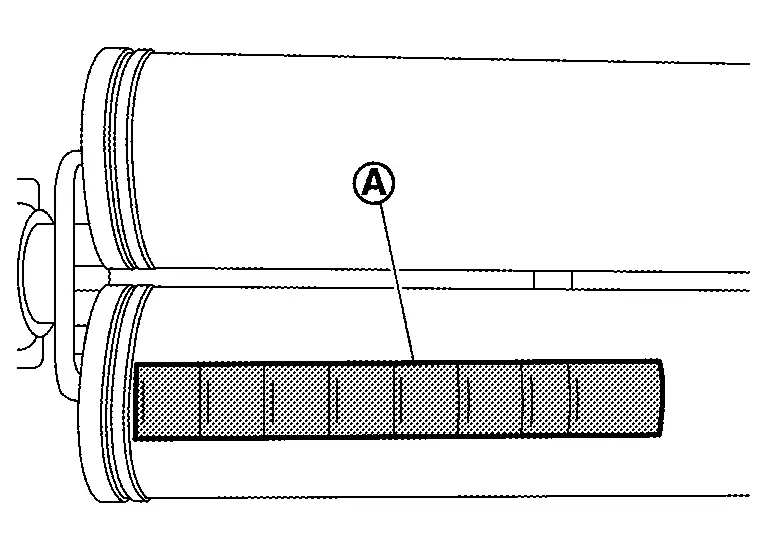

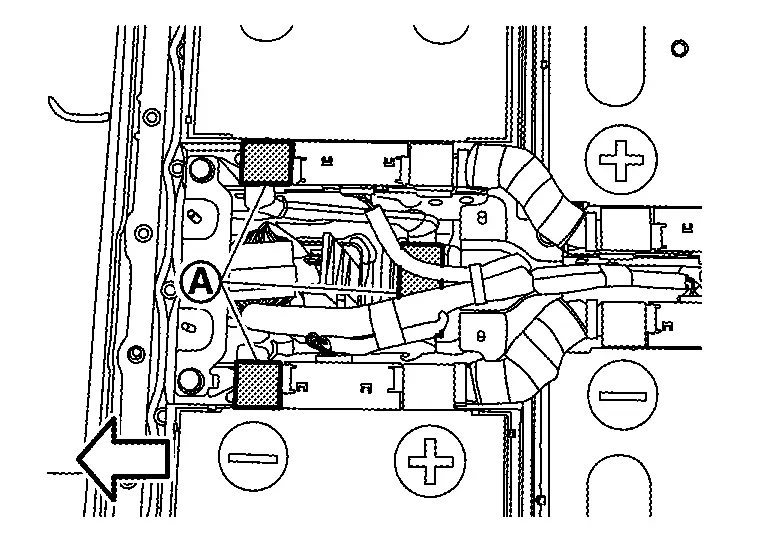

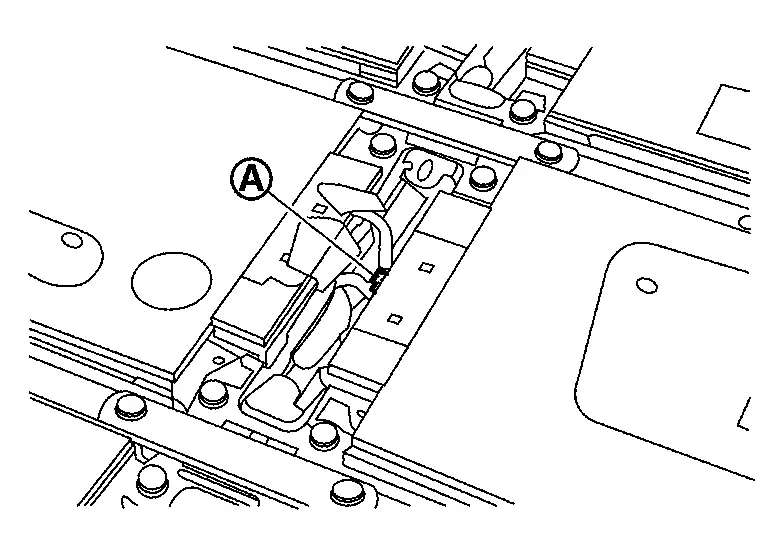

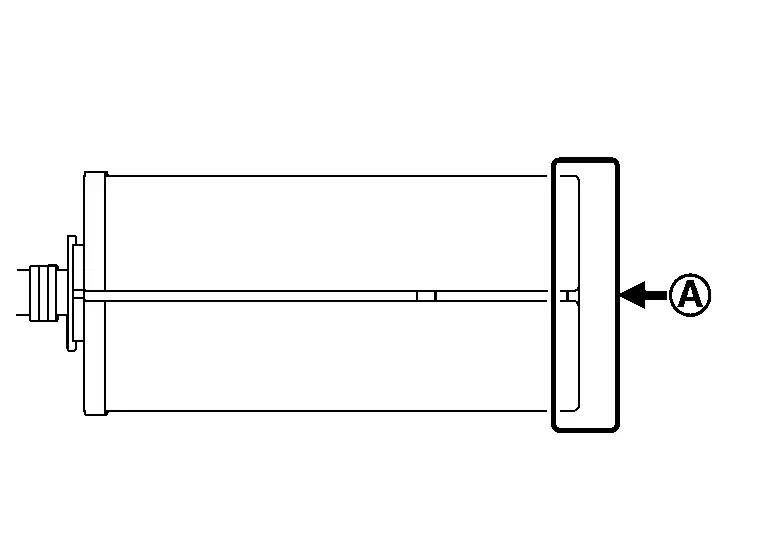

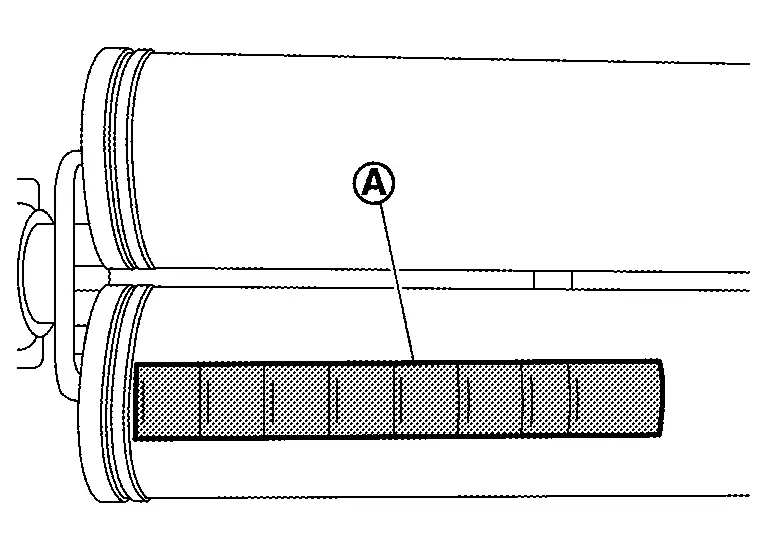

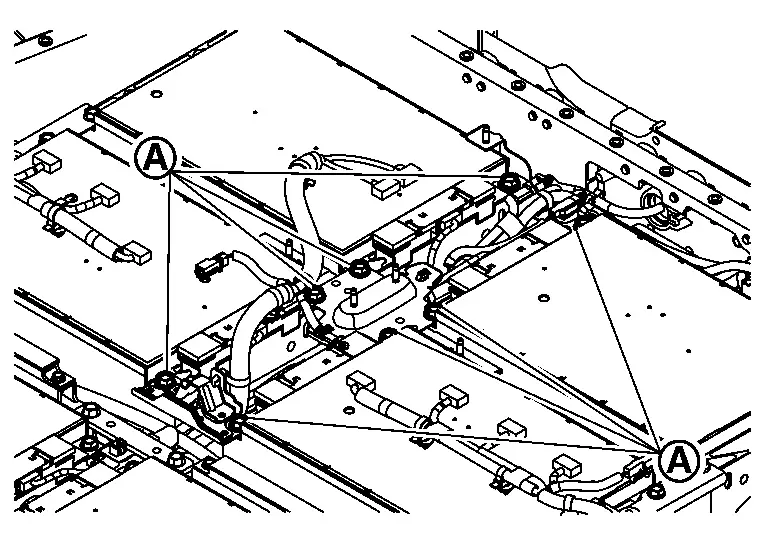

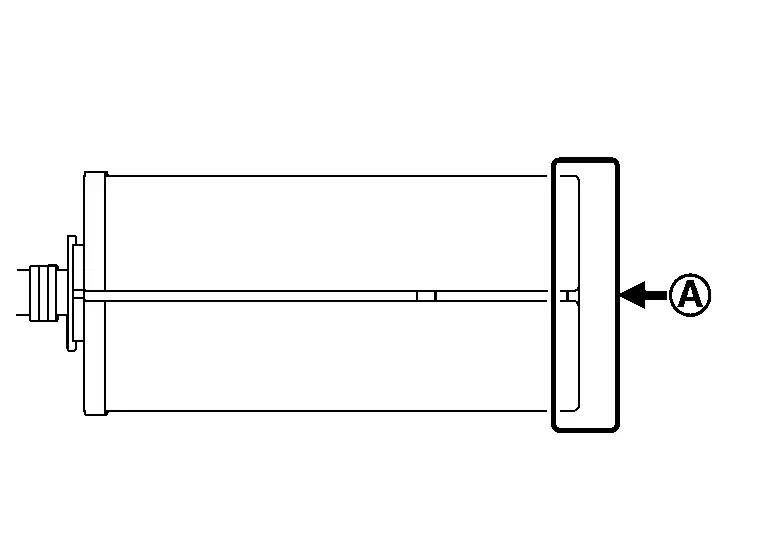

Remove breather and install adapter (A) of air leak tester [SST: KV99112400 (J-53357)].

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

NOTE:

NOTE:

Tighten wing nut by turning 6 to 8 times.

Install gauge (A) of air leak tester [SST: KV99111400 (-)].

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

CAUTION:

The gauge is a precision instrument. Be careful not to drop it when handling it.

Install service plug. Refer to HOW TO DISCONNECT HIGH VOLTAGE : Precautions.DANGER:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

NOTE:

NOTE:

Because the service plug location is open, install the service plug for sealing the case.

Blocks high power connector and Nissan Ariya vehicle communications harness connector with vinyl tape or equivalent for preventing air leakage from connection area.

-

Use wide vinyl tape that is capable of covering all of the high power connector and Nissan Ariya vehicle communications harness connector with one strip.

-

Apply carefully so that no wrinkles in the tape occur.

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

Block breather with vinyl tape prevent air from leaking.

-

Apply carefully so that no wrinkles in the tape occur.

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

Perform battery case pressure test according to the following procedure.

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

of air leak tester.

of air leak tester.

CAUTION:

Do not operate the pump before opening the cock of air leak tester. Doing so may damage the gauge. If the pump is operated before the cock is opened, first disconnect the air pump hose to release the pressure.

Operate the air pump slowly and apply the specified test pressure in the battery pack. If the gauge pressure does not rise, or if the gauge reading fluctuates, check for the location air leakage.| Specified test pressure | : 1.6 kPa (0.016 bar, 0.0163 kg/cm2, 0.232 psi) |

CAUTION:

-

Operate the air pump carefully when applying pressure. If pressure is applied suddenly to the gauge, the gauge may be damaged.

-

Do not apply pressure of 2.0 kPa (0.02 bar, 0.0204 kg/cm2, 0.29 psi) or more to the battery case or air leak tester.

| Repair limit | : 1.4 kPa (0.014 bar, 0.0142 kg/cm2, 0.203 psi) |

NOTE:

NOTE:

Check for air leakage from the sound of air escaping when pressure is applied.

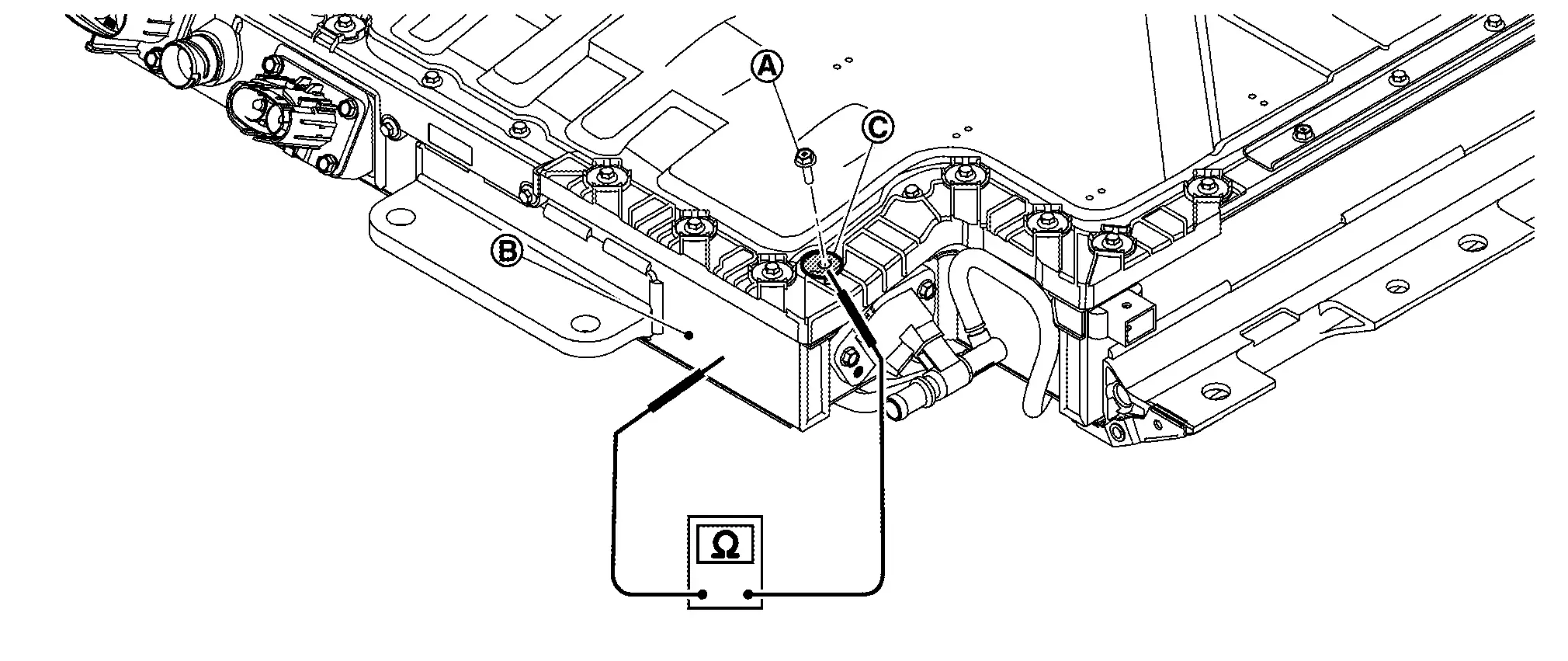

ELECTRIC EQUIPOTENTIAL TEST

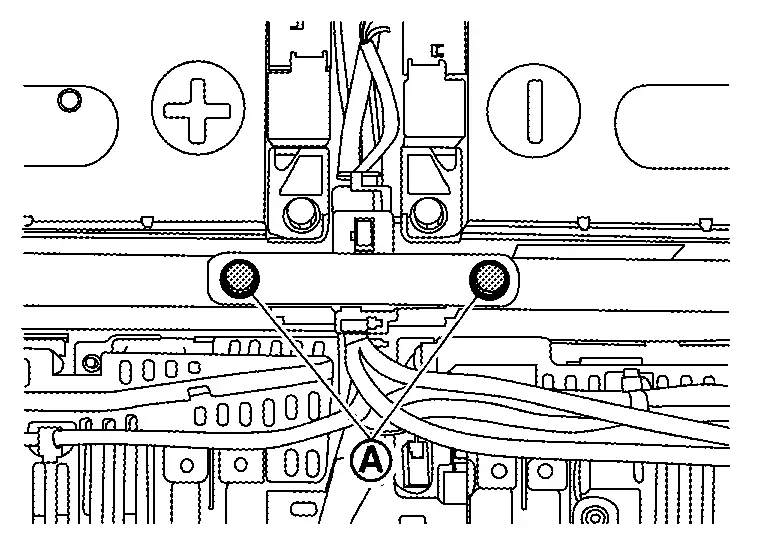

After assembling Li-ion battery pack, remove the battery pack upper case ground bolt  , then measure the resistance between the side of battery pack lower case

, then measure the resistance between the side of battery pack lower case  and the seating surface of ground bolt (location of coating peeling)

and the seating surface of ground bolt (location of coating peeling)  .

.

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

| Specified value | : Less than 0.1 Ω |

If the result deviates from the specified value, check the following and repair the malfunction parts.

-

Ground bolt connection condition

-

Corrosion on ground bolt mounting surface

-

Adhesion of paint, oil, dirt, or other substance on ground bolt mounting surface

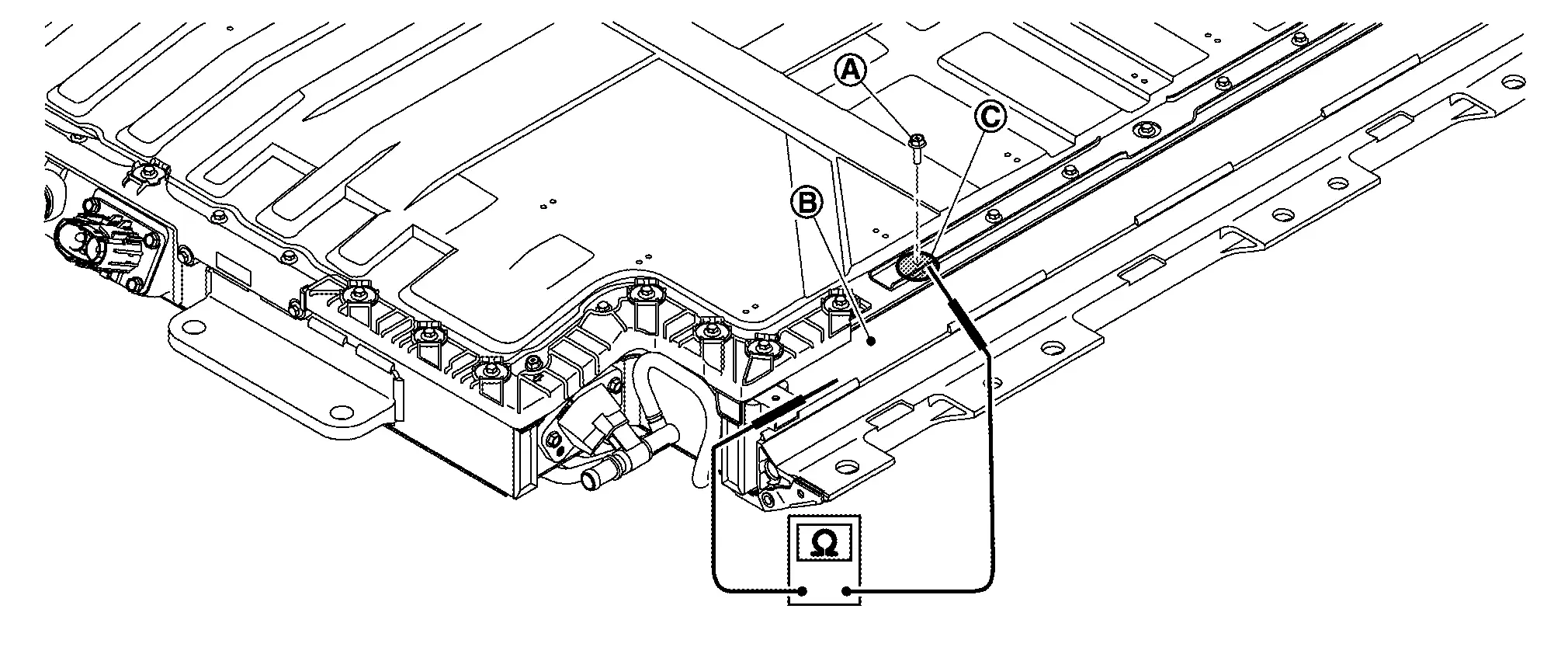

After assembling Li-ion battery pack, remove the retainer ground bolt  , then measure the resistance between the side of battery pack lower case

, then measure the resistance between the side of battery pack lower case  and the seating surface of ground bolt (location of coating peeling)

and the seating surface of ground bolt (location of coating peeling)  .

.

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

| Specified value | : Less than 0.1 Ω |

If the result deviates from the specified value, check the following and repair the malfunction parts.

-

Ground bolt connection condition

-

Corrosion on ground bolt mounting surface

-

Adhesion of paint, oil, dirt, or other substance on ground bolt mounting surface.

NOTE:

NOTE:

-

The figure shows retainer of left side.

-

Since retainers are symmetrical parts, do the same for the right retainer.

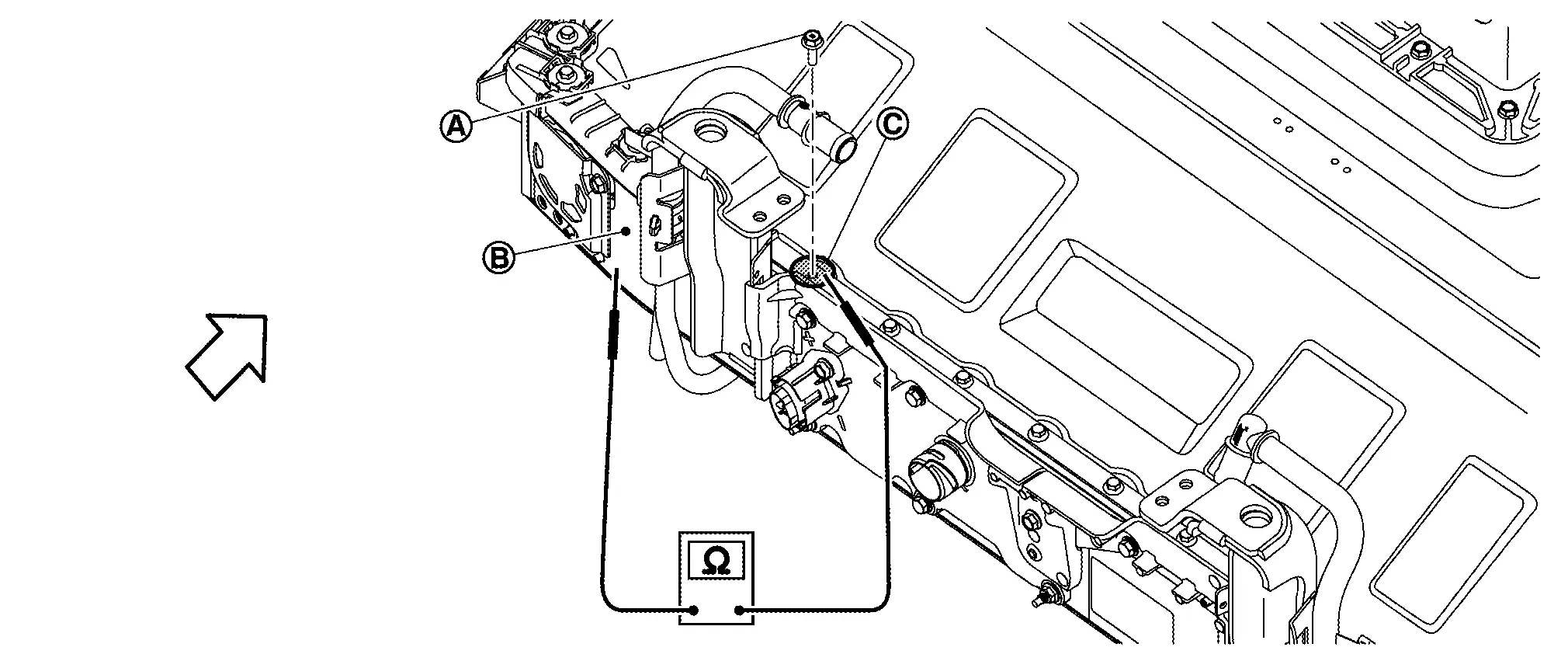

After assembling Li-ion battery pack, remove the rear retainer ground bolt  , then measure the resistance between the side of battery pack lower case

, then measure the resistance between the side of battery pack lower case  and the seating surface of ground bolt (location of coating peeling)

and the seating surface of ground bolt (location of coating peeling)  .

.

|

: Battery front |

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

| Specified value | : Less than 0.1 Ω |

If the result deviates from the specified value, check the following and repair the malfunction parts.

-

Ground bolt connection condition

-

Corrosion on ground bolt mounting surface

-

Adhesion of paint, oil, dirt, or other substance on ground bolt mounting surface.

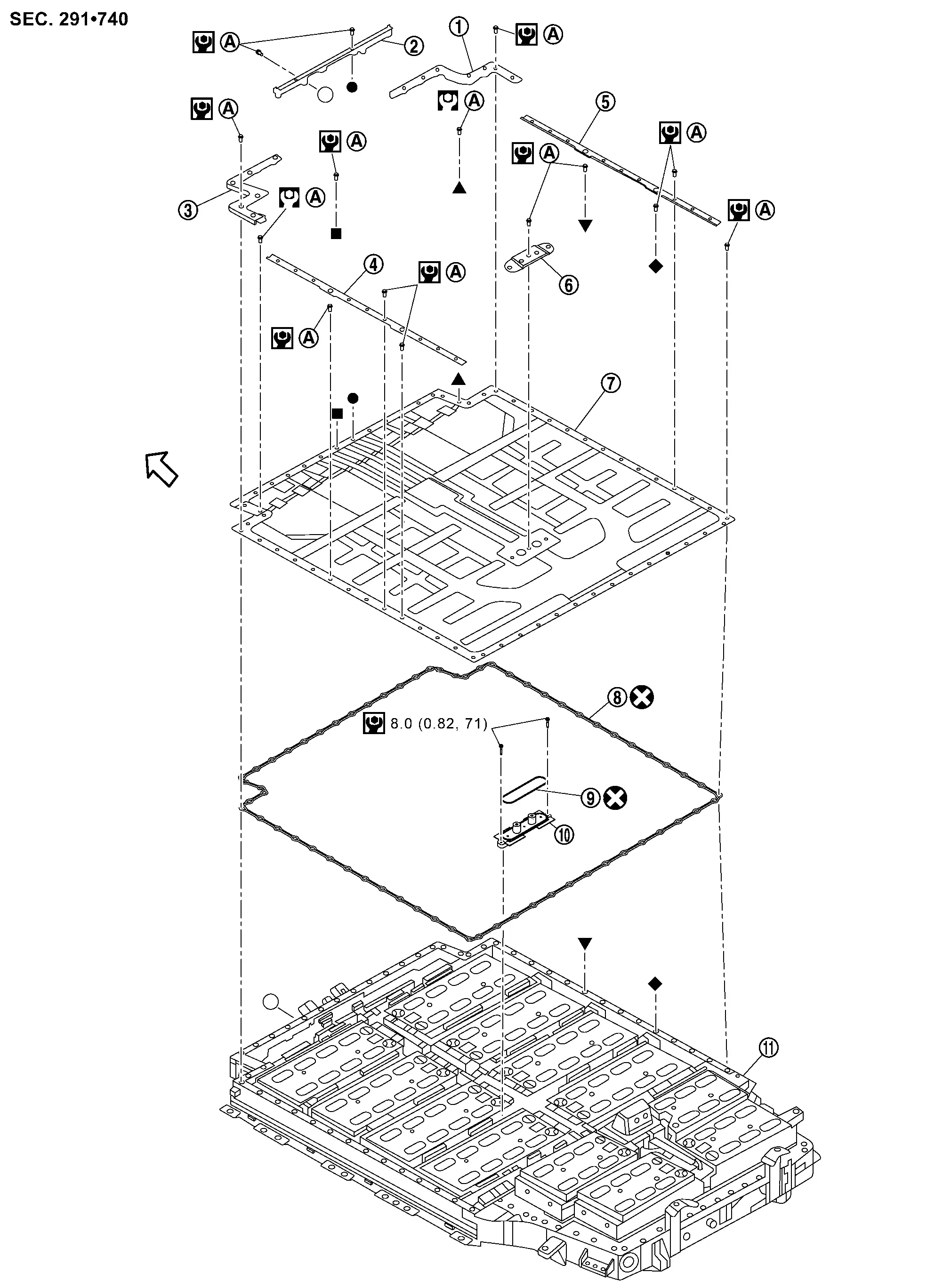

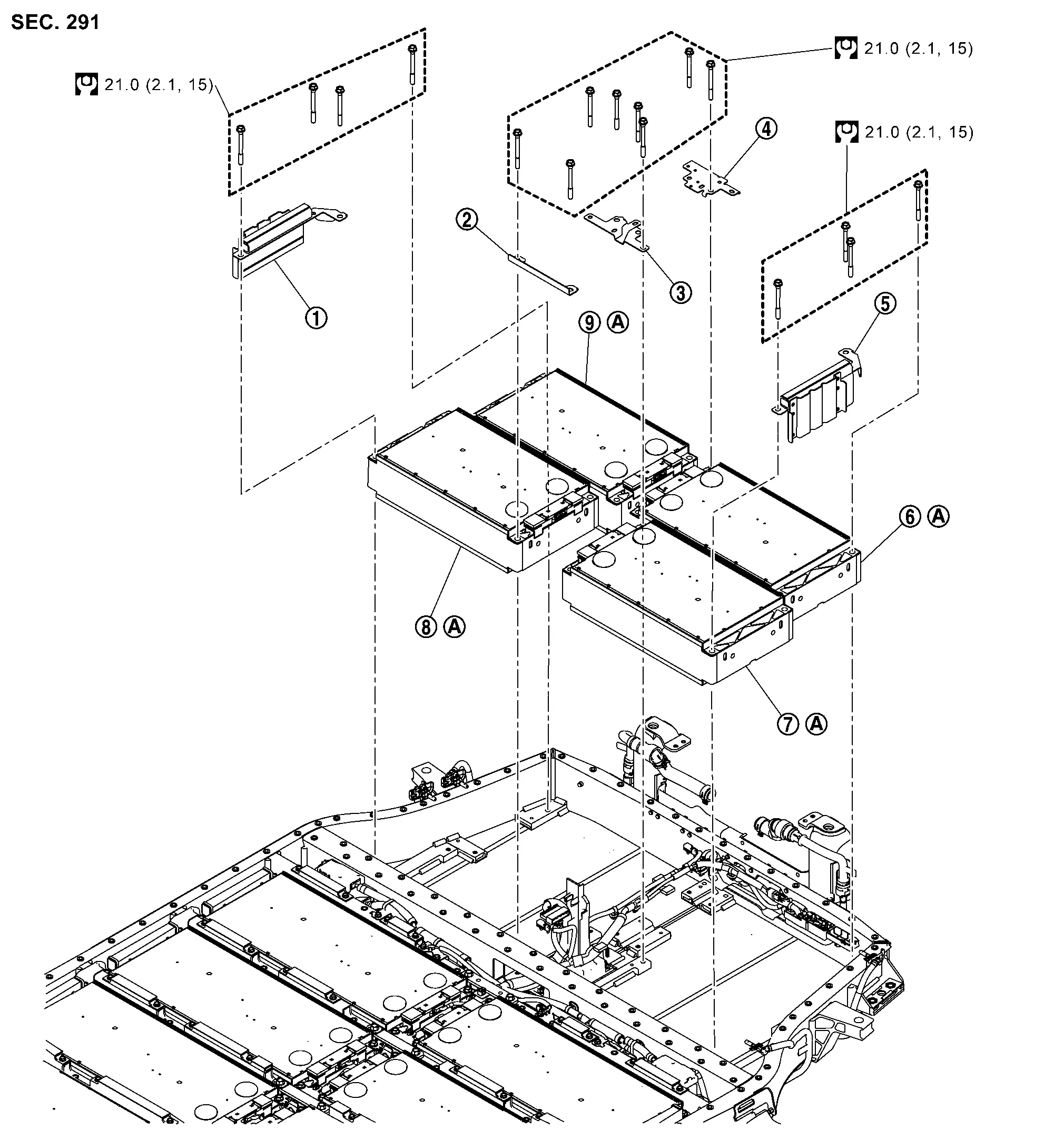

Battery Pack Lower Case. 2wd Nissan Ariya first Gen

Exploded View

|

Battery pack lower case |  |

Battery ventilation valve cover LH |  |

Rear box |

|

Seal |  |

Battery ventilation valve cover RH |  |

Terminal block |

|

Bracket with ept sealer |  |

Ept sealer | ||

|

Battery ventilation valve | ||||

|

: Nissan Ariya Vehicle front | ||||

|

: Always replace after every disassembly. | ||||

|

: N·m (kg-m, in-lb) |

Disassembly & Assembly

DANGER: Because hybrid vehicles and electric vehicles contain a high voltage battery, there is a risk of electric shock, electric leakage, or similar accidents if the Nissan Ariya vehicle is handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

Because hybrid vehicles and electric vehicles contain a high voltage battery, there is a risk of electric shock, electric leakage, or similar accidents if the Nissan Ariya vehicle is handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

WARNING:

-

Be sure to remove the service plug in order to shut off the high voltage circuits before performing inspection or maintenance of high voltage system harnesses and parts.

-

Be sure to put the removed service plug in pocket and carry it or store it in a tool box or other container so that another person does not accidentally connect it while work is in progress.

-

Be sure to put on insulating protective gear before beginning work on the high voltage system.

-

Clearly identify the persons responsible for high voltage work and ensure that other persons do not touch the Nissan Ariya vehicle. When not working, cover high voltage components with an anti-static cover sheet or similar item to prevent contact with other persons.

-

Refer to PRECAUTIONS FOR HIGH VOLTAGE : Precautions.

-

If the battery pack is to be disassembled, be sure to remove the Li-ion battery controller for preventing electric shock, fire, and damage to parts.

CAUTION:

There is the possibility of a malfunction occurring if the vehicle is changed to READY status while the service plug is removed. Therefore do not change the Nissan Ariya vehicle to READY status unless instructed to do so in the Service Manual.

ENVIRONMENT FOR LI-ION BATTERY DISASSEMBLY WORK

Must be an indoor environment.

-

The environment must utilize a shutter or other means to shut out the outside environment and prevent rain, snow, dust, or other substances from entering.

-

The environment must not cause the intrusion of sweat during work, or cause condensation to occur due to high temperature or humidity.

Metal powder, grease, and other foreign substances must not enter.

-

The indoor environment must also prevent metal powder, grease, and other foreign substances from entering due to maintenance performed on other Nissan Ariya vehicles and other sources during disassembly work.

-

During disassembly without internal work, temporarily close the battery pack upper case or cover it with an insulating cover.

The floor must be dry.

-

The floor must not be wet as a result of factors such as Nissan Ariya vehicle entry during rain or snow.

Work space

-

The work space must be approximately the size of one entire Nissan Ariya vehicle.

-

Take appropriate countermeasures so that persons other than the operator do not enter the work space, such as by placing signs indicating that disassembly work is in progress.

Standard fire fighting equipment

-

Always place a standard fire fighting equipment in the disassembly work area.

-

Depending on type of fire (Nissan Ariya vehicle or battery) use standard fire fighting equipment (water or extinguisher).

REAR BOX

Disassembly

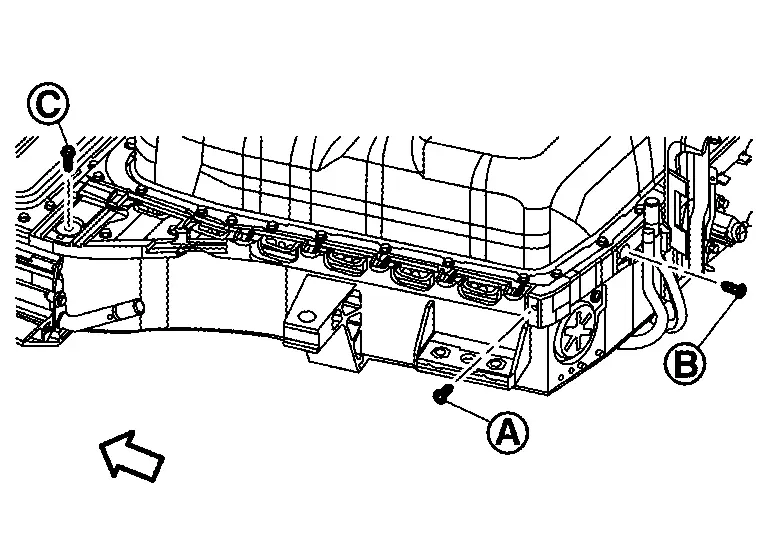

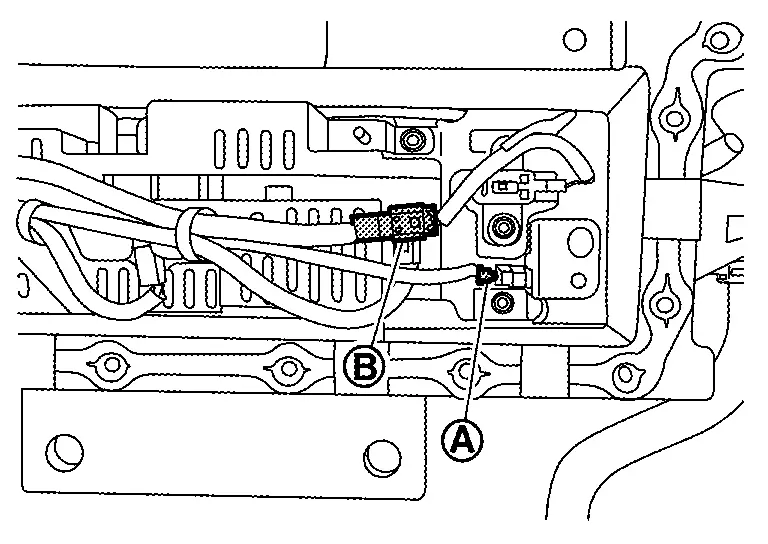

Open bus bar terminal block and remove nut  .

.

WARNING:

To prevent electric shock, wear insulated protective gear and use insulated tools.

To prevent electric shock, wear insulated protective gear and use insulated tools.

Remove connectors  ,

,  and

and  .

.

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

CAUTION:

Because there is the danger of electric shock, immediately insulate disconnected high voltage connectors with insulating tape.

Remove bolts  and nuts

and nuts  and the remove rear box

and the remove rear box  .

.

CAUTION:

Never loose high power bolts  and

and  .

.

WARNING:

To prevent electric shock, wear insulated protective gear and use insulated tools.

To prevent electric shock, wear insulated protective gear and use insulated tools.

If necessary, remove clip  and the remove Nissan Ariya vehicle communication harness (Battery PTC)

and the remove Nissan Ariya vehicle communication harness (Battery PTC) .

.

CAUTION:

Never loose bolt  .

.

Remove seal from rear box.

ASSEMBLY

Note the following items, and assemble in the reverse order of disassembly.

DANGER:-

There is the danger of electric shock caused by contact with the terminals. Be sure to wear insulated protective gear and use insulated tools.

There is the danger of electric shock caused by contact with the terminals. Be sure to wear insulated protective gear and use insulated tools.

-

Because there is a danger of electric shock and fire, never allow bus bar to contact a wrong terminal.

Because there is a danger of electric shock and fire, never allow bus bar to contact a wrong terminal.-

If bus bar contacts a wrong terminal, the circuit becomes energized and a short may occur.

-

Always keep the bus bar cover closed until immediately before the installation of bus bar.

-

BATTERY VENTILATION VALVE COVER

Disassembly

Remove right or left battery ventilation valve cover  .

.

WARNING:

To prevent electric shock, wear insulated protective gear and use insulated tools.

To prevent electric shock, wear insulated protective gear and use insulated tools.

Assembly

Install the above right or left ventilation valve cover by aligning with projection of battery pack lower case.

WARNING:

To prevent electric shock, wear insulated protective gear and use insulated tools.

To prevent electric shock, wear insulated protective gear and use insulated tools.

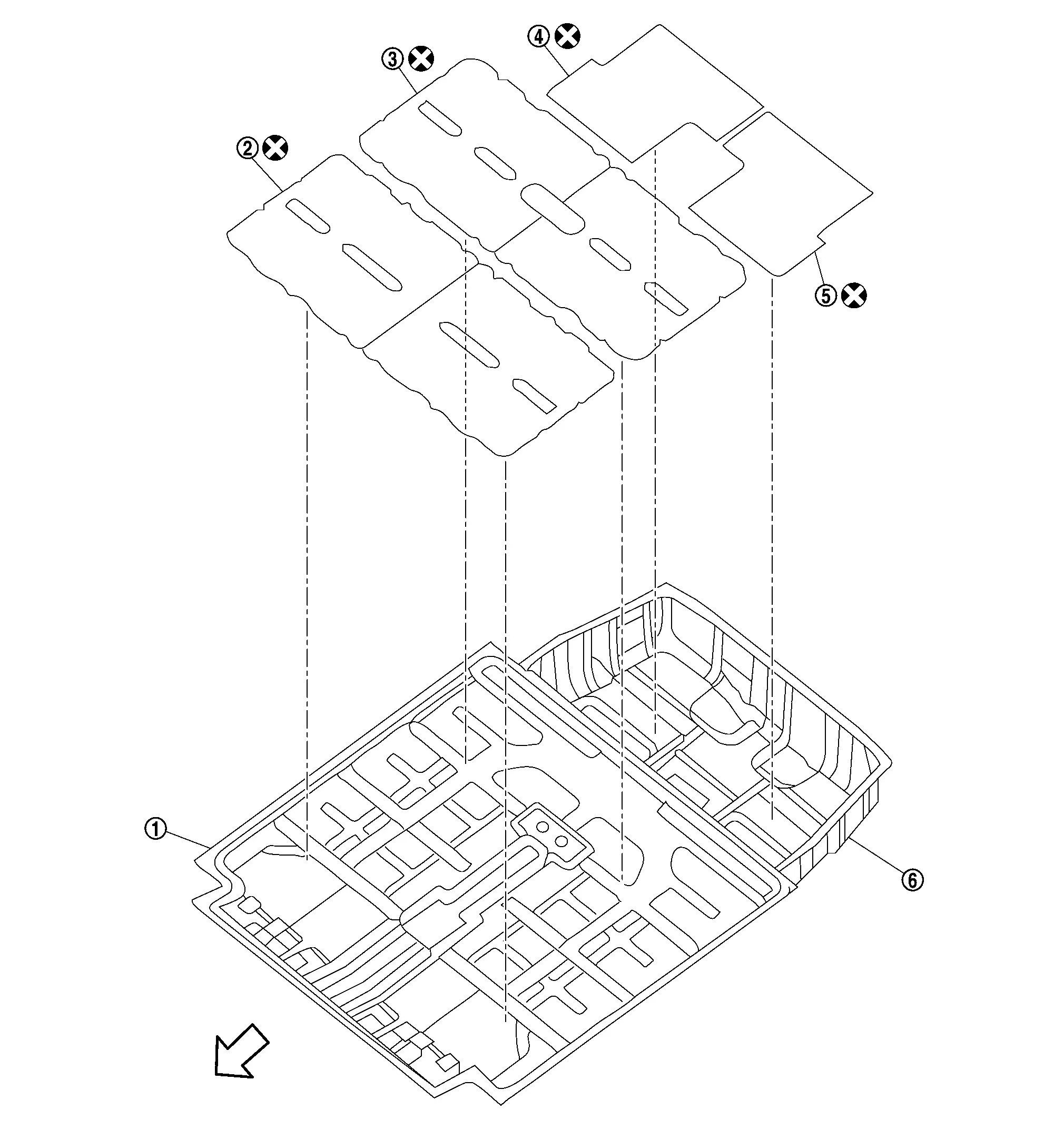

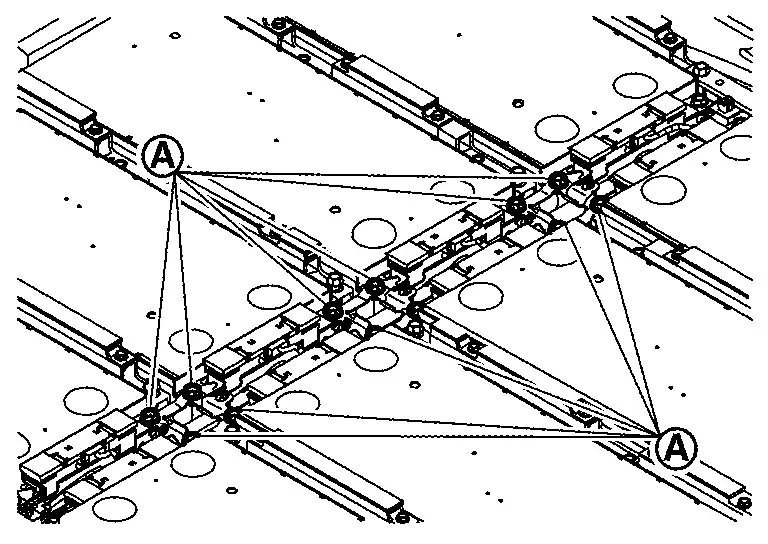

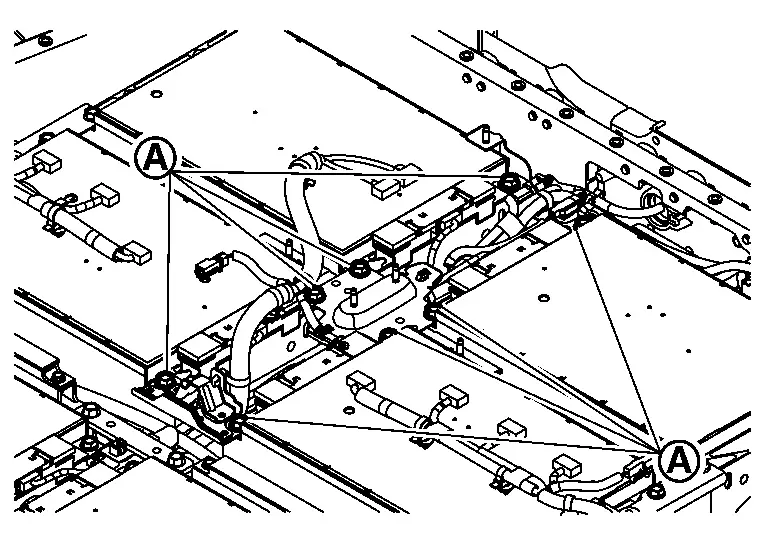

EPT SEALER REPLACEMENT

Check the figure because the procedure differs depending on the location.

to to  |

: Stick to bracket |

and and  |

: Stick to cross member of battery lower case. |

Perform parts from  to

to  according to the following procedure.Remove the bracket that requires replacement of EPT sealer.

according to the following procedure.Remove the bracket that requires replacement of EPT sealer.

WARNING:

To prevent electric shock, wear insulated protective gear and use insulated tools.

To prevent electric shock, wear insulated protective gear and use insulated tools.

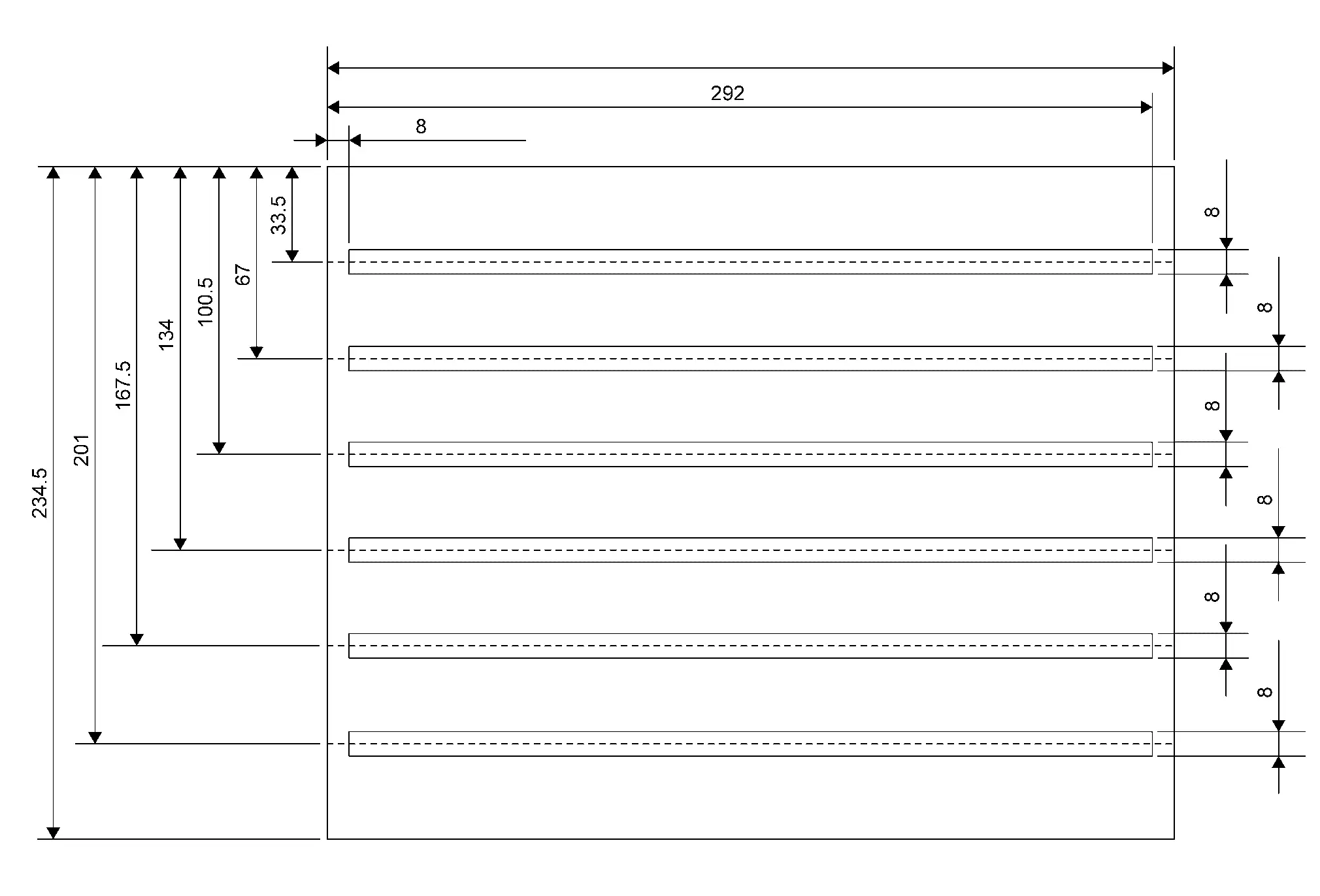

|

: 111 mm (4.37 in) × 23 mm (0.91 in) |

|

: 184 mm (7.24 in) × 23 mm (0.91 in) |

|

: 139 mm (5.47 in) × 23 mm (0.91 in) |

|

: 39 mm (1.54 in) × 23 mm (0.91 in) |

|

:58 mm (2.28)×23 (0.91) mm |

|

: EPT sealer |

|

: Bracket |

|

: 0.5 mm (0.020 in) |

CAUTION:

Do not deviate from the position of EPR seal shown in the figure.

Hold EPT seal firmly with the ball of fingers.

Perform parts from  and

and  according to the following procedure.

according to the following procedure.

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

|

: 150 mm (5.91 in) × 26 mm (1.02 in) |

|

: 100 mm (3.94 in) × 26 mm (1.02 in) |

.

.

|

: EPT sealer |

|

: 10 mm (0.39 in) |

CAUTION:

Do not deviate from the position of EPR seal shown in the figure.

NOTE:

NOTE:

-

Since the work is done with insulated gloves,

are used as dedicated handles.

are used as dedicated handles. -

Bend handles

down and stick them to the inclined parts.

down and stick them to the inclined parts.

Service Plug Bracket Nissan Ariya 1st generation

Exploded View

REMOVAL

|

Seal |  |

Service plug bracket |  |

Breather |

|

: Nissan Ariya Vehicle front | ||||

|

: Always replace after every disassembly. | ||||

|

: N·m (kg-m, in-lb) |

DISASSEMBLY

NOTE:

NOTE:

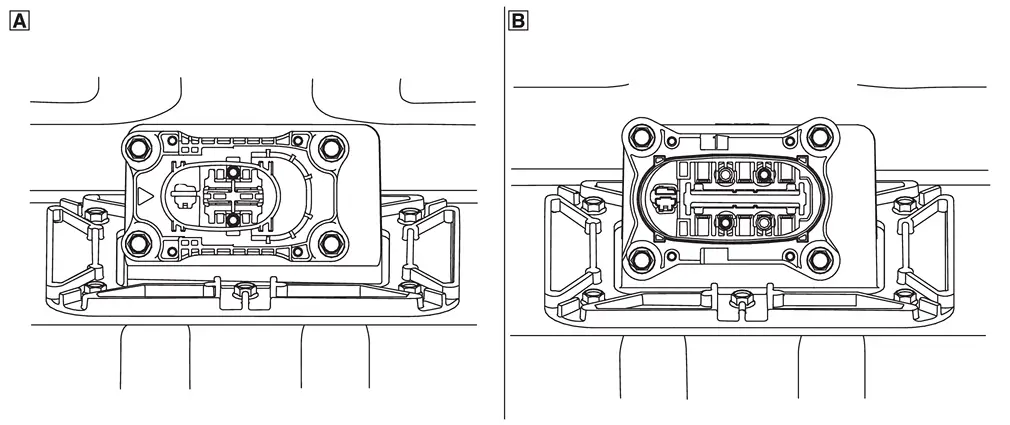

The size of service plug switch differs depends on Li-ion Battery specification. Remove the service plug and confirm its form.

: TYPE A

: TYPE A

: TYPE B

: TYPE B

TYPE A

|

Service plug bracket |  |

Service plug switch |  |

Engagement detection switch (service plug) harness |

|

Busbar 14 |  |

Busbar 13 |  |

Busbar 12 |

|

: Always replace after every disassembly. | ||||

|

: N·m (kg-m, in-lb) |

TYPE B

|

Service plug bracket |  |

Service plug switch |  |

Engagement detection switch (service plug) harness |

|

Busbar 14 |  |

Busbar 13 |  |

Busbar 12 |

|

: Always replace after every disassembly. | ||||

|

: N·m (kg-m, in-lb) |

Disassembly & Assembly

DANGER: Because hybrid vehicles and electric vehicles contain a high voltage battery, there is a risk of electric shock, electric leakage, or similar accidents if the Nissan Ariya vehicle is handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

Because hybrid vehicles and electric vehicles contain a high voltage battery, there is a risk of electric shock, electric leakage, or similar accidents if the Nissan Ariya vehicle is handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

WARNING:

-

Be sure to remove the service plug in order to shut off the high voltage circuits before performing inspection or maintenance of high voltage system harnesses and parts.

-

Be sure to put the removed service plug in pocket and carry it or store it in a tool box or other container so that another person does not accidentally connect it while work is in progress.

-

Be sure to put on insulating protective gear before beginning work on the high voltage system.

-

Clearly identify the persons responsible for high voltage work and ensure that other persons do not touch the Nissan Ariya vehicle. When not working, cover high voltage components with an anti-static cover sheet or similar item to prevent contact with other persons.

-

Refer to PRECAUTIONS FOR HIGH VOLTAGE : Precautions.

-

If the battery pack is to be disassembled, be sure to remove the Li-ion battery controller for preventing electric shock, fire, and damage to parts.

CAUTION:

There is the possibility of a malfunction occurring if the vehicle is changed to READY status while the service plug is removed. Therefore do not change the Nissan Ariya vehicle to READY status unless instructed to do so in the Service Manual.

ENVIRONMENT FOR LI-ION BATTERY DISASSEMBLY WORK

Must be an indoor environment.

-

The environment must utilize a shutter or other means to shut out the outside environment and prevent rain, snow, dust, or other substances from entering.

-

The environment must not cause the intrusion of sweat during work, or cause condensation to occur due to high temperature or humidity.

Metal powder, grease, and other foreign substances must not enter.

-

The indoor environment must also prevent metal powder, grease, and other foreign substances from entering due to maintenance performed on other Nissan Ariya vehicles and other sources during disassembly work.

-

During disassembly without internal work, temporarily close the battery pack upper case or cover it with an insulating cover.

The floor must be dry.

-

The floor must not be wet as a result of factors such as Nissan Ariya vehicle entry during rain or snow.

Work space

-

The work space must be approximately the size of one entire Nissan Ariya vehicle.

-

Take appropriate countermeasures so that persons other than the operator do not enter the work space, such as by placing signs indicating that disassembly work is in progress.

Standard fire fighting equipment

-

Always place a standard fire fighting equipment in the disassembly work area.

-

Depending on type of fire (Nissan Ariya vehicle or battery) use standard fire fighting equipment (water or extinguisher).

Disassembly

Remove battery pack upper rear. Refer to Removal & Installation.

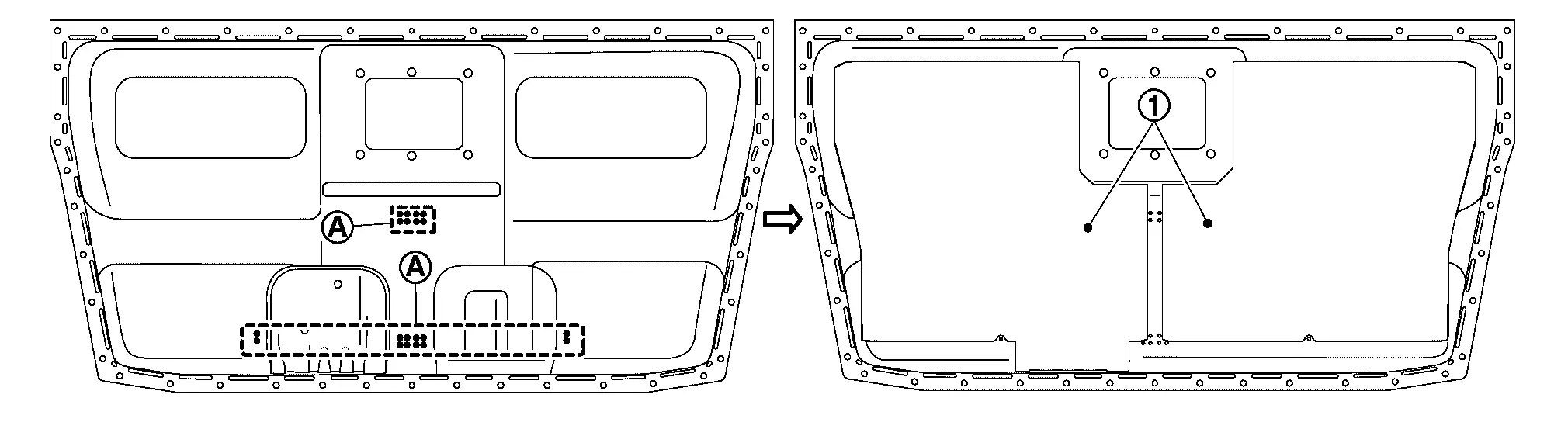

Remove the bolt of busbar 12 and

and  .

.

|

: Battery front |

WARNING:

To prevent electric shock, wear insulated protective gear and use insulated tools.

To prevent electric shock, wear insulated protective gear and use insulated tools.

Remove interlock detecting switch (Service plug) harness connector  .

.

|

: Battery front |

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

Remove nuts of service plug bracket.

Remove service plug bracket.

Remove seal from service plug bracket.

Remove bolts and remove busbar 12 from busbar 13 and busbar 14.

Remove bolts  .

.

: Service plug

: Service plug

Remove service plug  from service bracket

from service bracket  .

.

Remove interlock detecting switch (Service plug) harness  , busbar 13

, busbar 13  and busbar 14

and busbar 14  from service plug

from service plug  .

.

: Bolts

: Bolts

Assembly

Note the following items, and assemble in the reverse order of disassembly.

DANGER:-

There is the danger of electric shock caused by contact with the terminals. Be sure to wear insulated protective gear and use insulated tools.

There is the danger of electric shock caused by contact with the terminals. Be sure to wear insulated protective gear and use insulated tools.

-

Because there is a danger of electric shock and fire, never allow bus bar to contact a wrong terminal.

Because there is a danger of electric shock and fire, never allow bus bar to contact a wrong terminal.-

If bus bar contacts a wrong terminal, the circuit becomes energized and a short may occur.

-

Always keep the bus bar cover closed until immediately before the installation of bus bar.

-

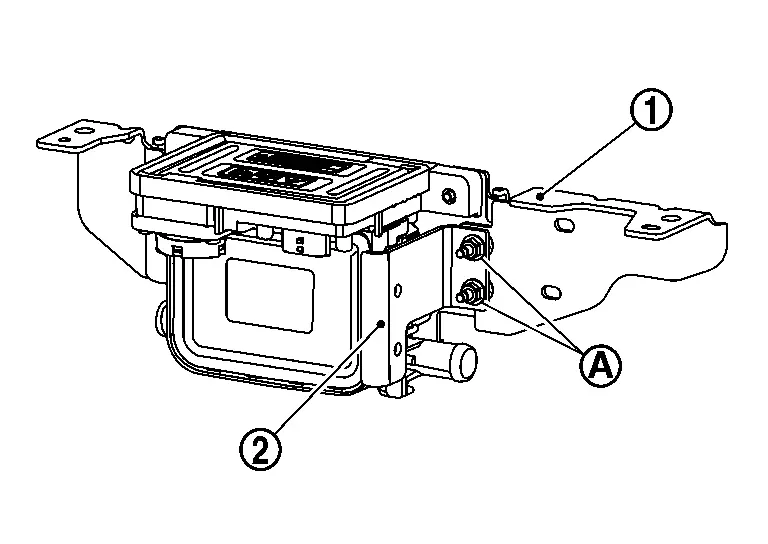

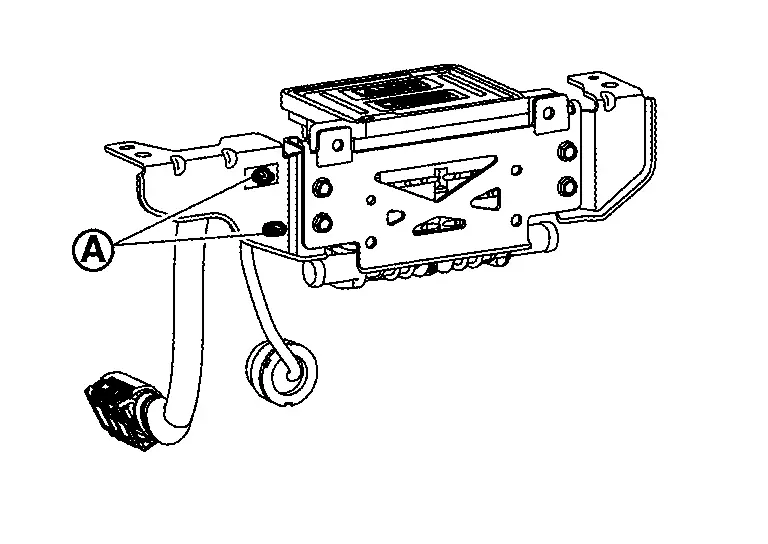

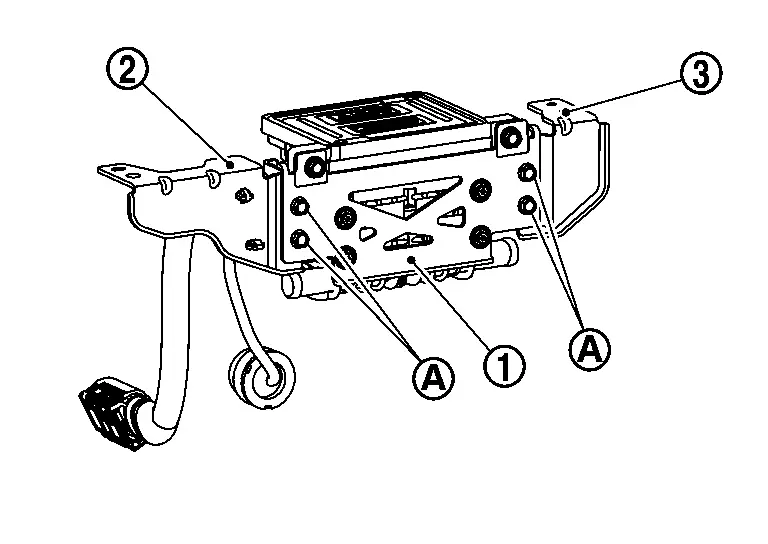

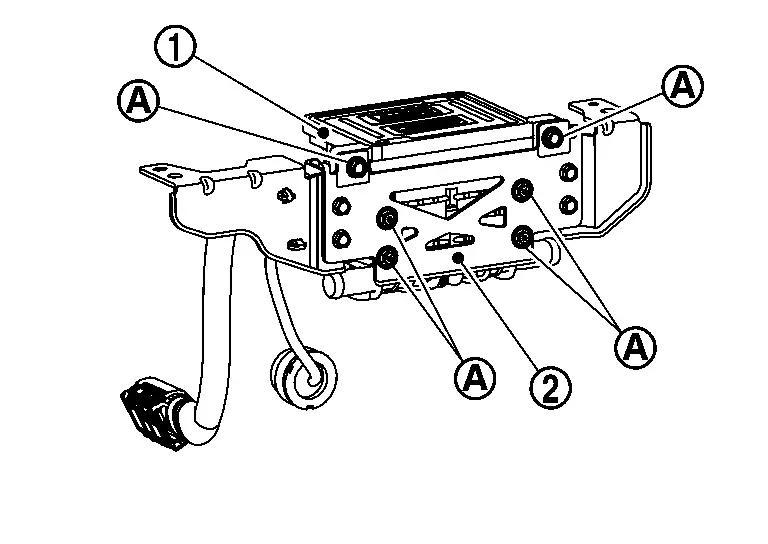

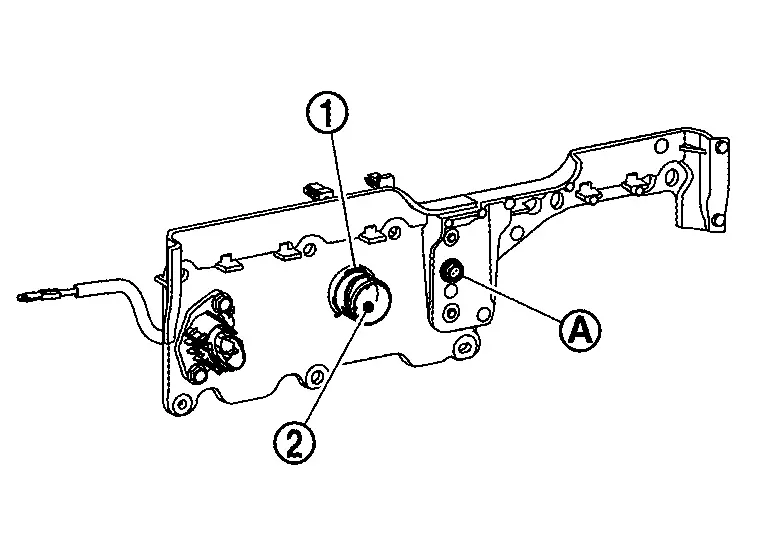

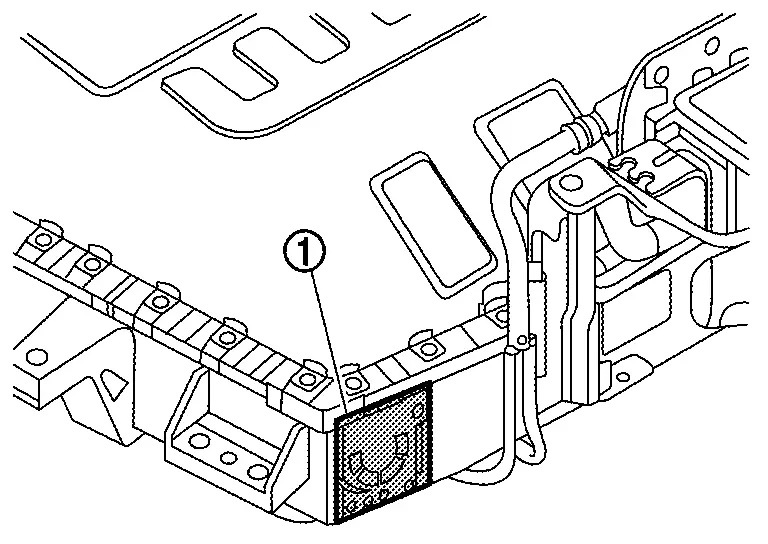

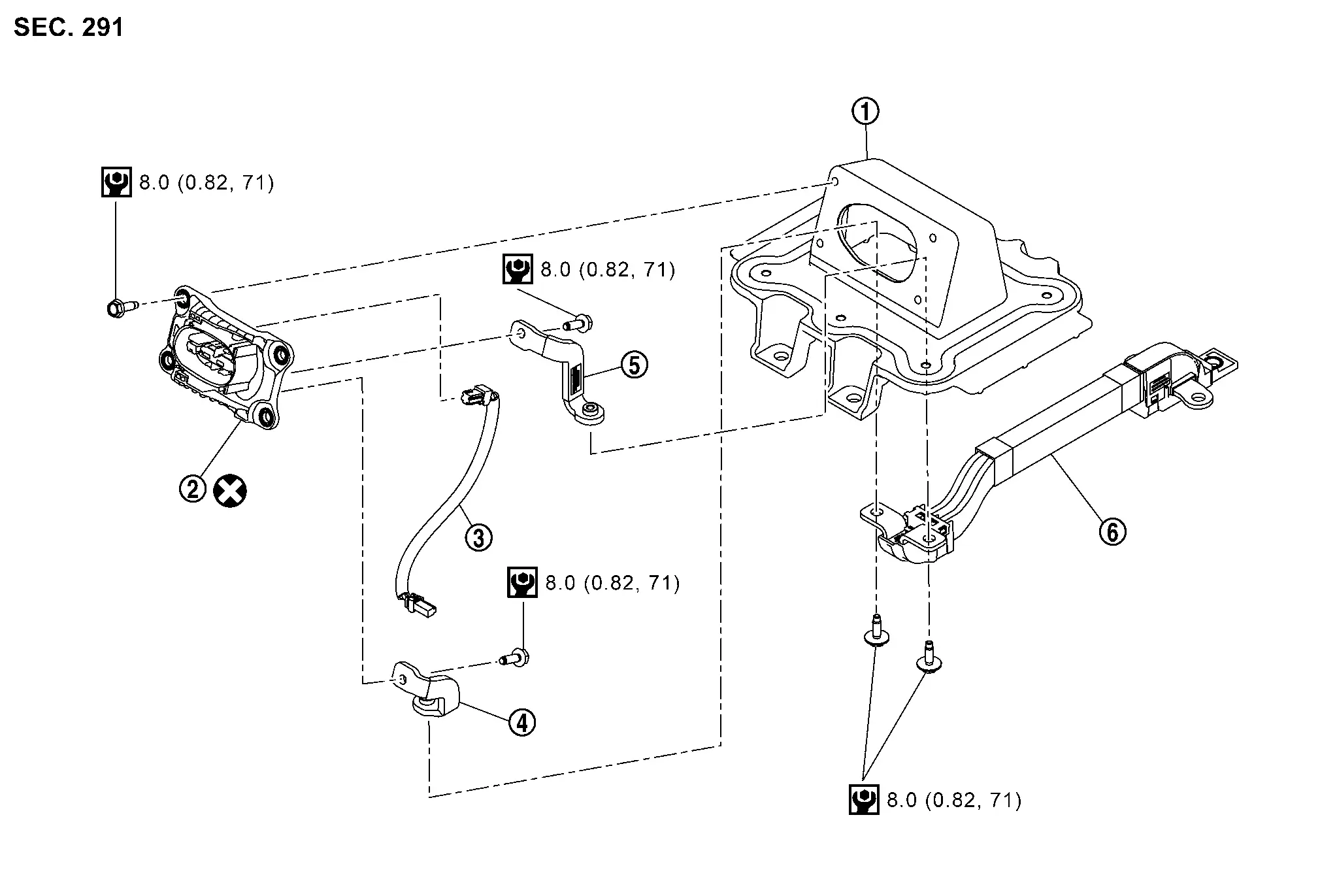

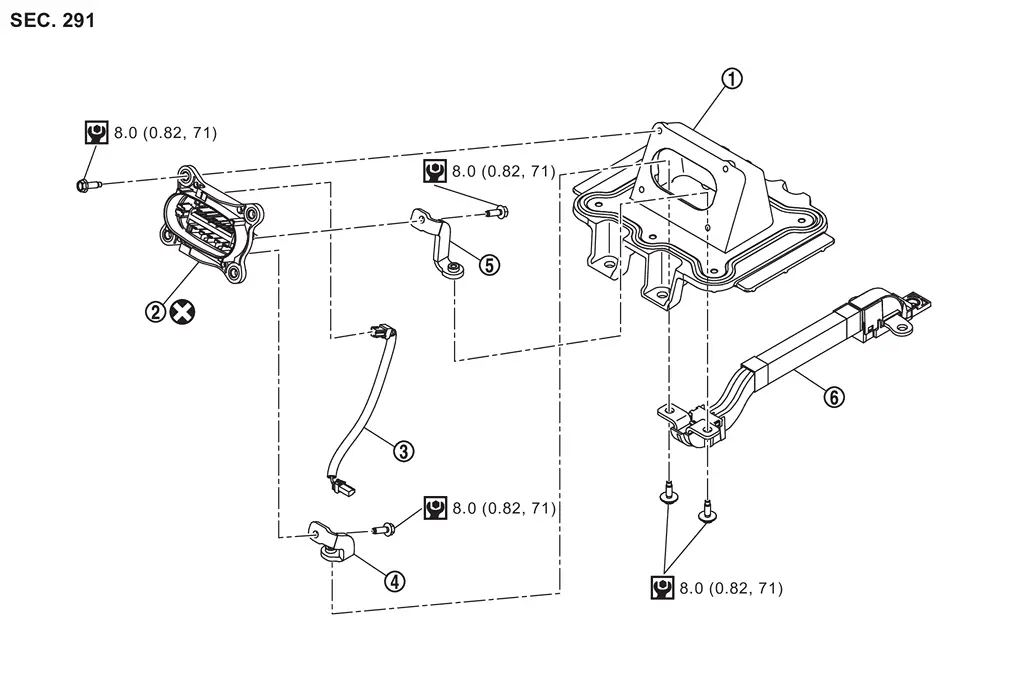

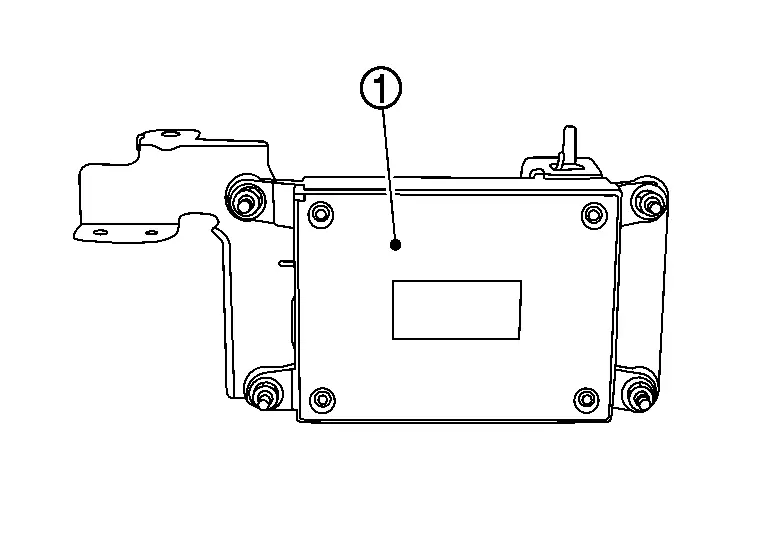

Li-Ion Battery Controller Nissan Ariya 2023

Exploded View

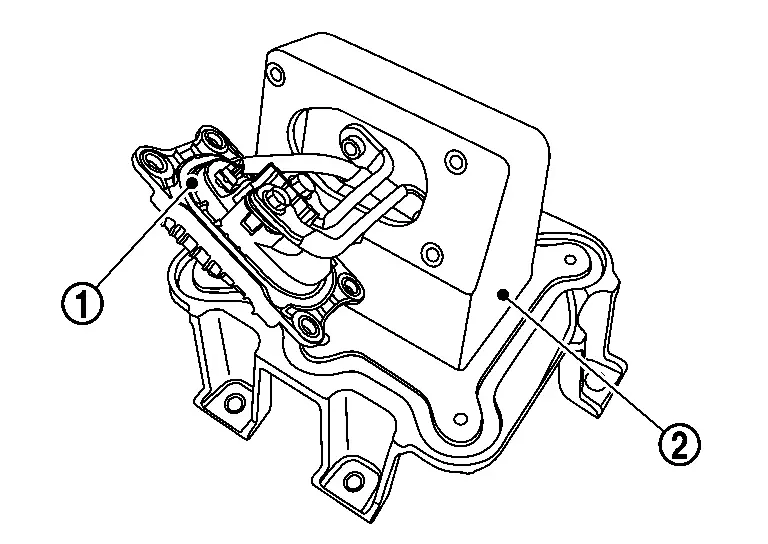

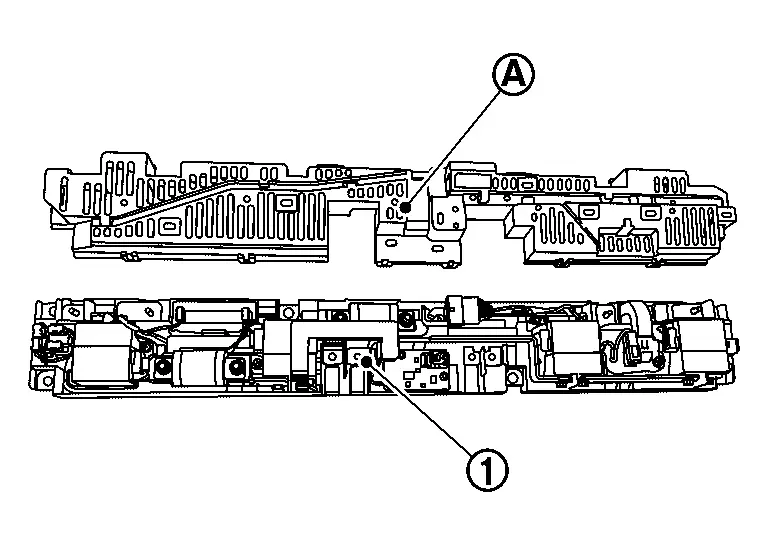

|

Bracket |  |

Li-ion battery controller |  |

Bracket |

|

Cell controller | ||||

|

: Nissan Ariya Vehicle front | ||||

|

: N·m (kg-m, in-lb) |

Removal & Installation

DANGER: Because hybrid vehicles and electric vehicles contain a high voltage battery, there is a risk of electric shock, electric leakage, or similar accidents if the Nissan Ariya vehicle is handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

Because hybrid vehicles and electric vehicles contain a high voltage battery, there is a risk of electric shock, electric leakage, or similar accidents if the Nissan Ariya vehicle is handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

WARNING:

-

Be sure to remove the service plug in order to shut off the high voltage circuits before performing inspection or maintenance of high voltage system harnesses and parts.

-

Be sure to put the removed service plug in pocket and carry it or store it in a tool box or other container so that another person does not accidentally connect it while work is in progress.

-

Be sure to put on insulating protective gear before beginning work on the high voltage system.

-

Clearly identify the persons responsible for high voltage work and ensure that other persons do not touch the Nissan Ariya vehicle. When not working, cover high voltage components with an anti-static cover sheet or similar item to prevent contact with other persons.

-

Refer to PRECAUTIONS FOR HIGH VOLTAGE : Precautions.

-

If the battery pack is to be disassembled, be sure to remove the Li-ion battery controller for preventing electric shock, fire, and damage to parts.

CAUTION:

There is the possibility of a malfunction occurring if the vehicle is changed to READY status while the service plug is removed. Therefore do not change the Nissan Ariya vehicle to READY status unless instructed to do so in the Service Manual.

ENVIRONMENT FOR LI-ION BATTERY DISASSEMBLY WORK

Must be an indoor environment.

-

The environment must utilize a shutter or other means to shut out the outside environment and prevent rain, snow, dust, or other substances from entering.

-

The environment must not cause the intrusion of sweat during work, or cause condensation to occur due to high temperature or humidity.

Metal powder, grease, and other foreign substances must not enter.

-

The indoor environment must also prevent metal powder, grease, and other foreign substances from entering due to maintenance performed on other Nissan Ariya vehicles and other sources during disassembly work.

-

During disassembly without internal work, temporarily close the battery pack upper case or cover it with an insulating cover.

The floor must be dry.

-

The floor must not be wet as a result of factors such as Nissan Ariya vehicle entry during rain or snow.

Work space

-

The work space must be approximately the size of one entire Nissan Ariya vehicle.

-

Take appropriate countermeasures so that persons other than the operator do not enter the work space, such as by placing signs indicating that disassembly work is in progress.

Standard fire fighting equipment

-

Always place a standard fire fighting equipment in the disassembly work area.

-

Depending on type of fire (Nissan Ariya vehicle or battery) use standard fire fighting equipment (water or extinguisher).

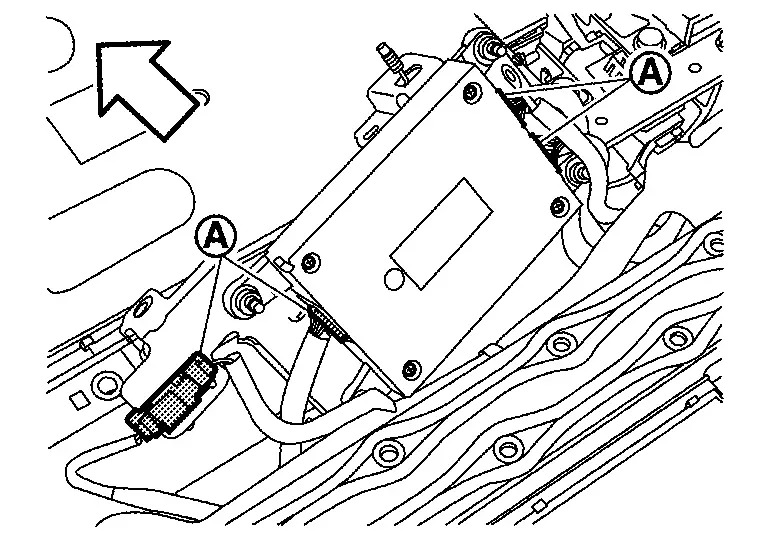

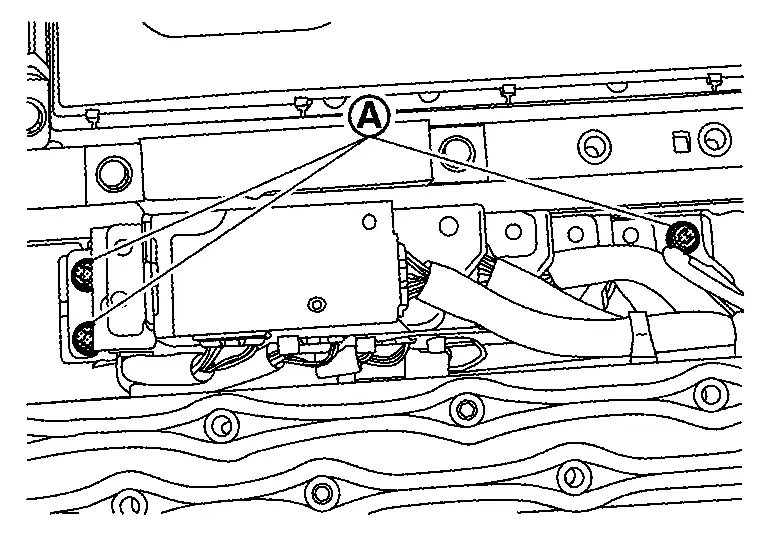

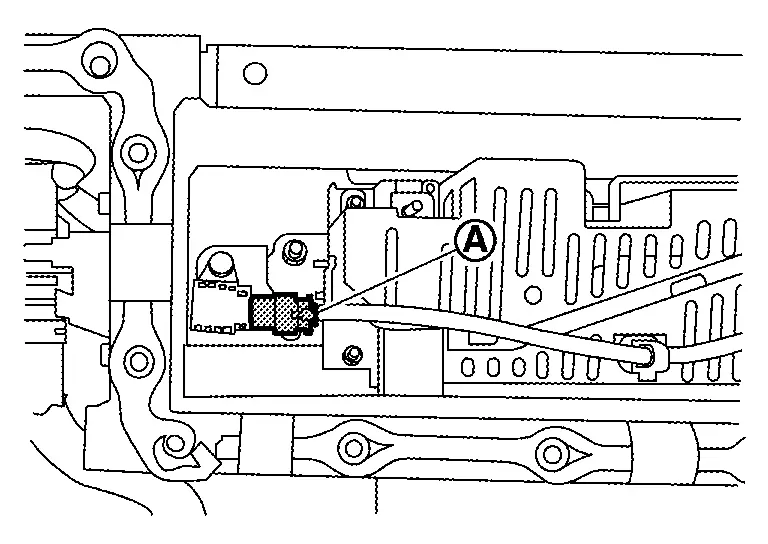

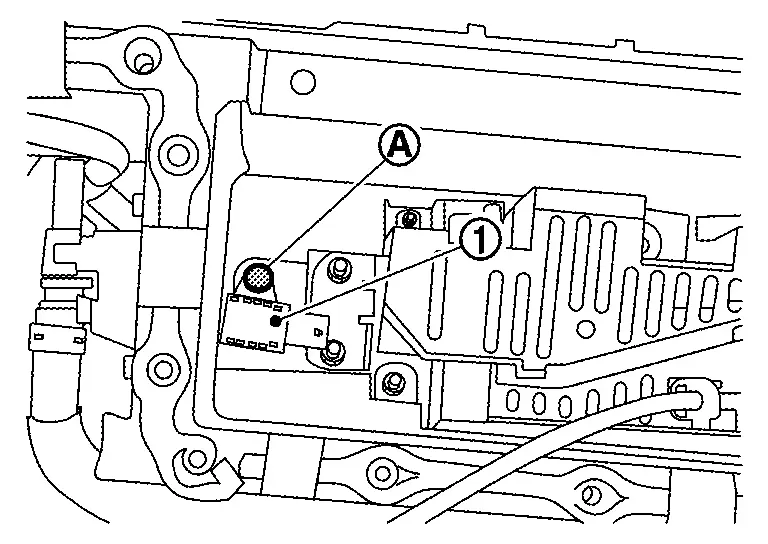

LI-ION BATTERY CONTROLLER

Disassembly

CAUTION:

When replace Li-ion battery controller, perform necessary work according to the procedure of "BATTERY PACK UPPER CASE : Removal & Installation". Refer to Work Item List.

Remove battery pack upper case front. Refer to Removal & Installation.

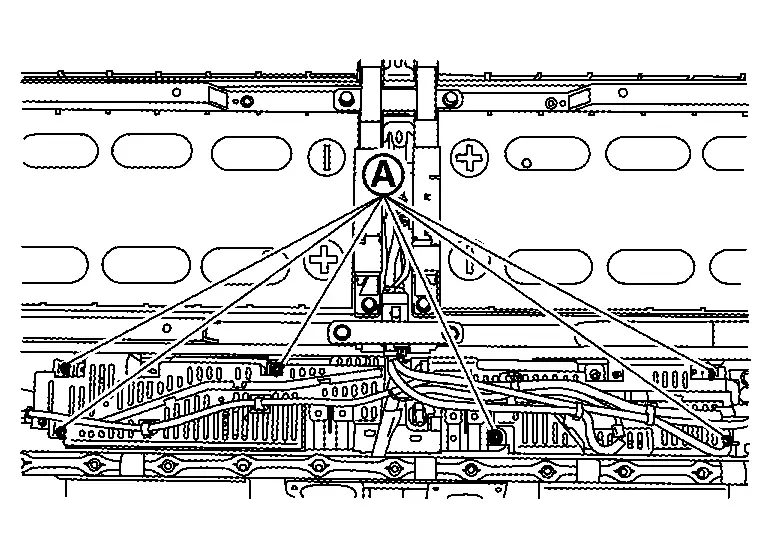

Remove nut of cable  .

.

|

: Battery front |

WARNING:

To prevent electric shock, wear insulated protective gear and use insulated tools.

To prevent electric shock, wear insulated protective gear and use insulated tools.

Remove the bolt  of bracket.

of bracket.

|

: Battery front |

WARNING:

To prevent electric shock, wear insulated protective gear and use insulated tools.

To prevent electric shock, wear insulated protective gear and use insulated tools.

Disconnect the harness connector  .

.

|

: Battery front |

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

CAUTION:

Because there is the danger of electric shock, immediately insulate removed connectors with insulating tape.

Remove Li-ion battery controller  from bracket.

from bracket.

Assembly

Note the following items, and assemble in the reverse order of disassembly.

DANGER:-

There is the danger of electric shock caused by contact with the terminals. Be sure to wear insulated protective gear and use insulated tools.

There is the danger of electric shock caused by contact with the terminals. Be sure to wear insulated protective gear and use insulated tools.

-

Because there is a danger of electric shock and fire, never allow bus bar to contact a wrong terminal.

Because there is a danger of electric shock and fire, never allow bus bar to contact a wrong terminal.-

If bus bar contacts a wrong terminal, the circuit becomes energized and a short may occur.

-

Always keep the bus bar cover closed until immediately before the installation of bus bar.

-

CELL CONTROLLER (LEFT SIDE)

DISASSEMBLY

Remove battery pack upper case front. Refer to Removal & Installation.

Remove Li-ion battery controller with bracket.

WARNING:

To prevent electric shock, wear insulated protective gear and use insulated tools.

To prevent electric shock, wear insulated protective gear and use insulated tools.

CAUTION:

Because there is the danger of electric shock, immediately insulate removed connectors with insulating tape.

Remove nut  on the bracket.

on the bracket.

WARNING:

To prevent electric shock, wear insulated protective gear and use insulated tools.

To prevent electric shock, wear insulated protective gear and use insulated tools.

Disconnect the harness connector from cell controller.

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

CAUTION:

Because there is the danger of electric shock, immediately insulate removed connectors with insulating tape.

Disconnect the cell controller from bracket.

Assembly

Note the following items, and assemble in the reverse order of disassembly.

DANGER:-

There is the danger of electric shock caused by contact with the terminals. Be sure to wear insulated protective gear and use insulated tools.

There is the danger of electric shock caused by contact with the terminals. Be sure to wear insulated protective gear and use insulated tools.

-

There two types of cell controller harnesses for high voltage and low voltage. When inserting high voltage harness connector to low voltage system, it may cause fire or damage parts. Carefully avoid mistake when inserting connectors.

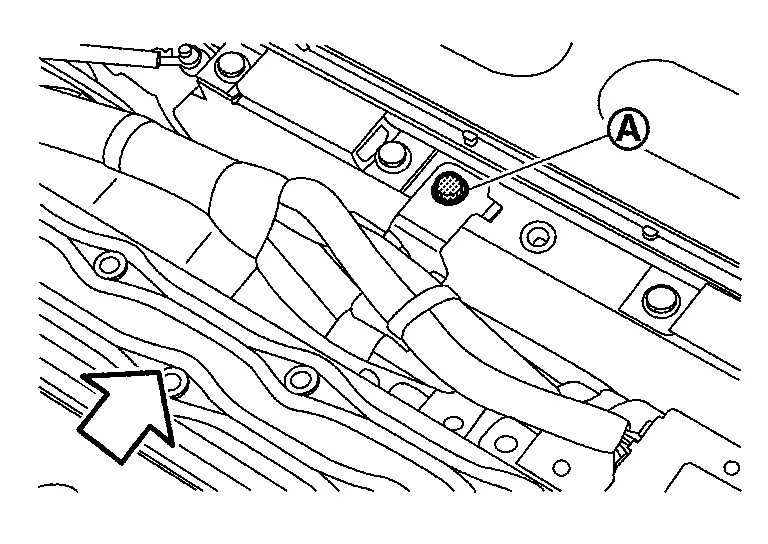

CELL CONTROLLER (RIGHT SIDE)

DISASSEMBLY

Remove battery pack upper case front. Refer to Removal & Installation.

Remove bolt on the bracket.

on the bracket.

WARNING:

To prevent electric shock, wear insulated protective gear and use insulated tools.

To prevent electric shock, wear insulated protective gear and use insulated tools.

|

: Battery front |

Remove nut  on the bracket.

on the bracket.

WARNING:

To prevent electric shock, wear insulated protective gear and use insulated tools.

To prevent electric shock, wear insulated protective gear and use insulated tools.

Disconnect the harness connector from cell controller.

WARNING:

To prevent electric shock, wear insulated protective gear.

To prevent electric shock, wear insulated protective gear.

CAUTION:

Because there is the danger of electric shock, immediately insulate removed connectors with insulating tape.

Remove cell controller from the bracket.

Assembly

Note the following items, and assemble in the reverse order of disassembly.

DANGER:-

There is the danger of electric shock caused by contact with the terminals. Be sure to wear insulated protective gear and use insulated tools.

There is the danger of electric shock caused by contact with the terminals. Be sure to wear insulated protective gear and use insulated tools.

-

There two types of cell controller harnesses for high voltage and low voltage. When inserting high voltage harness connector to low voltage system, it may cause fire or damage parts. Carefully avoid mistake when inserting connectors.

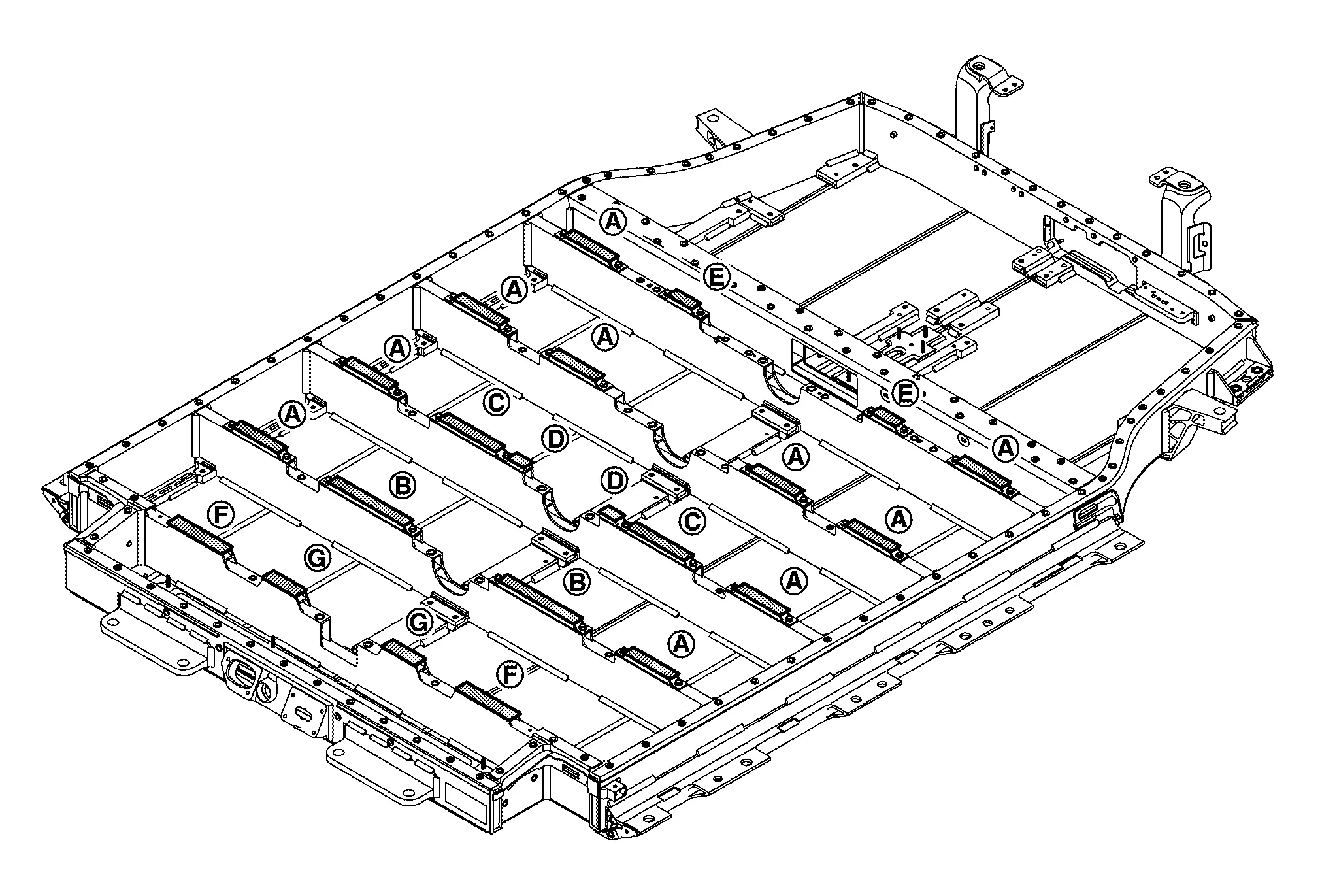

Busbar. 2wd Nissan Ariya 1st generation

Exploded View

DISASSEMBLY

|

Busbar 2 |  |

Busbar 3 |  |

Busbar 4 |

|

Busbar 5 |  |

Busbar 6 |  |

Busbar 7 |

|

Busbar 8 |  |

Busbar 9 |  |

Busbar 10 |

|

Busbar 11 |  |

Busbar 15 |  |

Busbar 16 |

|

Busbar 17 |  |

Busbar 18 |  |

Busbar 19 |

|

Busbar 20 |  |

Busbar 21 |  |

Busbar 22 |

|

Busbar 23 |  |

Nut cap | ||

|

: N·m (kg-m, in-lb) |

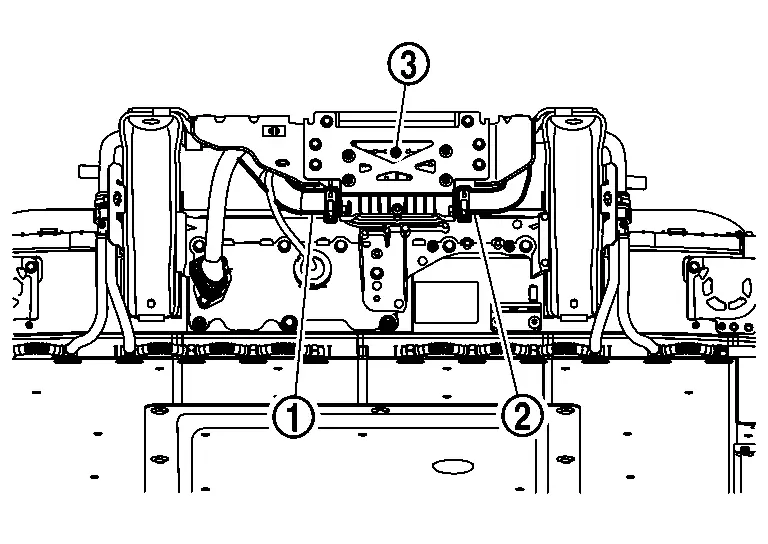

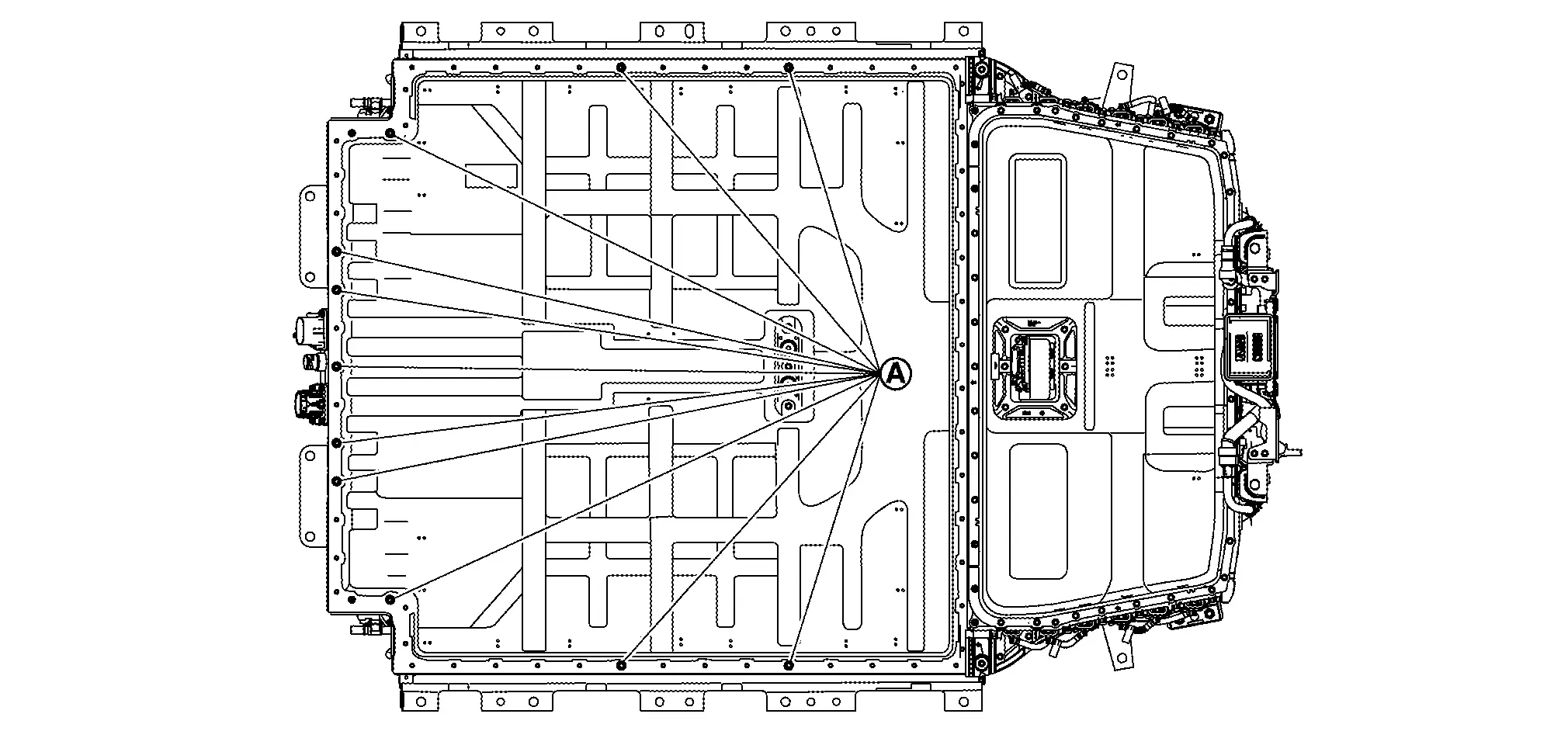

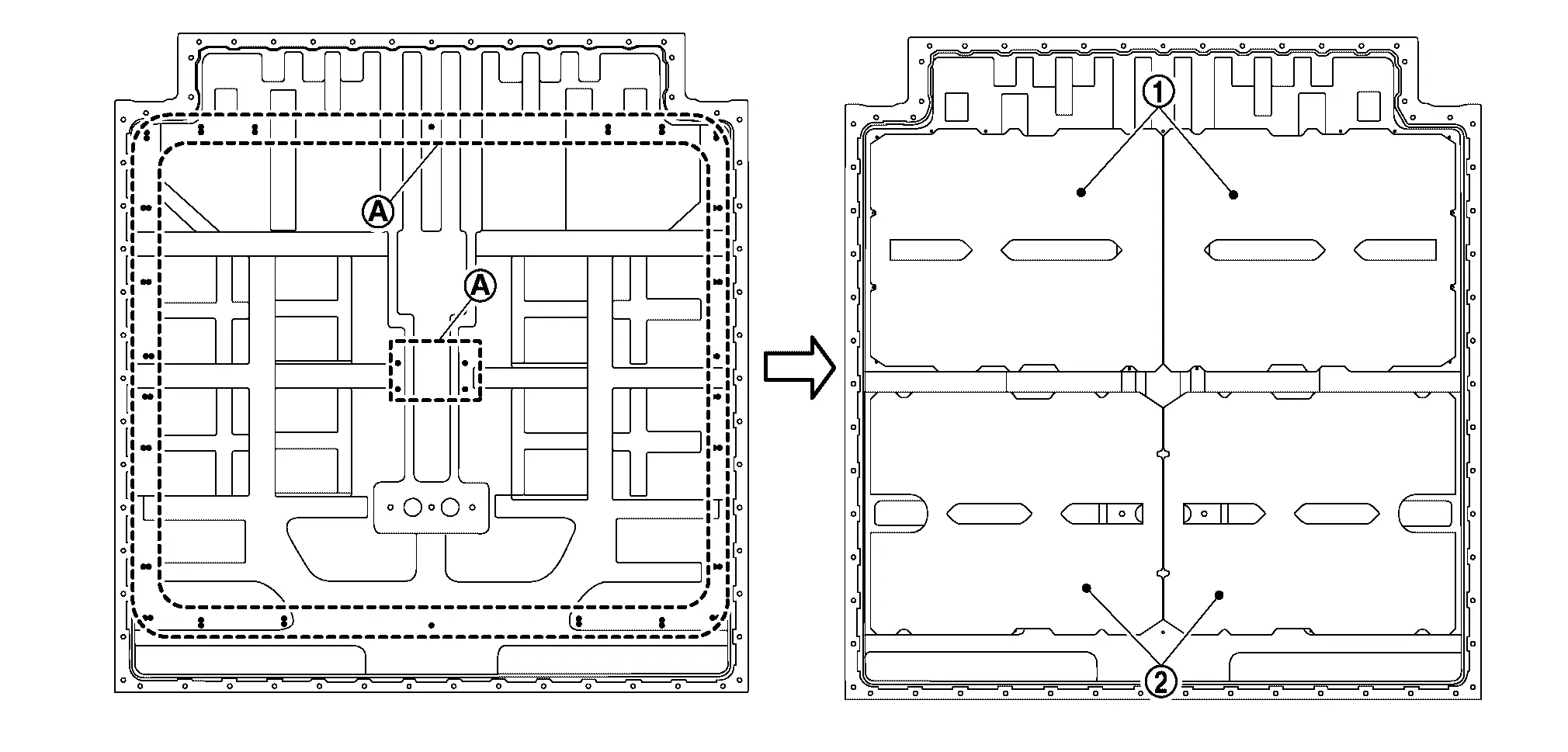

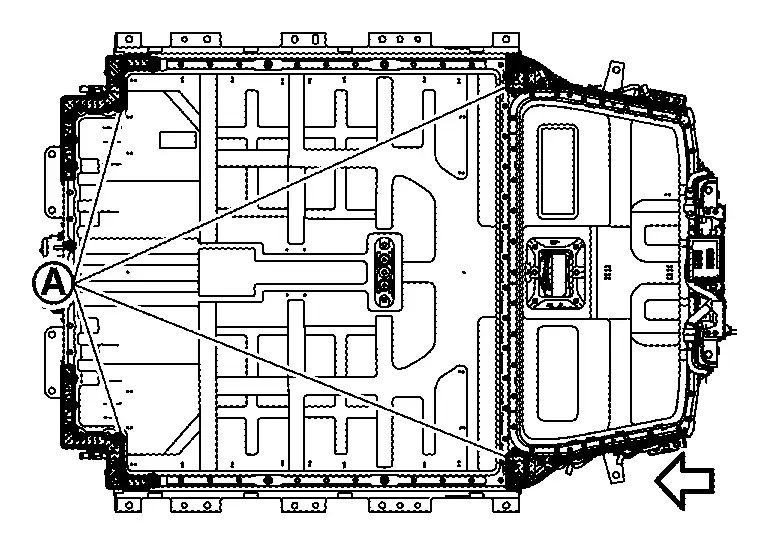

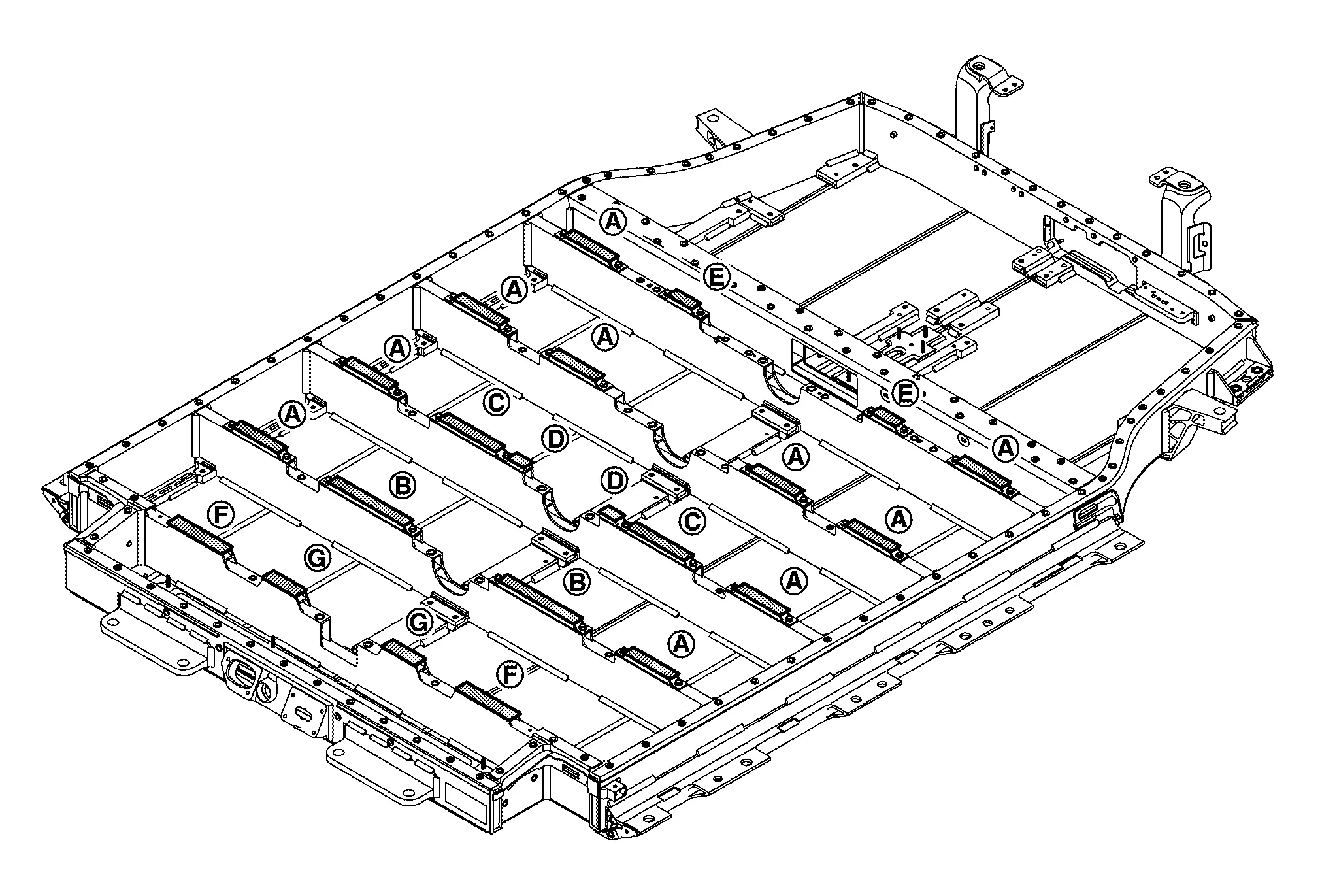

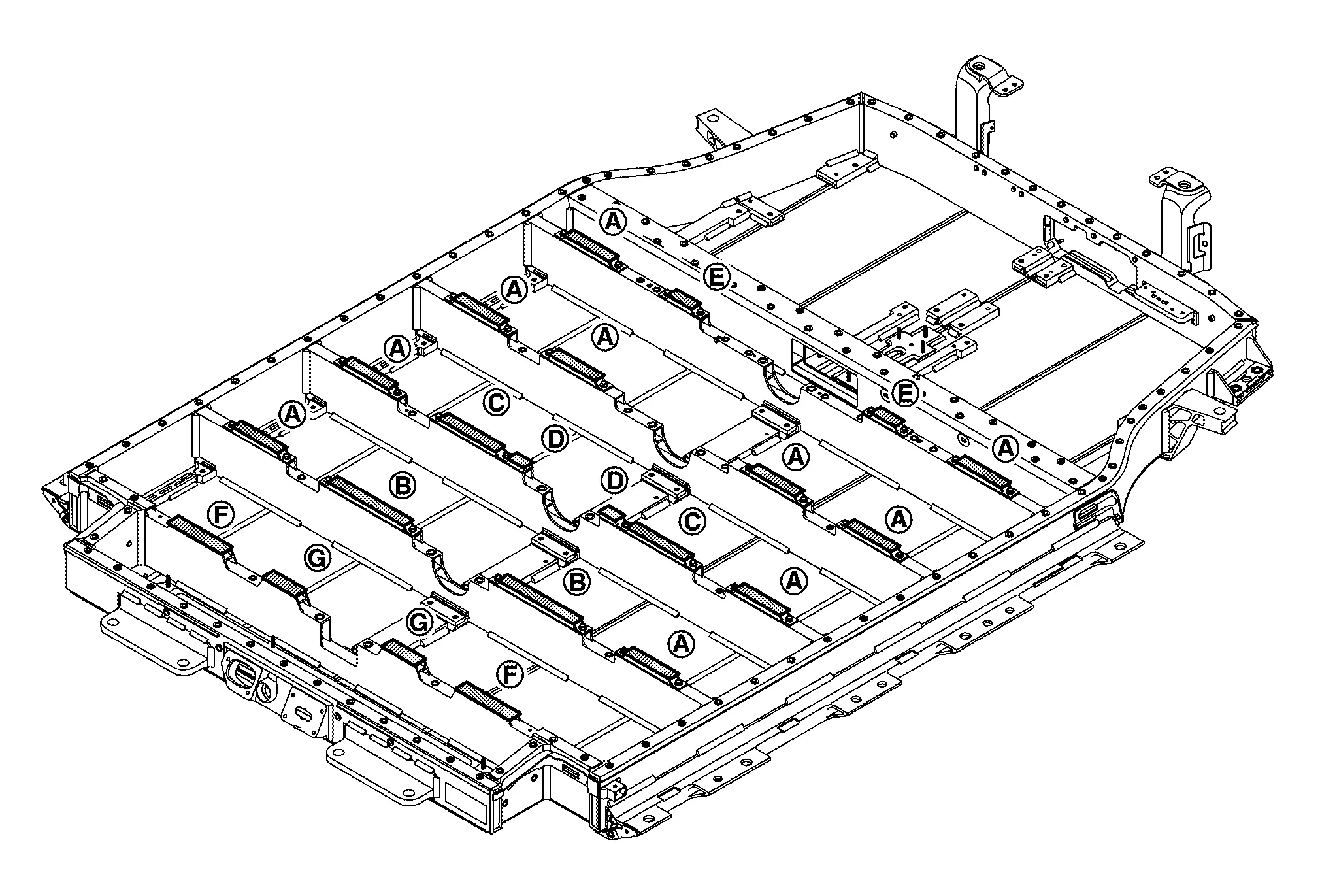

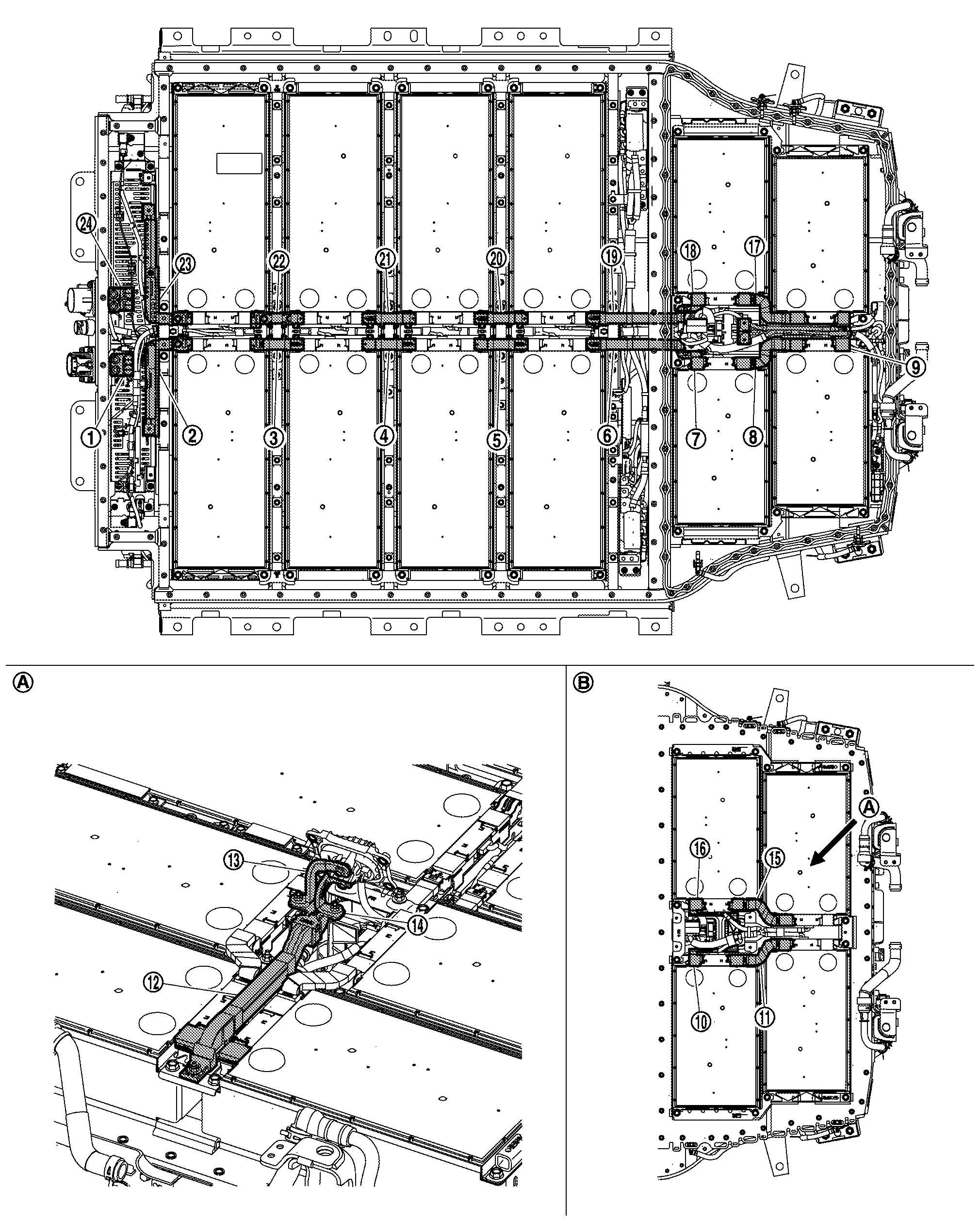

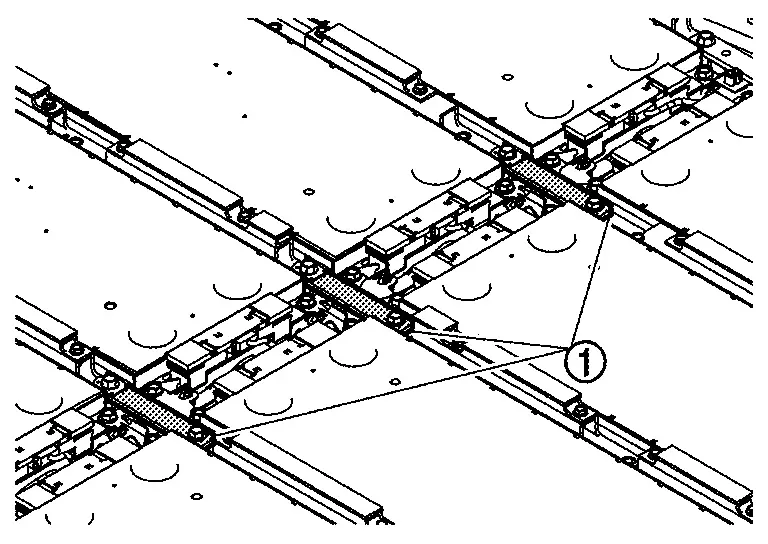

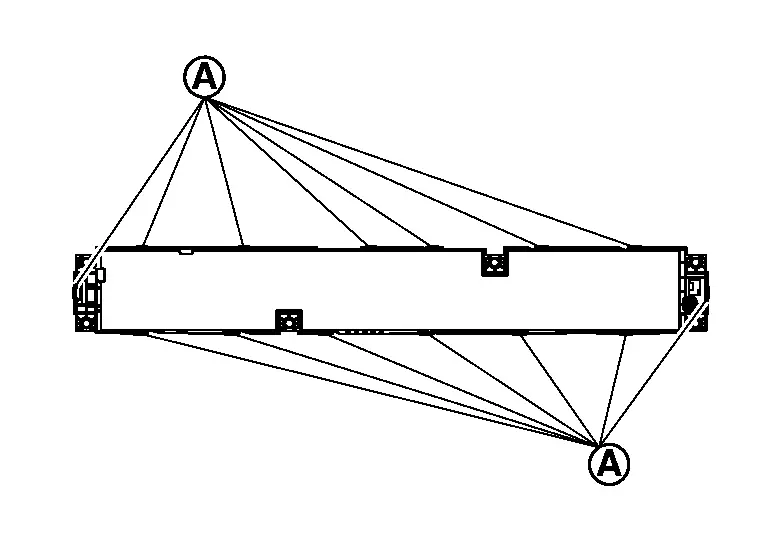

BUSBAR LAYOUT

|

Busbar 1 |  |

Busbar 2 |  |

Busbar 3 |

|

Busbar 4 |  |

Busbar 5 |  |

Busbar 6 |

|

Busbar 7 |  |

Busbar 8 |  |

Busbar 9 |

|

Busbar 10 |  |

Busbar 11 |  |

Busbar 12 |

|

Busbar 13 |  |

Busbar 14 |  |

Busbar 15 |

|

Busbar 16 |  |

Busbar 17 |  |

Busbar 18 |

|

Busbar 19 |  |

Busbar 20 |  |

Busbar 21 |

|

Busbar 22 |  |

Busbar 23 |  |

Busbar 24 |

|

: Around Service bracket | ||||

|

: Rear module stack 2nd floor |

Disassembly & Assembly

DANGER: Because hybrid vehicles and electric vehicles contain a high voltage battery, there is a risk of electric shock, electric leakage, or similar accidents if the Nissan Ariya vehicle is handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

Because hybrid vehicles and electric vehicles contain a high voltage battery, there is a risk of electric shock, electric leakage, or similar accidents if the Nissan Ariya vehicle is handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

WARNING:

-

Be sure to remove the service plug in order to shut off the high voltage circuits before performing inspection or maintenance of high voltage system harnesses and parts.

-

Be sure to put the removed service plug in pocket and carry it or store it in a tool box or other container so that another person does not accidentally connect it while work is in progress.

-

Be sure to put on insulating protective gear before beginning work on the high voltage system.

-

Clearly identify the persons responsible for high voltage work and ensure that other persons do not touch the Nissan Ariya vehicle. When not working, cover high voltage components with an anti-static cover sheet or similar item to prevent contact with other persons.

-

Refer to PRECAUTIONS FOR HIGH VOLTAGE : Precautions.

-

If the battery pack is to be disassembled, be sure to remove the Li-ion battery controller for preventing electric shock, fire, and damage to parts.

CAUTION:

There is the possibility of a malfunction occurring if the vehicle is changed to READY status while the service plug is removed. Therefore do not change the Nissan Ariya vehicle to READY status unless instructed to do so in the Service Manual.

ENVIRONMENT FOR LI-ION BATTERY DISASSEMBLY WORK

Must be an indoor environment.

-

The environment must utilize a shutter or other means to shut out the outside environment and prevent rain, snow, dust, or other substances from entering.

-

The environment must not cause the intrusion of sweat during work, or cause condensation to occur due to high temperature or humidity.

Metal powder, grease, and other foreign substances must not enter.

-

The indoor environment must also prevent metal powder, grease, and other foreign substances from entering due to maintenance performed on other Nissan Ariya vehicles and other sources during disassembly work.

-

During disassembly without internal work, temporarily close the battery pack upper case or cover it with an insulating cover.

The floor must be dry.

-

The floor must not be wet as a result of factors such as Nissan Ariya vehicle entry during rain or snow.

Work space

-

The work space must be approximately the size of one entire Nissan Ariya vehicle.

-

Take appropriate countermeasures so that persons other than the operator do not enter the work space, such as by placing signs indicating that disassembly work is in progress.

Standard fire fighting equipment

-

Always place a standard fire fighting equipment in the disassembly work area.

-

Depending on type of fire (Nissan Ariya vehicle or battery) use standard fire fighting equipment (water or extinguisher).

Busbar 1 and Busbar 24:

Refer to Disassembly & Assembly.

Busbar 12 to Busbar 14:

Refer to Disassembly & Assembly.

busbar 2 and Busbar 23

DISASSEMBLY

Remove nut cap  .

.

WARNING:

To prevent electric shock, wear insulated protective gear and use insulated tools.

To prevent electric shock, wear insulated protective gear and use insulated tools.

NOTE:

NOTE:

The figure shows busbar 2.

Remove nut  and then remove busbar 2

and then remove busbar 2  .

.

WARNING:

To prevent electric shock, wear insulated protective gear and use insulated tools.

To prevent electric shock, wear insulated protective gear and use insulated tools.

NOTE:

NOTE:

The figure shows busbar 2.

Remove busbar 23in the same way.

Assembly

Note the following items, and assemble in the reverse order of disassembly.

DANGER:-

There is the danger of electric shock caused by contact with the terminals. Be sure to wear insulated protective gear and use insulated tools.

There is the danger of electric shock caused by contact with the terminals. Be sure to wear insulated protective gear and use insulated tools.

-

Because there is a danger of electric shock and fire, never allow bus bar to contact a wrong terminal.

Because there is a danger of electric shock and fire, never allow bus bar to contact a wrong terminal.-

If bus bar contacts a wrong terminal, the circuit becomes energized and a short may occur.

-

Always keep the busbar cover closed until immediately before the installation of busbar.

-

busbar 3, busbar 4, busbar 21 and busbar 22

DISASSEMBLY

Remove bolts  and then remove busbar 3

and then remove busbar 3  .

.

WARNING:

To prevent electric shock, wear insulated protective gear and use insulated tools.

To prevent electric shock, wear insulated protective gear and use insulated tools.

NOTE:

NOTE:

The figure shows busbar 3.

Remove the other busbars in the same way.

Assembly

Note the following items, and assemble in the reverse order of disassembly.

DANGER:-

There is the danger of electric shock caused by contact with the terminals. Be sure to wear insulated protective gear and use insulated tools.

There is the danger of electric shock caused by contact with the terminals. Be sure to wear insulated protective gear and use insulated tools.

-

Because there is a danger of electric shock and fire, never allow bus bar to contact a wrong terminal.

Because there is a danger of electric shock and fire, never allow bus bar to contact a wrong terminal.-

If bus bar contacts a wrong terminal, the circuit becomes energized and a short may occur.

-

Always keep the bus bar cover closed until immediately before the installation of bus bar.

-

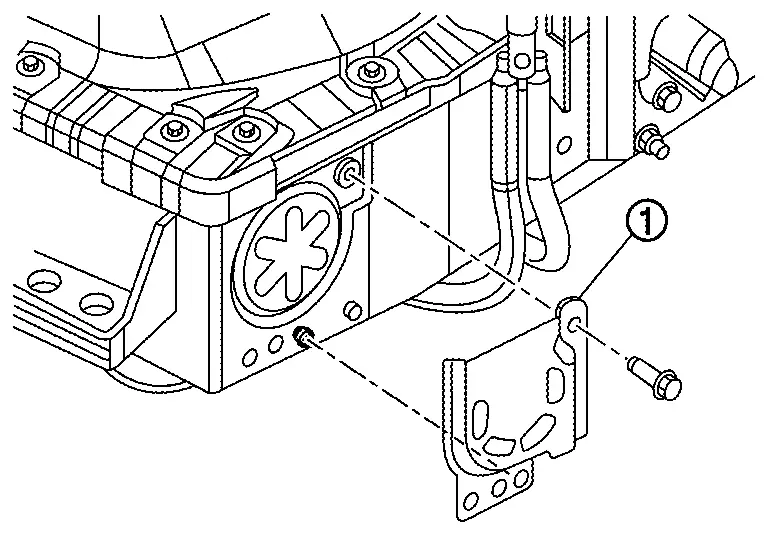

busbar 5 and busbar 20

DISASSEMBLY

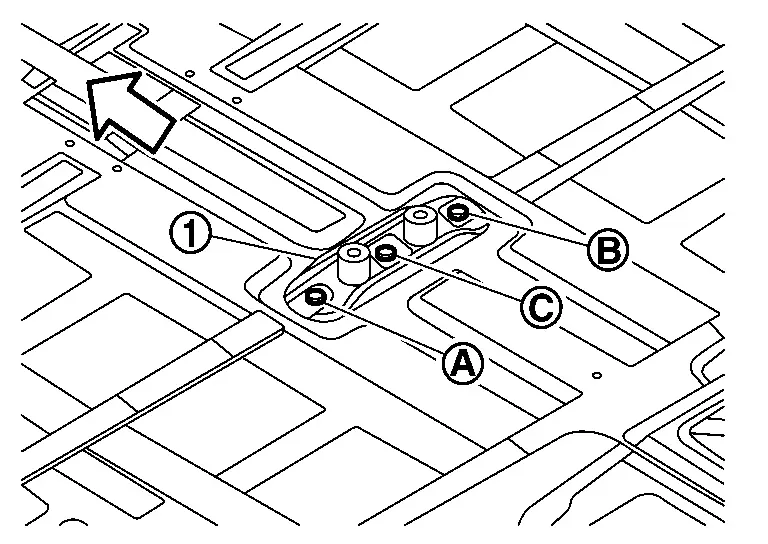

Remove bracket  .

.

|

: Bolts |

WARNING:

To prevent electric shock, wear insulated protective gear and use insulated tools.

To prevent electric shock, wear insulated protective gear and use insulated tools.

Remove bolts  and then remove busbar 5

and then remove busbar 5 .

.

WARNING:

To prevent electric shock, wear insulated protective gear and use insulated tools.

To prevent electric shock, wear insulated protective gear and use insulated tools.

NOTE:

NOTE:

The figure shows busbar 5.

Remove busbar 20 in the same way.

Assembly

Note the following items, and assemble in the reverse order of disassembly.

DANGER:-

There is the danger of electric shock caused by contact with the terminals. Be sure to wear insulated protective gear and use insulated tools.

There is the danger of electric shock caused by contact with the terminals. Be sure to wear insulated protective gear and use insulated tools.

-

Because there is a danger of electric shock and fire, never allow bus bar to contact a wrong terminal.

Because there is a danger of electric shock and fire, never allow bus bar to contact a wrong terminal.-

If bus bar contacts a wrong terminal, the circuit becomes energized and a short may occur.

-

Always keep the bus bar cover closed until immediately before the installation of bus bar.

-

busbar 6, busbar 7, busbar 18 and busbar 19

DISASSEMBLY

Remove the battery upper floor assembly. Refer to Disassembly & Assembly.

Remove bolt and nut

and nut . And then remove busbar 7

. And then remove busbar 7 .

.

WARNING:

To prevent electric shock, wear insulated protective gear and use insulated tools.

To prevent electric shock, wear insulated protective gear and use insulated tools.

Remove the bolt  . And then remove busbar 6

. And then remove busbar 6  .

.

WARNING:

To prevent electric shock, wear insulated protective gear and use insulated tools.

To prevent electric shock, wear insulated protective gear and use insulated tools.

Remove other busbar in the same way.

Assembly

Note the following items, and assemble in the reverse order of disassembly.

DANGER:-

There is the danger of electric shock caused by contact with the terminals. Be sure to wear insulated protective gear and use insulated tools.

There is the danger of electric shock caused by contact with the terminals. Be sure to wear insulated protective gear and use insulated tools.

-

Because there is a danger of electric shock and fire, never allow bus bar to contact a wrong terminal.

Because there is a danger of electric shock and fire, never allow bus bar to contact a wrong terminal.-

If bus bar contacts a wrong terminal, the circuit becomes energized and a short may occur.

-

Always keep the bus bar cover closed until immediately before the installation of bus bar.

-

busbar 8 and busbar 17

DISASSEMBLY

Remove the battery upper floor assembly. Refer to Disassembly & Assembly.

Remove the bolt  . And then busbar 8

. And then busbar 8  .

.

WARNING:

To prevent electric shock, wear insulated protective gear and use insulated tools.

To prevent electric shock, wear insulated protective gear and use insulated tools.

Remove busbar 17 in the same way.

Assembly

Note the following items, and assemble in the reverse order of disassembly.

DANGER:-

There is the danger of electric shock caused by contact with the terminals. Be sure to wear insulated protective gear and use insulated tools.

There is the danger of electric shock caused by contact with the terminals. Be sure to wear insulated protective gear and use insulated tools.

-

Because there is a danger of electric shock and fire, never allow bus bar to contact a wrong terminal.

Because there is a danger of electric shock and fire, never allow bus bar to contact a wrong terminal.-

If bus bar contacts a wrong terminal, the circuit becomes energized and a short may occur.

-

Always keep the bus bar cover closed until immediately before the installation of bus bar.

-

busbar 9

DISASSEMBLY

Remove the battery upper floor assembly. Refer to Disassembly & Assembly.

Remove busbar 8 and busbar 17.

Remove the bracket bolt  and

and  . And then move the harness to keep the work space.

. And then move the harness to keep the work space.

Remove the bolt . And then busbar 9

. And then busbar 9 .

.

WARNING:

To prevent electric shock, wear insulated protective gear and use insulated tools.

To prevent electric shock, wear insulated protective gear and use insulated tools.

Assembly

Note the following items, and assemble in the reverse order of disassembly.

DANGER:-

There is the danger of electric shock caused by contact with the terminals. Be sure to wear insulated protective gear and use insulated tools.

There is the danger of electric shock caused by contact with the terminals. Be sure to wear insulated protective gear and use insulated tools.

-

Because there is a danger of electric shock and fire, never allow bus bar to contact a wrong terminal.

Because there is a danger of electric shock and fire, never allow bus bar to contact a wrong terminal.-

If bus bar contacts a wrong terminal, the circuit becomes energized and a short may occur.

-

Always keep the bus bar cover closed until immediately before the installation of bus bar.

-

busbar 10 and busbar 16

DISASSEMBLY

Remove service plug bracket. Refer to Disassembly & Assembly.

Remove the bolt and nut

and nut . And then remove busbar 10

. And then remove busbar 10 .

.

WARNING:

To prevent electric shock, wear insulated protective gear and use insulated tools.

To prevent electric shock, wear insulated protective gear and use insulated tools.

Remove busbar 16 in the same way.

Assembly

Note the following items, and assemble in the reverse order of disassembly.

DANGER:-

There is the danger of electric shock caused by contact with the terminals. Be sure to wear insulated protective gear and use insulated tools.

There is the danger of electric shock caused by contact with the terminals. Be sure to wear insulated protective gear and use insulated tools.

-

Because there is a danger of electric shock and fire, never allow bus bar to contact a wrong terminal.

Because there is a danger of electric shock and fire, never allow bus bar to contact a wrong terminal.-

If bus bar contacts a wrong terminal, the circuit becomes energized and a short may occur.

-

Always keep the bus bar cover closed until immediately before the installation of bus bar.

-

busbar 11 and busbar 15

DISASSEMBLY

Remove the bolt  . And then busbar 11

. And then busbar 11  .

.

WARNING:

To prevent electric shock, wear insulated protective gear and use insulated tools.

To prevent electric shock, wear insulated protective gear and use insulated tools.

NOTE:

NOTE:

The figure shows busbar 11.

Remove busbar 15 in the same way.

Assembly

Note the following items, and assemble in the reverse order of disassembly.

DANGER:-

There is the danger of electric shock caused by contact with the terminals. Be sure to wear insulated protective gear and use insulated tools.

There is the danger of electric shock caused by contact with the terminals. Be sure to wear insulated protective gear and use insulated tools.

-

Because there is a danger of electric shock and fire, never allow bus bar to contact a wrong terminal.

Because there is a danger of electric shock and fire, never allow bus bar to contact a wrong terminal.-

If bus bar contacts a wrong terminal, the circuit becomes energized and a short may occur.

-

Always keep the bus bar cover closed until immediately before the installation of bus bar.

-

Battery Junction Box and Battery Harness Nissan Ariya 2023

Exploded View

BATTERY JUNCTION BOX

|

Nut cap |  |

Busbar 1 |  |

Busbar 20 |

|

Battery junction box |  |

Battery pack pressure sensor |  |

Bracket |

|

High-voltage harness connector |  |

High-voltage harness connector |  |

Battery pack water temperature sensor |

|

: N·m (kg-m, in-lb) | ||||

, , : Indicates that the part is connected at points with same symbol in actual Nissan Ariya vehicle. : Indicates that the part is connected at points with same symbol in actual Nissan Ariya vehicle. |

|||||

BATTERY HARNESS

|

Nissan Ariya Vehicle communication harness |  |

Bracket |  |

Nissan Ariya Vehicle communication harness |

|

Cell voltage detection harness |  |

Cell voltage detection harness |  |

Bracket |

|

Bracket |  |

Nissan Ariya Vehicle communication harness (battery PTC) |  |

Clip |

|

Busbar terminal block | ||||

|

: N·m (kg-m, in-lb) | ||||

|

: N·m (kg-m, ft-lb) | ||||

, , , ,  : Indicates that the part is connected at points with same symbol in actual Nissan Ariya vehicle. : Indicates that the part is connected at points with same symbol in actual Nissan Ariya vehicle. |

|||||

Disassembly & Assembly

DANGER: Because hybrid vehicles and electric vehicles contain a high voltage battery, there is a risk of electric shock, electric leakage, or similar accidents if the Nissan Ariya vehicle is handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

Because hybrid vehicles and electric vehicles contain a high voltage battery, there is a risk of electric shock, electric leakage, or similar accidents if the Nissan Ariya vehicle is handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

WARNING:

-

Be sure to remove the service plug in order to shut off the high voltage circuits before performing inspection or maintenance of high voltage system harnesses and parts.

-

Be sure to put the removed service plug in pocket and carry it or store it in a tool box or other container so that another person does not accidentally connect it while work is in progress.

-

Be sure to put on insulating protective gear before beginning work on the high voltage system.

-

Clearly identify the persons responsible for high voltage work and ensure that other persons do not touch the Nissan Ariya vehicle. When not working, cover high voltage components with an anti-static cover sheet or similar item to prevent contact with other persons.

-

Refer to PRECAUTIONS FOR HIGH VOLTAGE : Precautions.

-

If the battery pack is to be disassembled, be sure to remove the Li-ion battery controller for preventing electric shock, fire, and damage to parts.

CAUTION:

There is the possibility of a malfunction occurring if the vehicle is changed to READY status while the service plug is removed. Therefore do not change the Nissan Ariya vehicle to READY status unless instructed to do so in the Service Manual.

ENVIRONMENT FOR LI-ION BATTERY DISASSEMBLY WORK

Must be an indoor environment.

-

The environment must utilize a shutter or other means to shut out the outside environment and prevent rain, snow, dust, or other substances from entering.

-

The environment must not cause the intrusion of sweat during work, or cause condensation to occur due to high temperature or humidity.

Metal powder, grease, and other foreign substances must not enter.

-

The indoor environment must also prevent metal powder, grease, and other foreign substances from entering due to maintenance performed on other Nissan Ariya vehicles and other sources during disassembly work.

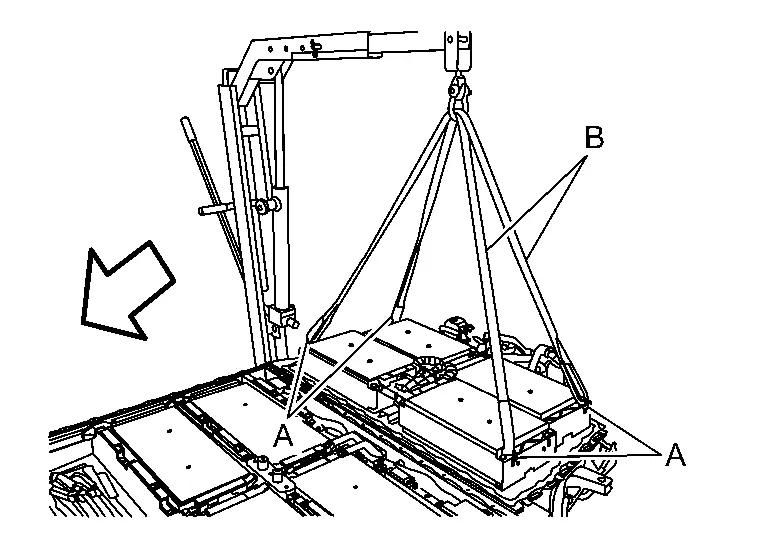

-