Nissan Ariya: Dtc Diagnosis

- B2480-93 Front Mode Door Motor Rh

- B2481-02 Ptc Heater

- B2483-19 Electric Compressor

- B2486-19 Electric Compressor

- B2489-17 Electric Compressor

- B248c-09 Refrigerant Leak

- B2494-13 Heated Steering Wheel Relay

- B2497-96 Battery Coolant Heater

- B24a0-49 A/c Auto Amp.

- B24a1-16 A/c Auto Amp. Power Supply

- B24a2-55 Configuration Error

- B24a4-11 Intake Sensor

- B24a9-11 Sunload Sensor

- B24a9-15 Sunload Sensor

- B24ae-15 Ptc Heater Outlet Air Temperature Sensor Lh

- B24b4-02 A/c Control

- B24c6-12 Blower Motor

- B24c7-98 Ptc Heater

- B24d2-19 Electric Compressor

- B24d3-08 Electric Compressor

- B24d4-08 A/c Control

- B24d8-4b Electric Compressor

- B24dd-19 Battery Coolant Heater

- B24ea-97 Electric Compressor

- B24ed-1c Electric Compressor

- B24ed-97 Electric Compressor

- B24ef-97 Electric Compressor

- B24f4-12 Heated Steering Wheel Relay

- B24fc-11 Ptc Heater Outlet Air Temperature Sensor Rh

- U1000-01 Can Comm Circuit

- U1010-49 Control Unit (can)

- U1ca2-08 Door Motor Communication

- U1ca3-08 Lin Communication

- U1caa-02 Front Mode Door Motor Lh

- U1cab-02 Intake Door Motor

- U1cac-02 Air Mix Door Motor Lh

- U1cad-02 Air Mix Door Motor Rh

- U1cae-02 Front Mode Door Motor Rh

- U1cb0-02 Battery Coolant Heater

- U1cb4-02 Humidity Sensor

- U1cb6-02 Rear Mode Door Motor

- U2143-87 Can Comm Circuit

- U2148-87 Can Comm Circuit

- U214e-87 Can Comm Circuit

- U214f-87 Can Comm Circuit

- U2150-87 Can Comm Circuit

- U2152-87 Can Comm Circuit

- U2154-87 Can Comm Circuit

- U215b-87 Can Comm Circuit

- U216b-87 Can Comm Circuit

- U2176-87 Can Comm Circuit

- U21a0-87 Can Comm Circuit

- B2440-11 Evaporator Discharge Refrigerant Temperature Sensor

- B2440-15 Evaporator Discharge Refrigerant Temperature Sensor

- B2441-11 Condenser Discharge Refrigerant Temperature Sensor

- B2441-15 Condenser Discharge Refrigerant Temperature Sensor

- B2442-11 Compressor Discharge Refrigerant Temperature Sensor

- B2442-15 Compressor Discharge Refrigerant Temperature Sensor

- B2443-11 Inner Condenser Discharge Refrigerant Temperature Sensor

- B2443-15 Inner Condenser Discharge Refrigerant Temperature Sensor

- B2446-23 Refrigerant Leak

- P1c00-44 Heat Pump Control Unit

- P1c00-46 Heat Pump Control Unit

- P1c00-47 Heat Pump Control Unit

- P1c00-49 Heat Pump Control Unit

- P1c01-71 High Pressure Refrigerant Channel Switching Valve

- P1c02-71 Low Pressure Refrigerant Channel Switching Valve

- P1c04-71 Electric Expansion Valve (cooler)

- P1c05-71 Electric Expansion Valve (heater)

- P1c06-1f Electric Compressor

- P1c07-49 Heat Pump Control Unit

- P1c0e-A2 Heat Pump Control Unit Power Supply

- P1c10-11 Refrigerant Temperature Sensor (battery Chiller Inlet)

- P1c10-12 Refrigerant Temperature Sensor (battery Chiller Inlet)

- P1c11-11 Refrigerant Temperature Sensor (battery Chiller Outlet)

- P1c11-12 Refrigerant Temperature Sensor (battery Chiller Outlet)

- P1c12-93 Expansion Valve (battery Chiller)

- U1d20-87 Electric Compressor

- U1d25-87 A/c Auto Amp.

- U2143-87 Can Comm Circuit

- U2148-87 Can Comm Circuit

- U214e-87 Can Comm Circuit

- U214f-87 Can Comm Circuit

- U2153-87 Can Comm Circuit

- U3d01-06 Heat Pump Control Unit

- Power Supply and Ground Circuit (a/c Auto Amp.)

- Power Supply and Ground Circuit (a/c Control)

- Power Supply and Ground Circuit (heat Pump Control Unit)

- Blower Motor Circuit

- Blower Motor

- Door Motor Circuit

- Electric Compressor

- Electric Compressor High Voltage Harness Connector (hvil Circuit)

- Ptc Heater

- Ptc Heater High Voltage Harness Connector (hvil Circuit)

- High Voltage Junction Box

B2480-93 Front Mode Door Motor Rh Nissan Ariya 1st generation

DTC Description

DTC DETECTION LOGIC

NOTE:

NOTE:

“Rear air mix door motor” is indicated on CONSULT display, however this means front mode door motor (passenger side) on this model.

If multiple of door motors DTC (B2480-93, B24DF-93, B24F5-93, B24F6-93, B24F7-93, B24F8-93) are detected, check “DOOR MOTOR CIRCUIT”. Refer to Diagnosis Procedure.

| DTC No. | CONSULT screen terms | DTC detection condition | |

|---|---|---|---|

| B2480-93 | Rear air mix door motor | Diagnosis condition | Power switch ON |

| Signal (Terminal) | LIN (door motor) signal | ||

| Threshold | Drive error of front mode door motor (passenger side) is detected | ||

| Diagnosis delay time | 2 seconds or more | ||

POSSIBLE CAUSE

-

Harness and connector [front mode door motor (passenger side) circuit is open or shorted to ground]

-

Front mode door motor (passenger side) installation condition

-

Front mode door motor (passenger side)

-

A/C auto amp.

FAIL-SAFE

—

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Set the Nissan Ariya vehicle to READY.

-

Select “Self Diagnostic Result” mode of “HVAC” using CONSULT.

Is DTC detected?

YES>>Refer to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

CHECK FRONT MODE DOOR MOTOR (PASSENGER SIDE) POWER SUPPLY

-

Power switch ON.

-

Check voltage between front mode door motor RH harness connector and A/C auto amp. harness connector.

| + | - | Voltage | ||

|---|---|---|---|---|

| Front mode door motor RH | A/C auto amp. | |||

| Connector | Terminal | Connector | Terminal | |

| M906 | 1 | M1 | 58 | 10.5 – 16 V |

Is the inspection result normal?

YES>>GO TO 2.

NO>>GO TO 5.

CHECK FRONT MODE DOOR MOTOR (PASSENGER SIDE) GROUND CIRCUIT FOR OPEN

-

Power switch OFF.

-

Disconnect front mode door motor RH connector and A/C auto amp. connector.

-

Check continuity between front mode door motor RH harness connector and A/C auto amp. harness connector.

Front mode door motor RH A/C auto amp. Continuity Connector Terminal Connector Terminal M906 2 M2 27 Existed

Is the inspection result normal?

YES>>GO TO 3.

NO>>Repair harness or connector.

CHECK FRONT MODE DOOR MOTOR (PASSENGER SIDE) LIN SIGNAL CIRCUIT

-

Connect front mode door motor RH connector and A/C auto amp. connector.

-

Power switch ON.

-

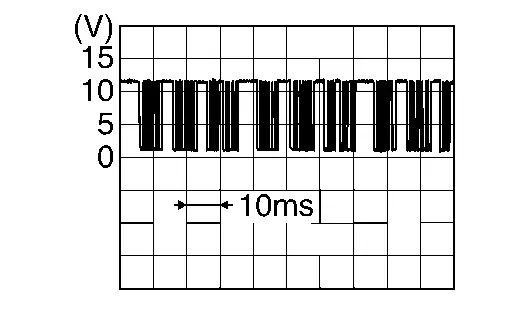

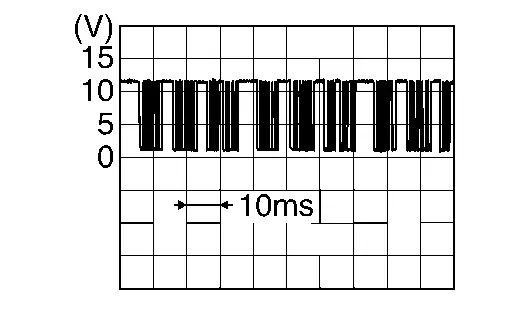

Confirm output waveform between front mode door motor RH harness connector and A/C auto amp. harness connector with oscilloscope.

+ - Output waveform Front mode door motor RH A/C auto amp. Connector Terminal Connector Terminal M906 3 M1 58

Is the inspection result normal?

YES>>GO TO 4.

NO>>GO TO 6.

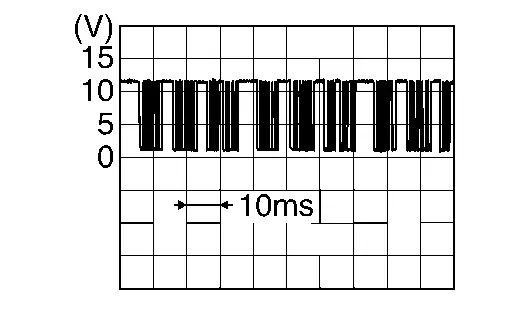

CHECK INSTALLATION OF FRONT MODE DOOR MOTOR (PASSENGER SIDE)

Check front mode door motor RH is properly installed. Refer to Exploded View.

Is the inspection result normal?

YES>>Replace front mode door motor RH. Refer to Removal & Installation.

NO>>Repair or replace malfunctioning part.

CHECK FRONT MODE DOOR MOTOR (PASSENGER SIDE) POWER SUPPLY CIRCUIT FOR OPEN

-

Power switch OFF.

-

Disconnect front mode door motor RH connector and A/C auto amp. connector.

-

Check continuity between front mode door motor RH harness connector and A/C auto amp. harness connector.

Front mode door motor RH A/C auto amp. Continuity Connector Terminal Connector Terminal M906 1 M2 21 Existed

Is the inspection result normal?

YES>>Replace A/C auto amp. Refer to Removal & Installation.

NO>>Repair harness or connector.

CHECK FRONT MODE DOOR MOTOR (PASSENGER SIDE) LIN SIGNAL CIRCUIT FOR OPEN

-

Power switch OFF.

-

Disconnect front mode door motor RH connector and A/C auto amp. connector.

-

Check continuity between front mode door motor RH harness connector and A/C auto amp. harness connector.

Front mode door motor RH A/C auto amp. Continuity Connector Terminal Connector Terminal M906 3 M2 2 Existed

Is the inspection result normal?

YES>>Replace A/C auto amp. Refer to Removal & Installation.

NO>>Repair harness or connector.

B2481-02 Ptc Heater Nissan Ariya 1st generation

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms | DTC detection condition | |

|---|---|---|---|

| B2481–02 | PTC heater LIN communication error | Diagnosis condition | Nissan Ariya Vehicle is READY |

| Signal (terminal) | LIN (PTC heater) signal | ||

| Threshold | Detects abnormalities in the signal transmitted from the PTC heater | ||

| Diagnosis delay time | 2 seconds or more | ||

POSSIBLE CAUSE

-

PTC heater

-

A/C auto amp.

-

Harness or connectors (PTC heater communication circuit is open or shorted)

FAIL-SAFE

PTC heater operation is stopped

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Power switch ON.

-

Select “Self Diagnostic Result” mode of “HVAC” using CONSULT.

Is DTC detected?

YES>>Refer to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

CHECK PTC HEATER LIN SIGNAL CIRCUIT FOR OPEN

-

Power switch OFF.

-

Disconnect PTC heater and A/C auto amp. connector.

-

Check continuity between PTC heater harness connector and A/C auto amp. harness connector.

PTC heater A/C auto amp. Continuity Connector Terminal Connector Terminal M323 9 M1 52 Existed

Is the inspection result normal?

YES>>GO TO 2.

NO>>Repair harness or connector.

CHECK PTC HEATER LIN SIGNAL CIRCUIT FOR SHORT

-

Disconnect following connectors.

-

Heat pump control unit

-

Li-ion battery

-

Electric compressor

-

-

Check continuity between PTC heater harness connector and ground.

PTC heater — Continuity Connector Terminal M323 9 Ground Not existed

Is the inspection result normal?

YES>>GO TO 3.

NO>>Repair harness or connector.

CHECK PTC HEATER POWER SUPPLY

-

Power switch ON.

-

Check voltage between PTC heater harness connector and ground.

+ - Voltage PTC heater Connector Terminal M323 6 Ground Battery voltage

Is the inspection result normal?

YES>>GO TO 4.

NO>>Repair or replace PTC heater 12 V power supply circuit.

CHECK PTC HEATER GROUND CIRCUIT FOR OPEN

-

Power switch OFF.

-

Check continuity between PTC heater harness connector and ground.

| PTC heater | — | Continuity | |

|---|---|---|---|

| Connector | Terminal | ||

| M323 | 8 | Ground | Existed |

Is the inspection result normal?

YES>>GO TO 5.

NO>>Repair harness or connector.

CHECK A/C AUTO AMP.

With CONSULT

With CONSULT

-

Reconnect all harness connectors disconnected.

-

Set the Nissan Ariya vehicle to READY.

-

Using CONSULT, perform “HVAC TEST” on “Active Test” of “HVAC”. Refer to CONSULT Function.

-

Check that the PTC heater operates normally in each mode.

Is the inspection result normal?

YES>>GO TO 6.

NO>>Replace A/C auto amp. (refer to Removal & Installation). Then GO TO 6.

PERFORM DTC CONFIRMATION PROCEDURE

Perform DTC confirmation procedure. Refer to DTC Description.

Is DTC detected?

YES>>Replace PTC heater. Refer to Removal & Installation.

NO>>INSPECTION END

B2483-19 Electric Compressor Nissan Ariya 2026

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms | DTC detection condition | |

|---|---|---|---|

| B2483–19 | Compressor internal circuit | Diagnosis condition | Nissan Ariya Vehicle is READY |

| Signal (terminal) | — | ||

| Threshold | When the electric compressor over current | ||

| Diagnosis delay time | Less than 1 seconds | ||

POSSIBLE CAUSE

Electric compressor

FAIL-SAFE

Electric compressor operation is stopped

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Power switch OFF.

-

Set the Nissan Ariya vehicle to READY.

-

Operate the air conditioning system.

-

Set the temperature to full cold.

-

Select “Self Diagnostic Result” mode of “HVAC” using CONSULT.

Is DTC detected?

YES>>Refer to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

REPLACE ELECTRIC COMPRESSOR

Replace electric compressor. Refer to Removal & Installation.

>>

INSPECTION END

B2486-19 Electric Compressor Nissan Ariya 2026

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms | DTC detection condition | |

|---|---|---|---|

| B2486–19 | Compressor low speed high load | Diagnosis condition | Nissan Ariya Vehicle is READY |

| Signal (terminal) | — | ||

| Threshold | When the driving load of the electric compressor reaches a maximum value during slow rotation | ||

| Diagnosis delay time | Less than 1 seconds | ||

POSSIBLE CAUSE

-

Electric compressor

-

Cooling fan

-

Overfilled refrigerant

-

Refrigerant cycle unusual

-

High voltage junction box

-

High voltage harness or connectors (electric compressor high voltage circuit is open)

FAIL-SAFE

Electric compressor speed increase

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Power switch OFF.

-

Set the Nissan Ariya vehicle to READY.

-

Operate the air conditioning system.

-

Set the temperature to full cold.

-

Select “Self Diagnostic Result” mode of “HVAC” using CONSULT.

Is DTC detected?

YES>>Refer to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

WARNING:

Since hybrid vehicles and electric Nissan Ariya vehicles contain a high voltage battery, there is the risk of electric shock, electric leakage, or similar accidents if the high voltage component and Nissan Ariya vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

Since hybrid vehicles and electric Nissan Ariya vehicles contain a high voltage battery, there is the risk of electric shock, electric leakage, or similar accidents if the high voltage component and Nissan Ariya vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

WARNING:

-

Be sure to remove the service plug in order to disconnect the high voltage circuits before performing inspection or maintenance of high voltage system harnesses and parts.

-

The removed service plug must always be carried in a pocket of the responsible worker or placed in the tool box during the procedure to prevent the plug from being connected by mistake.

-

Be sure to wear insulating protective equipment consisting of glove, shoes, face shield and glasses before beginning work on the high voltage system.

-

Never allow workers other than the responsible person to touch the Nissan Ariya vehicle containing high voltage parts. To keep others from touching the high voltage parts, these parts must be covered with an insulating sheet except when using them.

-

Refer to Precautions for High Voltage.

CAUTION:

Never bring the vehicle into the READY status with the service plug removed unless otherwise instructed in the Service Manual. A malfunction may occur if this is not observed.

CHECK REFRIGERANT FOR LEAKAGES

Check refrigerant for leakages. Refer to Leak Test.

Is the inspection result normal?

YES>>GO TO 2.

NO>>Repair or replace malfunctioning parts.

CHECK COOLING FAN OPERATION

Check cooling fan. Refer to Component Function Check.

Is the inspection result normal?

YES>>GO TO 3.

NO>>Repair or replace malfunctioning parts.

CHECK REFRIGERANT CYCLE

Check refrigerant cycle. Refer to Symptom Table.

Is the inspection result normal?

YES>>GO TO 4.

NO>>Repair or replace malfunctioning parts.

PRECONDITIONING

WARNING:

Follow the instructions below before starting the procedure.

-

Disconnect high voltage circuit. Refer to HOW TO DISCONNECT HIGH VOLTAGE : Precautions.

-

Check voltage in high voltage circuit. Refer to CHECK VOLTAGE IN HIGH VOLTAGE CIRCUIT : Precautions.

>>

GO TO 5.

CHECK ELECTRIC COMPRESSOR HIGH VOLTAGE CIRCUIT FOR OPEN

-

Power switch OFF.

-

Disconnect electric compressor and PTC heater connector.

-

Check continuity between electric compressor harness connector and PTC heater harness connector.

Electric compressor PTC heater Continuity Connector Terminal Connector Terminal H9 7 H2 2 Existed

Is the inspection result normal?

YES>>Replace electric compressor. Refer to Removal & Installation.

NO>>GO TO 6.

CHECK ELECTRIC COMPRESSOR HIGH VOLTAGE HARNESS FOR OPEN

-

Disconnect high voltage junction box connector.

-

Check continuity between electric compressor harness connector and high voltage junction box harness connector.

Electric compressor High voltage junction box Continuity Connector Terminal Connector Terminal H9 7 H11 18 Existed

Is the inspection result normal?

YES>>GO TO 7.

NO>>Replace high voltage harness between electric compressor and high voltage junction box.

CHECK FUSE INSIDE OF HIGH VOLTAGE JUNCTION BOX

NOTE:

NOTE:

A fuse is built into the high voltage junction box, and a continuity check is performed to check if the fuse has blown.

Check continuity between each terminal of the high voltage junction box.

| High voltage junction box | Continuity | |||

|---|---|---|---|---|

| Connector | Terminal | Connector | Terminal | |

| H11 | 18 ( ) ) |

H1 | 14 ( ) ) |

Existed |

Is the inspection result normal?

YES>>Replace electric compressor. Refer to Removal & Installation.

NO>>GO TO 8.

CHECK ELECTRIC COMPRESSOR

Check electric compressor. Refer to Component Inspection.

Is the inspection result normal?

YES>>Replace high voltage junction box. Refer to HIGH VOLTAGE JUNCTION BOX : Disassembly & Assembly.

NO>>Replace electric compressor (refer to Removal & Installation.), and then replace high voltage junction box. Refer to HIGH VOLTAGE JUNCTION BOX : Disassembly & Assembly.

Component Inspection

WARNING:

Since hybrid vehicles and electric Nissan Ariya vehicles contain a high voltage battery, there is the risk of electric shock, electric leakage, or similar accidents if the high voltage component and Nissan Ariya vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

Since hybrid vehicles and electric Nissan Ariya vehicles contain a high voltage battery, there is the risk of electric shock, electric leakage, or similar accidents if the high voltage component and Nissan Ariya vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

WARNING:

-

Be sure to remove the service plug in order to disconnect the high voltage circuits before performing inspection or maintenance of high voltage system harnesses and parts.

-

The removed service plug must always be carried in a pocket of the responsible worker or placed in the tool box during the procedure to prevent the plug from being connected by mistake.

-

Be sure to wear insulating protective equipment consisting of glove, shoes, face shield and glasses before beginning work on the high voltage system.

-

Never allow workers other than the responsible person to touch the Nissan Ariya vehicle containing high voltage parts. To keep others from touching the high voltage parts, these parts must be covered with an insulating sheet except when using them.

-

Refer to Precautions for High Voltage.

CAUTION:

Never bring the vehicle into the READY status with the service plug removed unless otherwise instructed in the Service Manual. A malfunction may occur if this is not observed.

PRECONDITIONING

WARNING:

Follow the instructions below before starting the procedure.

-

Disconnect high voltage circuit. Refer to HOW TO DISCONNECT HIGH VOLTAGE : Precautions.

-

Check voltage in high voltage circuit. Refer to CHECK VOLTAGE IN HIGH VOLTAGE CIRCUIT : Precautions.

>>

GO TO 2.

CHECK ELECTRIC COMPRESSOR

-

Power switch OFF.

-

Disconnect electric compressor connector.

-

Check voltage between electric compressor terminals using circuit tester diode mode.

+ - Voltage Electric compressor Terminal 8 7 0.4 – 1.0 V

Is the inspection result normal?

YES>>INSPECTION END

NO>>Replace electric compressor. Refer to Removal & Installation.

B2489-17 Electric Compressor Nissan Ariya 2023

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms | DTC detection condition | |

|---|---|---|---|

| B2489–17 | Compressor high voltage | Diagnosis condition | Nissan Ariya Vehicle is READY |

| Signal (terminal) | — | ||

| Threshold | When the high voltage system input voltage is more than 420 V | ||

| Diagnosis delay time | 2 seconds or more | ||

POSSIBLE CAUSE

-

Electric compressor

-

Li-ion battery

-

Front traction motor inverter

FAIL-SAFE

Electric compressor stopped operation.

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Set the Nissan Ariya vehicle to READY.

-

Operate the air conditioning system.

-

Set the temperature to full cold.

-

Select “Self Diagnostic Result” mode of “HVAC” using CONSULT.

Is DTC detected?

YES>>Refer to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

CHECK LI-ION BATTERY

Check Li-ion battery. Refer to Work Flow.

Is the inspection result normal?

YES>>GO TO 2 .

NO>>Repair or replace malfunctioning parts.

CHECK INVERTER (FRONT)

Check inverter (front). Refer to Work Flow.

Is the inspection result normal?

YES>>Replace electric compressor. Refer to Removal & Installation.

NO>>Repair or replace malfunctioning parts.

B248c-09 Refrigerant Leak Nissan Ariya 2023

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms | DTC detection condition | |

|---|---|---|---|

| B248C–09 | Refrigerant gas leak | Diagnosis condition | Power switch ON |

| Signal (terminal) | — | ||

| Threshold | Refrigerant is leaking or not in | ||

| Diagnosis delay time | — | ||

POSSIBLE CAUSE

-

Refrigerant is leaking or not in

-

Refrigerant pressure sensor

-

VCM

-

Harness or connectors (refrigerant pressure sensor and VCM circuit is open or shorted)

FAIL-SAFE

Electric compressor operation is stopped

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Power switch OFF.

-

Set the Nissan Ariya vehicle to READY.

-

Operate the air conditioning system.

-

Set the temperature to full cold.

-

Select “Self Diagnostic Result” mode of “HVAC” using CONSULT.

Is DTC detected?

YES>>Refer to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

CHECK REFRIGERANT PRESSURE SENSOR SYSTEM

Check refrigerant pressure sensor system. Refer to Diagnosis Procedure.

Is the inspection result normal?

YES>>GO TO 2.

NO>>Repair or replace malfunctioning part.

CHECK REFRIGERANT LEAK

Check refrigerant leak. Refer to Leak Test.

Is the inspection result normal?

YES>>INSPECTION END

NO>>Repair or replace malfunctioning part.

B2494-13 Heated Steering Wheel Relay Nissan Ariya 2026

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms | DTC detection condition | |

|---|---|---|---|

| B2494-13 | Heated steering wheel relay | Diagnosis condition | Power switch ON |

| Signal (Terminal) | Heated steering wheel relay control circuit | ||

| Threshold | Heated steering wheel relay control circuit is open or shorted to ground | ||

| Diagnosis delay time | 1 second or more | ||

POSSIBLE CAUSE

-

Fuse

-

Steering heater relay

-

A/C auto amp.

-

Harness or connectors (heated steering wheel relay control circuit is open or shorted to ground)

FAIL-SAFE

Heated steering wheel operation is stopped

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Power switch ON.

-

Select “Self Diagnostic Result” mode of “HVAC” using CONSULT.

Is DTC detected?

YES>>Refer to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

CHECK FUSE

-

Power switch OFF.

-

Check that the following fuse is not blown (open).

| Unit | Location | Fuse No. | Capacity |

|---|---|---|---|

| Steering heater relay | Fuse block (J/B) | #70 | 10A |

Is the fuse blown (open)?

YES>>Replace the blown (open) fuse after repairing the affected circuit if a fuse is blown (open).

NO>>GO TO 2.

CHECK STEERING HEATER RELAY CONTROL SIGNAL CIRCUIT

-

Disconnect A/C auto amp. connector.

-

Power switch ON.

-

Check voltage between A/C auto amp. harness connector and ground.

+ - Voltage A/C auto amp. Connector Terminal M1 56 Ground Battery voltage

Is the inspection result normal?

YES>>Replace A/C auto amp. Refer to Removal & Installation.

NO>>GO TO 3.

CHECK STEERING HEATER RELAY POWER SUPPLY CIRCUIT FOR OPEN

-

Power switch OFF.

-

Remove steering heater relay.

-

Power switch ON.

-

Check voltage between steering heater relay harness connector and ground.

+ - Voltage Steering heater relay Connector Terminal M118 1 Ground Battery voltage

Is the inspection result normal?

YES>>GO TO 4.

NO>>Repair harness or connector.

CHECK STEERING HEATER RELAY CONTROL SIGNAL CIRCUIT FOR OPEN

-

Power switch OFF.

-

Check continuity between steering heater relay harness connector and A/C auto amp. harness connector.

| Steering heater relay | A/C auto amp. | Continuity | ||

|---|---|---|---|---|

| Connector | Terminal | Connector | Terminal | |

| M118 | 2 | M1 | 56 | Existed |

Is the inspection result normal?

YES>>GO TO 5.

NO>>Repair harness or connector.

CHECK STEERING HEATER RELAY CONTROL SIGNAL CIRCUIT FOR SHORT

Check continuity between steering heater relay harness connector and ground.

| Steering heater relay | — | Continuity | |

|---|---|---|---|

| Connector | Terminal | ||

| M118 | 2 | Ground | Not existed |

Is the inspection result normal?

YES>>GO TO 6.

NO>>Repair harness or connector.

CHECK STEERING HEATER RELAY

Check steering heater relay. Refer to Component Inspection.

Is the inspection result normal?

YES>>INSPECTION END

NO>>Replace steering heater relay.

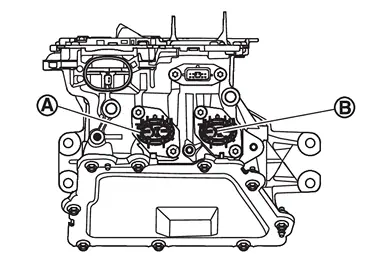

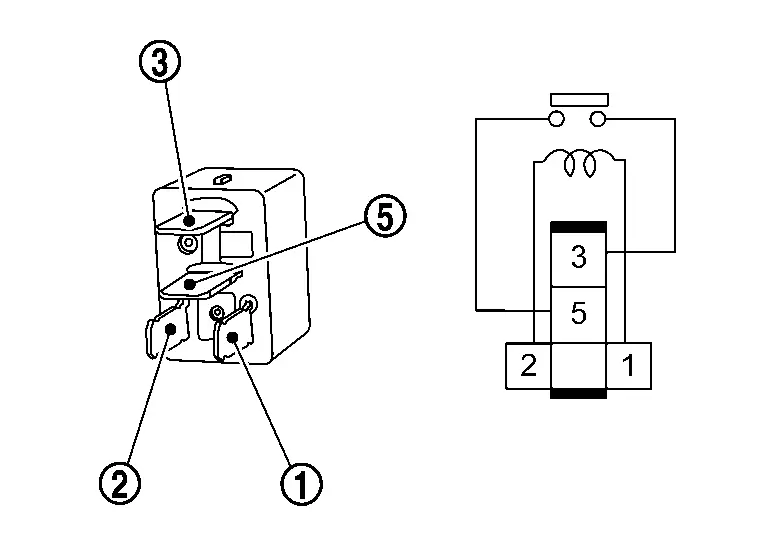

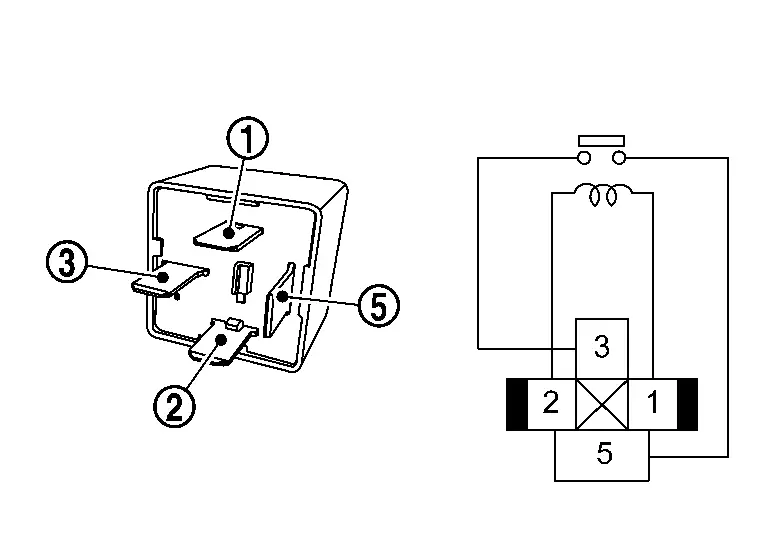

Component Inspection

CHECK STEERING HEATER RELAY

-

Power switch OFF.

-

Remove steering heater relay.

-

Check continuity between steering heater relay terminals.

Terminal Condition Continuity Steering heater relay

12 V direct current supply between terminals  and

and  .

. Existed No current supply Not existed

Is the inspection result normal?

YES>>INSPECTION END

NO>>Replace steering heater relay.

B2497-96 Battery Coolant Heater Nissan Ariya

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms | DTC detection condition | |

|---|---|---|---|

| B2497-96 | Battery coolant heater IGBT circuit 1 | Diagnosis condition | Nissan Ariya Vehicle is READY |

| Signal (terminal) | — | ||

| Threshold | When battery coolant heater IGBT circuit 1 short is detected | ||

| Diagnosis delay time | 2 seconds or more | ||

POSSIBLE CAUSE

Battery coolant heater

FAIL-SAFE

—

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Set the Nissan Ariya vehicle to READY.

-

Select “Self Diagnostic Result” mode of “HVAC” using CONSULT.

Is DTC detected?

YES>>Refer to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

REPLACE BATTERY COOLANT HEATER

Replace battery coolant heater.

>>

INSPECTION END

B24a0-49 A/c Auto Amp. Nissan Ariya first Gen

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms | DTC detection condition | |

|---|---|---|---|

| B24A0-49 | Air conditioning automatic amplifier | Diagnosis condition | Power switch ON |

| Signal (Terminal) | — | ||

| Threshold | A malfunction is detected in A/C auto amp. internal EEPROM memory functions. | ||

| Diagnosis delay time | 2 seconds or more | ||

POSSIBLE CAUSE

A/C auto amp.

FAIL-SAFE

—

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Power switch ON.

-

Select “Self Diagnostic Result” mode of “HVAC” using CONSULT.

Is DTC detected?

YES>>Refer to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

REPLACE A/C AUTO AMP.

Replace A/C auto amp. Refer to Removal & Installation.

>>

INSPECTION END

B24a1-16 A/c Auto Amp. Power Supply Nissan Ariya 1st generation

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms | DTC detection condition | |

|---|---|---|---|

| B24A1-16 | Air conditioning automatic amplifier power supply | Diagnosis condition | Power switch ON |

| Signal (Terminal) | Accessory power supply | ||

| Threshold | When the power of the A/C auto amp. goes down | ||

| Diagnosis delay time | Less than 1 second | ||

POSSIBLE CAUSE

-

A/C auto amp.

-

Harness or connector (accessory power supply circuits is open or short)

FAIL-SAFE

Air conditioning system operation is stopped

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Power switch ON.

-

Select “Self Diagnostic Result” mode of “HVAC” using CONSULT.

Is DTC detected?

YES>>Refer to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

CHECK A/C AUTO AMP. POWER SUPPLY AND GROUND CIRCUITS

Check A/C auto amp. power supply and ground circuits. Refer to Diagnosis Procedure.

Is the inspection result normal?

YES>>Replace A/C auto amp. Refer to Removal & Installation.

NO>>Repair or replace malfunctioning parts.

B24a2-55 Configuration Error Nissan Ariya first Gen

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms | DTC detection condition | |

|---|---|---|---|

| B24A2-55 | Configuration not implement | Diagnosis condition | Power switch ON |

| Signal (Terminal) | — | ||

| Threshold | Nissan Ariya Vehicle specification is not written | ||

| Diagnosis delay time | 2 seconds or more | ||

POSSIBLE CAUSE

Configuration is not completed

FAIL-SAFE

—

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Power switch ON.

-

Select “Self Diagnostic Result” mode of “HVAC” using CONSULT.

Is DTC detected?

YES>>Refer to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

PERFORM CONFIGURATION

Perform configuration. Refer to Work Procedure.

>>

INSPECTION END

B24a4-11 Intake Sensor Nissan Ariya 1st generation

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms | DTC detection condition | |

|---|---|---|---|

| B24A4-11 | Intake sensor | Diagnosis condition | Power switch ON |

| Signal (Terminal) | Intake sensor signal | ||

| Threshold | The intake sensor recognition temperature is too high [more than 100°C (212°F)] | ||

| Diagnosis delay time | 2 seconds or more | ||

POSSIBLE CAUSE

-

Intake sensor

-

A/C auto amp.

-

Harness or connectors (the sensor circuit is shorted to ground)

FAIL-SAFE

Electric compressor operation is stopped

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Power switch ON.

-

Select “Self Diagnostic Result” mode of “HVAC” using CONSULT.

Is DTC detected?

YES>>Refer to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

CHECK INTAKE SENSOR SIGNAL

-

Power switch ON.

-

Check voltage between A/C auto amp. harness connector.

A/C auto amp. Voltage Connector Terminal + - M2 23 26

Is the inspection result normal?

YES>>Replace A/C auto amp. Refer to Removal & Installation.

NO>>GO TO 2.

CHECK INTAKE SENSOR POWER SUPPLY

-

Power switch OFF.

-

Disconnect intake sensor connector.

-

Power switch ON.

-

Check voltage between intake sensor harness connector and ground.

+ - Voltage

(Approx.)Intake sensor Connector Terminal M316 1 Ground 5 V

Is the inspection result normal?

YES>>GO TO 3.

NO>>GO TO 4.

CHECK INTAKE SENSOR

Check intake sensor. Refer to Component Inspection.

Is the inspection result normal?

YES>>Replace A/C auto amp. Refer to Removal & Installation.

NO>>Replace intake sensor. Refer to Removal & Installation.

CHECK INTAKE SENSOR POWER SUPPLY CIRCUIT FOR SHORT

-

Power switch OFF.

-

Disconnect A/C auto amp. connector.

-

Check continuity between intake sensor harness connector and ground.

Intake sensor — Continuity Connector Terminal M316 1 Ground Not existed

Is the inspection result normal?

YES>>Replace A/C auto amp. Refer to Removal & Installation.

NO>>Repair harness or connector.

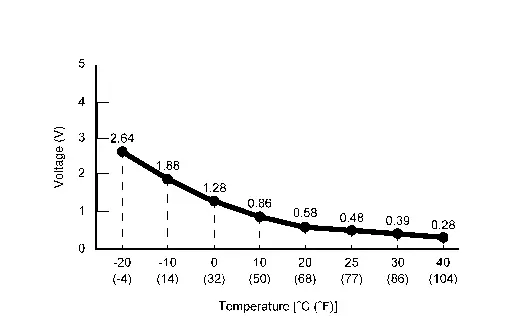

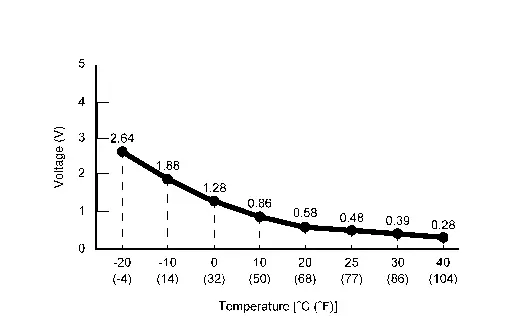

Component Inspection

CHECK INTAKE SENSOR

-

Power switch OFF.

-

Remove intake sensor. Refer to Removal & Installation.

-

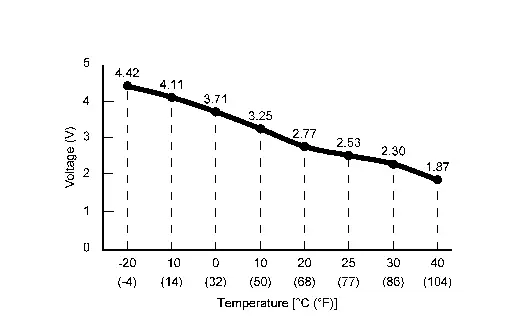

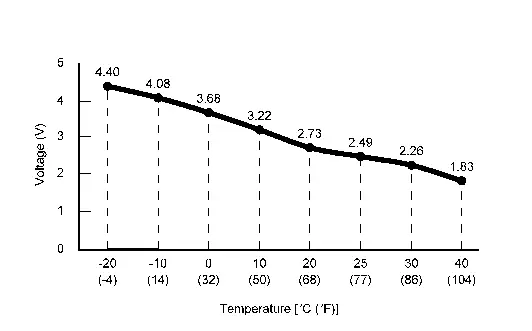

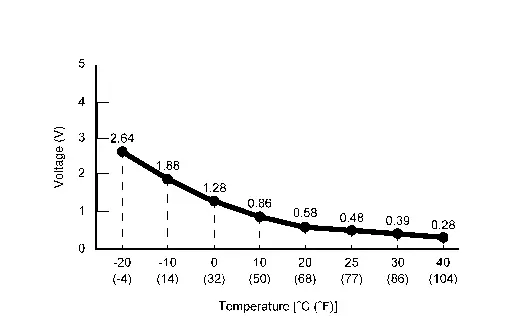

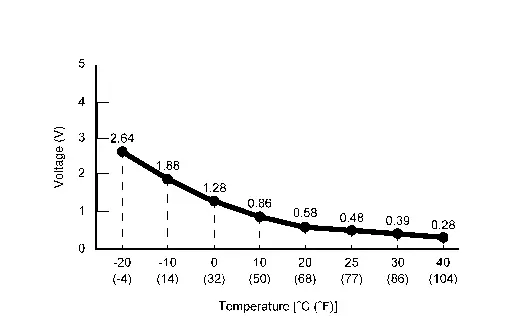

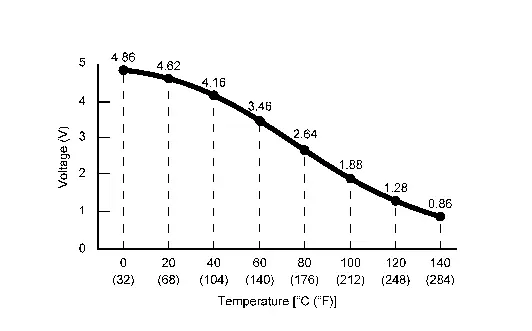

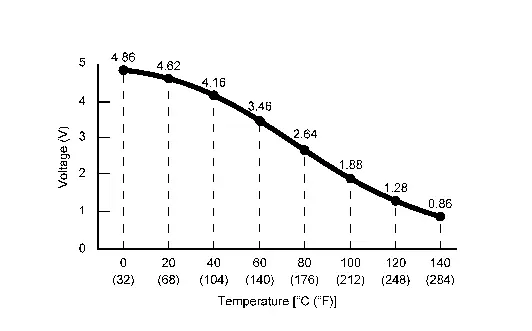

Check resistance between intake sensor harness connector terminals. Refer to applicable table for the normal value.

Terminal Condition Resistance: kΩ Temperature: °C (°F) 1 2 −20 (−4) 16.43 −10 (14) 9.90 0 (32) 6.19 10 (50) 4.01 20 (68) 2.67 25 (77) 2.20 30 (86) 1.83 40 (104) 1.28

Is the inspection result normal?

YES>>INSPECTION END

NO>>Replace intake sensor. Refer to Removal & Installation.

B24a9-11 Sunload Sensor Nissan Ariya SUV

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms | DTC detection condition | |

|---|---|---|---|

| B24A9-11 | SUNLOAD SENSOR | Diagnosis condition | Power switch ON |

| Signal (Terminal) | Sunload sensor signal | ||

| Threshold | Detected calorie at sunload sensor 1516 W/m2 (1304 kcal/m2·h) or more | ||

| Diagnosis delay time | 2 seconds or more | ||

POSSIBLE CAUSE

-

Sunload sensor

-

A/C auto amp.

-

Harness or connectors (the sensor circuit is shorted to ground)

FAIL-SAFE

—

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Power switch ON.

-

Select “Self Diagnostic Result” mode of “HVAC” using CONSULT.

Is DTC detected?

YES>>Refer to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

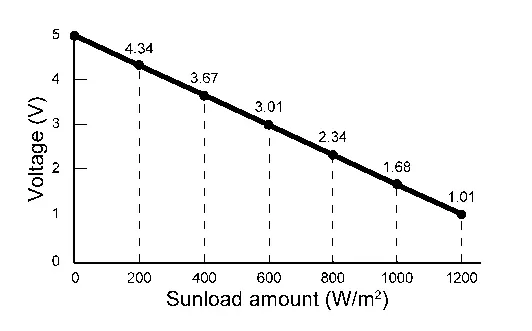

CHECK SUNLOAD SENSOR SIGNAL

-

Power switch ON.

-

Check that the voltage between the A/C auto amp. Nissan Ariya vehicle-side harness connectors changes when an approx. 60 W light is moved closer to or away from the sensor.

A/C auto amp. Condition Connector Terminal + - M1 47 78

NOTE:

NOTE:

-

The output voltage changes according to the sunload.

-

The sunload amount produced by direct sunshine in fair weather is equivalent to approx. 0.77 kW/m2.

-

Is the inspection result normal?

YES>>Replace A/C auto amp. Refer to Removal & Installation.

NO>>GO TO 2.

CHECK SUNLOAD SENSOR POWER SUPPLY

-

Power switch OFF.

-

Disconnect sunload sensor connector.

-

Power switch ON.

-

Check voltage between sunload sensor harness connector and ground.

+ - Voltage

(Approx.)Sunload sensor Connector Terminal M135 1 Ground 5 V

Is the inspection result normal?

YES>>GO TO 3.

NO>>GO TO 4.

REPLACE SUNLOAD SENSOR

-

Replace sunload sensor. Refer to Removal & Installation.

-

Perform DTC confirmation procedure. Refer to DTC Description.

Is DTC detected?

YES>>Replace A/C auto amp. Refer to Removal & Installation.

NO>>INSPECTION END

CHECK SUNLOAD SENSOR POWER SUPPLY CIRCUIT FOR SHORT

-

Power switch OFF.

-

Disconnect A/C auto amp. connector.

-

Check continuity between sunload sensor harness connector and ground.

Sunload sensor — Continuity Connector Terminal M135 1 Ground Not existed

Is the inspection result normal?

YES>>Replace A/C auto amp. Refer to Removal & Installation.

NO>>Repair harness or connector.

B24a9-15 Sunload Sensor Nissan Ariya: FE0

DTC Description

DTC DETECTION LOGIC

NOTE:

NOTE:

Sunload sensor may register a malfunction when indoors, at dusk, or at other times when light is insufficient. When performing the diagnosis indoors, use a lamp (60 W or more) that is pointed at the sunload sensor.

| DTC No. | CONSULT screen terms | DTC detection condition | |

|---|---|---|---|

| B24A9-15 | SUNLOAD SENSOR | Diagnosis condition | Power switch ON |

| Signal (Terminal) | Sunload sensor signal | ||

| Threshold | Detected calorie at sunload sensor 35.3 W/m2 (30 kcal/m2·h) or less | ||

| Diagnosis delay time | 2 seconds or more | ||

POSSIBLE CAUSE

-

Sunload sensor

-

A/C auto amp.

-

Harness or connectors (the sensor circuit is open or shorted to battery)

FAIL-SAFE

—

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Power switch ON.

-

Select “Self Diagnostic Result” mode of “HVAC” using CONSULT.

Is DTC detected?

YES>>Refer to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

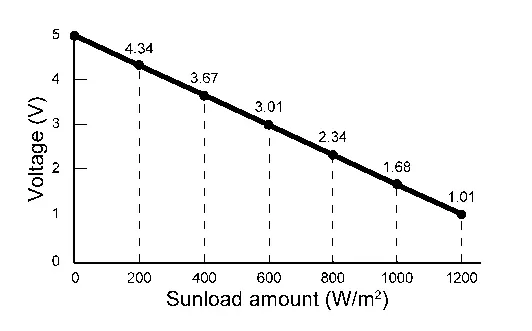

CHECK SUNLOAD SENSOR SIGNAL

-

Power switch ON.

-

Check that the voltage between the A/C auto amp. Nissan Ariya vehicle-side harness connectors changes when an approx. 60 W light is moved closer to or away from the sensor.

A/C auto amp. Condition Connector Terminal + - M1 47 78

NOTE:

NOTE:

-

The output voltage changes according to the sunload.

-

The sunload amount produced by direct sunshine in fair weather is equivalent to approx. 0.77 kW/m2.

-

Is the inspection result normal?

YES>>Replace A/C auto amp. Refer to Removal & Installation.

NO>>GO TO 2.

CHECK SUNLOAD SENSOR POWER SUPPLY

-

Power switch OFF.

-

Disconnect sunload sensor connector.

-

Power switch ON.

-

Check voltage between sunload sensor harness connector and ground.

+ - Voltage

(Approx.)Sunload sensor Connector Terminal M135 1 Ground 5 V

Is the inspection result normal?

YES>>GO TO 3.

NO>>GO TO 5.

CHECK SUNLOAD SENSOR GROUND CIRCUIT FOR OPEN

-

Power switch OFF.

-

Disconnect A/C auto amp. connector.

-

Check continuity between sunload sensor harness connector and A/C auto amp harness connector.

Sunload sensor A/C auto amp. Continuity Connector Terminal Connector Terminal M135 2 M1 78 Existed

Is the inspection result normal?

YES>>GO TO 4.

NO>>Repair harness or connector.

REPLACE SUNLOAD SENSOR

-

Replace sunload sensor. Refer to Removal & Installation.

-

Perform DTC confirmation procedure. Refer to DTC Description.

Is DTC detected?

YES>>Replace A/C auto amp. Refer to Removal & Installation.

NO>>INSPECTION END

CHECK SUNLOAD SENSOR POWER SUPPLY CIRCUIT FOR OPEN

-

Ignition switch OFF.

-

Disconnect A/C auto amp. connector.

-

Check continuity between sunload sensor harness connector and A/C auto amp. harness connector.

Sunload sensor A/C auto amp. Continuity Connector Terminal Connector Terminal M135 1 M1 47 Existed

Is the inspection result normal?

YES>>GO TO 6.

NO>>Repair harness or connector.

CHECK SUNLOAD SENSOR POWER SUPPLY CIRCUIT FOR SHORT

Check voltage between sunload sensor harness connector and ground.

| + | - |

Voltage (Approx.) | |

|---|---|---|---|

| Sunload sensor | |||

| Connector | Terminal | ||

| M135 | 1 | Ground | 0 V |

Is the inspection result normal?

YES>>Replace A/C auto amp. Refer to Removal & Installation.

NO>>Repair harness or connector.

B24ae-15 Ptc Heater Outlet Air Temperature Sensor Lh Nissan Ariya first Gen

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms | DTC detection condition | |

|---|---|---|---|

| B24AE-15 | PTC heater outlet air temp sensor left | Diagnosis condition | Power switch ON |

| Signal (Terminal) | PTC heater outlet air temperature sensor LH signal | ||

| Threshold | PTC heater outlet air temperature sensor (driver side) recognition temperature is too low [less than -42°C (-44°F)] | ||

| Diagnosis delay time | 2 seconds or more | ||

POSSIBLE CAUSE

-

PTC heater outlet air temperature sensor (driver side)

-

A/C auto amp.

-

Harness or connectors (the sensor circuit is open or shorted to battery)

FAIL-SAFE

PTC heater operation is stopped

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Power switch ON.

-

Select “Self Diagnostic Result” mode of “HVAC” using CONSULT.

Is DTC detected?

YES>>Refer to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

CHECK PTC HEATER OUTLET AIR TEMPERATURE SENSOR (DRIVER SIDE) SIGNAL

-

Power switch ON.

-

Check voltage between A/C auto amp. harness connector.

A/C auto amp. Voltage Connector Terminal + - M1 59 78

Is the inspection result normal?

YES>>Replace A/C auto amp. Refer to Removal & Installation.

NO>>GO TO 2.

CHECK PTC HEATER OUTLET AIR TEMPERATURE SENSOR (DRIVER SIDE) POWER SUPPLY

-

Power switch OFF.

-

Disconnect PTC heater outlet air temperature sensor LH connector.

-

Power switch ON.

-

Check voltage between PTC heater outlet air temperature sensor LH harness connector and ground.

+ - Voltage

(Approx.)PTC heater outlet air temperature sensor LH Connector Terminal M903 6 Ground 5 V

Is the inspection result normal?

YES>>GO TO 3.

NO>>GO TO 5.

CHECK PTC HEATER OUTLET AIR TEMPERATURE SENSOR (DRIVER SIDE) GROUND CIRCUIT FOR OPEN

-

Power switch OFF.

-

Disconnect A/C auto amp. connector.

-

Check continuity between PTC heater outlet air temperature sensor LH harness connector and A/C auto amp. harness connector.

PTC heater outlet air temperature sensor LH A/C auto amp. Continuity Connector Terminal Connector Terminal M903 26 M1 78 Existed

Is the inspection result normal?

YES>>GO TO 4.

NO>>Repair harness or connector.

CHECK PTC HEATER OUTLET AIR TEMPERATURE SENSOR (DRIVER SIDE)

Check PTC heater outlet air temperature sensor LH. Refer to Component Inspection.

Is the inspection result normal?

YES>>Replace A/C auto amp. Refer to Removal & Installation.

NO>>Replace PTC heater outlet air temperature sensor LH. Refer to Removal & Installation.

CHECK PTC HEATER OUTLET AIR TEMPERATURE SENSOR (DRIVER SIDE) POWER SUPPLY CIRCUIT FOR OPEN

-

Power switch OFF.

-

Disconnect A/C auto amp. connector.

-

Check continuity between PTC heater outlet air temperature sensor LH harness connector and A/C auto amp. harness connector.

PTC heater outlet air temperature sensor LH A/C auto amp. Continuity Connector Terminal Connector Terminal M903 6 M1 59 Existed

Is the inspection result normal?

YES>>GO TO 6.

NO>>Repair harness or connector.

CHECK PTC HEATER OUTLET AIR TEMPERATURE SENSOR (DRIVER SIDE) POWER SUPPLY CIRCUIT FOR SHORT

Check voltage between PTC heater outlet air temperature sensor LH harness connector and ground.

| + | - |

Voltage (Approx.) | |

|---|---|---|---|

| PTC heater outlet air temperature sensor LH | |||

| Connector | Terminal | ||

| M903 | 6 | Ground | 0 V |

Is the inspection result normal?

YES>>Replace A/C auto amp. Refer to Removal & Installation.

NO>>Repair harness or connector.

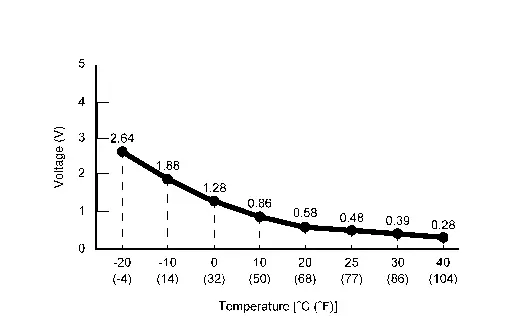

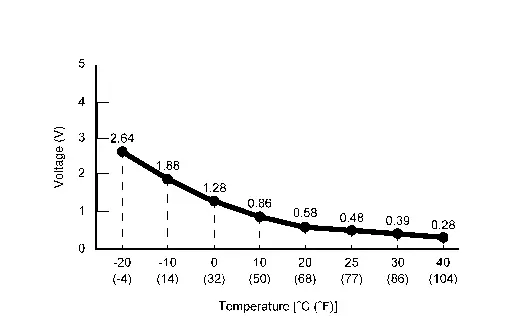

Component Inspection

CHECK PTC HEATER OUTLET AIR TEMPERATURE SENSOR

-

Power switch OFF.

-

Remove PTC heater outlet air temperature sensor. Refer to Removal & Installation.

-

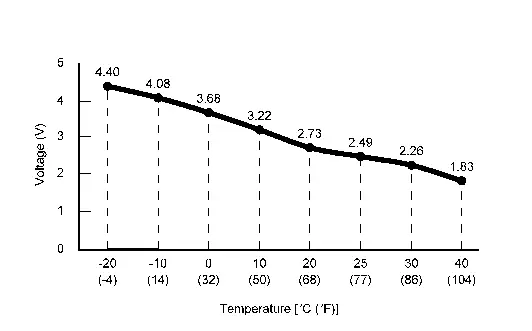

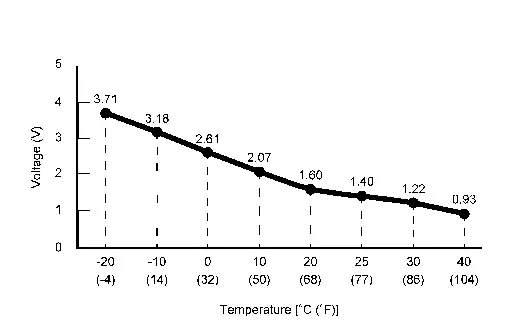

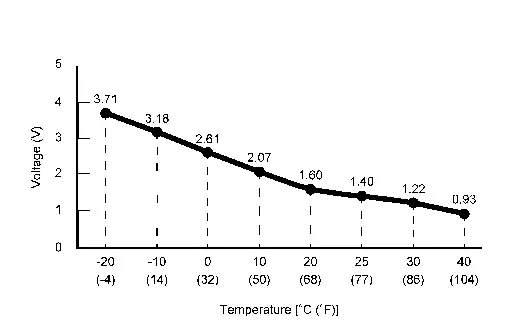

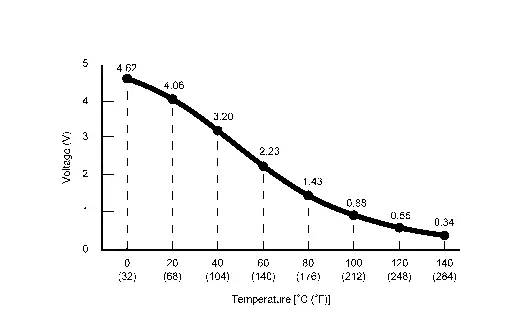

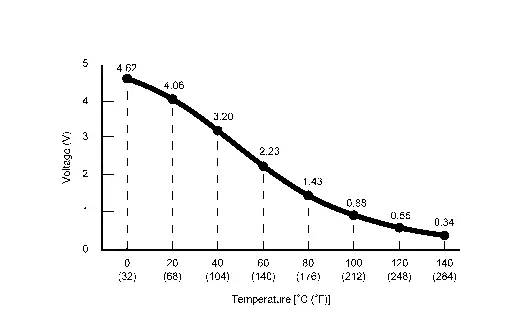

Check resistance between PTC heater outlet air temperature sensor harness connector terminals. Refer to applicable table for the normal value.

Terminal Condition Resistance: kΩ Temperature: °C (°F) 1 2 −20 (−4) 15.91 −10 (14) 9.59 0 (32) 6.00 10 (50) 3.88 20 (68) 2.58 25 (77) 2.13 30 (86) 1.77 40 (104) 1.24

Is the inspection result normal?

YES>>INSPECTION END

NO>>Replace PTC heater outlet air temperature sensor. Refer to Removal & Installation.

B24b4-02 A/c Control Nissan Ariya: FE0

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms | DTC detection condition | ||

|---|---|---|---|---|

| B24B4-02 | Air conditioning control | Diagnosis condition | Power switch ON | |

| Signal (terminal) | LIN (A/C control) signal | |||

| Threshold | Receive internal circuit error message via A/C control to LIN communication | |||

| Diagnosis delay time | 30 seconds or more | |||

POSSIBLE CAUSE

A/C control (internal circuit malfunction)

FAIL-SAFE

—

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Power switch ON.

-

Select “Self Diagnostic Result” mode of “HVAC” using CONSULT.

Is DTC detected?

YES>>Refer to Diagnosis Procedure.

NO-1 >>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2 >>Confirmation after repair: INSPECTION END

Diagnosis Procedure

PERFORM SELF DIAGNOSTIC RESULT

With CONSULT

With CONSULT

-

Power switch ON.

-

Select “Self Diagnostic Result” mode of “HVAC” with CONSULT.

-

Touch “ERASE”.

-

Power switch OFF.

-

Power switch ON.

-

Perform “DTC CONFIRMATION PROCEDURE”. Refer to DTC Description.

Is DTC detected again?

YES>>Replace A/C control. Refer to Removal & Installation.

NO>>INSPECTION END

B24c6-12 Blower Motor Nissan Ariya first Gen

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms | DTC detection condition | |

|---|---|---|---|

| B24C6-12 | BLOWER MOTOR CONTROL | Diagnosis condition | Blower motor ON |

| Signal (Terminal) | Blower motor control signal | ||

| Threshold | Blower motor control signal circuit is short to battery | ||

| Diagnosis delay time | 1 seconds or more | ||

POSSIBLE CAUSE

-

Harness or connectors (blower motor control signal circuit is shorted to battery)

-

Blower motor

-

A/C auto amp.

FAIL-SAFE

Blower motor operation is stopped

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Power switch ON.

-

Select “Self Diagnostic Result” mode of “HVAC” using CONSULT.

Is DTC detected?

YES>>Refer to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

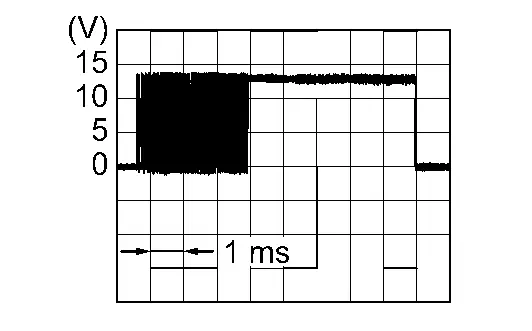

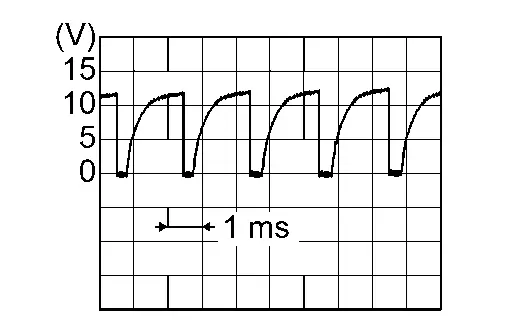

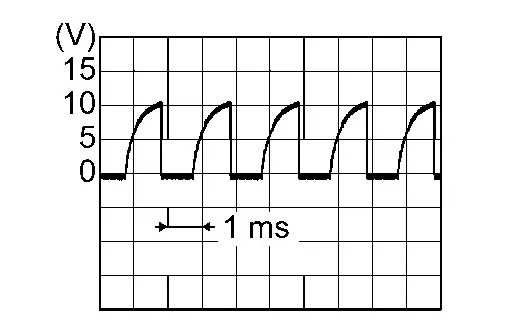

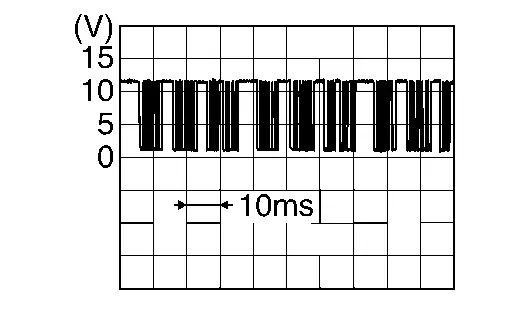

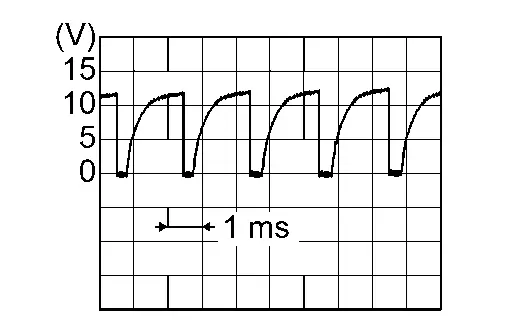

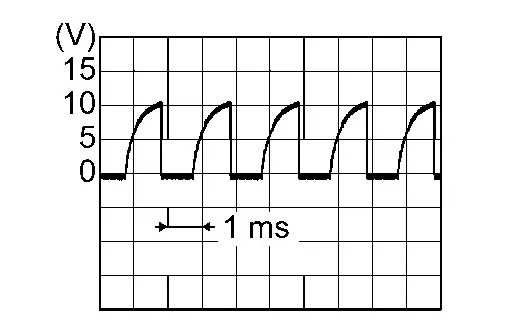

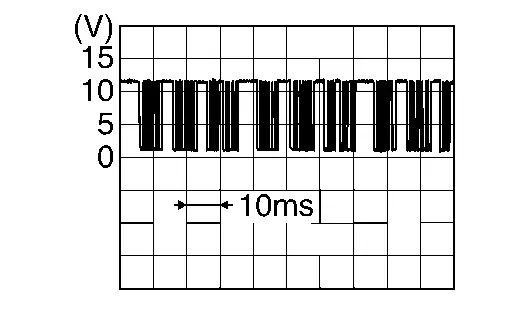

CHECK BLOWER MOTOR CONTROL SIGNAL

-

Power switch ON.

-

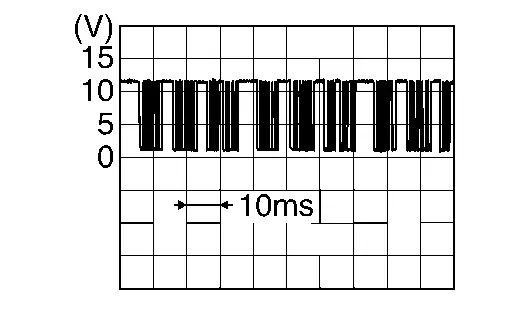

Check duty ratios between A/C auto amp. harness connectors by using an oscilloscope.

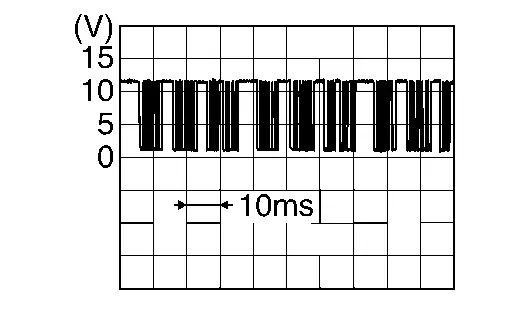

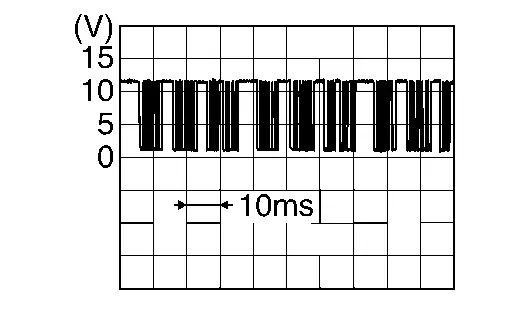

+ - Condition Output waveform A/C auto amp. Connector Terminal Connector Terminal M2 34 M1 58 Blower motor: OFF 10.5 – 16 V Blower motor: 1st speed (manual)

Blower motor: 7th speed (manual)

Is the inspection result normal?

YES>>Replace A/C auto amp. Refer to Removal & Installation.

NO>>GO TO 2.

CHECK BLOWER MOTOR CONTROL SIGNAL CIRCUIT FOR SHORT

-

Power switch OFF.

-

Disconnect blower motor connector and A/C auto amp. connector.

-

Check voltage between blower motor harness connector and ground.

+ - Voltage

(Approx.)Blower motor Connector Terminal M330 1 Ground 0 V

Is the inspection result normal?

YES>>GO TO 3.

NO>>Repair harness or connector.

REPLACE BLOWER MOTOR

-

Connect A/C auto amp. connector.

-

Replace blower motor. Refer to Removal & Installation.

-

Power switch ON.

-

Change fan speed from 1st – 7th, and check that blower motor operates normally.

Is the inspection result normal?

YES>>INSPECTION END

NO>>Replace A/C auto amp. Refer to Removal & Installation.

B24c7-98 Ptc Heater Nissan Ariya SUV

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms | DTC detection condition | |

|---|---|---|---|

| B24C7–98 | PTC heater internal temperature sensor | Diagnosis condition | Nissan Ariya Vehicle is READY |

| Signal (terminal) | — | ||

| Threshold | When the PTC heater circuit board internal temperature is 115°C (239°F) or more | ||

| Diagnosis delay time | 2 seconds or more | ||

POSSIBLE CAUSE

-

PTC heater

-

Blower motor system

-

Air mix door motor system

FAIL-SAFE

PTC heater operation is stopped

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Power switch OFF.

-

Set the Nissan Ariya vehicle to READY.

-

Operate the air conditioning system.

-

Set the temperature to full hot.

-

Select “Self Diagnostic Result” mode of “HVAC” using CONSULT.

Is DTC detected?

YES>>Refer to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

CHECK BLOWER MOTOR SYSTEM

Check the blower motor system. Refer to Diagnosis Procedure.

Is the inspection result normal?

YES>>GO TO 2.

NO>>Repair or replace malfunctioning parts.

CHECK AIR MIX DOOR MOTOR SYSTEM

Check the air mix door motor system. Refer to following DTC diagnosis procedure.

-

Air mix door motor LH: Refer to Diagnosis Procedure.

-

Air mix door motor RH: Refer to Diagnosis Procedure.

Is the inspection result normal?

YES>>Replace PTC heater. Refer to Removal & Installation.

NO>>Repair or replace malfunctioning parts.

B24d2-19 Electric Compressor Nissan Ariya 2026

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms | DTC detection condition | |

|---|---|---|---|

| B24D2-19 | Compressor HVIL circuit | Diagnosis condition | Nissan Ariya Vehicle is READY |

| Signal (terminal) | — | ||

| Threshold | When HVIL open circuit is detected in electric compressor system | ||

| Diagnosis delay time | Less than 1 seconds | ||

POSSIBLE CAUSE

-

High voltage harness connector connecting malfunction

-

High voltage harness connector

-

Electric compressor

FAIL-SAFE

Electric compressor operation is stopped

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Power switch OFF.

-

Set the Nissan Ariya vehicle to READY.

-

Operate the air conditioning system.

-

Set the temperature to full cold.

-

Select “Self Diagnostic Result” mode of “HVAC” using CONSULT.

Is DTC detected?

YES>>Refer to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

WARNING:

Since hybrid vehicles and electric Nissan Ariya vehicles contain a high voltage battery, there is the risk of electric shock, electric leakage, or similar accidents if the high voltage component and Nissan Ariya vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

Since hybrid vehicles and electric Nissan Ariya vehicles contain a high voltage battery, there is the risk of electric shock, electric leakage, or similar accidents if the high voltage component and Nissan Ariya vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

WARNING:

-

Be sure to remove the service plug in order to disconnect the high voltage circuits before performing inspection or maintenance of high voltage system harnesses and parts.

-

The removed service plug must always be carried in a pocket of the responsible worker or placed in the tool box during the procedure to prevent the plug from being connected by mistake.

-

Be sure to wear insulating protective equipment consisting of glove, shoes, face shield and glasses before beginning work on the high voltage system.

-

Never allow workers other than the responsible person to touch the Nissan Ariya vehicle containing high voltage parts. To keep others from touching the high voltage parts, these parts must be covered with an insulating sheet except when using them.

-

Refer to Precautions for High Voltage.

CAUTION:

Never bring the vehicle into the READY status with the service plug removed unless otherwise instructed in the Service Manual. A malfunction may occur if this is not observed.

DIAGNOSIS PROCEDURE

CAUTION:

Erase DTC after the work is completed.

PRECONDITIONING

WARNING:

Follow the instructions below before starting the procedure.

-

Disconnect high voltage circuit. Refer to HOW TO DISCONNECT HIGH VOLTAGE : Precautions.

-

Check voltage in high voltage circuit. Refer to CHECK VOLTAGE IN HIGH VOLTAGE CIRCUIT : Precautions.

>>

GO TO 2.

CHECK THE CONNECTION STATUS OF THE ELECTRIC COMPRESSOR HIGH VOLTAGE HARNESS CONNECTOR

Check that the high voltage harness connector of electric compressor is connected normally.

Is the inspection result normal?

YES>>GO TO 3.

NO>>Reconnect the high voltage harness connector. If reconnecting is impossible due to high voltage harness connector malfunction, replace the high voltage harness between electric compressor and high voltage junction box.

CHECK THE ELECTRIC COMPRESSOR HIGH VOLTAGE HARNESS CONNECTOR

-

Disconnect the electric compressor high voltage harness connector.

-

Check for any adhering foreign substances, cracking, or damage on the high voltage harness connector terminal of electric compressor.

Is the inspection result normal?

YES>>GO TO 4.

NO>>Replace the high voltage harness between electric compressor and high voltage junction box.

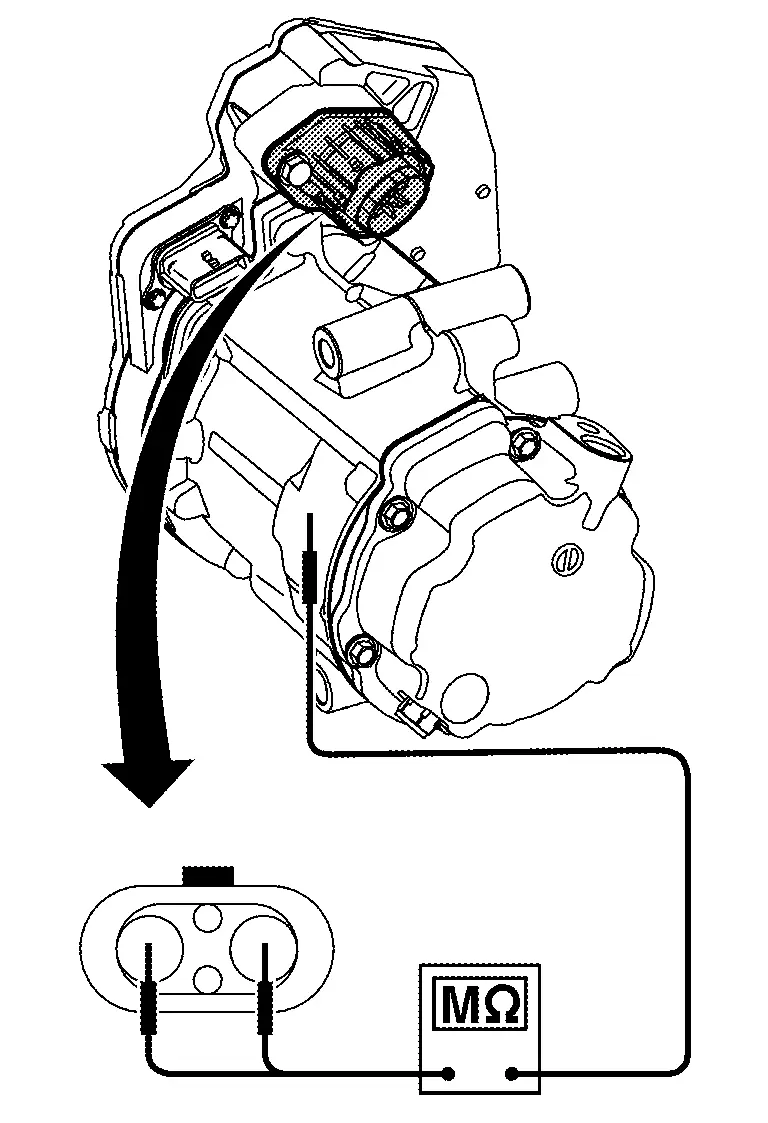

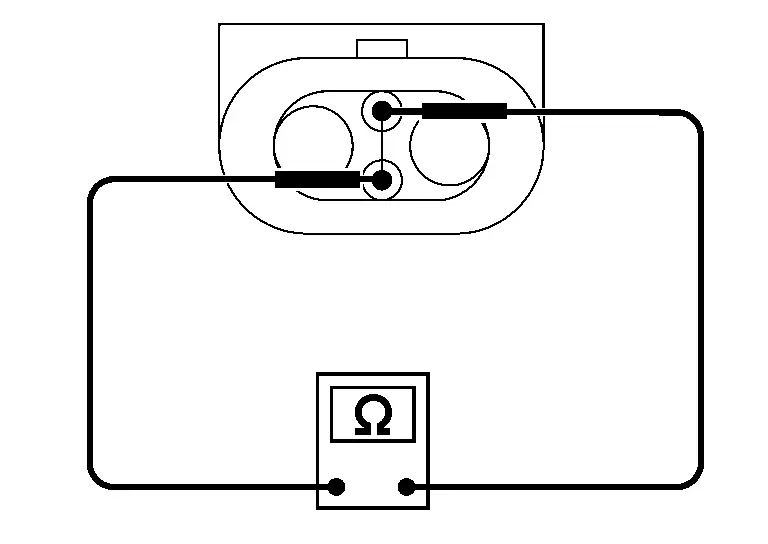

CHECK THE HVIL CIRCUIT OF THE ELECTRIC COMPRESSOR HIGH VOLTAGE HARNESS CONNECTOR

Check for continuity between HVIL circuit terminals of electric compressor Nissan Ariya vehicle side high voltage harness connector. Refer to Component Inspection.

Is the inspection result normal?

YES>>Replace electric compressor. Refer to Removal & Installation.

NO>>Replace the high voltage harness between electric compressor and high voltage junction box.

B24d3-08 Electric Compressor Nissan Ariya

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms | DTC detection condition | |

|---|---|---|---|

| B24D3–08 | Electric compressor communication | Diagnosis condition | Nissan Ariya Vehicle is READY |

| Signal (terminal) | LIN (high voltage component) signal | ||

| Threshold | Detects abnormalities in the signal transmitted from the high voltage component | ||

| Diagnosis delay time | 30 seconds or more | ||

POSSIBLE CAUSE

-

A/C auto amp.

-

Harness or connectors (high voltage component circuit is open or shorted)

FAIL-SAFE

Electric compressor operation is stopped

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Power switch OFF.

-

Set the Nissan Ariya vehicle to READY.

-

Select “Self Diagnostic Result” mode of “HVAC” using CONSULT.

Is DTC detected?

YES>>Refer to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

CHECK ELECTRIC COMPRESSOR LIN SIGNAL CIRCUIT FOR OPEN

-

Power switch OFF.

-

Disconnect electric compressor and A/C auto amp. connector.

-

Check continuity between electric compressor harness connector and A/C auto amp. harness connector.

Electric compressor A/C auto amp. Continuity Connector Terminal Connector Terminal F7 2 M1 52 Existed

Is the inspection result normal?

YES>>GO TO 2.

NO>>Repair harness or connector.

CHECK ELECTRIC COMPRESSOR LIN SIGNAL CIRCUIT FOR SHORT

-

Disconnect following connectors.

-

PTC heater

-

Heat pump control unit

-

Li-ion battery

-

-

Check continuity between electric compressor harness connector and ground.

| Electric compressor | — | Continuity | |

|---|---|---|---|

| Connector | Terminal | ||

| F7 | 2 | Ground | Not existed |

Is the inspection result normal?

YES>>GO TO 3.

NO>>Repair harness or connector.

PERFORM DTC CONFIRMATION PROCEDURE

-

Reconnected all disconnected harness connectors.

-

Perform DTC confirmation procedure. Refer to DTC Description.

Is DTC detected?

YES>>Replace A/C auto amp. Refer to Removal & Installation.

NO>>INSPECTION END

B24d4-08 A/c Control Nissan Ariya: FE0

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms | DTC detection condition | |

|---|---|---|---|

| B24D4-08 | LIN communication 2 | Diagnosis condition | Power switch ON |

| Signal (Terminal) | LIN (A/C control) signal | ||

| Threshold | Receive internal circuit error message via A/C control to LIN communication | ||

| Diagnosis delay time | 30 seconds or more | ||

POSSIBLE CAUSE

-

Fuse

-

Harness and connector (A/C control circuit is open or shorted)

-

A/C control

-

A/C auto amp.

FAIL-SAFE

If a LIN communication error exists between the A/C auto amp. and A/C control for 30 seconds or longer, air conditioning is controlled under the following conditions:

| Set temperature | : Setting before communication error occurs |

| Air outlet | : AUTO |

| Blower fan speed | : AUTO |

| Air inlet | : FRE (Fresh air intake) |

| Electric compressor | : ON |

DTC CONFIRMATION PROCEDURE

PERFORM SELF-DIAGNOSIS

With CONSULT

With CONSULT

-

Power switch ON.

-

Select “Self Diagnostic Result” mode of “HVAC” using CONSULT.

Is DTC detected?

YES>>Refer to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

CHECK FUSE

-

Power switch OFF.

-

Check that the following fuse is not blown (open).

Unit Location Fuse No. Capacity A/C control Fuse and fusible link block #81 10A  NOTE:

NOTE:

For details of fuse, connector and terminal arrangement. Refer to Wiring Diagram.

Is the fuse blown (open)?

YES>>Replace the blown (open) fuse after repairing the affected circuit if a fuse is blown (open).

NO>>GO TO 2.

CHECK A/C CONTROL POWER SUPPLY

-

Disconnect A/C control connector.

-

Power switch ON.

-

Check voltage between A/C control harness connector and ground.

+ - Voltage A/C control Connector Terminal M69 1 Ground Battery voltage

Is the inspection result normal?

YES>>GO TO 3.

NO>>Repair the A/C control power supply circuit.

CHECK A/C CONTROL GROUND CIRCUIT FOR OPEN

-

Power switch OFF.

-

Check continuity between A/C control harness connector and ground.

A/C control — Continuity Connector Terminal M69 6 Ground Existed

Is the inspection result normal?

YES>>GO TO 4.

NO>>Repair harness or connector.

CHECK A/C CONTROL LIN SIGNAL

-

Connect A/C control connector.

-

Power switch ON.

-

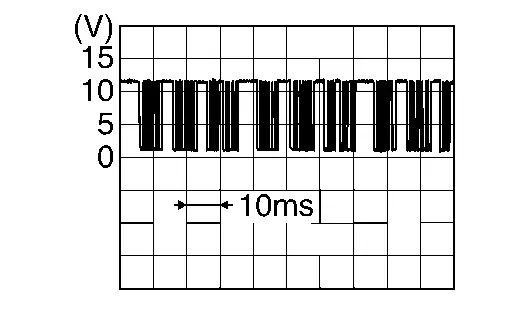

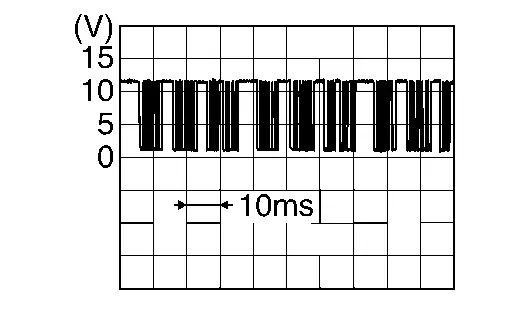

Confirm output waveform between A/C control harness connector and A/C auto amp. harness connector with oscilloscope.

+ - Output waveform A/C control A/C auto amp. Connector Terminal Connector Terminal M69 7 M1 58

Is the inspection result normal?

YES>>Replace A/C control. Refer to Removal & Installation.

NO>>GO TO 5.

CHECK LIN COMMUNICATION SIGNAL CIRCUIT FOR OPEN

-

Power switch OFF.

-

Disconnect A/C control connector and A/C auto amp. connector.

-

Check continuity between A/C control harness connector and A/C auto amp. harness connector.

A/C control A/C auto amp. Continuity Connector Terminal Connector Terminal M69 7 M1 68 Existed

Is the inspection result normal?

YES>>GO TO 6.

NO>>Repair harness or connector.

CHECK LIN COMMUNICATION SIGNAL CIRCUIT FOR SHORT

-

Check continuity between A/C control harness connector and ground.

A/C control — Continuity Connector Terminal M69 7 Ground Not existed -

Check voltage between A/C control harness connector and ground.

+ - Voltage

(Approx.)A/C control Connector Terminal M69 7 Ground 0 V

Is the inspection result normal?

YES>>Replace A/C auto amp. Refer to Removal & Installation.

NO>>Repair harness or connector.

B24d8-4b Electric Compressor Nissan Ariya first Gen

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms | DTC detection condition | |

|---|---|---|---|

| B24D8–4B | Compressor internal temperature sensor | Diagnosis condition | Nissan Ariya Vehicle is READY |

| Signal (terminal) | — | ||

| Threshold | The electric compressor ipm temperature is too high | ||

| Diagnosis delay time | Less than 1 seconds | ||

POSSIBLE CAUSE

-

Refrigerant leakage

-

Refrigerant insufficient

-

Refrigerant cycle unusual

FAIL-SAFE

Electric compressor operation is stopped or speed is limited

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Power switch OFF.

-

Set the Nissan Ariya vehicle to READY.

-

Operate the air conditioning system.

-

Set the temperature to full cold.

-

Select “Self Diagnostic Result” mode of “HVAC” using CONSULT.

Is DTC detected?

YES>>Refer to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

CHECK REFRIGERANT FOR LEAKAGES

Check refrigerant for leakages. Refer to Leak Test.

Is the inspection result normal?

YES>>GO TO 2.

NO>>Repair or replace malfunctioning parts.

CHECK REFRIGERANT CYCLE

Check refrigerant cycle. Refer to Inspection.

Is the inspection result normal?

YES>>GO TO 3.

NO>>Repair or replace malfunctioning parts.

RE-FILLING REFRIGERANT

Collect refrigerant, and charge the air conditioning system from a new service can with the specified amount refrigerant. Refer to Charge Refrigerant.

>>

INSPECTION END

B24dd-19 Battery Coolant Heater Nissan Ariya: FE0

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms | DTC detection condition | |

|---|---|---|---|

| B24DD-19 | Battery coolant heater HVIL circuit | Diagnosis condition | Nissan Ariya Vehicle is READY |

| Signal (terminal) | — | ||

| Threshold | When HVIL open circuit is detected in battery coolant heater system | ||

| Diagnosis delay time | Less than 1 seconds | ||

POSSIBLE CAUSE

-

High voltage harness connector connecting malfunction

-

High voltage harness connector

-

Battery coolant heater

FAIL-SAFE

Battery coolant heater operation is stopped

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Set the Nissan Ariya vehicle to READY.

-

Select “Self Diagnostic Result” mode of “HVAC” using CONSULT.

Is DTC detected?

YES>>Refer to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

DIAGNOSIS PROCEDURE

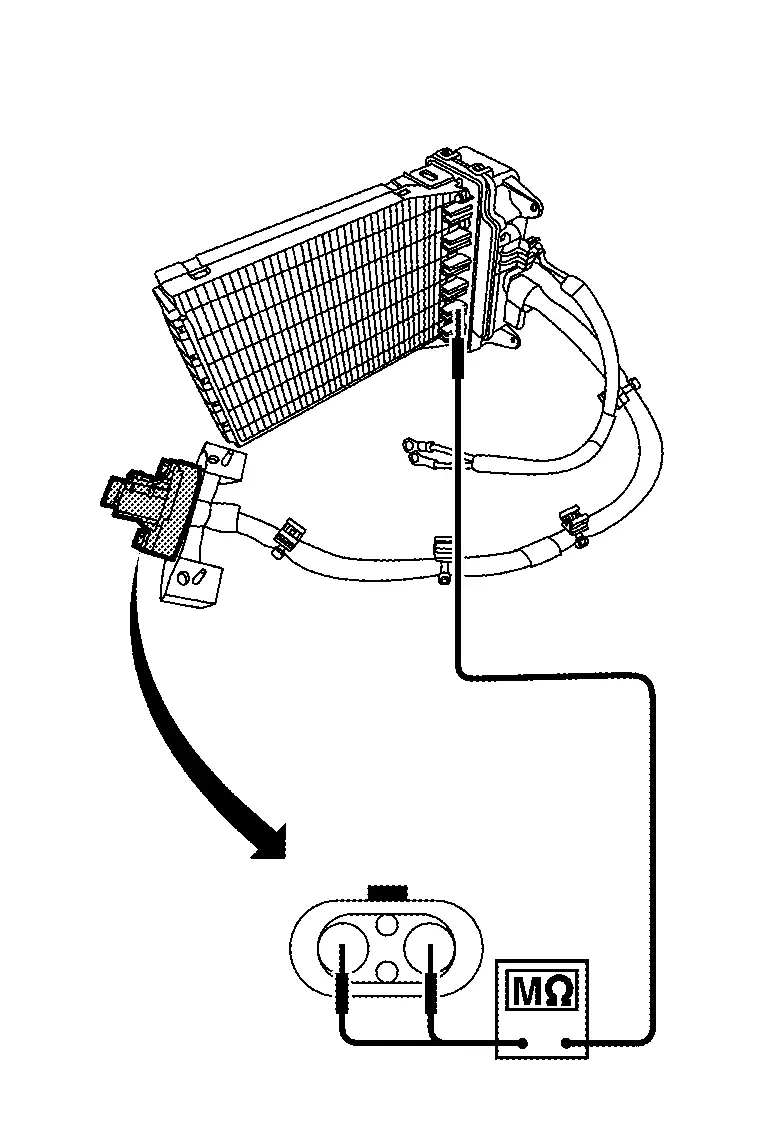

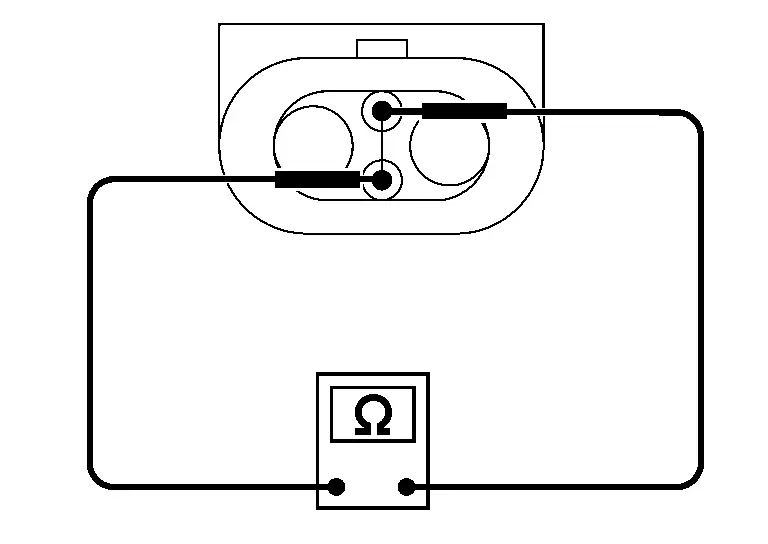

CHECK THE HVIL CIRCUIT OF THE BATTERY COOLANT HEATER HIGH VOLTAGE HARNESS CONNECTOR

Check for continuity between HVIL circuit terminals of battery coolant heater Nissan Ariya vehicle side high voltage harness connector. Refer to Diagnosis Procedure.

>>

INSPECTION END

B24ea-97 Electric Compressor Nissan Ariya

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms | DTC detection condition | |

|---|---|---|---|

| B24EA–97 | Compressor shutdown | Diagnosis condition | Nissan Ariya Vehicle is READY |

| Signal (terminal) | — | ||

| Threshold |

When the following DTC is detected

|

||

| Diagnosis delay time | Less than 1 seconds | ||

POSSIBLE CAUSE

Detecting the following DTC, the stopped due to electric compressor protection is detected.

-

B24D8–4B: Refer to DTC Description.

-

B24F9–1C: Refer to DTC Description.

FAIL-SAFE

Electric compressor operation is stopped or speed is limited

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Power switch OFF.

-

Set the Nissan Ariya vehicle to READY.

-

Operate the air conditioning system.

-

Set the temperature to full cold.

-

Select “Self Diagnostic Result” mode of “HVAC” using CONSULT.

Is DTC detected?

YES>>Refer to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

NOTE:

NOTE:

DTC B24EA–97 is displayed together with (any of) DTC B24D8–4B or B24F9–1C, perform the diagnosis procedure of each DTC.

CHECK DTC

Perform the following DTC diagnosis procedure.

-

B24D8–4B: Refer to DTC Description.

-

B24F9–1C: Refer to DTC Description.

>>

INSPECTION END

B24ed-1c Electric Compressor Nissan Ariya SUV

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms | DTC detection condition | |

|---|---|---|---|

| B24ED–1C | Compressor current consumption error | Diagnosis condition | Nissan Ariya Vehicle is READY |

| Signal (terminal) | — | ||

| Threshold |

When A/C auto amp. receives a voltage shortage signal from the electric compressor (Electric compressor required rotation speed is 1 or more) |

||

| Diagnosis delay time | Less than 1 second | ||

POSSIBLE CAUSE

-

Electric compressor

-

Li-ion battery

-

Front traction motor inverter

-

High voltage junction box

-

High voltage harness or connectors (electric compressor high voltage circuit is open or shorted)

FAIL-SAFE

Electric compressor stopped operation.

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Power switch OFF.

-

Set the Nissan Ariya vehicle to READY.

-

Operate the air conditioning system.

-

Set the temperature to full cold.

-

Select “Self Diagnostic Result” mode of “HVAC” using CONSULT.

Is DTC detected?

YES>>Refer to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

Diagnosis Procedure

WARNING:

Since hybrid vehicles and electric Nissan Ariya vehicles contain a high voltage battery, there is the risk of electric shock, electric leakage, or similar accidents if the high voltage component and Nissan Ariya vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

Since hybrid vehicles and electric Nissan Ariya vehicles contain a high voltage battery, there is the risk of electric shock, electric leakage, or similar accidents if the high voltage component and Nissan Ariya vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

WARNING:

-

Be sure to remove the service plug in order to disconnect the high voltage circuits before performing inspection or maintenance of high voltage system harnesses and parts.

-

The removed service plug must always be carried in a pocket of the responsible worker or placed in the tool box during the procedure to prevent the plug from being connected by mistake.

-

Be sure to wear insulating protective equipment consisting of glove, shoes, face shield and glasses before beginning work on the high voltage system.

-

Never allow workers other than the responsible person to touch the Nissan Ariya vehicle containing high voltage parts. To keep others from touching the high voltage parts, these parts must be covered with an insulating sheet except when using them.

-

Refer to Precautions for High Voltage.

CAUTION:

Never bring the vehicle into the READY status with the service plug removed unless otherwise instructed in the Service Manual. A malfunction may occur if this is not observed.

DIAGNOSIS PROCEDURE

CAUTION:

Erase DTC after the work is completed.

CHECK LI-ION BATTERY

Check Li-ion battery. Refer to Work Flow.

Is the inspection result normal?

YES>>GO TO 2.

NO>>Repair or replace malfunctioning parts.

CHECK INVERTER (FRONT)

Check inverter (front). Refer to Work Flow.

Is the inspection result normal?

YES>>GO TO 3.

NO>>Repair or replace malfunctioning parts.

PRECONDITIONING

WARNING:

Follow the instructions below before starting the procedure.

-

Disconnect high voltage circuit. Refer to HOW TO DISCONNECT HIGH VOLTAGE : Precautions.

-

Check voltage in high voltage circuit. Refer to CHECK VOLTAGE IN HIGH VOLTAGE CIRCUIT : Precautions.

>>

GO TO 4.

CHECK ELECTRIC COMPRESSOR HIGH VOLTAGE HARNESS POWER SUPPLY CIRCUIT FOR OPEN

-

Disconnect electric compressor and high voltage junction box connector.

-

Check continuity between electric compressor high voltage harness connector and high voltage junction box high voltage harness connector.

Electric compressor High voltage junction box Continuity Connector Terminal Connector Terminal H9 8 H11 19 Existed

Is the inspection result normal?

YES>>GO TO 5.

NO>>Replace high voltage harness between electric compressor and high voltage junction box.

CHECK ELECTRIC COMPRESSOR HIGH VOLTAGE HARNESS GROUND CIRCUIT

Check continuity between electric compressor high voltage harness connector and high voltage junction box high voltage harness connector.

| Electric compressor | High voltage junction box | Continuity | ||

|---|---|---|---|---|

| Connector | Terminal | Connector | Terminal | |

| H9 | 7 | H11 | 18 | Existed |

Is the inspection result normal?

YES>>GO TO 6.

NO>>Replace high voltage harness between electric compressor and high voltage junction box.

CHECK HIGH VOLTAGE CIRCUIT

Check high voltage junction box high voltage harness and Li-ion battery high voltage harness. Refer to Wiring Diagram.

Is the inspection result normal?

YES>>Replace electric compressor. Refer to Removal & Installation.

NO>>Replace high voltage harness between high voltage junction box and Li-ion battery.

B24ed-97 Electric Compressor Nissan Ariya 1st generation

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms | DTC detection condition | |

|---|---|---|---|

| B24ED–97 | Compressor current consumption error | Diagnosis condition | Nissan Ariya Vehicle is READY |

| Signal (terminal) | — | ||

| Threshold |

The input current to the electric compressor too high (13.5 A or more) |

||

| Diagnosis delay time | Less than 1 seconds | ||

POSSIBLE CAUSE

-

Electric compressor

-

Cooling fan

-

Overfilled refrigerant

-

Refrigerant cycle unusual

FAIL-SAFE

Electric compressor speed is limited

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

-

Power switch OFF.

-

Set the Nissan Ariya vehicle to READY.

-

Operate the air conditioning system.

-

Set the temperature to full cold.

-

Select “Self Diagnostic Result” mode of “HVAC” using CONSULT.

Is DTC detected?

YES>>Refer to Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.