Nissan Ariya: Symptom Diagnosis

Refrigeration System Symptoms Nissan Ariya 2026

Trouble Diagnosis For Unusual Pressure

Diagnose using a manifold gauge whenever system’s high and/or low side pressure(s) is/are unusual. The marker above the gauge scale in the following tables indicates the standard (usual) pressure range. Refer to above table (Ambient air temperature-to-operating pressure table) since the standard (usual) pressure, however, differs from Nissan Ariya vehicle to vehicle.

Symptom Table

| Gauge indication | Refrigerant cycle | Probable cause | Corrective action |

|---|---|---|---|

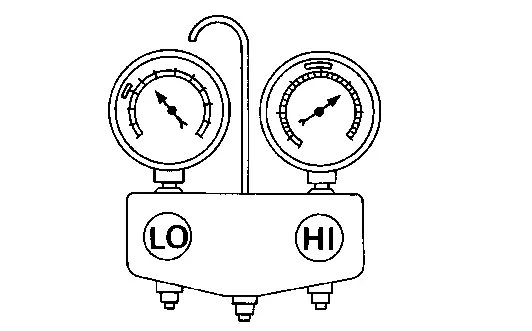

|

Both high- and low-pressure sides are too high.

|

The pressure returns to normal soon after sprinkling water on condenser. | Overfilled refrigerant. | Collect all refrigerant, evacuate refrigerant cycle again, and then refill it with the specified amount of refrigerant. |

| Air flow to condenser is insufficient. |

Insufficient condenser cooling performance.

|

|

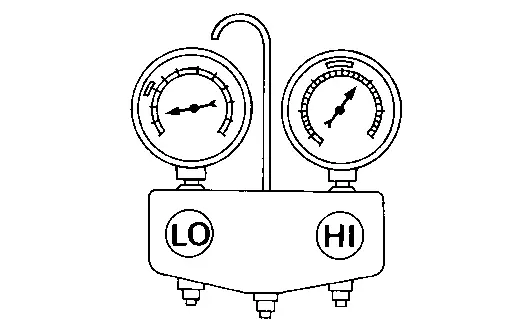

|

| When compressor is stopped, a high-pressure reading quickly drops by approximately 196 kPa (2 bar, 2 kg/cm2, 28.4 psi). It then gradually decreases. | Air mixed in refrigerant cycle. | Collect all refrigerant, evacuate refrigerant cycle again, and then refill it with the specified amount of refrigerant. | |

| Low-pressure pipe become hot. | Electric expansion valve opening / control error. |

Check DTC with consult

|

|

|

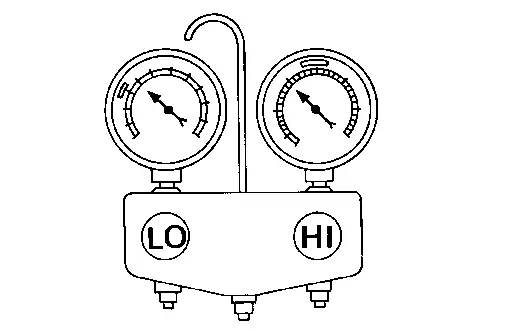

High-pressure side is excessively high and low-pressure side is too low.

|

High-pressure pipe and upper side of condenser become hot, however, liquid tank does not become so hot. | Clogged or crushed high-pressure pipe located between compressor and condenser. | Repair or replace the malfunctioning parts. |

|

High-pressure side is too low and low-pressure side is too high.

|

|

Malfunction in compressor system (insufficient compressor pressure operation).

|

Replace compressor. |

|

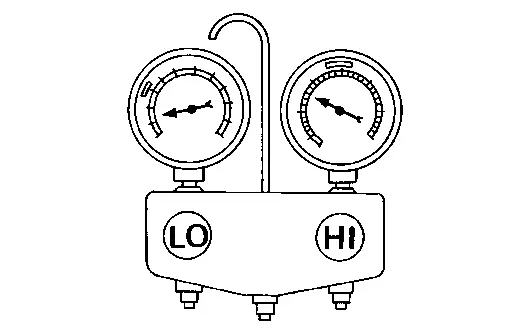

Both high- and low-pressure sides are too low.

|

|

Electric expansion valve opening / control error. |

Check DTC with consult

|

| Evaporator becomes frosted. | Clogged or crushed low-pressure pipe. | Repair or replace malfunctioning parts. | |

| Malfunction in intake sensor. | Check intake sensor system. Refer to Diagnosis Procedure. | ||

| There is a small temperature difference between the high and low pressure pipes for refrigerant cycle. |

|

|

Noise Nissan Ariya 2023

Symptom Table

| Symptom | Noise source | Probable cause | Corrective action |

|---|---|---|---|

| Unusual noise from compressor when A/C is ON. | Inside of compressor | Wear, breakage, or clogging of foreign material in inner parts. | Check compressor oil. Refer to Inspection. |

| Compressor body | Loosened compressor mounting bolts. | Check bolts for tightness. Refer to Exploded View. | |

| Unusual noise from cooler piping. | Cooler piping (pipe and flexible hose) | Improper installation of clip and bracket. | Check the installation condition of the cooler piping. Refer to Exploded View. |

Nissan Ariya (FE0) 2023-2026 Service & Repair Manual

Symptom Diagnosis

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image