Nissan Ariya: Dtc/circuit Diagnosis

- P161d-61 Immobilizer. Motor Control

- P161e-68 Immobilizer. Motor Control

- P161f-64 Immobilizer. Motor Control

- B2033-4a Dongle Ng

- B2042-4a Electric Shift Authentication Fail

- B2043-4a Electric Shift Id Discord

- B2070-68 Key Registration

- B2090-14 Nats Antenna Amp.

- B2f70-01 Stop Lamp

- B2f71-23 Stop Lamp

- Stop Lamp Switch

- Hood Switch

- Horn Function

P161d-61 Immobilizer. Motor Control Nissan Ariya SUV

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC detecting condition | |

|---|---|---|---|

| P161D-61 | IMMOBILIZER | Diagnosis condition | Power switch ON |

| Signal (terminal) | — | ||

| Threshold | When key registration has not been completed normally after replacing Intelligent Key unit. | ||

| Diagnosis delay time | 1 second or less | ||

POSSIBLE CAUSE

-

Improper key registration operation

-

Power steering control module

-

Intelligent Key unit

FAIL-SAFE

Inhibit setting the vehicle to READY

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

-

Power switch ON.

-

Select “Self Diagnostic Result” mode of “MOTOR CONTROL” using CONSULT.

Is the DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

CHECK DTC PRIORITY

If DTC P161D-61 is displayed with DTC B2033-4A, first perform the trouble diagnosis for DTC B2033- 4A.

Is DTC B2033–4A detected?

YES>>Perform diagnosis of applicable. DTC B2033–4A: Refer to DTC Description.

NO>>GO TO 2.

INTELLIGENT KEY REGISTRATION

-

Perform registration of all Intelligent Keys using CONSULT.

For registration procedures, refer to CONSULT immobilizer mode and follow the on-screen instructions.

-

Erase DTC.

-

Perform DTC confirmation procedure for DTC P161D-61.Refer to DTC Description.

Is DTC P161D-61 detected?

YES>>GO TO 3.

NO>>INSPECTION END

REPLACE INTELLIGENT KEY UNIT

-

Replace Intelligent Key unit. Refer to Removal and Installation.

-

Erase DTC.

-

Perform DTC confirmation procedure for DTC P161D-61. Refer to DTC Description.

-

Check that the DTC is not detected.

>>

INSPECTION END

P161e-68 Immobilizer. Motor Control Nissan Ariya

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC detecting condition | |

|---|---|---|---|

| P161E-68 | IMMOBILIZER | Diagnosis condition | Power switch ON |

| Signal (terminal) | — | ||

| Threshold |

|

||

| Diagnosis delay time | 1 second or less | ||

POSSIBLE CAUSE

-

When registration with Intelligent Key unit is not completed normally after replacement inverter (front).

-

Intelligent Key unit

-

Inverter (front)

CAUTION:

When inverter (front) and Intelligent Key unit are replacement at the same time, may detect DTC P161E-68.

When replacement any parts, replace one by one.

FAIL-SAFE

Inhibit setting the vehicle to READY

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

-

Power switch ON.

-

Select “Self Diagnostic Result” mode of “MOTOR CONTROL” using CONSULT.

Is the DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

PRECONDITIONING

Does bring the intelligent key inside the Nissan Ariya vehicle and turn on the power switch, when replaced the inverter (front)?

YES>>GO TO 3.

NO>>GO TO 2.

INVERTER REGISTRATION

Bring the intelligent key inside the Nissan Ariya vehicle and turn on the power switch.

Is the DTC detected?

YES>>GO TO 3.

NO>>INSPECTION END

REPLACE INTELLIGENT KEY UNIT

Replace Intelligent Key unit. Refer to Removal and Installation.

Is the DTC detected?

YES>>GO TO 4.

NO>>INSPECTION END

REPLACE INVERTER (FRONT)

Replace inverter (front). Refer to INVERTER (FRONT) : Removal & Installation.

>>

INSPECTION END

P161f-64 Immobilizer. Motor Control Nissan Ariya: FE0

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC detecting condition | |

|---|---|---|---|

| P161F-64 | IMMOBILIZER | Diagnosis condition | Power switch ON |

| Signal (terminal) | — | ||

| Threshold | When inverter (front) detects an immobilizer malfunction and READY set is prohibited. | ||

| Diagnosis delay time | 1 second or less | ||

POSSIBLE CAUSE

Inverter (front)

FAIL-SAFE

Inhibit setting the vehicle to READY

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

-

Power switch ON.

-

Select “Self Diagnostic Result” mode of “MOTOR CONTROL” using CONSULT.

Is the DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

REPLACE INVERTER (FRONT)

Replace inverter (front).Refer to INVERTER (FRONT) : Removal & Installation.

>>

INSPECTION END

B2033-4a Dongle Ng Nissan Ariya

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC detection condition | |

|---|---|---|---|

| B2033–4A | Dongle not good | Diagnosis condition | Power switch ON |

| Signal (terminal) | CAN communication signal | ||

| Threshold | The ID verification results NG | ||

| Diagnosis delay time | 1 second or more | ||

POSSIBLE CAUSE

-

Harness or connector

(CAN communication line is open or shorted)

-

Intelligent Key unit

-

Power steering control module

FAIL-SAFE

—

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

-

Power switch ON.

-

Select “Self Diagnostic Result” mode of “INTELLIGENT KEY” using CONSULT.

Is the DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

PERFORM INITIALIZATION

-

Perform initialization of Intelligent Key unit and registration of all Intelligent Keys using CONSULT.

For initialization and registration procedures, refer to CONSULT immobilizer mode and follow the on-screen instructions.

-

Check that the Nissan Ariya vehicle can be set to READY using registered Intelligent Key.

Is the inspection result normal?

YES>>INSPECTION END

NO>>GO TO 2.

REPLACE INTELLIGENT KEY UNIT

Replace Intelligent Key unit. Refer to Removal and Installation.

Is the DTC detected?

YES>>GO TO 3.

NO>>INSPECTION END

REPLACE POWER STEERING CONTROL MODULE

Replace power steering control module. Refer to EPS CONTROL UNIT : Removal & Installation.

>>

INSPECTION END

B2042-4a Electric Shift Authentication Fail Nissan Ariya SUV

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC detecting condition | |

|---|---|---|---|

| B2042–4A | Electric shift authentication fail | Diagnosis condition | When power switch is turned from OFF to ON |

| Signal (terminal) | CAN communication signal | ||

| Threshold | When Intelligent Key unit cannot detect CAN communication with electric shift control module | ||

| Diagnosis delay time | 1 second or less | ||

POSSIBLE CAUSE

-

Harness or connectors

(CAN communication line is open or shorted)

-

Electric shift control module

FAIL-SAFE

Prohibit shifting the shift selector from P position

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

-

Power switch ON.

-

Check DTC in “Self Diagnostic Result” mode of “INTELLIGENT KEY” using CONSULT.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

CHECK DTC PRIORITY OF INTELLIGENT KEY UNIT

-

Select “Self Diagnostic Result” mode of “INTELLIGENT KEY” using CONSULT.

-

If DTC B2042–4A is displayed with two or more DTCs are detected, refer to DTC inspection priority chart, and determine trouble diagnosis.

Is applicable DTC detected?

YES>>Perform the trouble diagnosis related to the detected DTC. Refer to DTC Index.

NO>>GO TO 2.

CHECK DTC PRIORITY OF ELECTRIC SHIFT CONTROL MODULE

Select “Self Diagnostic Result” mode of “SHIFT” using CONSULT.

Is the DTC detected?

YES>>Perform the trouble diagnosis related to the detected DTC. Refer to DTC Index.

NO>>Replace electric shift control module. Refer to ELECTRIC SHIFT CONTROL MODULE : Removal & Installation.

B2043-4a Electric Shift Id Discord Nissan Ariya 1st generation

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC detecting condition | |

|---|---|---|---|

| B2043–4A | Electric shift ID discord | Diagnosis condition | When registering electric shift control module |

| Signal (terminal) | CAN communication signal | ||

| Threshold | Electric shift control module registration has not been completed normally | ||

| Diagnosis delay time | 1 second or less | ||

POSSIBLE CAUSE

Improper electric shift control module registration operation

FAIL-SAFE

Prohibit shifting the shift selector from P position

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

-

Power switch ON.

-

Check DTC in “Self Diagnostic Result” mode of “INTELLIGENT KEY” using CONSULT.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

REPLACE ELECTRIC SHIFT CONTROL MODULE

Replace electric shift control module. Refer to ELECTRIC SHIFT CONTROL MODULE : Removal & Installation.

>>

INSPECTION END

B2070-68 Key Registration Nissan Ariya 2023

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC detecting condition | |

|---|---|---|---|

| B2070–68 | Key registration | Diagnosis condition | — |

| Signal (terminal) | — | ||

| Threshold | Intelligent Key that does not match the Nissan Ariya vehicle is registered. | ||

| Diagnosis delay time | 1 second or less | ||

POSSIBLE CAUSE

-

Improper registration operation

-

Intelligent Key

-

Intelligent Key unit

FAIL-SAFE

—

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

-

Perform initialization of Intelligent Key unit and registration of all Intelligent Keys using CONSULT.

-

Select “Self Diagnostic Result” mode of “INTELLIGENT KEY” using CONSULT.

Is the DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

REPLACE INTELLIGENT KEY

-

Replace Intelligent Key that matches the Nissan Ariya vehicle.

-

Perform initialization of Intelligent Key unit and registration of Intelligent Key using CONSULT.

For initialization and registration procedures, refer to CONSULT immobilizer mode and follow the on-screen instructions.

-

Erase DTC.

-

Perform DTC confirmation procedure for B2070–68. Refer to DTC Description.

Is the DTC detected?

YES>>GO TO 2.

NO>>INSPECTION END

REPLACE INTELLIGENT KEY UNIT

Replace Intelligent Key unit.Refer to Removal and Installation.

>>

INSPECTION END

B2090-14 Nats Antenna Amp. Nissan Ariya first Gen

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC detecting condition | |

|---|---|---|---|

| B2090–14 | NATS antenna amplifier | Diagnosis condition | Power switch ON |

| Signal (terminal) | NATS antenna amp. signal | ||

| Threshold | Inactive communication between NATS antenna amp. and Intelligent Key unit | ||

| Diagnosis delay time | 1 second or less | ||

POSSIBLE CAUSE

-

Harness or connectors

(NATS antenna amp. circuit is open or shorted.)

-

Power switch (NATS antenna amp.)

-

Intelligent Key unit

FAIL-SAFE

—

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

-

Power switch ON.

-

Select “Self Diagnostic Result” mode of “INTELLIGENT KEY” using CONSULT.

Is the DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

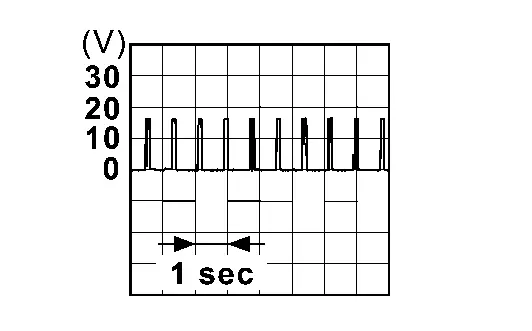

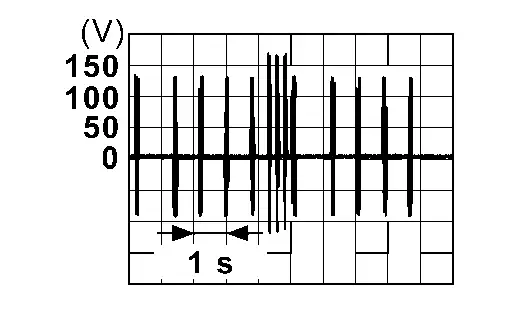

CHECK NATS ANTENNA AMP. COMMUNICATION SIGNAL

Check signal between power switch harness connector and ground using an oscilloscope.

| (+) | (–) | Condition |

Signal (Reference value) | ||

|---|---|---|---|---|---|

| Power switch | |||||

| Connector | Terminal | ||||

| M143 | 2 | Ground | Intelligent Key battery is removed | When a registered Intelligent Key backside is contacted to power switch | 0 V |

| Other than above |

|

||||

| 3 | When a registered Intelligent Key backside is contacted to power switch | 0 V | |||

| Other than above |

|

||||

Is the inspection result normal?

YES>>Replace power switch. Refer to Removal and Installation.

NO>>GO TO 2.

CHECK NATS ANTENNA AMP. COMMUNICATION SIGNAL CIRCUIT

-

Power switch OFF.

-

Disconnect Intelligent Key unit connector and power switch connector.

-

Check continuity between power switch harness connector and Intelligent Key unit harness connector.

Power switch Intelligent Key unit Continuity Connector Terminal Connector Terminal M143 2 M79 19 Existed 3 20 -

Check continuity between power switch harness connector and ground.

Power switch — Continuity Connector Terminal M143 2 Ground Not existed 3

Is the inspection result normal?

YES>>GO TO 3.

NO>>Repair or replace harness.

REPLACE INTELLIGENT KEY UNIT

Replace Intelligent Key unit. Refer to Removal and Installation.

>>

INSPECTION END

B2f70-01 Stop Lamp Nissan Ariya 2026

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC detecting condition | |

|---|---|---|---|

| B2F70-01 | Stop lamp | Diagnosis condition | When brake pedal is depressed |

| Signal (terminal) |

|

||

| Threshold | BCM makes a comparison between stop lamp switch 1 signal and stop lamp switch 2 signal. It judges from their values to detect the malfunctioning circuit 10 consecutive times | ||

| Diagnosis delay time | Depress brake pedal 10 times | ||

POSSIBLE CAUSE

-

Harness or connectors

(Stop lamp switch circuit is open or shorted)

-

Stop lamp switch

-

Fuse

FAIL-SAFE

—

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

-

Depress brake pedal 10 times.

-

Power switch ON.

-

Check DTC in “Self Diagnostic Result” mode of “BCM” using CONSULT.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

CHECK STOP LAMP SWITCH

-

Select “Brake switch 1” and “Brake switch 2” in “Data Monitor” mode of “SIGNAL BUFFER” of “BCM” using CONSULT.

-

Check “Brake switch 1” and “Brake switch 2” indication under the following condition.

Monitor item Condition Indication Brake switch 1 Brake pedal Depressed OFF Not depressed ON Brake switch 2 Depressed ON Not depressed OFF

Is the indication normal?

YES>>INSPECTION END

NO-1>>Brake switch 1: GO TO 2.

NO-2>>Brake switch 2: GO TO 7.

CHECK FUSE

-

Power switch OFF.

-

Check that the following fuse is not blown (open).

Signal name Fuse No. Ignition power supply 39 (5 A)

Is the fuse blown (open)?

YES>>Replace the blown (open) fuse after replacing the cause of blown (open).

NO >>GO TO 3.

CHECK STOP LAMP SWITCH SIGNAL-1

-

Disconnect BCM connector.

-

Power switch ON.

-

Check voltage between BCM harness connector and ground.

(+) (–) Condition Voltage BCM Connector Terminal M9 111 Ground Stop lamp switch ON (brake pedal is not depressed) 9 – 16 V Stop lamp switch OFF (brake pedal is depressed) 0 V

Is the inspection normal?

YES>>INSPECTION END

NO>>GO TO 4.

CHECK STOP LAMP SWITCH POWER SUPPLY CIRCUIT-1

-

Power switch OFF.

-

Disconnect stop lamp switch connector.

-

Power switch ON.

-

Check voltage between stop lamp switch harness connector and ground.

(+) (–) Voltage Stop lamp switch Connector Terminal E115 4 Ground Battery voltage

Is the inspection result normal?

YES>>GO TO 5.

NO>>Check harness for open or short between stop lamp switch and fuse.

CHECK STOP LAMP SWITCH SIGNAL CIRCUIT-1

-

Power switch OFF.

-

Check continuity between stop lamp switch harness connector and BCM harness connector.

Stop lamp switch BCM Continuity Connector Terminal Connector Terminal E115 3 M9 111 Existed -

Check continuity between stop lamp switch harness connector and ground.

Stop lamp switch — Continuity Connector Terminal E115 3 Ground Not existed

Is the inspection result normal?

YES>>GO TO 6.

NO>>Repair or replace harness.

CHECK STOP LAMP SWITCH

Refer to Component Inspection.

Is the inspection result normal?

YES>>INSPECTION END

NO>>Replace stop lamp switch. Refer to BRAKE PEDAL : Exploded View.

CHECK FUSE

-

Power switch OFF.

-

Check that the following fuse is not blown (open).

Signal name Fuse No. Battery power supply 13 (10 A)

Is the fuse blown (open)?

YES>>Replace the blown (open) fuse after replacing the cause of blown (open).

NO >>GO TO 8.

CHECK STOP LAMP SWITCH SIGNAL-2

-

Disconnect BCM connector.

-

Check voltage between BCM harness connector and ground.

(+) (–) Condition Voltage BCM Connector Terminal M9 110 Ground Stop lamp switch ON (brake pedal is depressed) 9 – 16 V Stop lamp switch OFF (brake pedal is not depressed) 0 V

Is the inspection normal?

YES>>INSPECTION END

NO>>GO TO 9.

CHECK STOP LAMP SWITCH POWER SUPPLY CIRCUIT-2

-

Disconnect stop lamp switch connector.

-

Check voltage between stop lamp switch harness connector and ground.

(+) (–) Voltage Stop lamp switch Connector Terminal E115 1 Ground Battery voltage

Is the inspection result normal?

YES>>GO TO 10.

NO>>Check harness for open or short between stop lamp switch and fuse.

CHECK STOP LAMP SWITCH SIGNAL CIRCUIT-2

-

Check continuity between stop lamp switch harness connector and BCM harness connector.

Stop lamp switch BCM Continuity Connector Terminal Connector Terminal E115 2 M9 110 Existed -

Check continuity between stop lamp switch harness connector and ground.

Stop lamp switch — Continuity Connector Terminal E115 2 Ground Not existed

Is the inspection result normal?

YES>>GO TO 6.

NO>>Repair or replace harness.

B2f71-23 Stop Lamp Nissan Ariya: FE0

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen items | DTC detecting condition | |

|---|---|---|---|

| B2F71-23 | Stop lamp | Diagnosis condition | Power switch ON |

| Signal (terminal) | Stop lamp switch 1 signal | ||

| Threshold | When stop lamp switch 1 signal is input even though the brake pedal is not depressed | ||

| Diagnosis delay time | 10 hours or more | ||

POSSIBLE CAUSE

-

Harness or connectors

(Stop lamp switch circuit is short to battery)

-

Stop lamp switch

-

Fuse

-

BCM

FAIL-SAFE

—

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

-

Not depress brake pedal and wait for 10 hours or more.

-

Power switch ON.

-

Check DTC in “Self Diagnostic Result” mode of “BCM” using CONSULT.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

CHECK FUSE

-

Power switch OFF.

-

Check that the following fuse is not blown (open).

Signal name Fuse No. Ignition power supply 39 (5 A)

Is the fuse blown (open)?

YES>>Replace the blown (open) fuse after replacing the cause of blown (open).

NO >>GO TO 2.

CHECK STOP LAMP SWITCH SIGNAL

-

Disconnect BCM connector.

-

Power switch ON.

-

Check voltage between BCM harness connector and ground.

(+) (–) Condition Voltage BCM Connector Terminal M9 111 Ground Stop lamp switch ON (brake pedal is not depressed) 9 – 16 V Stop lamp switch OFF (brake pedal is depressed) 0 V

Is the inspection normal?

YES>>Replace BCM. Refer to Removal and Installation.

NO>>GO TO 3.

CHECK STOP LAMP SWITCH POWER SUPPLY CIRCUIT

-

Power switch OFF.

-

Disconnect stop lamp switch connector.

-

Power switch ON.

-

Check voltage between stop lamp switch harness connector and ground.

(+) (–) Voltage Stop lamp switch Connector Terminal E115 4 Ground Battery voltage

Is the inspection result normal?

YES>>GO TO 4.

NO>>Check harness for open or short between stop lamp switch and fuse.

CHECK STOP LAMP SWITCH SIGNAL CIRCUIT

-

Power switch OFF.

-

Check continuity between stop lamp switch harness connector and BCM harness connector.

Stop lamp switch BCM Continuity Connector Terminal Connector Terminal E115 3 M9 111 Existed -

Check continuity between stop lamp switch harness connector and ground.

Stop lamp switch — Continuity Connector Terminal E115 3 Ground Not existed

Is the inspection result normal?

YES>>GO TO 5.

NO>>Repair or replace harness.

CHECK STOP LAMP SWITCH

Refer to Component Inspection.

Is the inspection result normal?

YES>>Replace BCM. Refer to Removal and Installation.

NO>>Replace stop lamp switch. Refer to BRAKE PEDAL : Exploded View.

Stop Lamp Switch Nissan Ariya 2023

Component Inspection

CHECK STOP LAMP SWITCH

-

Power switch OFF.

-

Disconnect stop lamp switch connector.

-

Check continuity between stop lamp switch terminals.

Stop lamp switch Condition Continuity Terminal 1 2 Brake pedal Not depressed Not existed Depressed Existed 3 4 Not depressed Existed Depressed Not existed

Is the inspection result normal?

YES>>INSPECTION END

NO>>Replace stop lamp switch. Refer to BRAKE PEDAL : Exploded View.

Hood Switch Nissan Ariya SUV

Component Function Check

CHECK FUNCTION

-

Select “Hood switch” in “DATA MONITOR” mode of “IPDM E/R” using CONSULT.

-

Check “Hood switch” indication under the following condition.

Monitor item Condition Indication Hood switch Hood Open Open Close Close

Is the indication normal?

YES>>Hood switch is OK.

NO>>Refer to Diagnosis Procedure.

Diagnosis Procedure

CHECK HOOD SWITCH SIGNAL

-

Power switch OFF.

-

Disconnect hood switch connector.

-

Check voltage between hood switch harness connector and ground.

(+) (–) Condition Voltage

(Approx.)Hood switch Connector Terminal E84 2 Ground Open the hood 6 – 16 V

Is the inspection result normal?

YES>>GO TO 3.

NO>>GO TO 2.

CHECK HOOD SWITCH SIGNAL CIRCUIT

-

Disconnect IPDM E/R connector.

-

Check continuity between IPDM E/R harness connector and hood switch harness connector.

IPDM E/R Hood switch Continuity Connector Terminal Connector Terminal E42 52 E84 2 Existed -

Check continuity between IPDM E/R harness connector and ground.

IPDM E/R — Continuity Connector Terminal E42 52 Ground Not existed

Is the inspection result normal?

YES>>Replace IPDM E/R. Refer to Removal and Installation.

NO>>Repair or replace harness.

CHECK HOOD SWITCH GROUND CIRCUIT

Check continuity between hood switch harness connector and ground.

| Hood switch | — | Continuity | |

|---|---|---|---|

| Connector | Terminal | ||

| E84 | 1 | Ground | Existed |

Is the inspection result normal?

YES>>GO TO 4.

NO>>Repair or replace harness.

CHECK HOOD SWITCH

Refer to Component Inspection.

Is the inspection result normal?

YES>>GO TO 5.

NO>>Replace hood lock assembly. Refer to Removal & Installation.

CHECK INTERMITTENT INCIDENT

Refer to Intermittent Incident.

>>

INSPECTION END

Component Inspection

CHECK HOOD SWITCH

-

Power switch OFF.

-

Disconnect hood switch connector.

-

Check continuity between hood switch terminals.

Hood switch Condition Continuity Terminal 1 2 Hood Open Existed Close Not existed

Is the inspection result normal?

YES>>INSPECTION END

NO>>Replace hood lock assembly. Refer to Removal & Installation.

Horn Function Nissan Ariya first Gen

Component Function Check

CHECK FUNCTION

-

Power switch OFF.

-

Perform “HORN” in “ACTIVE TEST” mode of “IPDM E/R” using CONSULT.

-

Check the horn operation.

Test item Description HORN On Horn low/high Sounds (for 0.5 sec.)

Is the operation normal?

YES>>INSPECTION END

NO>>Refer to Diagnosis Procedure.

Diagnosis Procedure

CHECK HORN FUNCTION

Check horn function with horn switch.

Do horns sound?

YES>>GO TO 2.

NO>>Perform the trouble diagnosis for horn circuit. Refer to Wiring Diagram.

CHECK IPDM E/R POWER SUPPLY CIRCUIT

-

Power switch OFF.

-

Disconnect horn relay connector and IPDM E/R connector.

-

Check continuity between IPDM E/R harness connector and horn relay harness connector.

IPDM E/R Horn relay Continuity Connector Terminal Connector Terminal E37 9 E77 2 Existed -

Check continuity between IPDM E/R harness connector and ground.

IPDM E/R — Continuity Connector Terminal E37 9 Ground Not existed

Is the inspection result normal?

YES>>GO TO 3.

NO>>Repair or replace harness.

CHECK INTERMITTENT INCIDENT

Refer to Intermittent Incident.

>>

INSPECTION END

Nissan Ariya (FE0) 2023-2026 Service & Repair Manual

Dtc/circuit Diagnosis

- P161d-61 Immobilizer. Motor Control

- P161e-68 Immobilizer. Motor Control

- P161f-64 Immobilizer. Motor Control

- B2033-4a Dongle Ng

- B2042-4a Electric Shift Authentication Fail

- B2043-4a Electric Shift Id Discord

- B2070-68 Key Registration

- B2090-14 Nats Antenna Amp.

- B2f70-01 Stop Lamp

- B2f71-23 Stop Lamp

- Stop Lamp Switch

- Hood Switch

- Horn Function

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image